A kind of 4D intelligent airgel and preparation method thereof

An airgel and intelligent technology, applied in the field of intelligent material preparation and application, can solve the problems of poor performance controllability and complicated preparation process, and achieve the effect of low cost, simple process and strong designability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

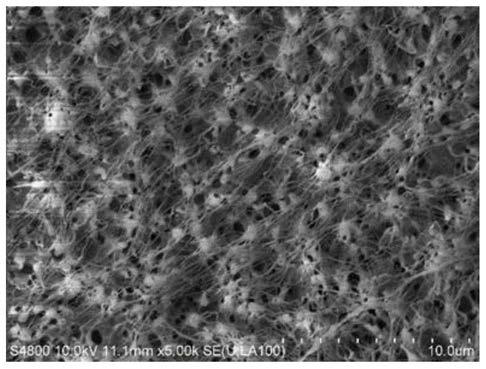

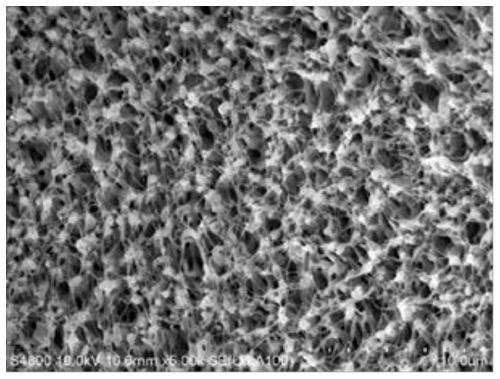

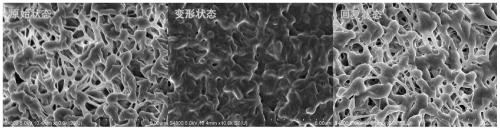

Image

Examples

Embodiment 1

[0034]Weigh 8.0g of polyvinyl alcohol, add it to 100.0ml of deionized water at room temperature and stir at a stirring speed of 300.0rad / min for 3.0h. After the polyvinyl alcohol is fully swollen, slowly heat it to 98.0°C Then start timing, keep stirring at a constant temperature of 98.0°C, the stirring speed is 300.0rad / min, and the stirring time is 4.0h, until the polyvinyl alcohol is fully dissolved, the solution is uniform, clear, transparent and free of particles, and then cooled naturally to room temperature to obtain dispersion Uniform clear and transparent polyvinyl alcohol solution. At room temperature, the pH value of the above polyvinyl alcohol solution system was adjusted to 3.5 with acetic acid, and then the stirring was continued at a stirring speed of 300.0 rad / min and a stirring time of 1.0 h. Then add 4.0ml of glutaraldehyde to the above solution and continue to stir and disperse. The stirring speed is 300.0rad / min, and the stirring time is 5.0h to obtain the ...

Embodiment 2

[0036] Weigh 8.0g of polyvinyl alcohol, add it to 100.0ml of deionized water at room temperature and stir at a stirring speed of 300.0rad / min for 3.0h. After the polyvinyl alcohol is fully swollen, slowly heat it to 98.0°C Then start timing, keep stirring at a constant temperature of 98.0°C, the stirring speed is 300.0rad / min, and the stirring time is 4.0h, until the polyvinyl alcohol is fully dissolved, the solution is uniform, clear, transparent and free of particles, and then cooled naturally to room temperature to obtain dispersion Uniform clear and transparent polyvinyl alcohol solution. At room temperature, the pH value of the polyvinyl alcohol solution system was adjusted to 3.0 with hydrochloric acid, and then the stirring was continued at a stirring speed of 300.0 rad / min and a stirring time of 1.0 h. Then add 4.0ml of glutaraldehyde to the above solution and continue to stir and disperse. The stirring speed is 300.0rad / min and the stirring time is 3.0h to obtain the ...

Embodiment 3

[0038] Weigh 6.0g of polyvinyl alcohol, add it into 100.0ml of deionized water at room temperature and stir at a stirring speed of 300.0rad / min for 3.0h. After the polyvinyl alcohol is fully swollen, slowly heat it to 95.0°C Then start timing, keep stirring at a constant temperature of 95.0°C, the stirring speed is 300.0rad / min, and the stirring time is 4.0h, until the polyvinyl alcohol is fully dissolved, the solution is uniform, clear, transparent and free of particles, and then cooled naturally to room temperature to obtain dispersion Uniform clear and transparent polyvinyl alcohol solution. At room temperature, the pH value of the above polyvinyl alcohol solution system was adjusted to 3.5 with acetic acid, and then the stirring was continued at a stirring speed of 300.0 rad / min and a stirring time of 1.0 h. Then add 5.0ml of glutaraldehyde to the above solution and continue to stir and disperse. The stirring speed is 300.0rad / min and the stirring time is 5.0h to obtain th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com