Method for refining camellia oil by adopting short-path distillation

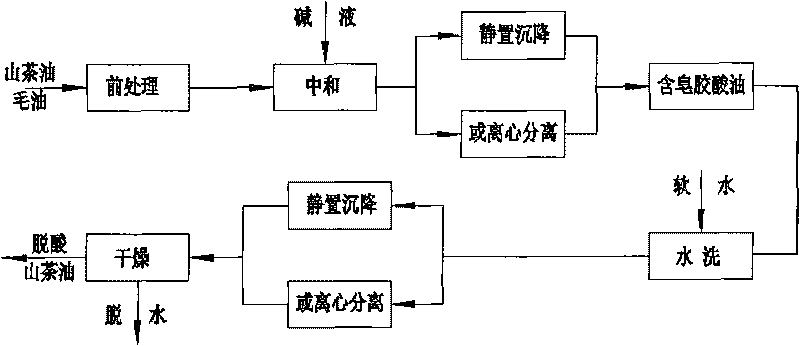

A short-path distillation, camellia oil technology, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems of loss and large loss of camellia oil, and achieve the effect of reducing implementation costs and avoiding secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

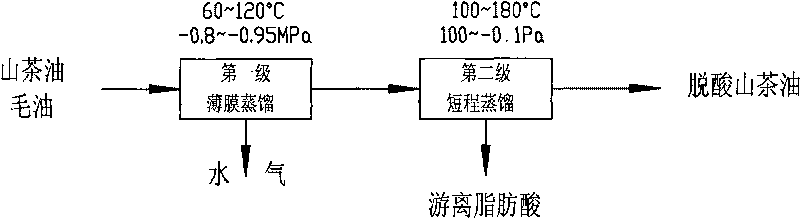

Method used

Image

Examples

Embodiment 1

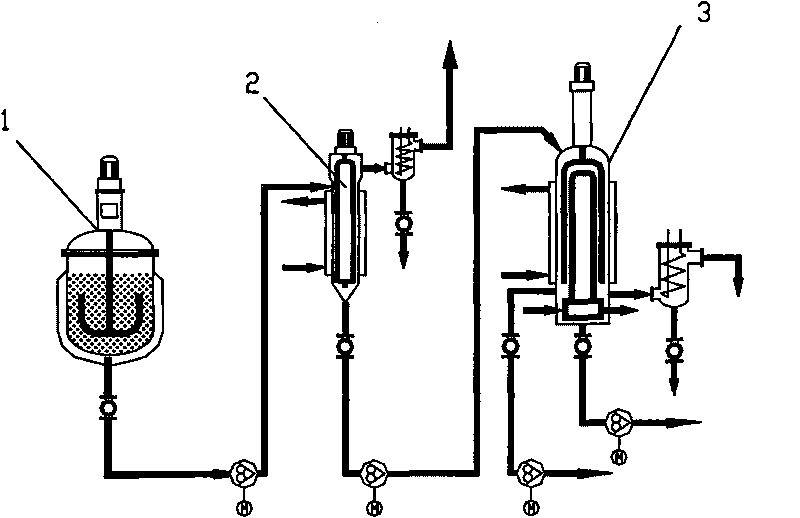

[0027] (1) Weighing a certain pressed camellia oil crude oil 10Kg, its measurement acid value AV is 8mgKOH / g; This pressed camellia oil crude oil directly enters buffer tank 1 place, is imported into the first stage film evaporator 2 by metering pump Dehydration and degassing are carried out at a temperature of 80°C and a pressure of -0.9Mpa. After dehydration and degassing, the pressed camellia oil continues to enter the next short-path distiller for deacidification and separation.

[0028] (2) The pressed camellia oil after dehydration and degassing is imported into the second-stage short-path distiller 3 through a pump, and deacidified and separated. 0.35Kg, deacidified camellia oil 9.6Kg, its measured acid value AV is 0.9mgKOH / g. The invention directly processes camellia oil crude oil without pretreatment, simple process and less loss.

Embodiment 2

[0030] (1) Weighing 20Kg of camellia oil crude oil extracted by a certain solvent, its measurement acid value AV is 6mgKOH / g, the camellia oil extracted by this solvent directly enters buffer tank 1, and is imported into the first-stage thin film evaporator by metering pump 2. Carry out dehydration and degassing, specifically at a temperature of 120°C and a pressure of -0.8Mpa. The solvent-extracted camellia oil after dehydration and degassing continues to enter the next short-path distiller for deacidification and separation.

[0031] (2) dehydration, solvent extraction after degassing camellia oil is input in the second stage short-path distiller 3 through pump, carry out deacidification separation, concrete condition is that distillation temperature is 150 ℃, and pressure is the free fatty acid weight that separates under 1Pa About 0.5Kg, deacidified camellia oil 19.2Kg, its measured acid value AV is 0.8mgKOH / g.

Embodiment 3

[0033] (1) Weigh 20Kg of pressed camellia oil from Huiying camellia oil factory in Hengyang, Hunan, and its measured acid value AV is 6.5mgKOH / g. The camellia oil extracted by this solvent is directly put into buffer tank 1, and is input to the first stage by metering pump The thin film evaporator 2 performs dehydration and degassing, specifically at a temperature of 100°C and a pressure of -0.85Mpa. The solvent-extracted camellia oil after dehydration and degassing continues to enter the next short-path distiller for deacidification and separation.

[0034] (2) The solvent extracted camellia oil after dehydration and degassing is pumped into the second-stage short-path distiller 3 for deacidification and separation. The specific conditions are that the distillation temperature is 140° C. and the pressure is the free fatty acid separated under 0.1 Pa. The weight is about 0.55Kg, and the deacidified camellia oil is 19.3Kg, and its measured acid value AV is 0.6mgKOH / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com