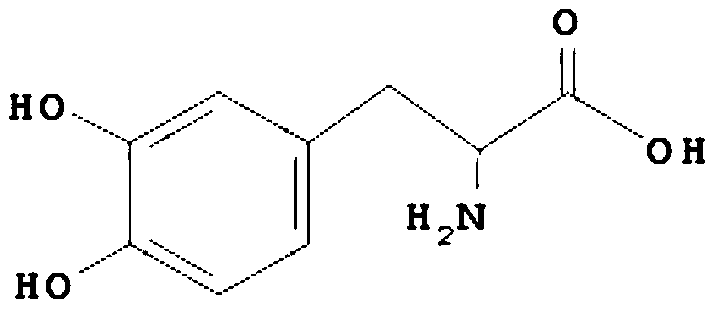

Method for improving efficiency of catalytic production of L-dopa by tyrosine phenol lyase

A technology of levodopa and tyrosine phenol, which is applied in the field of enzyme catalysis, can solve the problems of low yield of L-DOPA, difficult control of reaction conditions, poor stability, etc., and achieve improved conversion rate and product concentration, low cost, The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0022] tyrosine phenol lyase

[0023] LB medium: tryptone 10g / L, yeast extract 0.5g / L, sodium chloride 10g / L, pure water.

[0024] Fermentation medium: tryptone 12g / L, yeast extract 24g / L, glycerin 5g / L, potassium dihydrogen phosphate 2.31g / L, dipotassium hydrogen phosphate trihydrate 16.43g / L, pure water.

[0025] 1) Pick a single colony and inoculate it into a 4ml LB medium test tube, add kanamycin (50mg / L), 37°C, 220rpm, and cultivate for 12h to obtain first-grade seeds;

[0026] 2) The primary seeds were inoculated into 100ml of fermentation medium shake flask, 37°C, 220rpm, cultured for 4h, added IPTG to a final concentration of 1mM, 25°C, 220rpm, cultured for 12h;

[0027] 3) Centrifuge the bacterial liquid in step (2) to collect the bacterial cells, and place in a -20°C refrigerator.

example 2

[0028] Example 2: Extraction of Tyrosine Phenol Lyase

[0029] 1) Add 3 times the volume of water to the bacteria, and ultrasonically disrupt the cells for 20 minutes;

[0030] 2) High-speed centrifugation to obtain supernatant enzyme liquid;

example 3

[0031] Example 3: Conversion of tyrosine phenol lyase to produce L-dopa

[0032] 1) 1L substrate solution: 14g / L sodium pyruvate, 10g / L catechol, 40g / L ammonium chloride, 2g / L sodium sulfite, 1g / L EDTA, adjust pH to 8.0;

[0033] 2) Add 10-100g of enzyme solution, add 1L of substrate solution, stir well, seal and shake at 25°C;

[0034] 3) Add a substrate (an equivalent amount of sodium pyruvate and quinone) every half hour, and control the substrate concentration of the two substrates to not be higher than 10g / L;

[0035] 4) When the product concentration reaches more than 20g / L, add 20g / L of crystals to induce a large amount of crystallization of the product in advance;

[0036] 5) When the residual concentration of catechol falls below 0.2g / L, stop the reaction, and the accumulated L-dopa concentration reaches above 130g / L.

[0037] 6) The reaction feed liquid is acidified with dilute sulfuric acid or dilute hydrochloric acid to dissolve the crystals, and then centrifuged...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com