Streptomycete and method for producing vanillin by using the same to biologically transform ferulic acid

A technology of biotransformation and streptomyces, applied in the biological field, can solve the problems of high production cost, low yield of vanillin, and many by-products, and achieve the effect of low cost, simple extraction steps, and few by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Screening of Streptomyces sp.V-1

[0023] Take the soil around the fruit tree, weigh 5 grams and dissolve it in 100 ml of normal saline, mix well, take 10 ml and add it to 50 ml of GY transformation medium. Ferulic acid with a volume ratio of 1% was shaken at 120 rpm for 20 hours, and this process was repeated 3 to 5 times. The cultured bacterial solution was diluted 1,000,000 times, spread on the solid medium, and cultured statically at 30°C for 20 hours. Select the grown single colony and inoculate 50 ml of GY transformation medium, add 1% ferulic acid in the mass-volume ratio after shaking for 24 hours, and shake at 120 rpm for 20 hours to screen for the ability to transform ferulic acid into pandan Finally, a bacterial strain with better degradation ability and a large amount of vanillin accumulation was obtained, namely Streptomyces sp.V-1, which was preserved in the China Center for Type Culture Collection on July 12, 2006. The number is CCTCC M 20606...

Embodiment 2

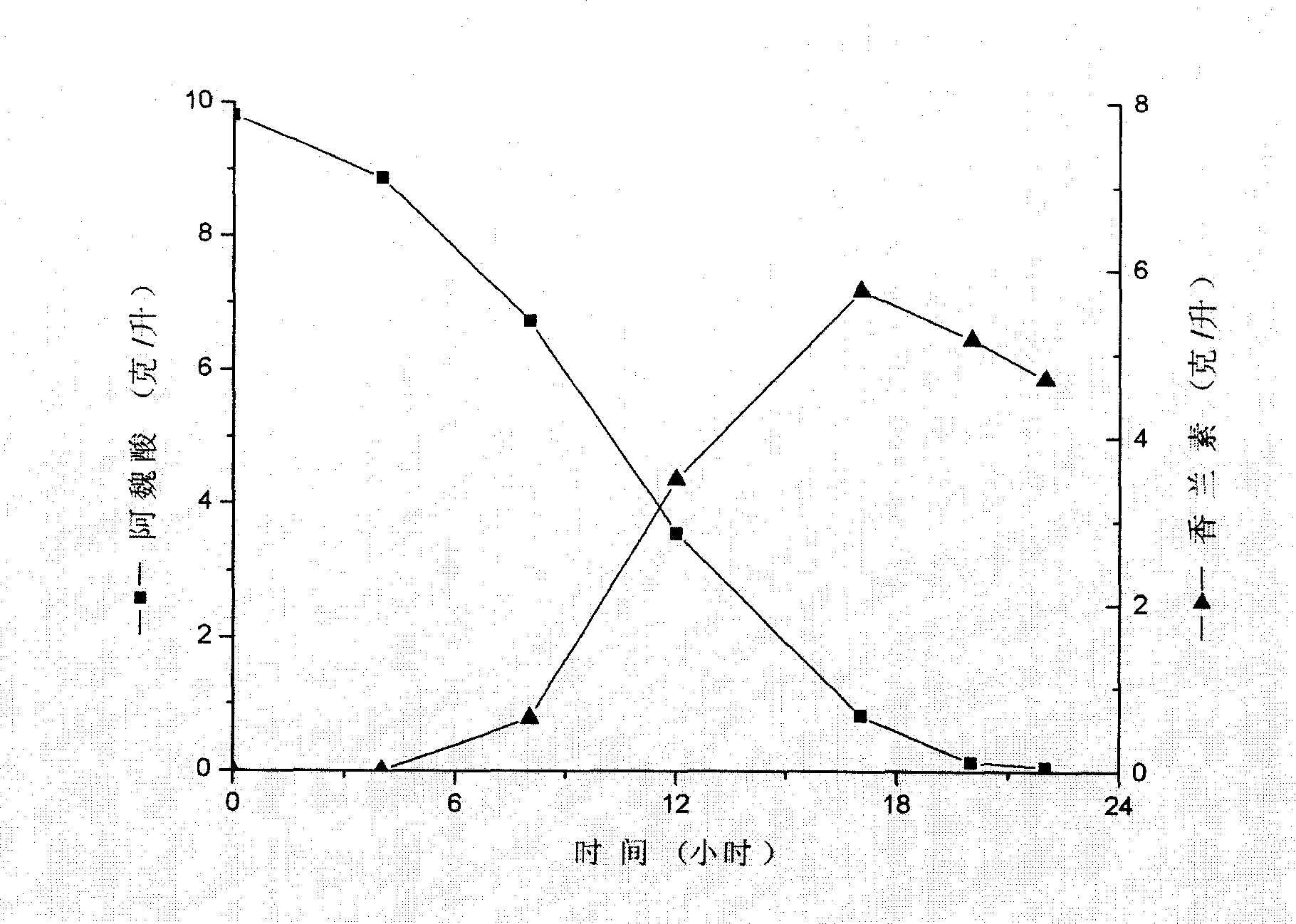

[0028] Streptomyces sp.V-1 cells were inserted into the GY transformation medium with an inoculum of 6% volume percentage after 24 hours of seed culture, and 5 g / L ferulic acid was added after 18 hours of cell culture, and the conditions were 30 ° C Shake culture at 120 rpm. After 20 hours, samples were taken to determine the concentration of vanillin.

[0029] Streptomyces sp.V-1 of the present embodiment biotransforms ferulic acid to produce vanillin, and the detailed steps involved are as follows:

[0030](1) Slant culture: inoculate Streptomyces sp.V-1 on a solid slant medium, and culture at 30°C for 24 hours;

[0031] (2) Preparation of seed culture solution: inoculate the slant culture obtained in step (1) into a liquid seed medium, and vibrate at 30°C at 120 rpm for 24 hours to obtain a seed culture solution;

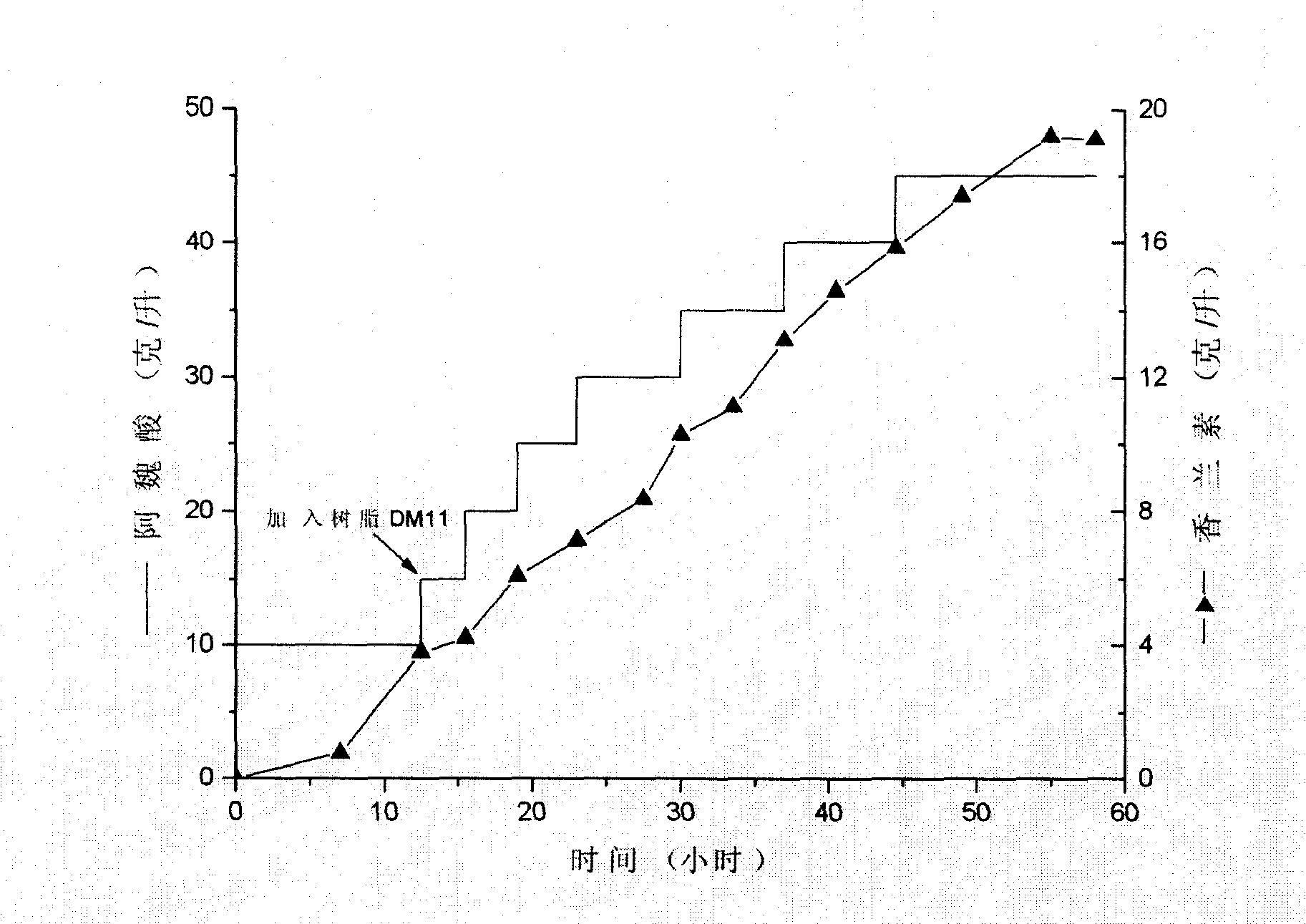

[0032] (3) Transformed cell culture: use the seed culture solution obtained in step (2), insert the inoculation amount of 6% by volume into the GY transformati...

Embodiment 3

[0038] Streptomyces sp.V-1 cells were inserted into the GY transformation medium with an inoculum of 6% volume percentage after 24 hours of seed cultivation, and 5 g / L ferulic acid was added after the cells were cultivated for 28 hours. Shake culture at 120 rpm. After 20 hours, samples were taken to determine the concentration of vanillin.

[0039] The Streptomyces sp.V-1 biotransformation ferulic acid of this embodiment produces vanillin, and the detailed steps involved are as follows:

[0040] (1) Slant culture: inoculate Streptomyces sp.V-1 on a solid slant medium, and culture at 30°C for 24 hours;

[0041] (2) Preparation of seed culture solution: inoculate the slant culture obtained in step (1) into a liquid seed medium, and vibrate at 30°C at 120 rpm for 24 hours to obtain a seed culture solution;

[0042] (3) Transformed cell culture: use the seed culture solution obtained in step (2), insert an inoculum size of 6% by volume into the GY transformation medium, and cult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com