Curved surface composite cover plate and preparation method thereof

A curved surface and cover plate technology, applied in glass manufacturing equipment, chemical instruments and methods, manufacturing tools, etc., can solve the problems of damaged display screen, high production cost, fast oxidation of forming mold, etc., and achieve good shape memory characteristics, excellent Explosion-proof characteristics, not easy to deform and crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment provides a curved glass and a preparation method thereof, comprising the following steps:

[0044] Step 1. Obtain the 0.68mm Corning Gorilla Glass 3, cut it and cut it to the required size to obtain the cut glass.

[0045] Carve and polish the cut glass to obtain glass sheets.

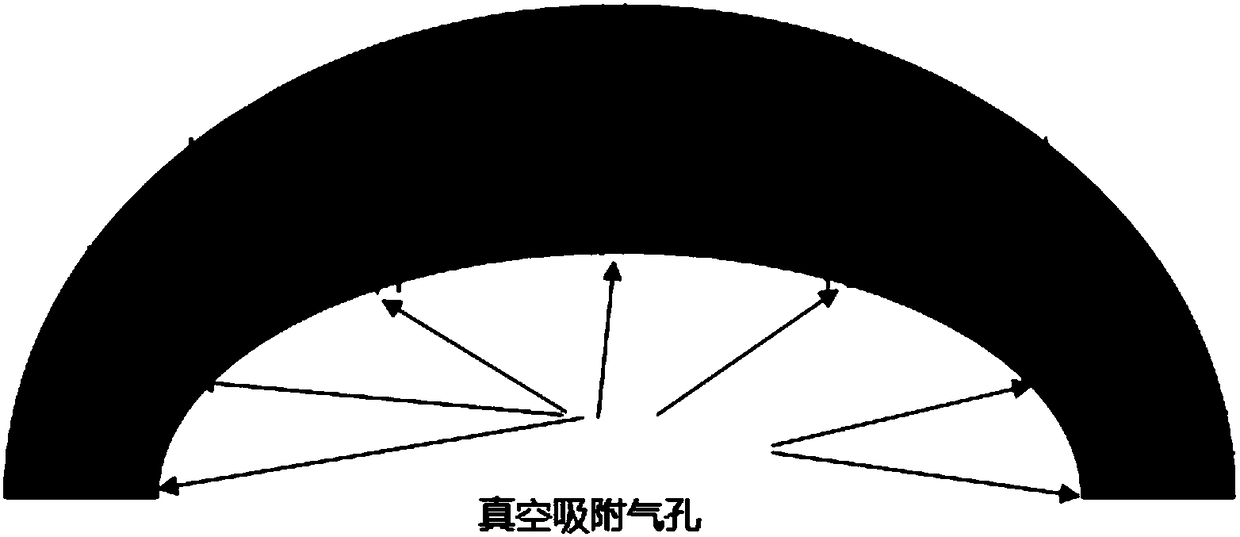

[0046] Step 2. Prepare the imitation curved surface fixture according to the four-side profile curve of the required curved surface glass. In this embodiment, the structure of the curved surface fixture is as follows figure 1 As shown, the above-mentioned curved surface fixture is also provided with vacuum adsorption air holes, which is convenient for the glass sheet to be effectively fixed in the curved surface fixture. Fix the glass sheet in the curved surface fixture, make the glass sheet maintain the curved shape of the curved surface under external force, and clean it. The above-mentioned curved surface fixture is made of low-cost steel, which reduces the preparation cost ...

Embodiment 2

[0056] This embodiment provides a curved glass and a preparation method thereof, comprising the following steps:

[0057] Step 1. Obtain the 0.68mm Corning Gorilla Glass 3, cut it and cut it to the required size to obtain the cut glass.

[0058] Carve and polish the cut glass to obtain glass sheets.

[0059] Step 2, use such as figure 1 The shown curved surface fixture clamps and fixes the glass sheet, so that the glass sheet maintains the curved shape of the curved surface under external force, and cleans. The above-mentioned curved surface fixture is made of iron.

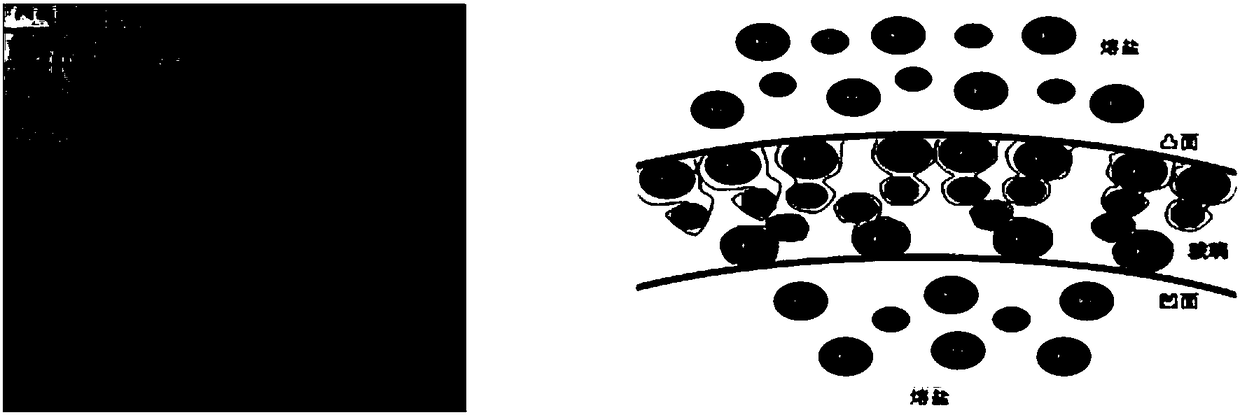

[0060] Step 3. Put the glass sheet fixed in the curved surface fixture into the chemical molten salt furnace for the first tempering treatment. The tempering conditions are: the molten salt is potassium nitrate solution, the temperature is 420°C, and the time is 1.5h. Cool and clean. Preparing semi-tempered glass whose tempering depth is 1 / 10-1 / 1.5 of the preset tempering depth of the glass sheet.

[0061] St...

Embodiment 3

[0068] This embodiment provides a curved glass and a preparation method thereof, comprising the following steps:

[0069] Step 1. Obtain 0.33mm CSG white glass, cut it and cut it to the required size to obtain cut glass.

[0070] Carve and polish the cut glass to obtain glass sheets.

[0071] Step 2, prepare as Figure 5 As shown in the curved surface fixture, the curved surface fixture is a rectangular parallelepiped frame, and the inner wall of the frame is provided with a wedge-shaped clamping part for clamping the four edges of the glass sheet, so that the glass sheet can maintain the curved shape of the curved surface under external force and can be cleaned. The material of the above-mentioned curved surface fixture is iron, and the cost is low.

[0072] Step 3. Put the glass sheet fixed in the curved surface fixture into the chemical molten salt furnace for the first tempering treatment. The tempering conditions are: the molten salt is potassium nitrate solution, the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface radius | aaaaa | aaaaa |

| Surface radius | aaaaa | aaaaa |

| Surface radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com