Hydrogel with adjustable adhesion in wet environment and preparation and use methods of hydrogel

A technology of hydrogel and adhesion, which is applied in the field of hydrogel with adjustable adhesion, which can solve the problems of uncontrollable adhesion, weak adhesion and deformation of hydrogel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment 1 provides a hydrogel with adjustable adhesion in a wet environment and its preparation and use method, which specifically includes the following process:

[0026] 1. Preparation of ureido ethyl methacrylate

[0027] Add 56 grams of 30% ammonia solution with a mass fraction of 10% to a three-necked flask and cool to 10°C, vacuumize to remove the air, pass nitrogen protection, and use nitrogen protection throughout the reaction, then use a constant pressure funnel to drop 155 grams of methacrylic acid isocyanide Ethyl ester, reacted for 2 hours after the dropwise addition, and then reacted for 10 hours at 25°C. As the reaction progressed, the reaction solution became uniform and transparent, and finally white crystals precipitated. The precipitated white crystals were filtered, dried in vacuo, washed several times with petroleum ether, and dried under reduced pressure to obtain 170 g of ureidoethyl methacrylate (yield: 90%).

[0028] 2. Preparation of hy...

Embodiment 2

[0033] This embodiment 2 provides a hydrogel with adjustable adhesion in a wet environment and its preparation and use method, which specifically includes the following process:

[0034] 1. Preparation of hydrogel

[0035] Mix 750 μL of monomer acrylonitrile, 750 μL of acrylic acid, 0.6 g of ureidoethyl methacrylate, and 0.1 g of polyethylene glycol with double bonds at both ends of the long-chain crosslinking agent. The solvent is 6 mL of dimethyl sulfoxide and thermal initiator Add 32 mg of azobisisobutyronitrile into a round bottom flask and mix evenly, then add it into a reaction pool consisting of a pair of glass plates, and react at a temperature of 70°C for 8 hours to obtain an organic gel, and then the prepared organic gel The gel was immersed in water for 3 days, and the water was changed every 12 hours, so that the dimethyl sulfoxide in the organic gel was completely replaced with an aqueous solution, and some residual chemical substances were washed away at the same...

experiment example 1

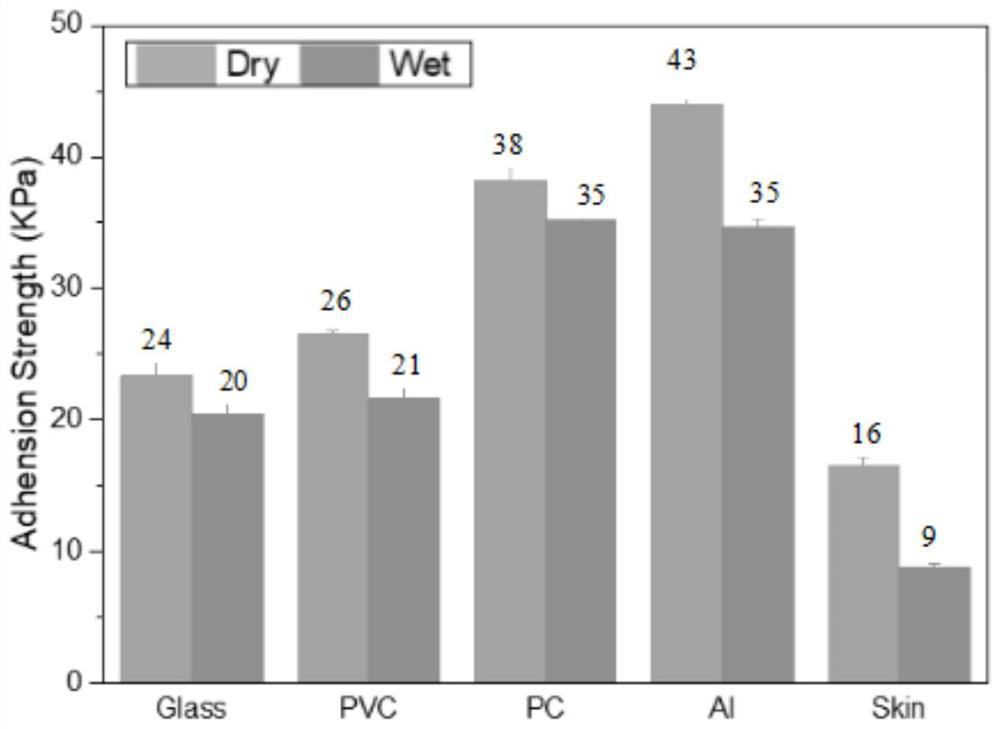

[0040] In order to investigate the adhesion performance of the hydrogel prepared in the present invention on different materials, the hydrogel prepared in Example 1 was tested in dry and wet environments respectively on glass material (Glass), poly Adhesion force on vinyl chloride material (PVC), polycarbonate material (PC), aluminum material (Al) and skin tissue (Skin). The flat side of the hydrogel was stuck on a glass slide, and the other side had microstructures with micropatterns, and the adhesion force between the side with microstructures and different materials was tested. Test results such as figure 1 as shown, figure 1 In the two sets of test data results of different materials, the first set is the data result in the dry environment, and the second set is the data result in the wet environment.

[0041] Depend on figure 1 It can be seen that the hydrogel prepared in Example 1 has the best adhesion on aluminum and polycarbonate materials, followed by polyvinyl chl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com