Method for recovering waste water from sodium dichloroisocyanurate production

A technology of sodium dichloroisocyanurate and recovery methods, which is applied in chemical instruments and methods, natural water treatment, degassed water/sewage treatment, etc., and can solve the problems of non-direct discharge, reuse of brine, high investment and operating costs, etc. problems, to achieve the effect of easy realization, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

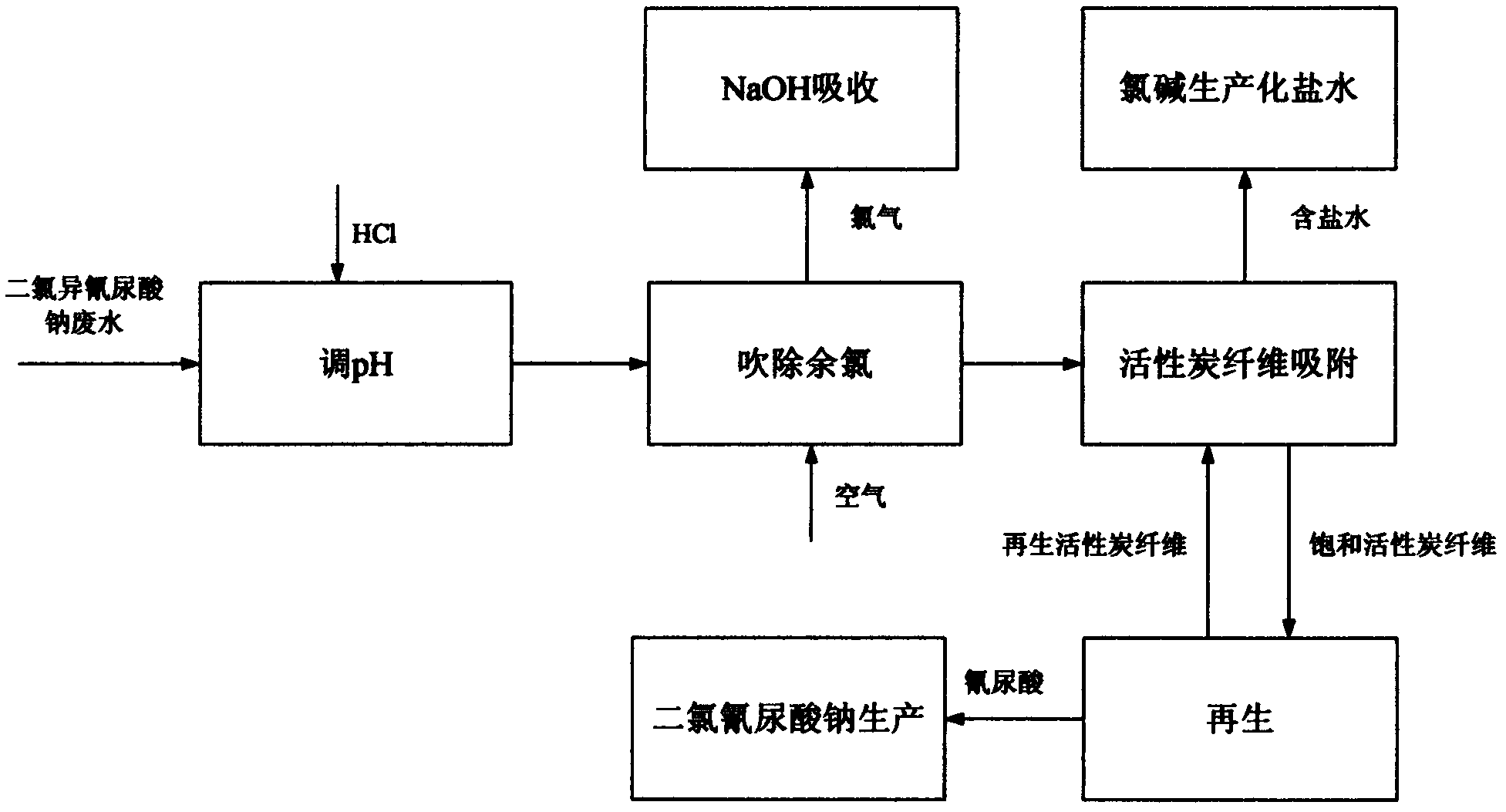

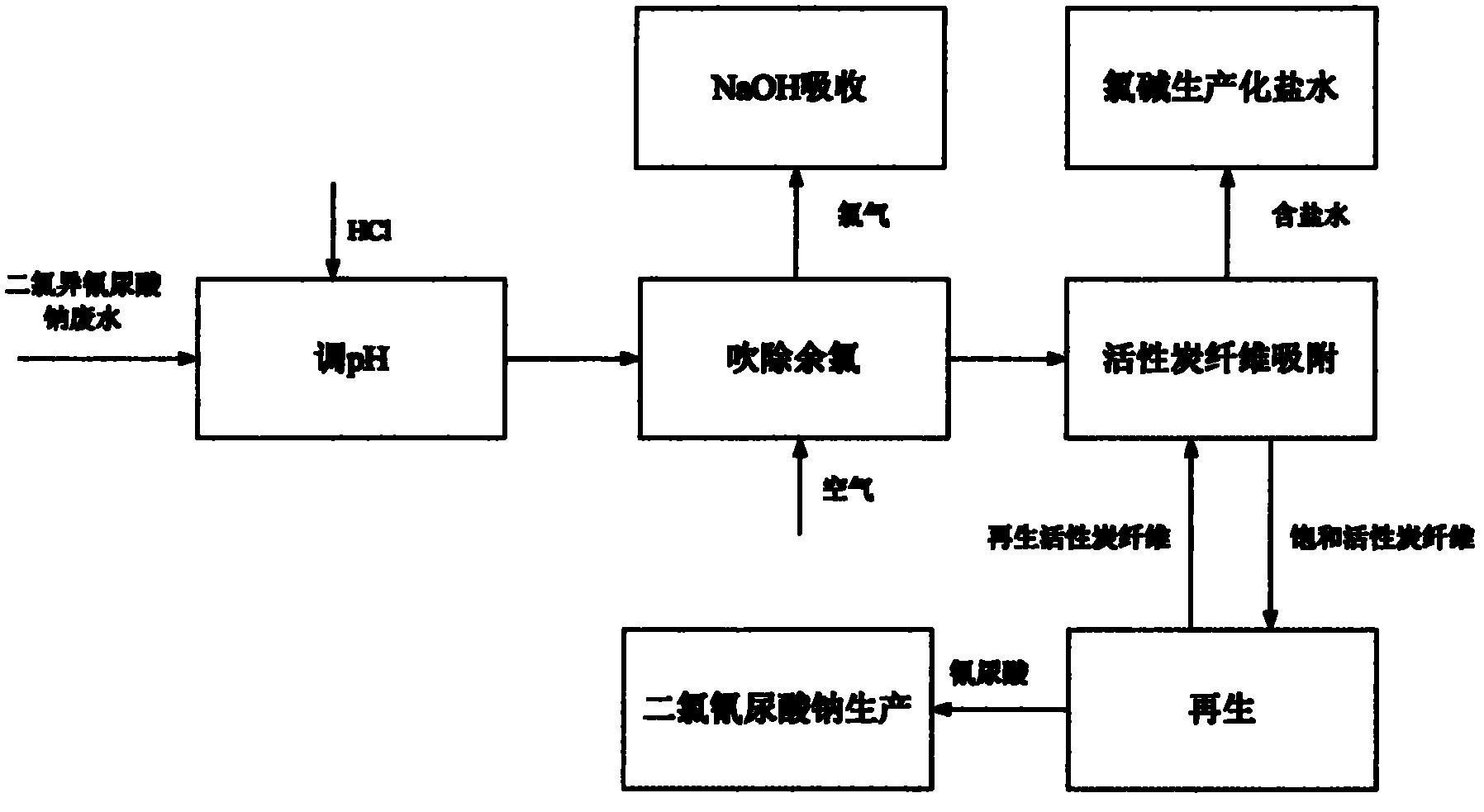

Image

Examples

Embodiment 1

[0022] Example 1 Hydrochloric acid acidification of sodium dichloroisocyanurate production wastewater, the amount of hydrochloric acid added is 1% of the wastewater, the chlorine in the wastewater is blown off with air, the air enters the tower kettle, is extracted from the top of the tower, and the wastewater is added from the top of the tower. Ta Ke is mined. The chlorine at the top of the tower enters the alkali absorption tower and is absorbed. The alkali liquid in the alkali absorption tower is 10% sodium hydroxide. The wastewater from the tower reactor enters the activated carbon fiber adsorption column for dynamic adsorption. The height to diameter ratio of the activated carbon fiber column is 10:1, the operating temperature is normal temperature, and the wastewater flow rate is 1BV. The total ammonia nitrogen content in the water from the fiber column is 3.0 mg / L, and the NaCl content is 8.5%, and the aqueous solution is sent to the chlor-alkali workshop to continue to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com