Bidirectional torsional lead shear damper

A technology of damper and damping layer, which is applied in the direction of building components, shockproof, etc., can solve the problems of reducing energy consumption performance, lead plastic deformation, etc., and achieves the effects of convenient manufacture, small working performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

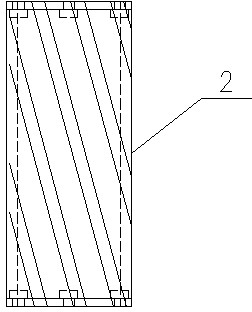

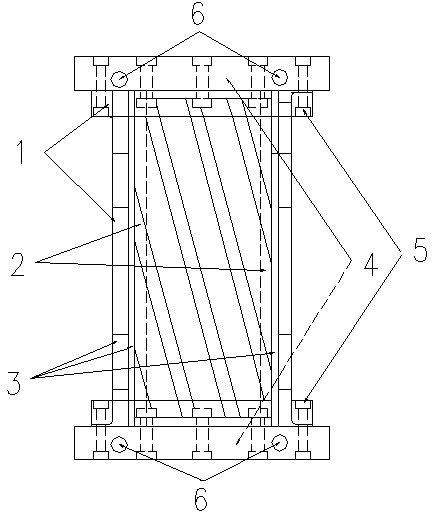

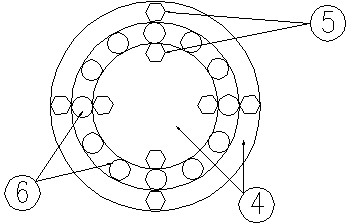

[0018] Further illustrate the present invention in conjunction with accompanying drawing and embodiment, as Figure 1-6 As shown, the embodiment of the present invention is an outer and inner hollow steel cylinder, the upper and lower ends of the outer hollow steel cylinder 1 and the inner hollow steel cylinder 2 are fixed to the bearing plate 4 by bolts 5, and the bearing plate 4 The inner and outer rings rotate relatively, and the interlayer between the outer hollow steel cylinder 1 and the inner hollow steel cylinder 2 is the damping layer 3, and the damping layer 3 is made of lead or magnesium alloy or Zn-Al alloy high damping solid material. The lead used in the example is embedded in the hollow part of the inner and outer cylinders. Under the action of axial load along the cylinder, the inner and outer rings of the bearing plate 4 rotate relative to each other. Because the hollowed out parts of the inner and outer cylinders are designed with oblique grooves at opposite a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com