Accurate measurement fed-batch device for fermentation tank and fed-batch method for high-concentration solution

A fermenter and feed-feeding technology, which is applied in the field of precise metering feed-feeding devices for fermenters and high-concentration solution feed-feeding fields, to achieve the effects of fewer interference factors, lower production costs, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

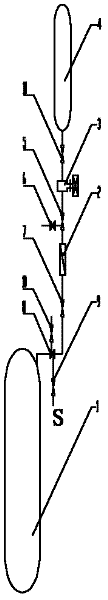

[0035] Accurate metering feeding device for fermenter. Fermentation tank 1 is sequentially connected with feeding pipe valve 8, filter rear valve 7, membrane filter 2, metering pump outlet valve 5, metering pump 3, metering pump inlet valve 11 and feeding tank 4 through pipelines; steam exhaust Valve 6 is connected to the fermenter 1 side of metering pump outlet valve 5 by pipeline, exhaust valve 10 is connected to the fermenter 1 side of feeding pipe valve 8 through pipeline; one end of steam valve 9 is connected to The other end of the steam valve 9 is connected to the steam pipeline S on the side of the valve 7 after the filter of the feeding pipe valve 8 .

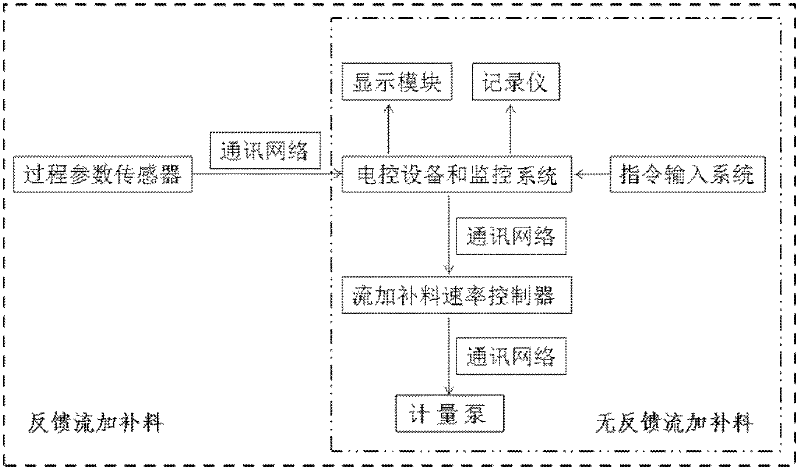

[0036] The electronic monitoring system is composed of a process parameter sensor, an instruction input system, an electronic control device, a feed rate controller, a display module, a recorder and a monitoring system connected through a signal line of a communication network. The command input system inputs commands...

Embodiment 2

[0038] 50m 3 Non-feedback feeding sugar supplementation and feedback feeding defoaming for tank citric acid fermentation:

[0039] Two sets of precise metering feed feeding devices, one feed feeding device feeds glucose syrup, which is the glucose syrup feed device; the other feed defoamer feed device, which is the defoamer feed device.

[0040] The membrane filter 2 of the glucose syrup feeding device has a membrane pore size of 0.2 μm, stores the glucose syrup with a solid content of 76% in the feeding tank, and keeps the metering pump inlet valve 11 open. When the fermentation tank is actually sterilized, close the metering pump outlet valve 5 and the feed pipe valve 8, open the exhaust valve 10, and sterilize the pipeline between the flow feed valve 8 and the fermenter 1. Open filter back valve 7, steam exhaust valve 6 and steam valve 9, feed steam from steam pipe S, and sterilize the pipeline between the membrane filter 2 and the valve 8 of the feeding pipe. After the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com