Shape memory polymer composite body with spatially-expanded three-wing beam and its preparation method

A memory polymer and spatial unfolding technology, applied in chemical instruments and methods, synthetic resin layered products, lamination, etc., can solve problems such as unstable control of the unfolding stretching process, complicated unfolding mechanics, and complicated manufacturing processes, etc., to achieve Effect of high specific strength, light material weight and high specific modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

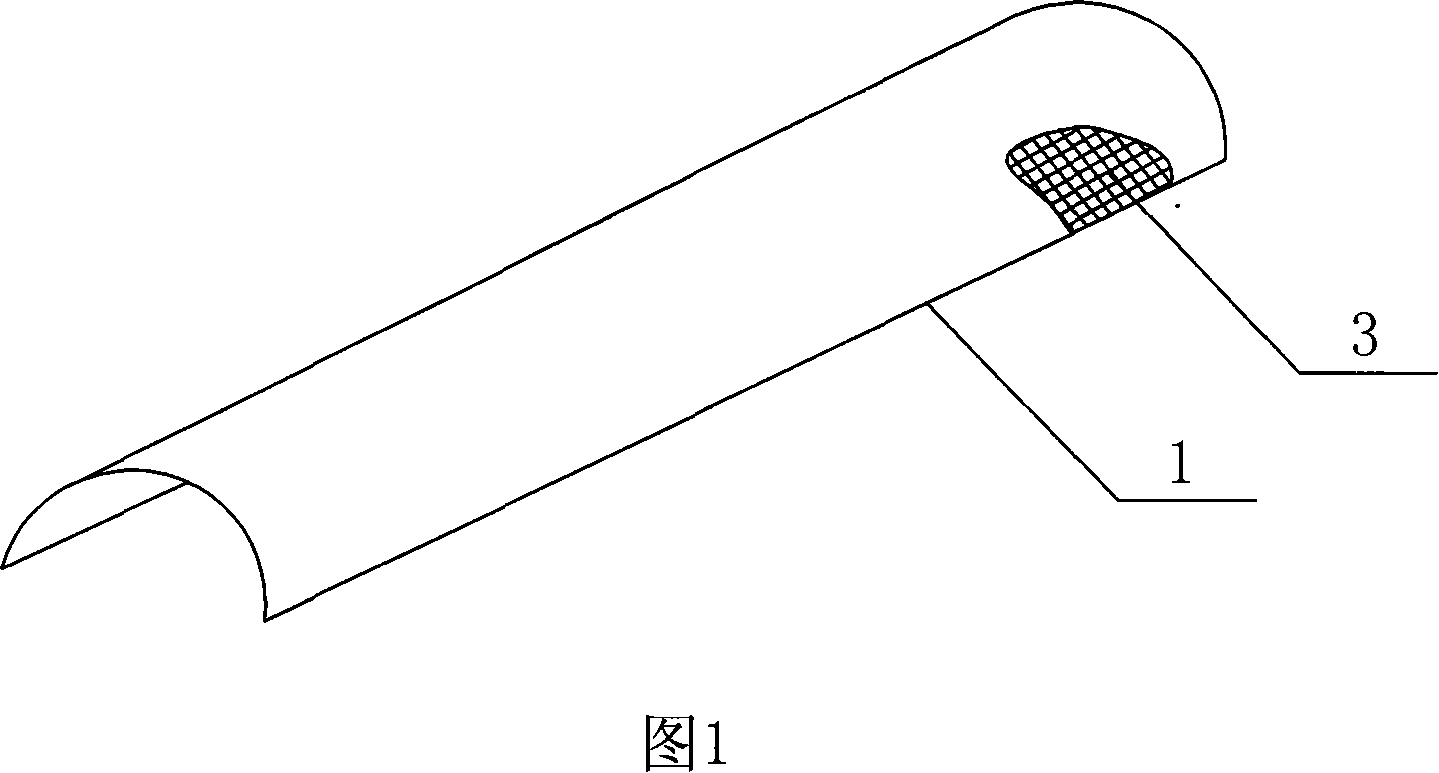

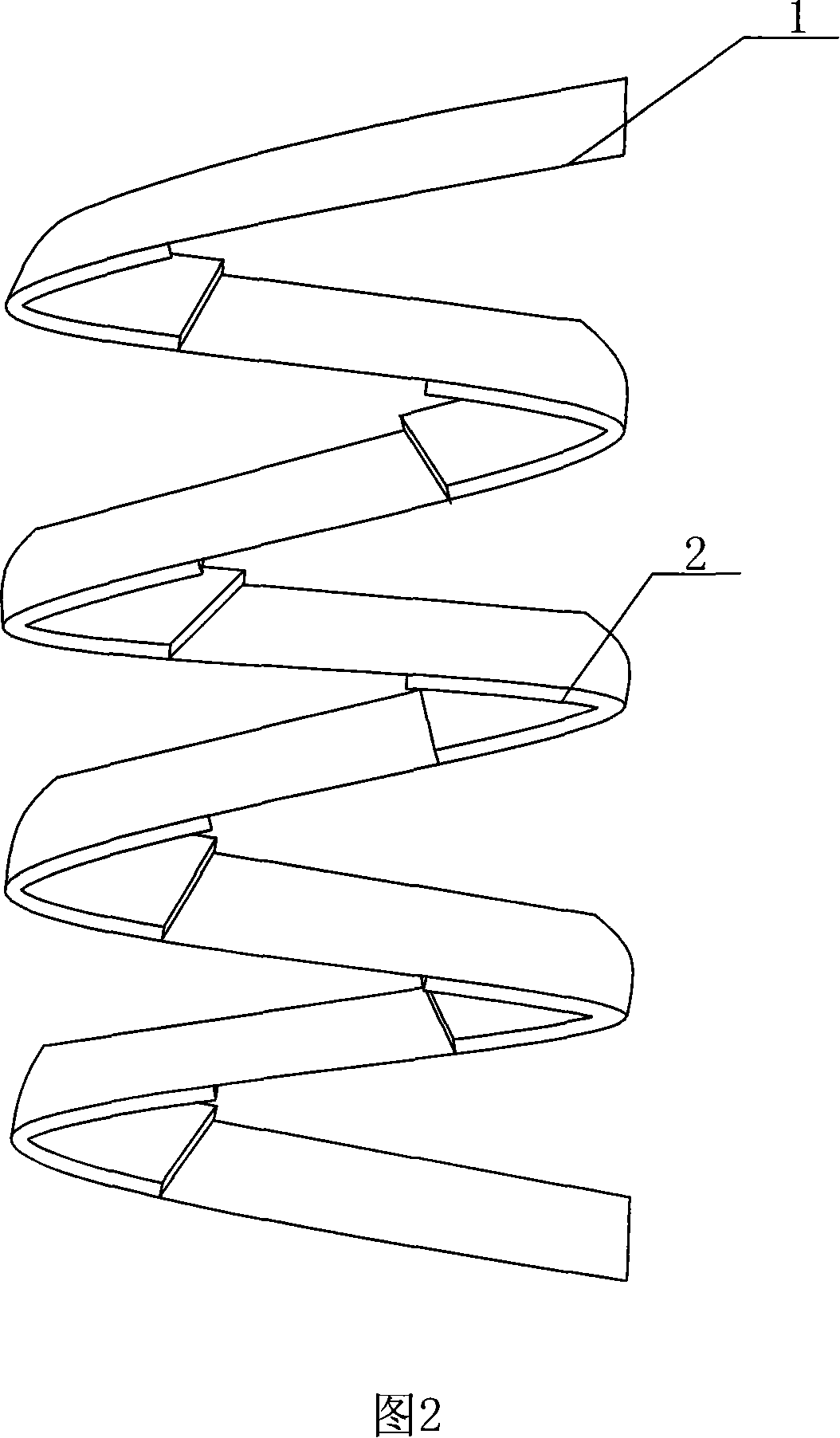

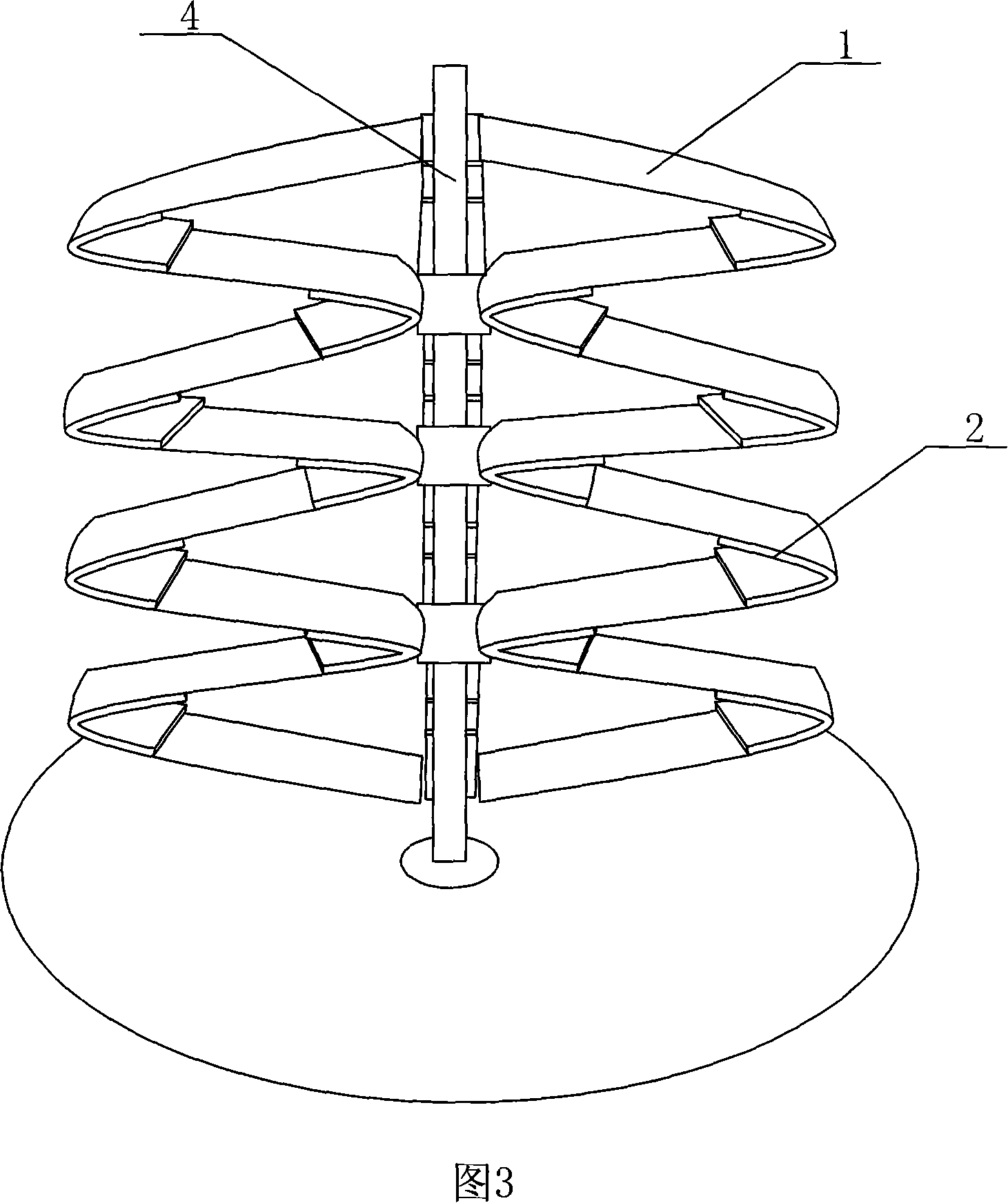

[0016] Specific Embodiment 1: The present embodiment will be specifically described below in conjunction with FIG. 1 and FIG. 2. This embodiment consists of a shape-memory polymer composite material layer 1 and an alloy material layer 2. The shape of the shape-memory polymer composite material layer 1 In a superimposed shape, a resistance wire mesh 3 is laid inside the shape memory polymer composite material layer 1 , and an alloy material layer 2 is connected to the inner side of the curved part of the shape memory polymer composite material layer 1 . The contraction process of the shape memory polymer composite of a complete space expansion three-wing spar: the alloy material layer in the shape memory polymer composite is connected to the stringer 4, and the built-in resistance wire mesh is connected to the shape memory polymer composite material layer Electricity makes the structure reach the shape transition temperature of the shape memory polymer composite material, at thi...

specific Embodiment approach 2

[0017] Embodiment 2: The present embodiment will be described in detail below. The shape memory polymer composite material layer 1 in this embodiment is composed of a shape memory polymer material layer and a fiber reinforced material layer; the shape memory polymer material layer is in The weight percentage content in the shape memory polymer composite material layer 1 is 40-99%, the weight percentage content of the fiber reinforced material layer in the shape memory polymer composite material layer 1 is 1-60%, other compositions and connections The relationship is the same as that of the specific embodiment one.

specific Embodiment approach 3

[0018] Specific Embodiment Three: The present embodiment will be specifically described below. The shape memory polymer material described in this embodiment is shape memory polyurethane resin, polyurethane shape memory polymer, isocyanate shape memory polymer, styrene shape memory polymer material, epoxy-based thermoplastic shape memory polymer or thermosetting shape memory polymer, and other compositions and connections are the same as those in Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com