Alumina fiber and alumina fiber aggregate

A technology of fiber aggregates and alumina, which is applied in the direction of transportation and packaging, artificial filaments made of inorganic materials, textiles and papermaking, etc. It can solve the problems of reduced number of fibers, difficulty in maintaining thickness and resilience for a long time, and achieve shape recovery sex good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] "Example 1"

[0050]In such a way that the alumina component is 73% by mass and the silica component is 27% by mass, 5000 g of an aqueous aluminum hydroxychloride solution having an alumina solid content concentration of 20.0% by mass is mixed with a colloidal solution having a silica concentration of 20.0% by mass. 1850 g of silica was mixed, and further, the solid content of partially saponified polyvinyl alcohol (manufactured by Denki Kagaku Kogyo Co., Ltd.) with a degree of polymerization of 1700 was mixed so that the total solid content of the alumina component and the silica component was 8% by mass. 1096 g of an aqueous solution having a concentration of 10% by mass was then dehydrated and concentrated under reduced pressure to prepare a spinning stock solution with a viscosity of 3300 mPa·s. For this spinning stock solution, from the 300 holes with a diameter of 0.2 mmφ at equal intervals on the peripheral surface of a hollow disk with a diameter of 350 mmφ, the...

Embodiment 2~5

[0077] "Examples 2-5", "Comparative Examples 1-3"

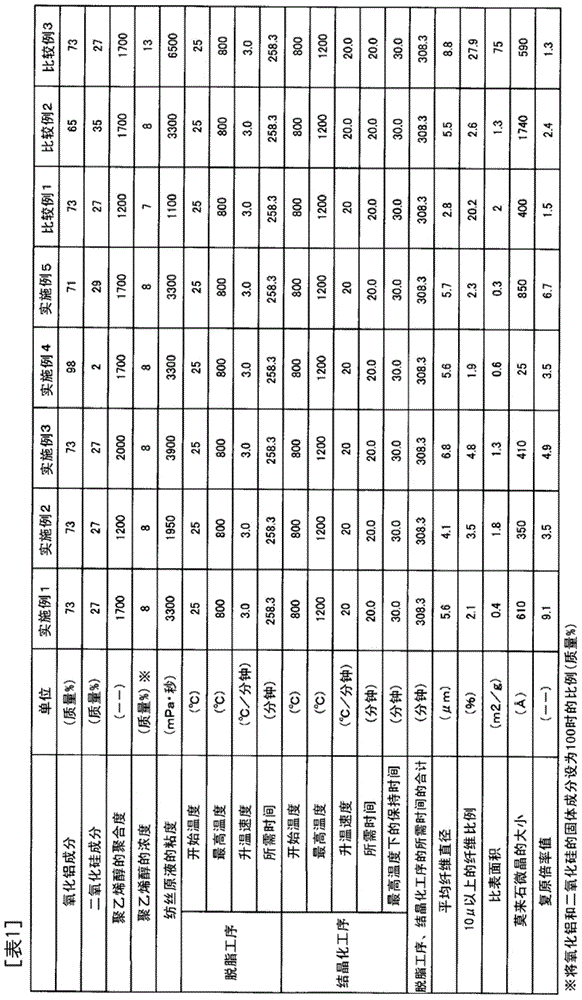

[0078] In addition to changing the composition of alumina and silica in the spinning dope and the type and concentration of polyvinyl alcohol added to the spinning dope, prepare alumina fiber aggregates under the same conditions as in Example 1, and measure its physical properties. The composition of alumina and silica, the type and concentration of polyvinyl alcohol, the operating conditions of the device, and the evaluation results are shown in Table 1 together with Example 1.

[0079]

Embodiment 6~8

[0080] "Examples 6-8", "Comparative Examples 4, 5"

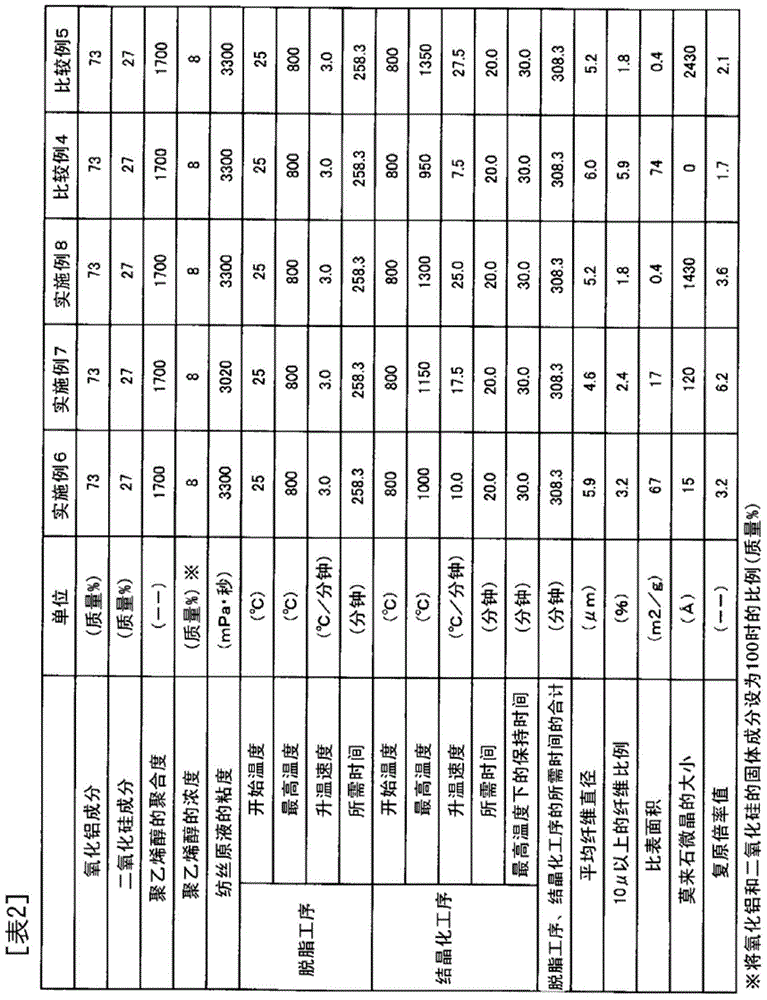

[0081] The fiber precursor was produced with the same composition as in Example 1, the maximum temperature of the crystallization process was changed in the range of 950°C to 1350°C, and the time required for the temperature rise of the crystallization process was changed accordingly. Except for the rate of temperature increase, alumina fibers and an alumina fiber aggregate composed of the fibers were prepared under the same conditions as in Example 1, and their physical properties were measured. Table 2 shows the compositions of alumina and silica, the type and concentration of polyvinyl alcohol, the operating conditions of the apparatus, and the evaluation results.

[0082]

[0083]From the results shown in Table 1, the aggregate of alumina fibers whose average fiber diameter is 3.0 μm to 8.0 μm and whose fiber diameter is larger than 10 μm is 5% or less shows a good shape. Resilience. On the other hand, when the alum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com