Production equipment and method of nano silver colloid

A production equipment and nano-silver technology, applied in chemical instruments and methods, mixing methods, dissolution and other directions, can solve the problems of no real-time concentration monitoring and low nano-silver colloid concentration, and achieve continuous production process, high production concentration and energy consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

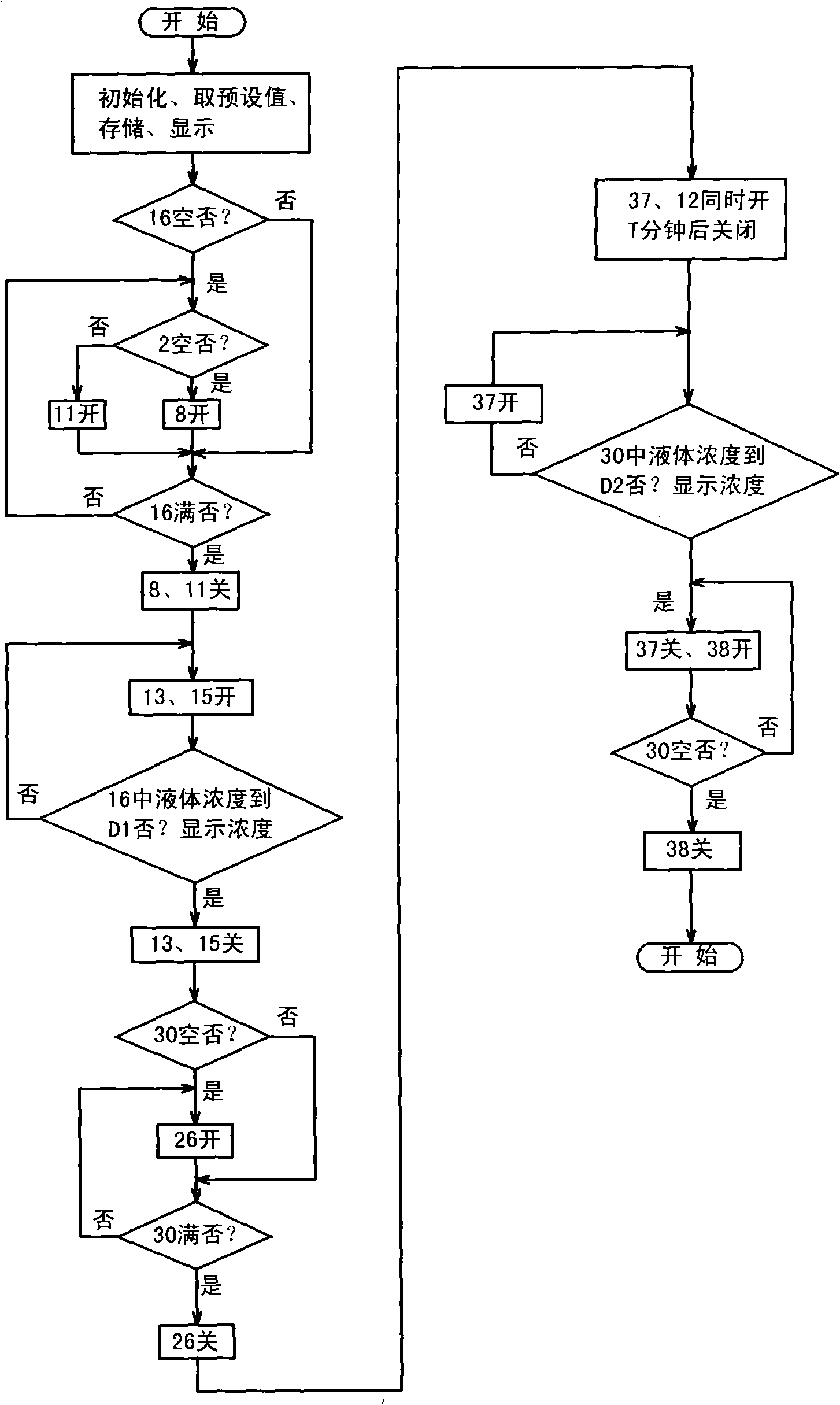

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and preferred embodiments.

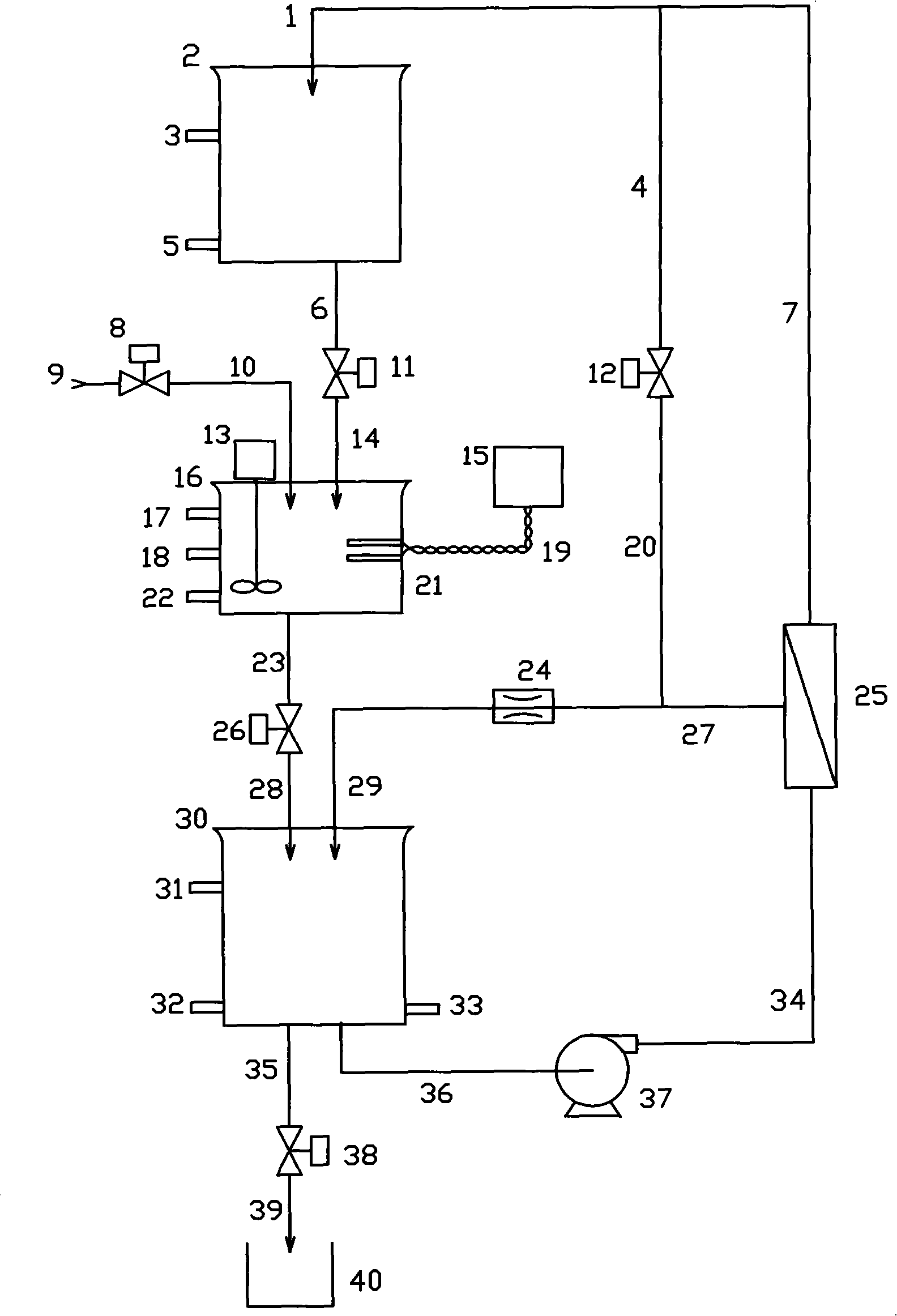

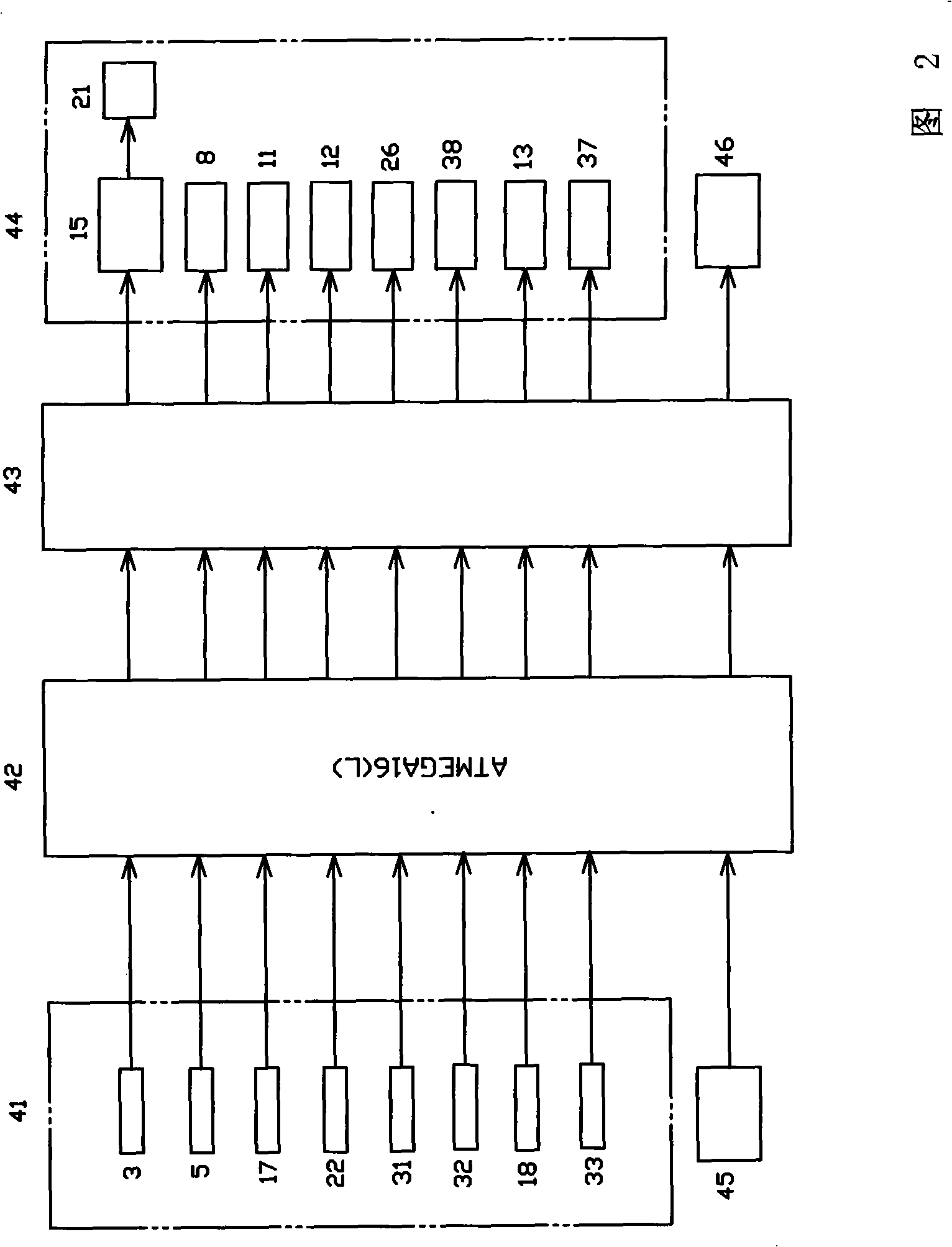

[0016] refer to figure 1 , Fig. 2: the nano-silver colloid production equipment of the preferred embodiment of the present invention comprises: single-chip microcomputer 42 (containing solidification software) and the detection unit 41 (concentration sensor 18,33 and liquid level sensor 3, 5, 17, 22, 31, 32), drive unit 43, actuator 44 (solenoid valve 8, 11, 12, 26, 38, booster pump 37, agitator 13, electric steady current source 15 and its pure silver electrode 21), the setting unit 45 and the display unit 46 also include: silver dispersion tank 16, intermediate product-product tank 30, recovery tank 2, reverse osmosis membrane module 25, concentration ratio device 24, pipelines 1, 4, 6, 7, 9, 10, 14, 20, 23, 27, 28, 29, 34, 35, 36, 39.

[0017] Concentration sensor 18, liquid level sensor 17, liquid level sensor 22, agitator 13 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com