Electroshape memory composite material, preparation method and applications

A composite material and memory technology, which is applied in the field of electric shape memory composite materials and its preparation, can solve the problems such as the large influence of glass transition temperature, achieve good electric shape memory characteristics, shorten response time, improve modulus and tensile strength The effect of elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

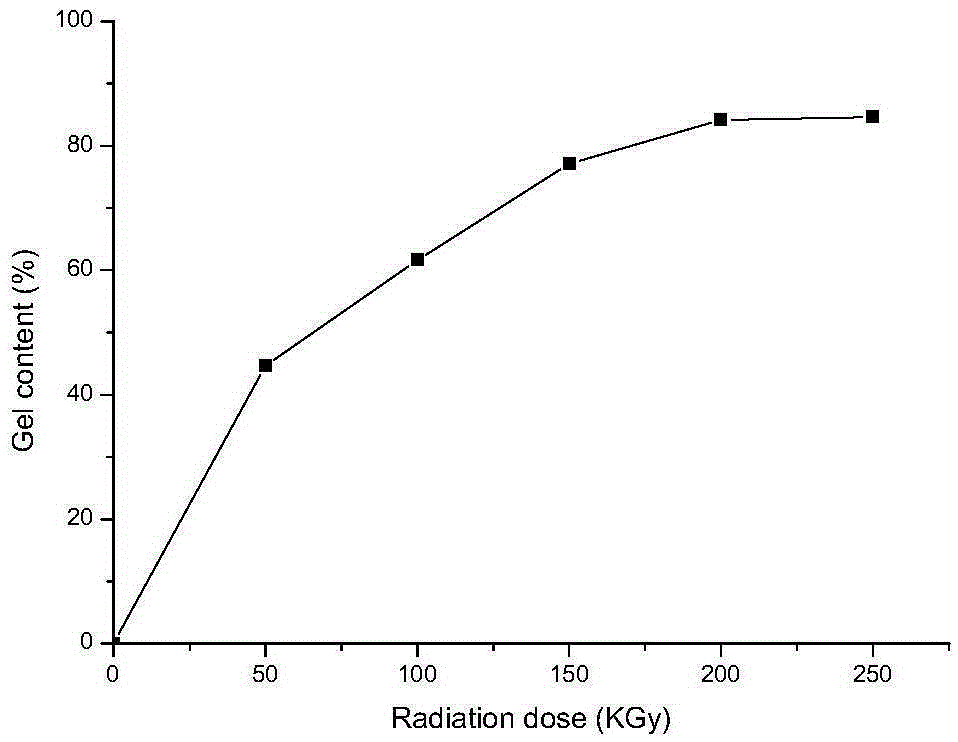

[0024] 1. Preparation of electro-induced shape memory composite material: the sample of SIS / LDPE=30 / 70 was packaged in a plastic bag, and the irradiation source was used under the condition of limited air 60 The γ-ray irradiation of Co, the irradiation dose is respectively 50, 100, 150, 200, 250KGy, then adding content is 12% graphite, after mixing, kneading in X (S) K-400 rubber mixer, at 180 ℃ temperature, making it a uniform mixing material.

[0025] 2. Performance test

[0026] The tensile strength is measured with reference to GB1039-1992, and the tensile speed is 100mm / min.

[0027] Determination of gel content: Chop up the sample and weigh about 0.5g, wrap it in a 300-mesh copper mesh, use toluene as a solvent, and heat it to boil and reflux in a Soxhlet extractor for 72h. Then take out the sample package, wash it twice with acetone, dry it in vacuum at 60°C for 6 hours, take it out and weigh it, and calculate the gel content by formula (1).

[0028] Gel content = (m...

Embodiment 2

[0055] Embodiment 2: the preparation of electrographite / SIS / LDPE composite material

[0056] The sample of SIS:LDPE=30 / 70 is packaged in a plastic bag, and the irradiation source is adopted under the condition of limited air 60 The gamma ray irradiation of Co, the irradiation dosage is 100KGy respectively, then add content and be 24% graphite, after mixing, carry out molding on the XLZ-25T type plate vulcanizing machine, control mold temperature 180 ℃, pressure 10MPa, then cool 10min, make A flake of the blend with a thickness of about 2 mm was obtained.

Embodiment 3

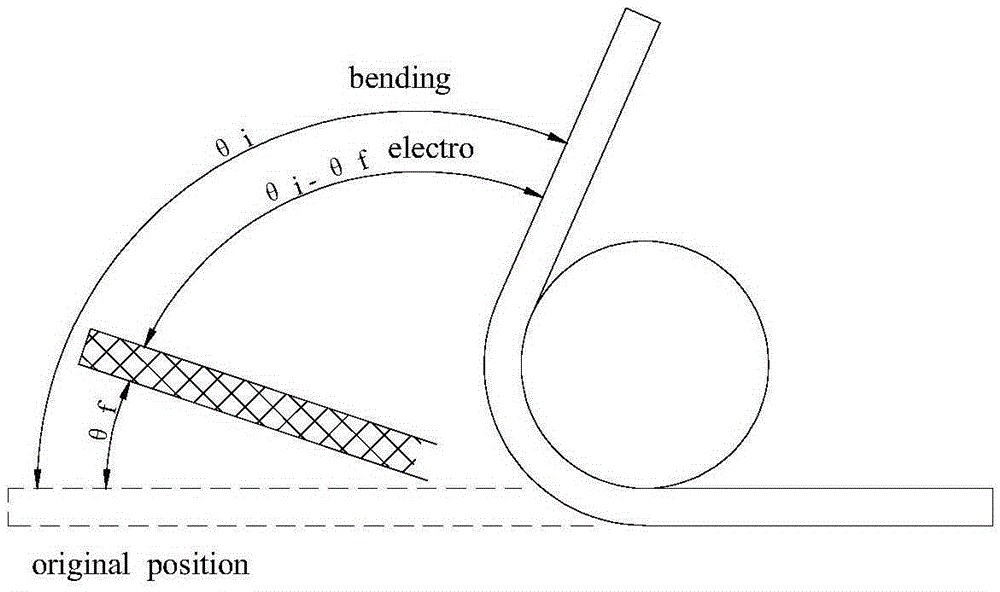

[0057] Example 3: Application

[0058] The electro-graphite / SIS / LDPE composite material sheet in Example 2 is used in the micro-pump in the micro-electro-mechanical system. Under the application of 20-120v voltage, it has the ability to recover completely from deformation and can adapt to large deformation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com