Polymer emulsion interface agent for base layer coating treatment and preparation method thereof

A technology of polymer emulsion and base layer treatment, applied in the field of polymer emulsion type interface agent, which can solve the problems of poor adhesion, poor sealing, and unusable substrates with smooth surfaces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

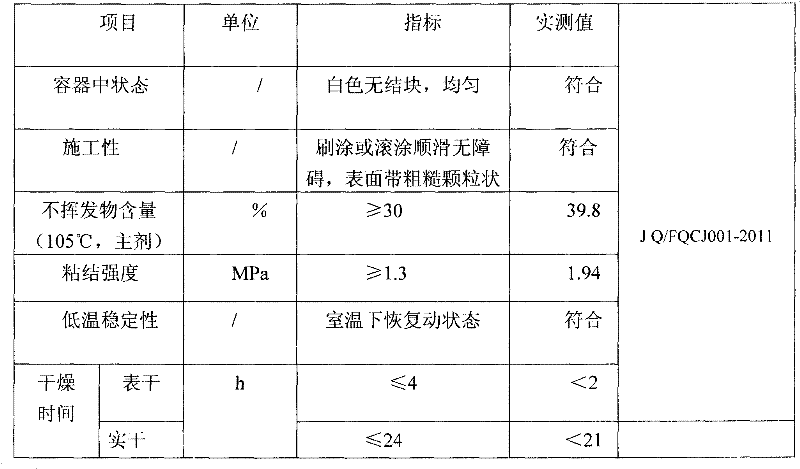

[0287] The present invention will be described in detail below in conjunction with embodiments

[0288] (1) The specific components and weight percentages of component A are as follows:

[0289] 1. Hydroxyethyl cellulose 0.3%

[0290] 2. Disperse wetting agent 0.5%

[0291] 3. Quartz powder 15%

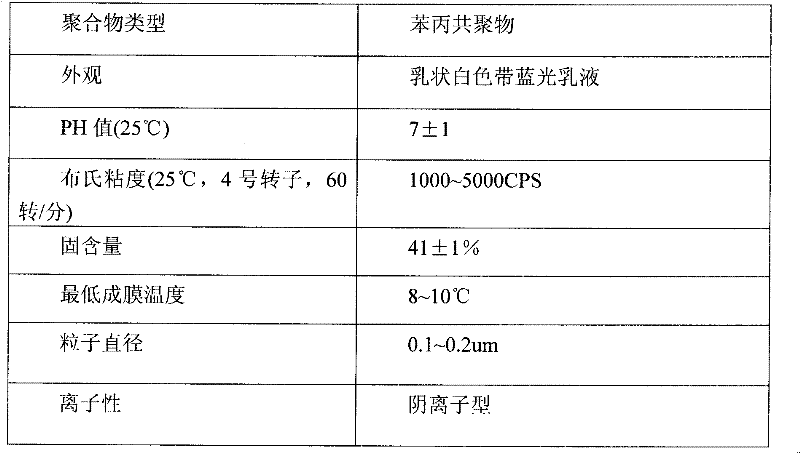

[0292] 4. Styrene and acrylic ester polymer emulsion 56%

[0293] 5. Preservative 0.2%

[0294] 6. Anti-mold agent 0.1%

[0295] 7. Multifunctional additives 0.1%

[0296] 8. Thickener 0.3%

[0297] 9. Defoamer 0.3%

[0298] 10. Film forming aid 0.5%

[0299] 11. Water 26.7%.

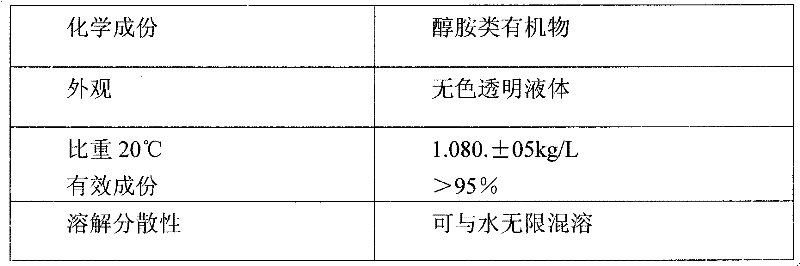

[0300] In the examples, 1) The dispersing wetting agent is mainly composed of sodium tripolyphosphate, the product model is Sn5040, and the manufacturer: Shanghai Snow Chemical Co., Ltd.; 2) The quartz powder uses 800 mesh quartz powder; 3) Styrene and acrylic acid Polymer emulsion, the main monomers are styrene and acrylic ester, the product model is RS998A, and the manufacturer: Guangdong Badfu Industrial Co., Ltd. 4) Methyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com