Preparation method and application of eucommia ulmoide gum shape memory material

A technology of memory material and eucommia gum, applied in the preparation and application field of eucommia gum shape memory material, achieving good application prospects and improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

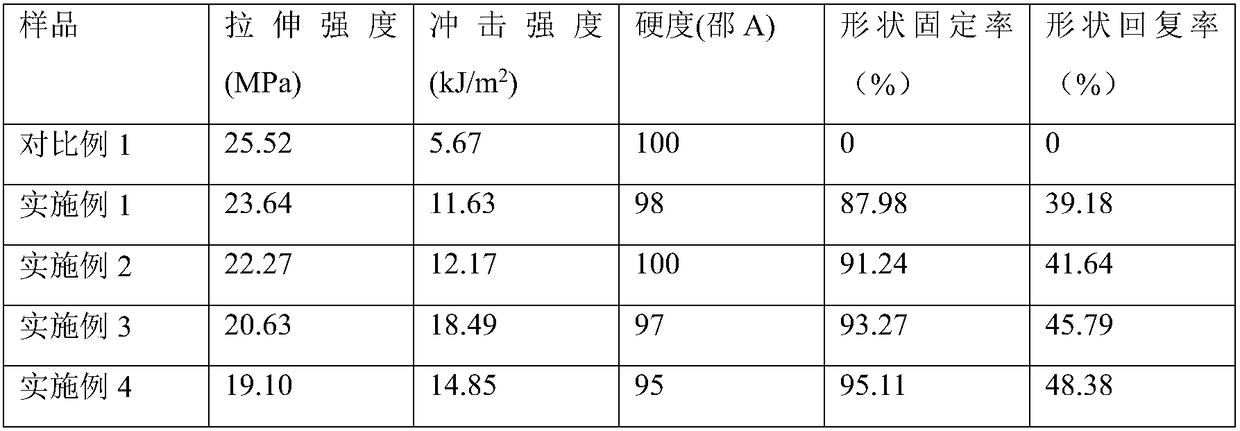

Examples

Embodiment 1

[0018] Mix 30g of eucommia gum with 70g of polypropylene, 5g of zinc oxide, 0.4g of NS, 3g of SA, 2g of anti-264, 1g of anti-1010, and 0.5g of sulfur in an internal mixer. Set the temperature at 155°C, add TPI, PP, and all small materials into the internal mixer, and banbury for 15 minutes; add S at 15 minutes, and continue banbury for 5 minutes; the total banbury time is 20 minutes, and the sheet is removed by cold roll. During the tableting process, set the temperature at 175°C; put in the rubber material, preheat for 15 minutes; deflate 10 times, heat press for 3 minutes; cold press for 15 minutes.

Embodiment 2

[0020] Mix 40g of eucommia gum with 60g of polypropylene, 5g of zinc oxide, 0.4g of NS, 3g of SA, 2g of anti-264, 1g of anti-1010, and 0.5g of sulfur in an internal mixer. Set the temperature at 155°C, add TPI, PP, and all small materials into the internal mixer, and banbury for 15 minutes; add S at 15 minutes, and continue banbury for 5 minutes; the total banbury time is 20 minutes, and the sheet is removed by cold roll. During the tableting process, set the temperature at 175°C; put in the rubber material, preheat for 15 minutes; deflate 10 times, heat press for 3 minutes; cold press for 15 minutes.

Embodiment 3

[0022] Mix 50g of eucommia gum with 50g of polypropylene, 5g of zinc oxide, 0.4g of NS, 3g of SA, 2g of anti-264, 1g of anti-1010, and 0.5g of sulfur in an internal mixer. Set the temperature at 155°C, add TPI, PP, and all small materials into the internal mixer, and banbury for 15 minutes; add S at 15 minutes, and continue banbury for 5 minutes; the total banbury time is 20 minutes, and the sheet is removed by cold roll. During the tableting process, set the temperature at 175°C; put in the rubber material, preheat for 15 minutes; deflate 10 times, heat press for 3 minutes; cold press for 15 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com