A gas separation membrane with shape memory properties

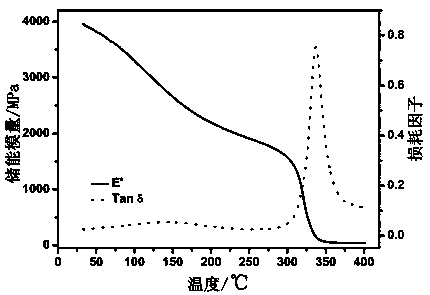

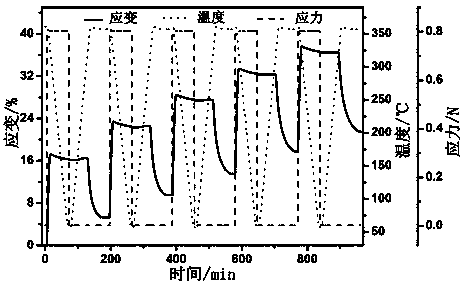

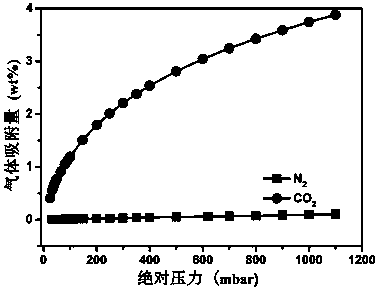

A gas separation membrane, memory technology, applied in separation methods, semi-permeable membrane separation, dispersed particle separation, etc., to achieve the effect of good gas separation selectivity and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing a gas separation membrane with shape memory performance:

[0028] 1. Add 4,4'-diaminodiphenyl ether (4.4mmol) into a 250 mL three-necked flask, add 36 mL N,N-dimethylacetamide, and then add 2-(4-aminobenzene base)-5-aminobenzoxazole (4.4mmol), stirred and dissolved under nitrogen atmosphere. Then 2,4,6-triaminopyrimidine (0.8 mmol) was added and mechanically stirred for 10 min.

[0029] 2. Weigh 4,4'-(hexafluoroisopropylene) diphthalic anhydride (10 mmol) and slowly add it to the diamine solution in step 1 in 5 times, and stir for 36 hours at room temperature under the protection of nitrogen to obtain a certain viscosity Polyamic acid solution.

[0030] 3. Vacuum and degas the polyamic acid solution at room temperature for 0.5 h, then pour it onto a glass substrate, raise the temperature from room temperature to 60°C, and keep it warm for 8h; then raise the temperature to 100°C, and keep it warm for 1h; continue to raise the temperature to 200°...

Embodiment 2

[0036] 1. Add 4,4'-diaminodiphenyl ether (4.25mmol) into a 250 mL three-neck flask, add 36 mL N,N-dimethylacetamide, and then add 2-(4-aminophenyl)- 5-Aminobenzoxazole (4.25 mmol), stirred and dissolved under nitrogen atmosphere. Then 2,4,6-triaminopyrimidine (1.0 mmol) was added and mechanically stirred for 10 min.

[0037] 2. Weigh 4,4'-(hexafluoroisopropylene) diphthalic anhydride (10 mmol) and slowly add it to the diamine solution in step 1 in 10 times, and stir for 72 hours at room temperature under the protection of nitrogen to obtain a certain viscosity polyamic acid solution.

[0038] 3. Vacuum and degas the polyamic acid at room temperature for 0.5 h, then pour it onto the glass substrate, raise the temperature from room temperature to 80°C, and keep it warm for 6h; then raise the temperature to 120°C, keep it warm for 1h; continue to raise the temperature to 220°C °C, keep warm for 1h; finally raise the temperature to 320°C, keep warm for 1h.

[0039] 4. Same as E...

Embodiment 3

[0042] 1. Add 4,4'-diaminodiphenyl ether (3.95mmol) into a 250 mL three-neck flask, add 36 mL of N,N-dimethylacetamide, and then add 2-(4-aminophenyl)- 5-Aminobenzoxazole (3.95 mmol), stirred and dissolved under nitrogen atmosphere. Then 2,4,6-triaminopyrimidine (1.4 mmol) was added and mechanically stirred for 20 min.

[0043] 2. Weigh 4,4'-(hexafluoroisopropylene) diphthalic anhydride (10 mmol) and slowly add it to the diamine solution in step 1 in 3 times, and stir for 48 hours at room temperature under the protection of nitrogen to obtain a certain viscosity polyamic acid solution.

[0044] 3. Vacuum and degas the polyamic acid at room temperature for 1.0 h, then pour it onto the glass substrate, raise the temperature from room temperature to 60°C, and keep it warm for 8h; then raise the temperature to 130°C, keep it warm for 1h; continue to raise the temperature to 230°C ℃, keep warm for 1h; continue to raise the temperature to 330°C, keep warm for 1h.

[0045] 4. Same...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com