System for fermenting synthesis gas to produce alcohol and processing method thereof

A synthesis gas and alcohol technology, applied in the field of fermentation engineering, can solve the problems of low concentration of fermentation products and high concentration of alcohol, and achieve the effect of avoiding losses and improving gas utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

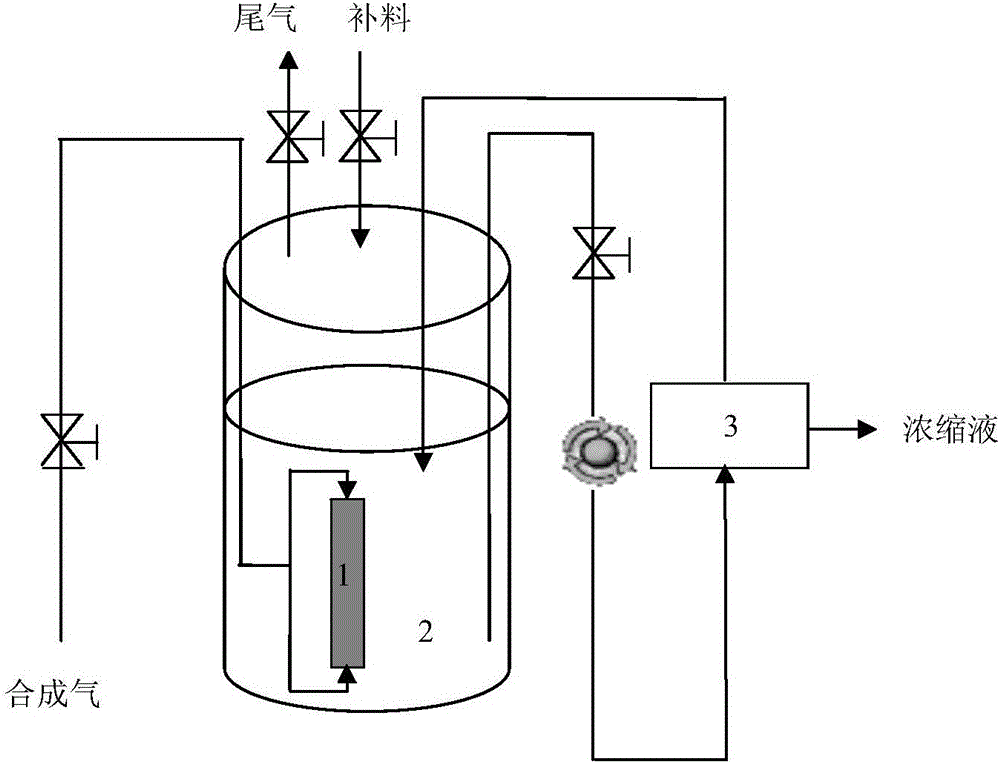

[0088] As shown in 1, this embodiment provides a system for fermenting syngas to produce alcohols. The system includes a bubble-free gas supply membrane module 1, a bioreactor 2 and a pervaporation membrane module 3, wherein the bubble-free gas supply membrane Module 1 is placed in bioreactor 2, the air inlet of bubble-free gas supply membrane module 1 is connected to syngas, the fermentation broth outlet of bioreactor 2 is connected to the feed port of pervaporation membrane module 3, and the pervaporation membrane module 3 The retentate outlet of the bioreactor 2 is connected with the material inlet of the bioreactor 2.

[0089] Wherein, the bubble-free air-supply membrane module 1 is placed below the liquid level of the fermentation liquid in the bioreactor 2, and is in direct contact with the fermentation liquid in the bioreactor 2; the bubble-free air-supply membrane module 1 is set individually, and the air is fed at both ends;

[0090] The gas partial pressure in the bu...

Embodiment 2

[0099] This embodiment provides a system for fermenting synthesis gas to produce alcohols. The system described in Embodiment 1 is the same as that in Embodiment 1 except that the pore size of the hollow polypropylene hollow fiber membrane is 0.8 μm. The system structure is the same.

[0100] The processing method of the system is:

[0101] (1) Place 7.5L of sterile ATCC1745PETC medium after seed cultivation in bioreactor 2 with a liquid volume of 5.0L. Before inoculation, use N 2 Aeration for 3 hours will contain CO, H 2 , CO 2 and N 2 Syngas (volume concentration: CO20%, H 2 5%, CO 2 15% and N 2 60%) was aerated for 3 hours by the bubble-free air supply membrane module 1 at an aeration rate of 0.05 L / min, and entered into the bioreactor 2 for fermentation treatment, the fermentation temperature was 30°C, the pH of the fermentation treatment was 6.0, and the inoculum size was 10 %, the pressure in the bioreactor 2 is 1 atmosphere, fermented for 10 days, no candy is ...

Embodiment 3

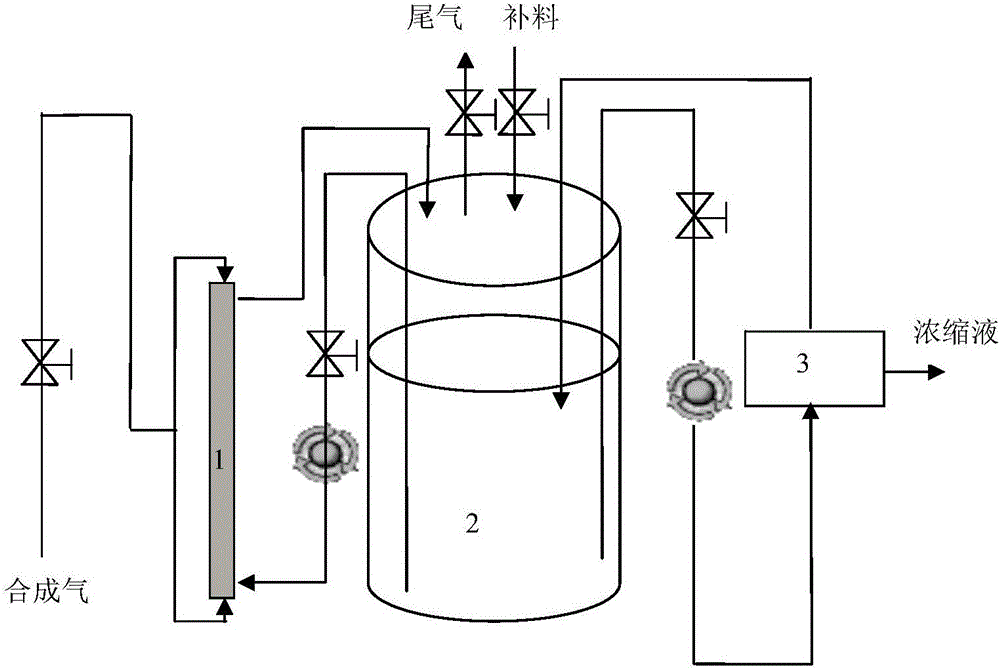

[0121] Such as figure 2 As shown, this embodiment provides a system for fermenting syngas to produce alcohols. The system includes a bubble-free gas supply membrane module 1, a bioreactor 2 and a pervaporation membrane module 3, wherein the bubble-free gas supply membrane module 1 Placed outside the bioreactor 2, the air inlet of the bubble-free gas supply membrane module 1 is connected to the synthesis gas, the outlet of the fermentation broth of the bioreactor 2 is connected to the feed port of the pervaporation membrane module 3, and the interception of the pervaporation membrane module 3 The liquid outlet is connected with the material inlet of the bioreactor 2.

[0122] Wherein, the fermentation liquid in the bioreactor 2 is connected to the liquid inlet of the bubble-free gas supply membrane module 1 through a delivery pump, and the liquid outlet of the bubble-free gas supply membrane module 1 is connected to the feed port of the bioreactor 2 .

[0123] The gas partial...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com