Preparation method for polylactic acid porous shape memory film

A polylactic acid and pore shape technology, applied in the field of polymer materials, can solve the problems of long production cycle, limited production volume, complicated preparation process, etc., and achieve the effects of short production cycle, good shape memory performance and ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

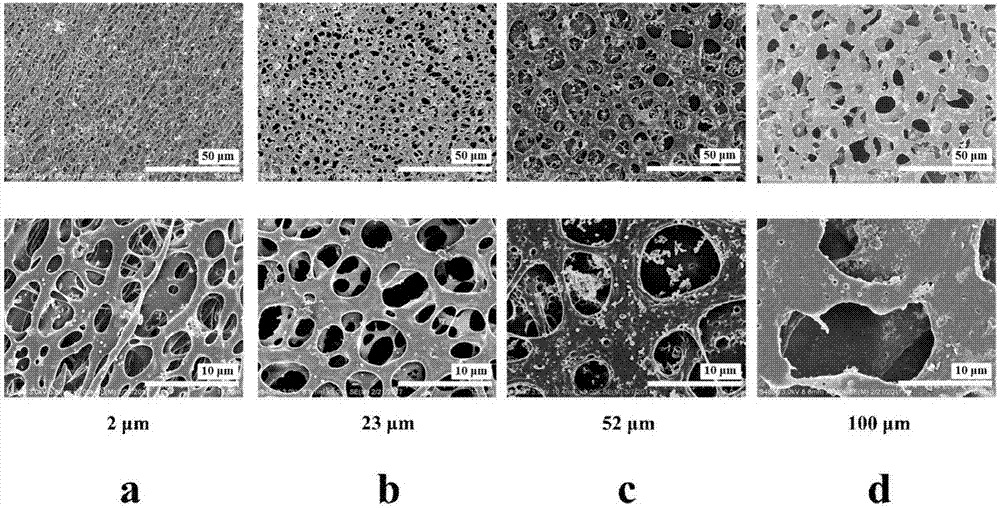

[0032] Embodiment 1: 1) take by weighing 2.0 grams of polylactic acid and 2.0 grams of polyethylene oxide and dissolve in 50 milliliters of chloroform, stir for 12 hours with a magnet, and make the mass ratio of polylactic acid / polyethylene oxide be 1 / 1 , a polymer solution with a mass fraction of 8%; a polylactic acid / polyethylene oxide film was prepared at room temperature using a 2 μm wiper using a polyethylene film as a substrate.

[0033] 2) After placing the film in the air for 30 minutes, soak it in distilled water at room temperature for 48 hours, replace the distilled water every 12 hours, and etch the polyethylene oxide in the film. The etched film was placed in a vacuum oven and dried under vacuum conditions at room temperature for 12 hours to remove moisture in the film, and finally a polylactic acid porous shape memory film was obtained. After the above-mentioned finally obtained thin film was sprayed with gold, it was detected by a scanning electron microscope, a...

Embodiment 2

[0034] Embodiment 2: 1) take by weighing 2.0 grams of polylactic acid and 2.0 grams of polyethylene oxide and be dissolved in 50 milliliters of chloroform, magnetic sub-stirring 12 hours, the mass ratio that makes polylactic acid / polyethylene oxide is 1 / 1 , a polymer solution with a mass fraction of 8%; a polylactic acid / polyethylene oxide film was prepared at room temperature using a 22 μm wiper using a polyethylene film as a substrate.

[0035] 2) After placing the film in the air for 30 minutes, soak it in distilled water at room temperature for 48 hours, replace the distilled water every 12 hours, etch the polyethylene oxide in the film. The etched film was placed in a vacuum oven and dried under vacuum conditions at room temperature for 12 hours to remove moisture in the film, and finally a polylactic acid porous shape memory film was obtained. After the above-mentioned finally obtained thin film was sprayed with gold, it was detected by a scanning electron microscope, an...

Embodiment 3

[0036] Embodiment 3: 1) take by weighing 2.0 grams of polylactic acid and 2.0 grams of polyethylene oxide and be dissolved in 50 milliliters of chloroform, magnetic sub-stirring 12 hours, the mass ratio that makes polylactic acid / polyethylene oxide is 1 / 1 , a polymer solution with a mass fraction of 8%; a polylactic acid / polyethylene oxide film was prepared at room temperature using a 52 μm wiper on a polyethylene film substrate.

[0037]2) After placing the film in the air for 30 minutes, soak it in distilled water at room temperature for 48 hours, replace the distilled water every 12 hours, and etch the polyethylene oxide in the film. The etched film was placed in a vacuum oven and dried under vacuum conditions at room temperature for 12 hours to remove moisture in the film, and finally a polylactic acid porous shape memory film was obtained. After the above-mentioned finally obtained thin film was sprayed with gold, it was detected by a scanning electron microscope, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com