Method for preparing NiTi memory alloy springs by amorphous molds

A technology of memory alloy springs and memory alloy wires, which is applied in the manufacture of springs from wires, stove types, household appliances, etc., can solve the problems of single structural shape and low production efficiency of shape memory alloy springs, and achieve the effect of high dislocation density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

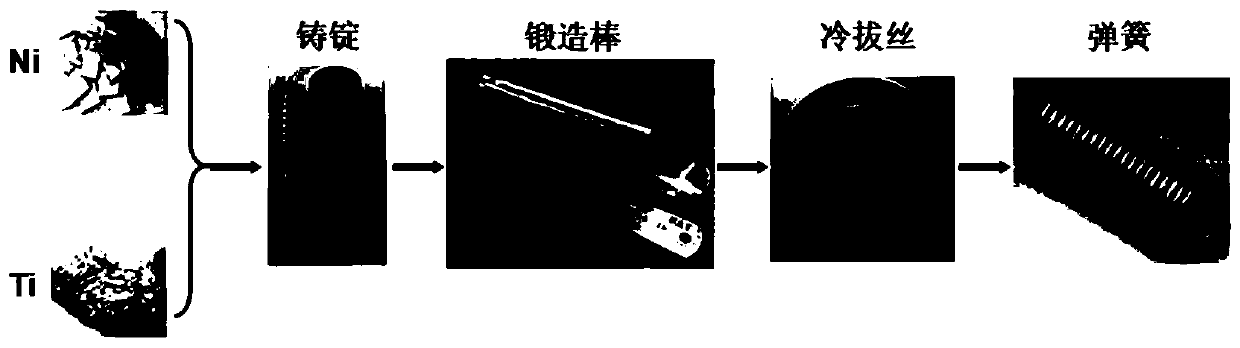

[0038] The present embodiment provides a kind of method that amorphous mold prepares NiTi memory alloy spring, and its flow process is as follows figure 1 shown, including the following steps:

[0039] 1) Cold drawing treatment:

[0040] Choose the NiTi memory alloy wire that diameter is 0.6mm circular cross-section, the chemical composition of this NiTi memory alloy wire is NiTi alloy, wherein the atomic percentage of Ni element is 50.8at%, the balance is Ti; This NiTi memory alloy wire is NiTi alloy The ingot is made by hot forging at 850°C and hot drawing at 500°C;

[0041] The NiTi memory alloy wire is cut to a suitable length and subjected to cold drawing treatment of 40% cold deformation;

[0042] 2) winding into a spring: using an inner core spring winding machine to wind the NiTi memory alloy wire after step 1) cold drawing into a spring with an inner diameter of 5 mm and an effective number of turns n=6;

[0043]3) Shape heat treatment: put the spring wound in step...

Embodiment 2

[0045] The present embodiment provides a kind of method that amorphous mold prepares NiTi memory alloy spring, and its flow process is as follows figure 1 shown, including the following steps:

[0046] 1) Cold drawing treatment:

[0047] Choose the NiTi memory alloy wire that diameter is 0.8mm circular cross-section, the chemical composition of this NiTi memory alloy wire is NiTi alloy, wherein the atomic percentage of Ni element is 50.8at%, the balance is Ti; This NiTi memory alloy wire is NiTi alloy The ingot is made by hot forging at 850°C and hot drawing at 500°C;

[0048] The NiTi memory alloy wire is cut to a suitable length and subjected to cold drawing treatment of 40% cold deformation;

[0049] 2) winding into a spring: using an inner core spring winding machine to wind the NiTi memory alloy wire after step 1) cold drawing into a spring with an inner diameter of 5 mm and an effective number of turns n=6;

[0050] 3) Shape heat treatment: put the spring wound in ste...

Embodiment 3

[0052] The present embodiment provides a kind of method that amorphous mold prepares NiTi memory alloy spring, and its flow process is as follows figure 1 shown, including the following steps:

[0053] 1) Cold drawing treatment:

[0054] Choose the NiTi memory alloy wire that diameter is 1.0mm circular section, the chemical composition of this NiTi memory alloy wire is NiTi alloy, wherein the atomic percentage of Ni element is 50.8at%, the balance is Ti; This NiTi memory alloy wire is NiTi alloy The ingot is made by hot forging at 850°C and hot drawing at 500°C;

[0055] The NiTi memory alloy wire is cut to a suitable length and subjected to cold drawing treatment of 40% cold deformation;

[0056] 2) winding into a spring: using an inner core spring winding machine to wind the NiTi memory alloy wire after step 1) cold drawing into a spring with an inner diameter of 5 mm and an effective number of turns n=6;

[0057] 3) Shape heat treatment: put the spring wound in step 2) i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com