Plastic pellets and yarn

A technology of plastic pellets and yarns, applied in the directions of yarns, textiles and papermaking, can solve problems such as application limitations in the textile field, and achieve the effect of good shape fixation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

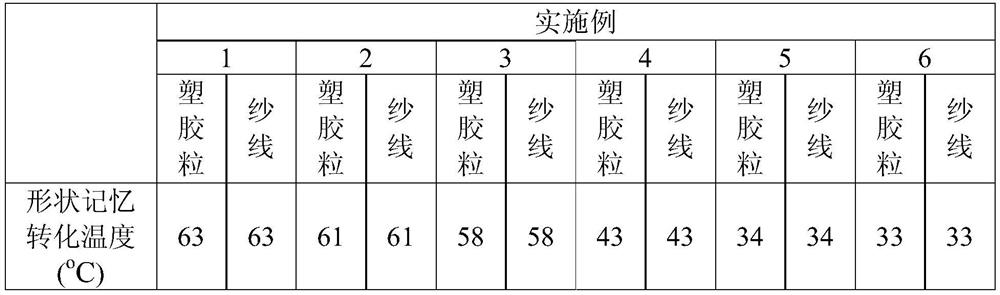

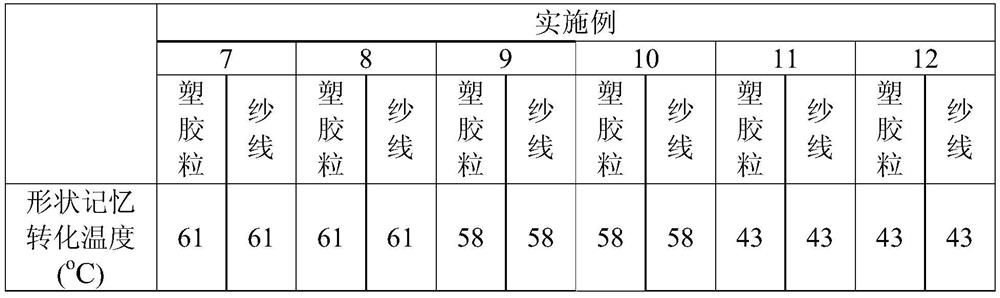

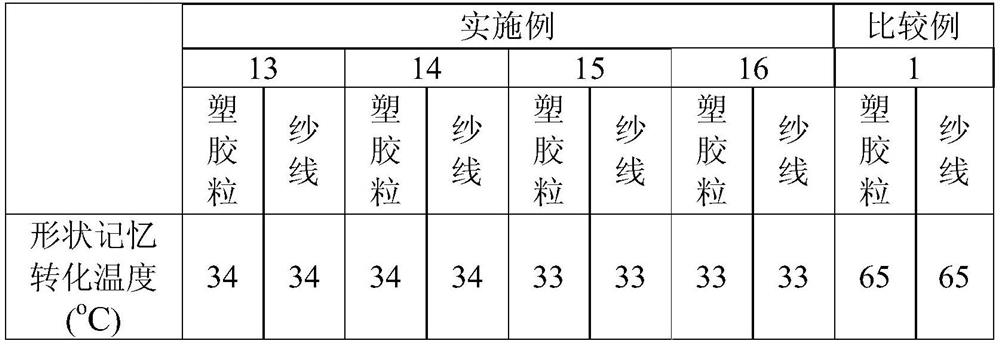

Examples

preparation example Construction

[0023] On the other hand, in the present embodiment, the method for preparing plastic pellets includes the following steps, for example. First, the shape-memory polyurethane, polyurethane and polyurethane-based dispersant are uniformly mixed and then dried to remove moisture. In one embodiment, the temperature for drying the shape memory polyurethane, the polyurethane and the polyurethane dispersant is, for example, between 85° C. and 105° C., and the drying time is, for example, more than 8 hours. Next, the mixed and dried shape memory polyurethane, polyurethane and polyurethane dispersant are fed into a twin-screw extruder for high-speed shear kneading to obtain plastic pellets. In one embodiment, in the kneading process, the processing temperature is, for example, between 185° C. and 220° C., and the screw speed is, for example, between 50 rpm and 400 rpm.

[0024] It is worth noting that, in this embodiment, the plastic particles include shape memory polyurethane, polyure...

Embodiment 1

[0036] Preparation of plastic pellets

[0037] First, 93 parts by weight of shape-memory polyurethane, 5 parts by weight of polyurethane and 2 parts by weight of polyurethane-type dispersant were evenly mixed, and then dried at 85° C. for 8 hours to remove moisture and prevent generation of air bubbles. Next, feed the above-mentioned mixed and dried shape memory polyurethane, polyurethane and polyurethane dispersant into a twin-screw extruder, and perform high-speed shear kneading at a processing temperature of 200°C and a screw speed of 200rpm , to prepare the plastic particles of Example 1.

[0038] yarn preparation

[0039] First, the plastic pellets of Example 1 were dried at 105° C. for 8 hours to remove moisture. Next, the dried plastic particles of Example 1 were melt-spun under the conditions of a melt-spinning temperature of 200° C. and a take-up speed of 200 m / min to obtain the yarn of Example 1.

Embodiment 2

[0041] Preparation of plastic pellets

[0042] First, 88 parts by weight of shape-memory polyurethane, 10 parts by weight of polyurethane and 2 parts by weight of polyurethane-type dispersant were uniformly mixed, and then dried at 85° C. for 8 hours to remove moisture and prevent generation of air bubbles. Next, feed the above-mentioned mixed and dried shape memory polyurethane, polyurethane and polyurethane dispersant into a twin-screw extruder, and perform high-speed shear kneading at a processing temperature of 200°C and a screw speed of 200rpm , to prepare the plastic particles of Example 2.

[0043] yarn preparation

[0044] First, the plastic pellets of Example 2 were dried at 105° C. for 8 hours to remove moisture. Next, the dried plastic pellets of Example 2 were melt-spun under the conditions of a melt-spinning temperature of 200° C. and a take-up speed of 200 m / min, so as to prepare the yarn of Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com