A method of manufacturing fiber with memory function

A manufacturing method and functional technology, applied in the field of fiber manufacturing and polymer fiber manufacturing, can solve the problems of lower production efficiency and unsatisfactory results, etc., and achieve the effect of smooth unwinding, good structural stability, and soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

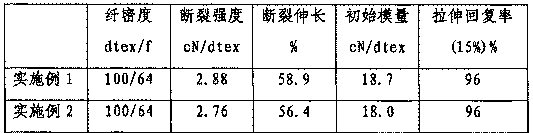

Embodiment 1

[0036] A method for manufacturing a fiber with a memory function, the method of manufacturing is carried out according to the following process:

[0037] The manufacture method of core spinning dope is:

[0038]1.1) Dry copper foam, dry it at 100°C for 4 hours, then place it in a stainless steel kettle, evacuate it to below 0.2 standard atmospheric pressure, and at a temperature of 95°C, inject docosane liquid into the stainless steel kettle to impregnate the foam copper, apply 0.1 The pressure of MPa, keeps 4 hours, makes modified copper foam;

[0039] 1.2) Preparation of fiber-forming polymer solution: mix the raw materials polytetramethylene ether glycol and 4,4-diphenylmethane diisocyanate, and react at 75°C for 50 minutes to prepare a prepolymer, in which 4,4-diphenyl The molar ratio of methyl methane diisocyanate to polytetramethylene ether glycol is (1.80~2.00): 1; after the prepolymerization is completed, N,N-dimethylacetamide solvent is added to the prepolymer to mak...

Embodiment 2

[0058] A method for manufacturing fibers with a memory function, the method of manufacturing is carried out according to the following processes:

[0059] The manufacture method of core spinning dope is:

[0060] 1.1) Dry the copper foam, dry it at 120°C for 6 hours, then place it in a stainless steel kettle, evacuate it to below 0.2 standard atmospheric pressure, and at a temperature of 98°C, inject docosane liquid into the stainless steel kettle to impregnate the foam copper, apply 0.2 The pressure of MPa, keeps 6 hours, makes modified copper foam;

[0061] 1.2) Preparation of fiber-forming polymer solution: mix raw materials polytetramethylene ether glycol and 4,4-diphenylmethane diisocyanate, and react at 90°C for 90 minutes to prepare a prepolymer, in which 4,4-diphenyl The molar ratio of methyl methane diisocyanate to polytetramethylene ether glycol is (1.80~2.00): 1; after the prepolymerization is completed, N,N-dimethylacetamide solvent is added to the prepolymer to m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com