Delaying coking non-silicon defoaming agent with multiple active components and preparation method thereof

A non-silicon defoamer, delayed coking technology, applied in chemical instruments and methods, foam dispersion/prevention, chemical/physical process, etc., can solve the problem of low efficiency, slow penetration and diffusion, and high temperature resistance of non-silicon defoamer It can achieve the effect of large spreading coefficient, small dosage and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

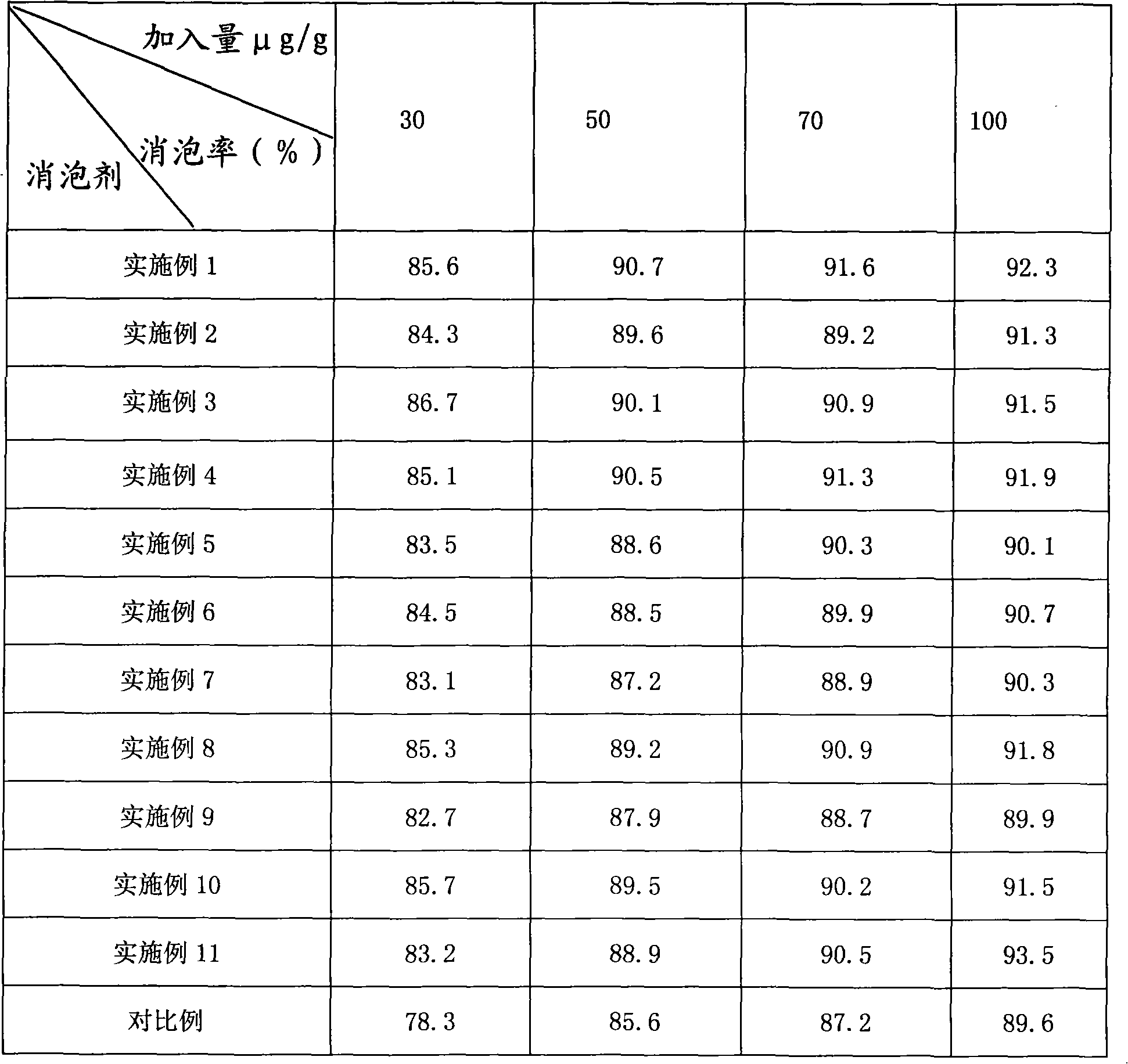

Examples

Embodiment 1

[0025] Add the starter ethanol and the catalyst sodium hydroxide into the autoclave, feed ethylene oxide and propylene oxide at a temperature of 130°C and a pressure of 0.5 MPa, and the molar ratio of ethylene oxide to propylene oxide is 50 : 100, keep warm for 5h, cool, filter and refine to obtain polyether.

[0026] Mix isooctyl alcohol and stearyl alcohol at a weight ratio of 80:20 at room temperature for 15 minutes to obtain a higher carbon alcohol mixture.

[0027] Weigh 30g of polyether, 35g of higher alcohol mixture, 15g of octadecyl stearate and 20g of paraffin into the reaction kettle, stir, slowly raise the temperature to 50°C, react for 2 hours, and finally end the stirring, cool and filter to remove The solid impurities are the defoamer product with a viscosity of 350cs.

Embodiment 2

[0029] The preparation of polyether is the same as in Example 1.

[0030] Weigh 40g of polyether, 35g of higher alcohol mixture, 10g of octadecyl stearate and 15g of hydrogenated diesel oil into the reaction kettle, stir, slowly raise the temperature to 100°C, react for 1 hour, and finally end the stirring, after cooling Filter to remove solid impurities to obtain a defoamer product with a viscosity of 380cs.

Embodiment 3

[0032] The preparation of polyether is the same as in Example 1.

[0033] Add polyether, stearic acid and toluenesulfonic acid into the reaction kettle, react at 160°C for 4 hours under stirring, lower the temperature to 50°C, adjust the pH value to neutral with potassium hydroxide aqueous solution, and finally use saturated chlorination The sodium solution extracts and removes the salt impurities to obtain the modified polyether.

[0034] Mix 3-heptanol and cetyl alcohol at a weight ratio of 70:30 at room temperature for 15 minutes to obtain a mixture of higher alcohols.

[0035]Weigh 50g of modified polyether, 25g of higher carbon alcohol mixture, 10g of ethylene bisstearamide and 15g of kerosene into the reaction kettle, stir, slowly raise the temperature to 80°C, react for 1.5 hours, and finally stop the stirring, cool and filter to remove The solid impurity namely obtains the defoamer product that viscosity is 480cs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com