Bidirectional Linear Actuator Based on Shape Memory Material Actuator

A technology of linear actuators and memory materials, which is applied to mechanisms that generate mechanical power, machines/engines, and mechanical equipment. It can solve problems that limit the application of piezoelectric actuators, complex structures, and small driving strokes, and achieve controllable displacement and volume. The effect of small, large drive output displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

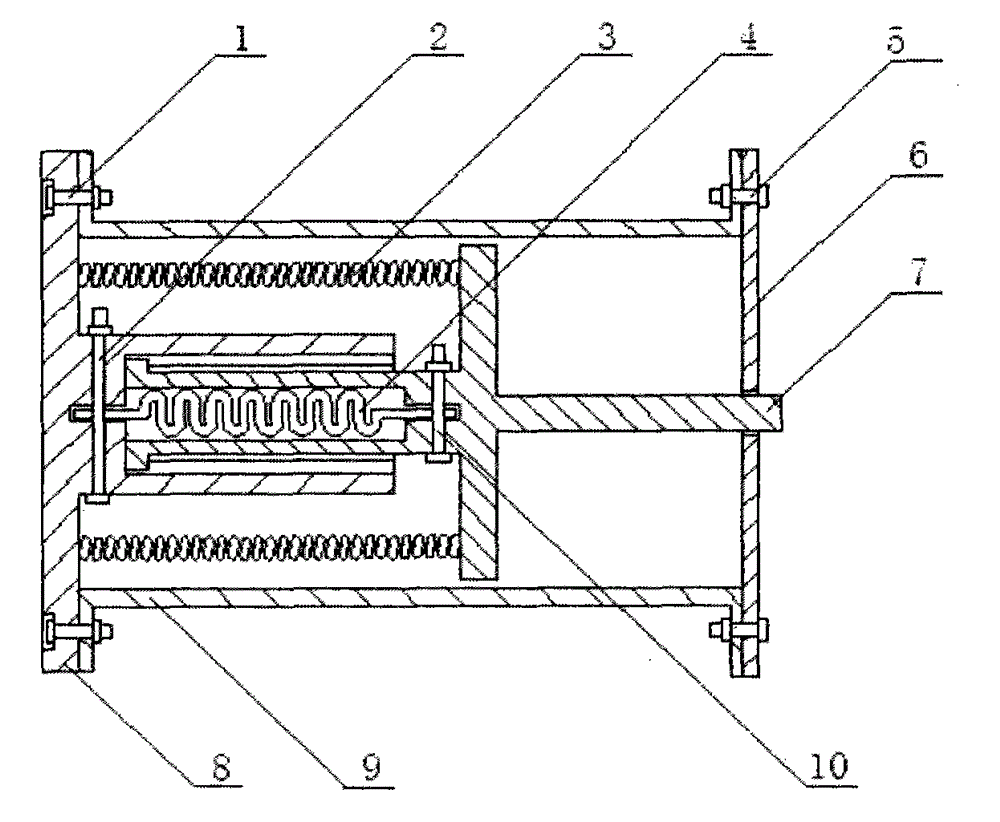

[0009] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A two-way linear drive based on shape memory material actuators, the stator 8 and the end cover 6 are fixedly installed on the two ends of the housing 9 through the stator mounting bolts 1 and the end cover mounting bolts 5 respectively, and the housing 9 can be The mover 7 is configured to move axially, and the two sides of the mover 7 are respectively inserted into the center holes of the stator 8 and the end cover 6, and an S-shaped shape is fitted in the center hole of the mover 7 side. The memory polymer composite actuator 4, the two ends of the S-shaped shape memory polymer composite actuator 4 are fixedly connected to the stator 8 and the mover 7 through the stator bolt 2 and the mover bolt 10 respectively, and the shape Both ends of memory alloy tension spring 3 are connected with stator 8 and mover 7 respectively.

[0010] The present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com