Indirect contact co-culture system capable of realizing engineering amplification

A co-culture system and engineering technology, applied in general culture methods, tissue cell/virus culture devices, tissue culture, etc., can solve problems such as difficult to achieve engineering amplification, unable to meet the production needs of cell products, etc., to achieve the benefits of cell Effects on Physiological Function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

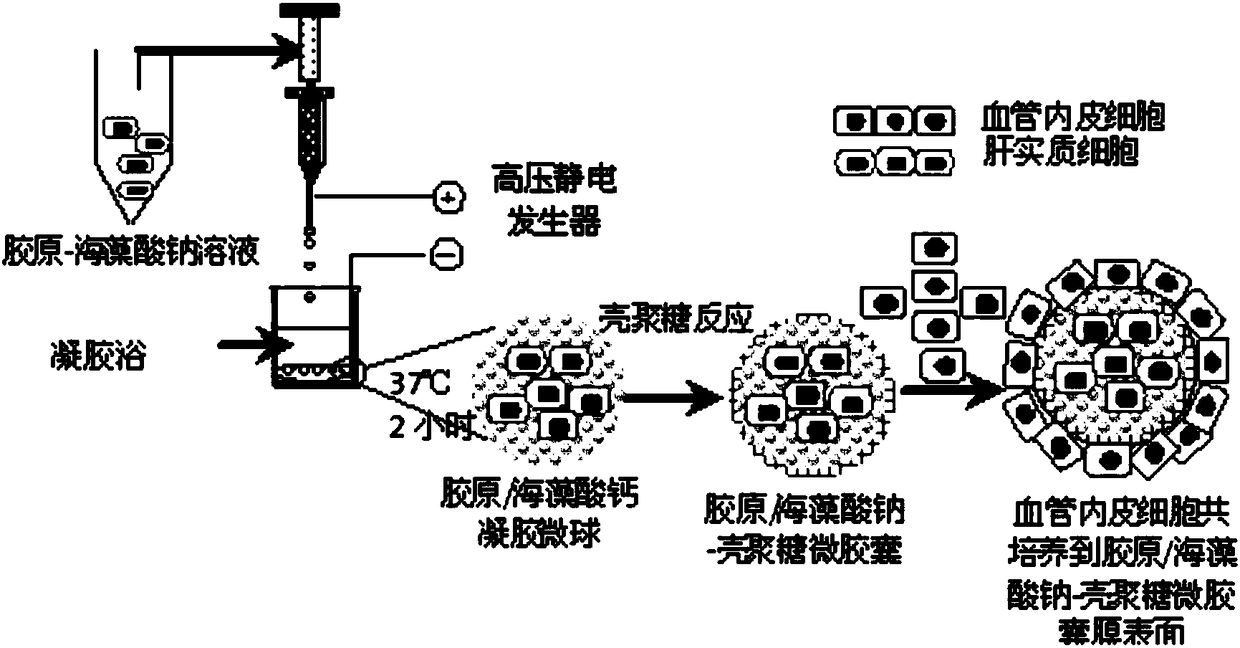

[0030] 【1】Prepare sodium alginate solution with a concentration of 30g / L;

[0031] [2] Prepare a collagen solution with a concentration of 5g / L and adjust it to neutral with NaOH;

[0032] [3] Prepare the gel bath solution, which contains calcium chloride (concentration 7g / L), sodium chloride (concentration 3g / L), sodium dihydrogen phosphate (concentration 1g / L) and F68 solution (1g / L) in the gel bath. L);

[0033] 【4】Preparation of chitosan solution, the concentration is 5g / L;

[0034] [5] Mix the sodium alginate solution prepared in step [1] with the collagen solution prepared in step [2] in a volume ratio of 2:1;

[0035] [6] Collect the hepatic parenchymal cells cultured to the logarithmic growth phase by centrifugation, and evenly disperse them into the mixed solution prepared in step [5] at a density of 1×106 / ml;

[0036] [7] The mixture of sodium alginate and collagen containing hepatic parenchymal cells prepared in step [6] forms a stable jet under a high-voltage el...

Embodiment 2

[0049] 【1】Prepare sodium alginate solution with a concentration of 40g / L;

[0050] [2] Prepare a collagen solution with a concentration of 4g / L and adjust it to neutral with NaOH;

[0051] [3] Prepare the gel bath solution, which contains calcium chloride (concentration 7g / L), sodium chloride (concentration 3g / L), sodium dihydrogen phosphate (concentration 1g / L) in the gel bath;

[0052] 【4】Preparation of chitosan solution, the concentration is 5g / L;

[0053] [5] Mix the sodium alginate solution prepared in step [1] with the collagen solution prepared in step [2] in a volume ratio of 1:2;

[0054] 【6】The fetal mouse fibroblasts cultured to the logarithmic growth phase were collected by centrifugation, according to 2×10 5 The density of / ml is uniformly dispersed in the mixed solution prepared in step [5];

[0055] [7] The mixture of sodium alginate and collagen containing fetal mouse fibroblasts prepared in step [6] and the gel bath solution prepared in step [3] were passed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com