Patents

Literature

99 results about "Aluminum hydroxychloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

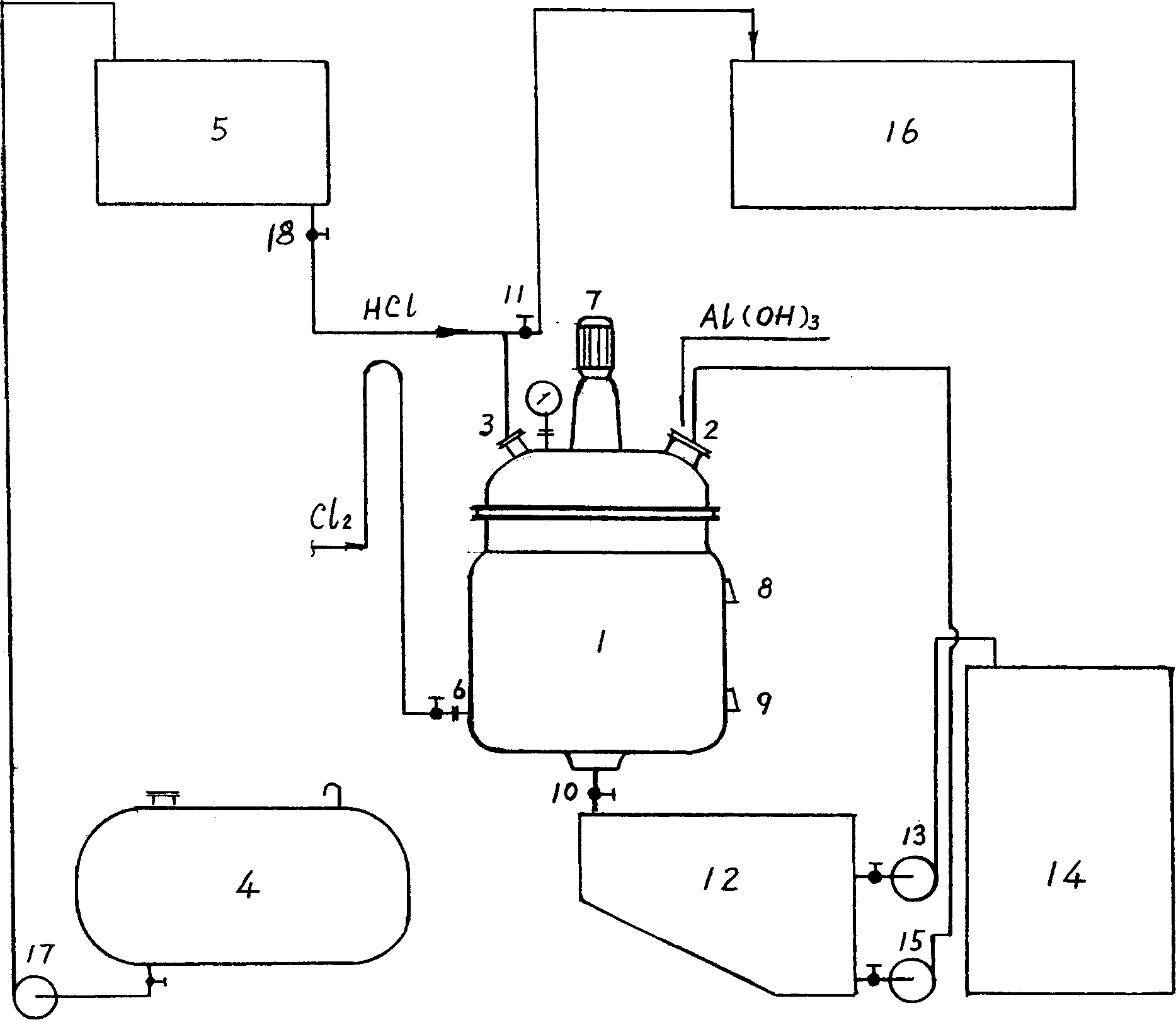

Process and equipment for preparing aluminium polychloride

InactiveCN1381401ASimple production processSimplify productivityAluminium chloridesAluminium chlorohydrateAluminium hydroxide

A process for preparing aluminium polychloride from hydrochloric acid and aluminium hydroxide includes such steps as blowing appropriate quantity of chlorine gas into the mixed solution of hydrochloric acid and aluminium hydroxide, reaction of chlorine gas on water in the solution to generate hydrochloric acid and hypochlorous acid as catalyst for next reaction, and reaction of hydrochloric acid on aluminium hydroxide to generate aluminium hydroxychloride. Its advantages are simple process and equipment, short period, and high sterilizing, seaweed-killing and decolouring function. The productis an efficient water deaner.

Owner:牛程鹏

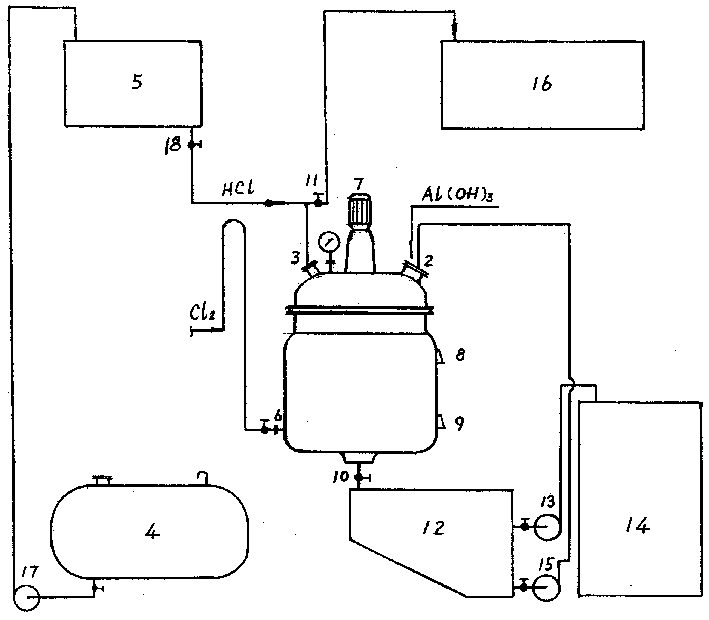

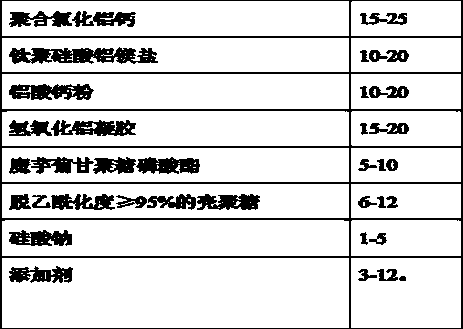

Multi-element composite flocculant for treating printing and dying wastewater and textile wastewater and preparing method thereof

ActiveCN103420468AImprove flocculation efficiencyReduce dosageWater/sewage treatment by flocculation/precipitationPhosphateAluminium silicate

The invention relates to a multi-element composite flocculant for treating printing and dying wastewater and textile wastewater and a preparing method of the multi-element composite flocculant. The flocculant comprises polymeric aluminium, titanium polysilicic acid aluminium silicate, calcium aluminate powder, aluminium hydroxide gel, konjac glucomannan phosphate, chitosan, sodium silicate and an additive, wherein the deacetylation degree of the chitosan is larger than or equal to 95%. Through appropriate selection of components and proportion, the multi-element composite flocculant has the advantages of being high in flocculation efficiency, small in dosage, wide in temperature application range and pH application range and the like. The multi-element composite flocculant can be used for treatment and purification of the printing and dying wastewater and the textile wastewater and has wide industrialized application prospects and market values.

Owner:广州市豫泉净水材料有限公司

High-argillization coal washing agent

InactiveCN103977909AControl the degree of hydrolysisFully dispersedFlotationAluminium chlorideFoaming agent

The invention discloses a high-argillization coal washing agent. The high-argillization coal washing agent is characterized by comprising a collecting agent, a foaming agent and a flocculating agent, wherein the collecting agent is 390-440g / t of N9883; the foaming agent is 400-430g / t of fusel; the flocculating agent comprises polyacrylamide and polymeric aluminum; the control concentration of the polymeric aluminum is 0.5-1.2 percent; the preparation concentration of the polyacrylamide is 0.1-0.15 percent; the usage of the polyacrylamide is required to be controlled to be 0.1-1 percent according to a volume ratio. Compared with the prior art, the high-argillization coal washing agent has the advantages that slime water is timely clarified, so that coal can be washed by clean water, slime is recovered, and the coal washing water is recycled.

Owner:SHANDONG DONGSHAN WANGLOU COAL MINE

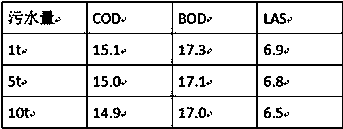

Polyacrylamide sewage treating agent and preparation method thereof

The invention discloses a polyacrylamide sewage treating agent and a preparation method thereof. The sewage treating agent is prepared from the following components in parts by weight: 30-40 parts of aluminum polychlorid, 15-25 parts of polyacrylamide, 3-8 parts of quartz sand, 1-5 parts of diatomite, 3-6 parts of dimethyl diallyl ammonium chloride, 5-10 parts of acrylamide, 0.5-2 parts of fatty amine, 0.5-1 part of polyethylene glycol 2000, 0.8-1.5 parts of polysorbate, 0.1-0.5 part of EDTA, 1-5 parts of hydroxypropyl methyl cellulose and 60-70 parts of deionized water. The preparation method comprises the following steps: respectively adding 10-20 parts of dimethyl diallyl ammonium chloride, acrylamide, EDTA, polyethylene glycol 2000, polysorbate and deionized water into a reaction kettle, uniformly stirring, adding fatty amine under nitrogen protection, and heating to react to obtain an intermediate I; and mixing the residual components to obtain an intermediate II, and finally mixing the intermediates I and II to obtain the polyacrylamide sewage treating agent.

Owner:格润化学(东营)有限公司

Method for preparing coagulant and application thereof

ActiveCN104724803AReduced adsorption activityAvoid volumeWater/sewage treatment by flocculation/precipitationAluminium chlorideAluminium hydroxide

The invention discloses a method for preparing a coagulant and an application thereof. The method comprises the following steps: by taking industrial aluminium hydroxide as a main raw material, reacting with a sodium hydroxide solution under high temperature, cooling to room temperature, adding a hydrochloric acid solution into the reaction solution, controlling the basicity of the reaction solution to 2.4-2.7, and rapidly stirring to obtain an aluminium trichloride mixed solution with high basicity containing an active aluminium hydroxide gel; and heating and aging to obtain the coagulant after uniformly mixing the aluminium trichloride mixed solution with high basicity containing the active aluminium hydroxide gel. The invention also discloses an application of the coagulant prepared by the method for removing heavy metals in the water body. The preparation method provided by the invention is simple in process, low in energy consumption and small in device corrosion; and the obtained coagulant is good in stability without changing within 6 months, convenient to use and has a good removing effect on the heavy metals and the COD in the water body.

Owner:重庆能兴科技发展有限公司

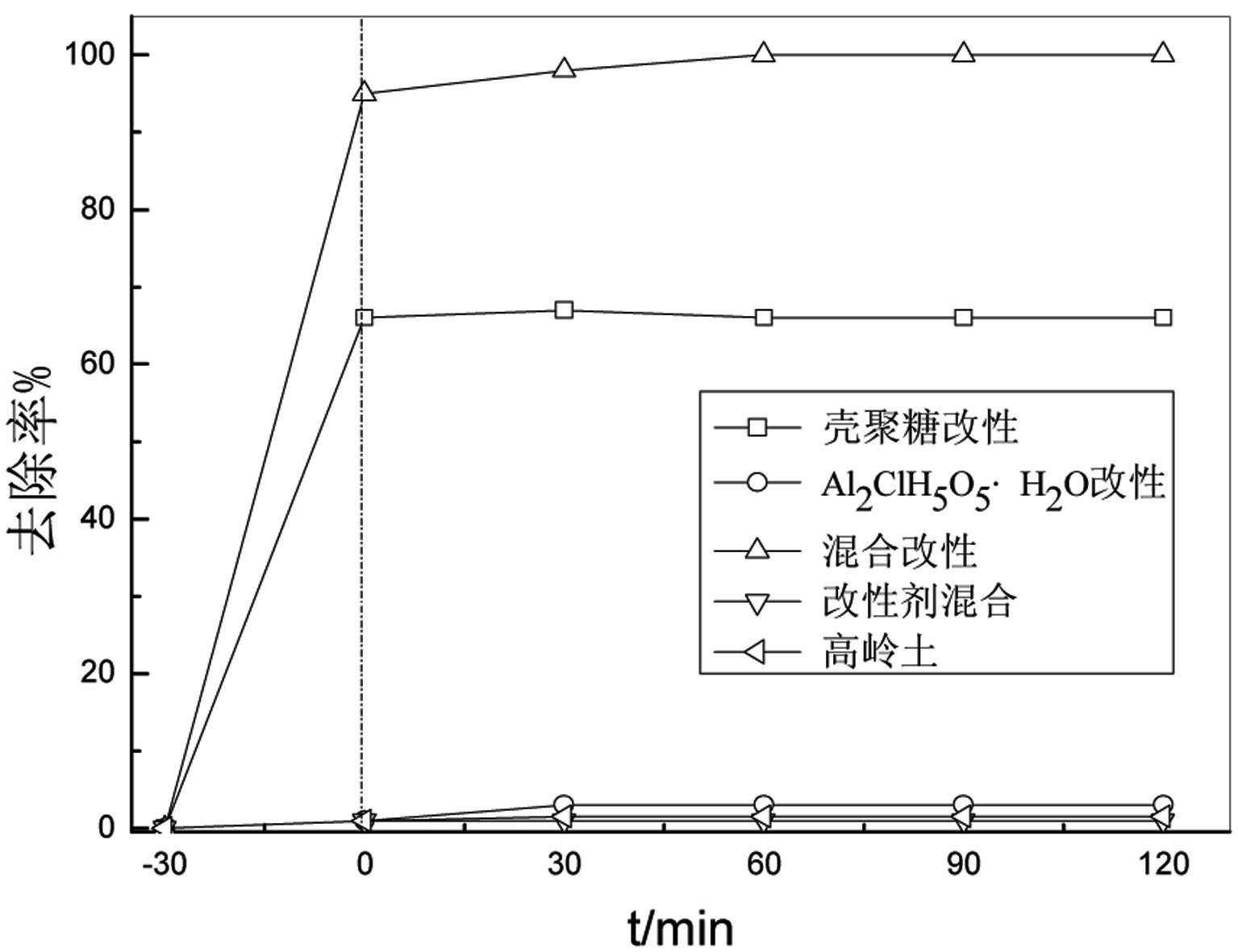

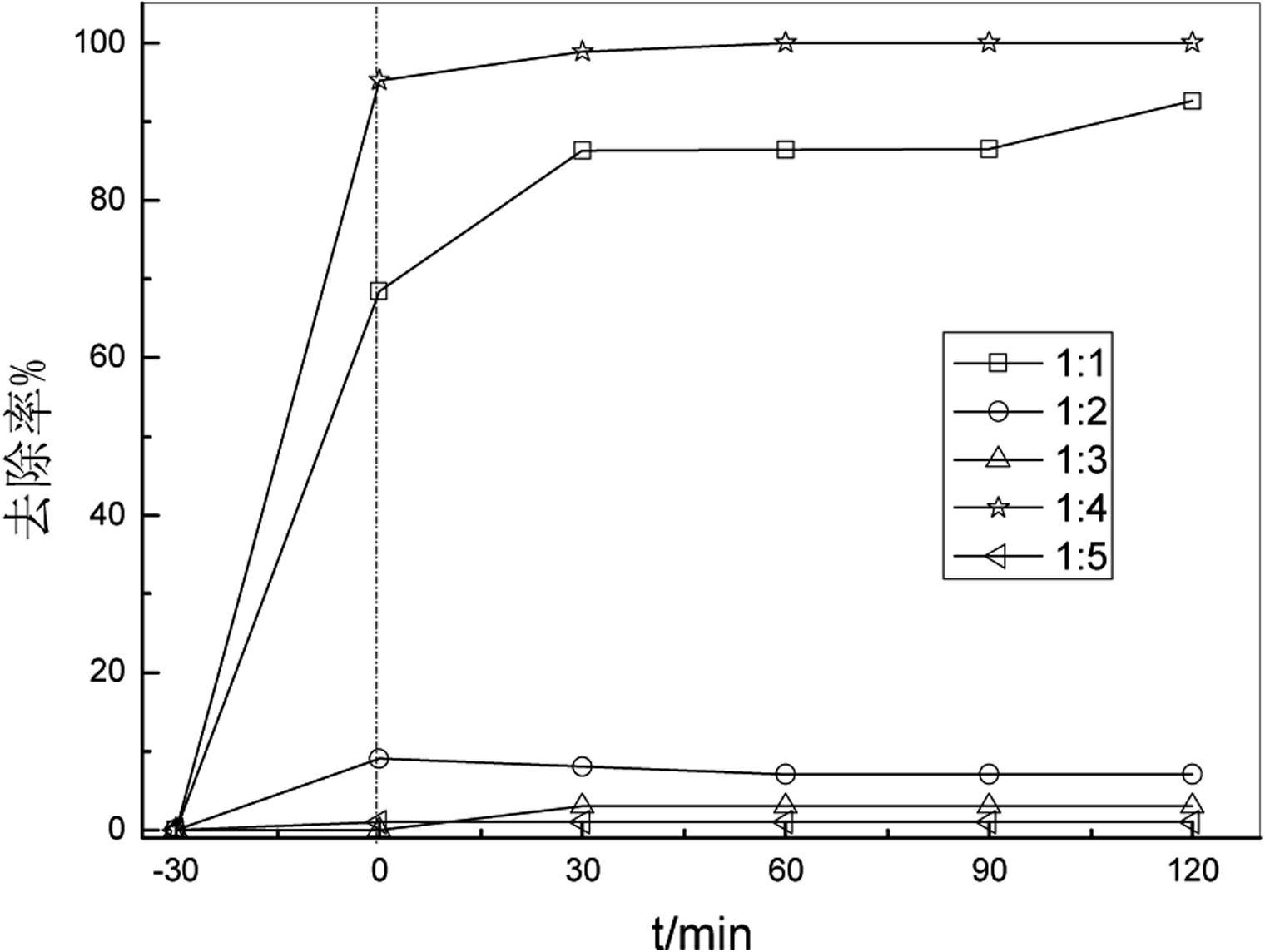

Preparation method of modified kaoline alga flocculating agent and application thereof

ActiveCN102249386AEasy to prepareLow costWater/sewage treatment by flocculation/precipitationFlocculationPollution

The invention discloses a preparation method of a modified kaoline alga flocculating agent and application thereof. The alga flocculating agent is prepared by mixing a mixture of chitosan and aluminum hydroxychloride serving as a modifier with kaoline. The preparation method of the kaoline alga flocculating agent provided by the invention has the advantages of easiness for operation, low cost and no secondary pollution because the modifier and a substrate are environment-friendly materials; and simultaneously, the flocculating agent has a high-efficiency flocculation action and a good alga removing effect.

Owner:CHINA THREE GORGES UNIV

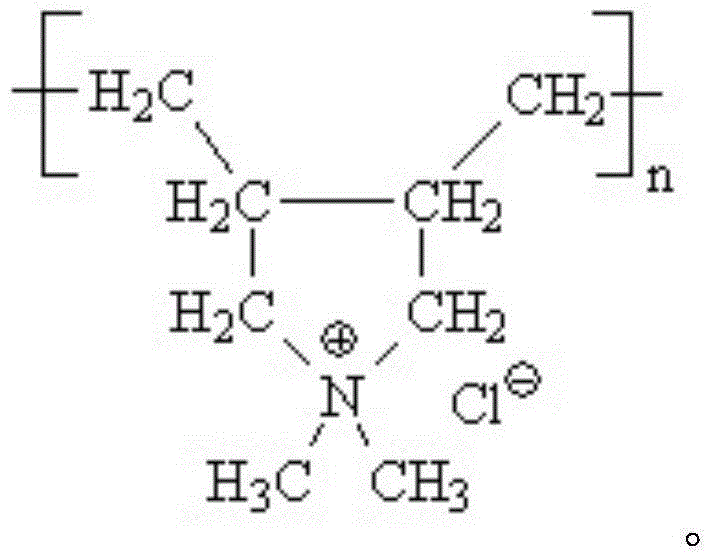

Organic macromolecular flocculating agent for polymer-bearing sewage and preparation method for organic macromolecular flocculating agent

ActiveCN105060446AImprove flocculation abilityEfficient removalWater/sewage treatment by flocculation/precipitationSide effectPoly(diallyldimethylammonium chloride)

The invention discloses an organic macromolecular flocculating agent for polymer-bearing sewage and a preparation method for the organic macromolecular flocculating agent. Before a mixing reaction, the organic macromolecular flocculating agent comprises the following components in percentage by mass: 30-40 percent of polymeric aluminum, wherein the mass of non-ion polyacrylamide is 5 percent of the mass of polymeric aluminum; the mass ratio of poly diallyldimethylammonium chloride to the polymeric aluminum is 1-2: 2-3. After a polymerization reaction, the weak cation type organic macromolecular flocculating agent can be obtained; an extremely good flocculating effect is achieved, and organic impurities and emulsified oil in polymer-bearing crude oil wastewater can be effectively removed; furthermore, a small quantity of produced floccules are produced, and the form is stable; the organic macromolecular flocculating agent is prepared by a compounding method and has the advantages of simple technology, readily available raw material, good water purification effect, low cost, small use amount and the like, and has no toxic and side effects.

Owner:E TECH ENERGY TECH DEV CORP

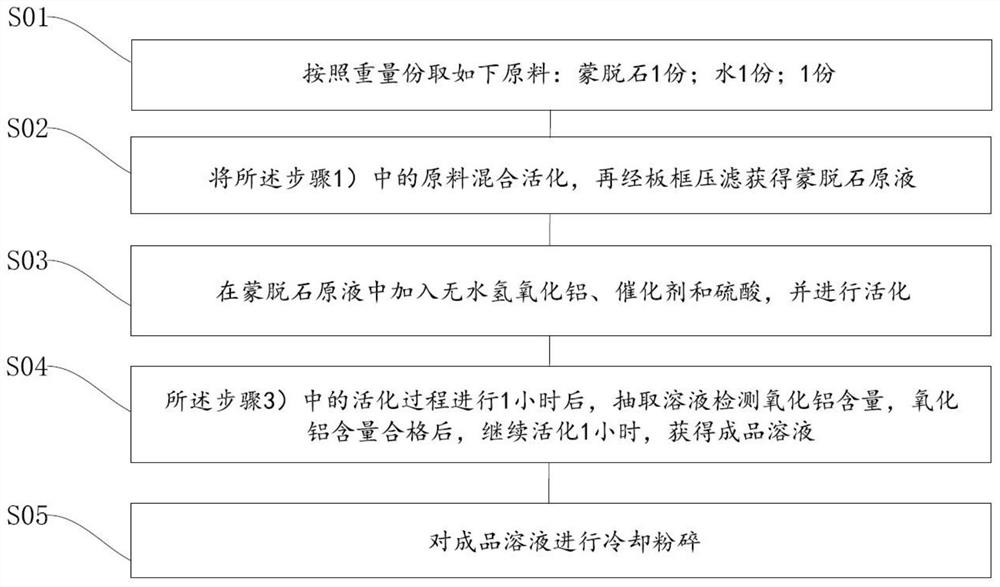

Preparation method of oily sewage treatment agent for petrochemical industry

PendingCN113716634ASolve difficult problemsEasy to handleWater contaminantsWater/sewage treatmentIron sulfateAluminium chloride

The invention discloses a preparation method of an oily sewage treatment agent for petrochemical industry, and belongs to the technical field of sewage treatment. The preparation method comprises the following steps: 1), taking 1 part of montmorillonite, 1 part of water and 1 part of sulfuric acid; 2) mixing and activating the raw materials in the step 1), and performing plate-frame press filtration to obtain a montmorillonite stock solution; and 3) adding anhydrous aluminum hydroxide, a catalyst and sulfuric acid into the montmorillonite stock solution, and activating; and after the activation process in the step 3) is carried out for 1 hour and the content of aluminum oxide is qualified, continuously activating for 1 hour to obtain a finished product solution. According to the invention, with the agent containing the aluminum hydroxide, the sulfuric acid, the catalyst and the montmorillonite stock solution, the difficult problem that COD, SS, petroleum and total phosphorus are difficult to degrade is solved, the wastewater treatment process of the whole petrochemical industry is further improved, the problem of poor treatment effect of an existing sewage treatment agent (aluminum polychlorid, polyferric sulfate, aluminum sulfate) and other products is solved, and the problem of difficult load operation of later biochemical treatment is solved.

Owner:内蒙古美赢环保科技有限公司

Efficient flame-retardant cable material for railway locomotive

InactiveCN105733107AImprove resistance to dialysisImprove flame retardant performanceRubber insulatorsPolyolefinMoisture resistance

The invention discloses an efficient flame-retardant cable material for a railway locomotive. The efficient flame-retardant cable material is prepared from the following raw materials in parts by weight: 5-7 parts of magnesium hydroxide, 9-11 parts of kaolin, 6-8 parts of polyaluminum chloride, 6-8 parts of tin-bismuth alloy powder, 26-33 parts of polypropylene, 6-7 parts of ammonium polyphosphate, 7-9 parts of conductive mica powder, 3-4 parts of stearic acid, 1-2 parts of polyacrylamide, 0.4-0.6 part of an anti-oxidant 1680, 48-55 parts of ethylene propylene terpolymer, 30-35 parts of polyolefin, a proper amount of absolute ethyl alcohol and a proper amount of deionized water. According to the efficient flame-retardant cable material, the water resistance and moisture resistance of the material can be remarkably improved, and dialysis resistance, in a high polymer material, of a filler is improved; the efficient flame-retardant cable material is efficient, flame-retardant, moisture-proof and waterproof, safe and environmentally-friendly, good in heat resistance, high in oil resistance and chemical resistance, long in service life, and worthy of being popularized.

Owner:ANHUI KANGLIYA CO LTD

Method for preparing water purifying agent containing polyaluminium chloride from aluminium ash

ActiveCN109534466ALow investment costLow running costWater/sewage treatment by flocculation/precipitationAluminateNitrogen gas

The invention provides a method for preparing a water purifying agent containing polyaluminium chloride from aluminium ash, comprising the steps of: roasting aluminium ash, calcium carbonate and / or calcium oxide in an oxidizing atmosphere; allowing the roasted product to react with hydrochloric acid to prepare the water purifying agent containing polyaluminium chloride, and water washing the obtained filter residue to be used as the solid residue used for other purposes or being piled up and buried. The method oxidizes the metal aluminum contained in the aluminum ash into aluminum oxide, oxidizes the contained aluminum nitride into aluminum oxide and nitrogen, allows the aluminum oxide with low reaction activity to react to generate calcium aluminate, and thus the aluminum oxide is activated, thereby solving the flammable and explosive problems of generating hydrogen gas during metal aluminum hydrolysis or acidolysis, and solving the problem of purified water containing ammonium nitrogen caused by ammonium generated by ammonium nitride hydrolysis enters the water purifying agent; furthermore, polyaluminum chloride water purifying agent and polyaluminum ferric chloride composite water purifying agent are prepared. The process is simplified, the investment and operation cost are low, and the filter residue is a general solid waste.

Owner:山东铝晖环保科技有限公司

Rare earth compounded coagulating agent for treating waste water and its preparation method

InactiveCN1394815AThe effect of treating printing and dyeing wastewater is goodReduce dosageSedimentation separationWater/sewage treatment by flocculation/precipitationAluminium chlorohydrateSulfur

The present invention relates to a rare earth compounded coagulating agent for treating waste water, and the effective components of its solid product are Al2O3 27%-29%, Ln2O3 0.5%-6.0% and SO4(2-) 0.5%-6.5%, and its basic degree is 55%-68%. It is made up by using aluminium polychloride as main component and adding the elements of rare earth and sulfur, etc. through a certain compounding process, in which the introduction quantity of the rare earth compound can be controlled in that the mole ratio o f Ln / Al is 0.0055:1 to 0.06624:1. Said ivnention also provides the preparation method of said coagualting agent.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

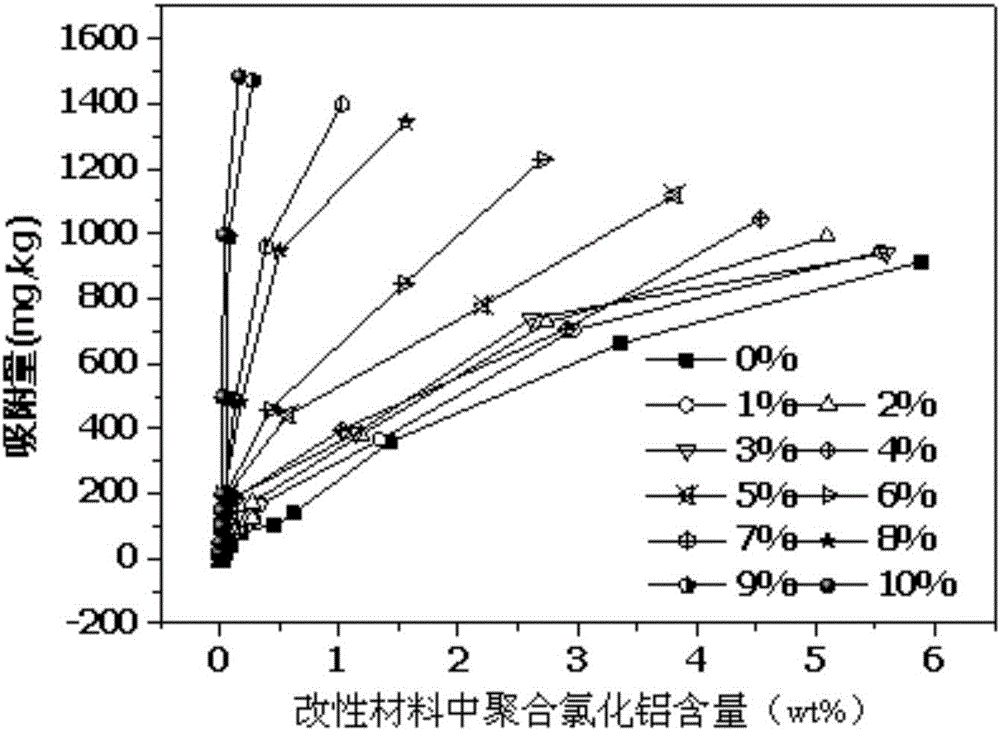

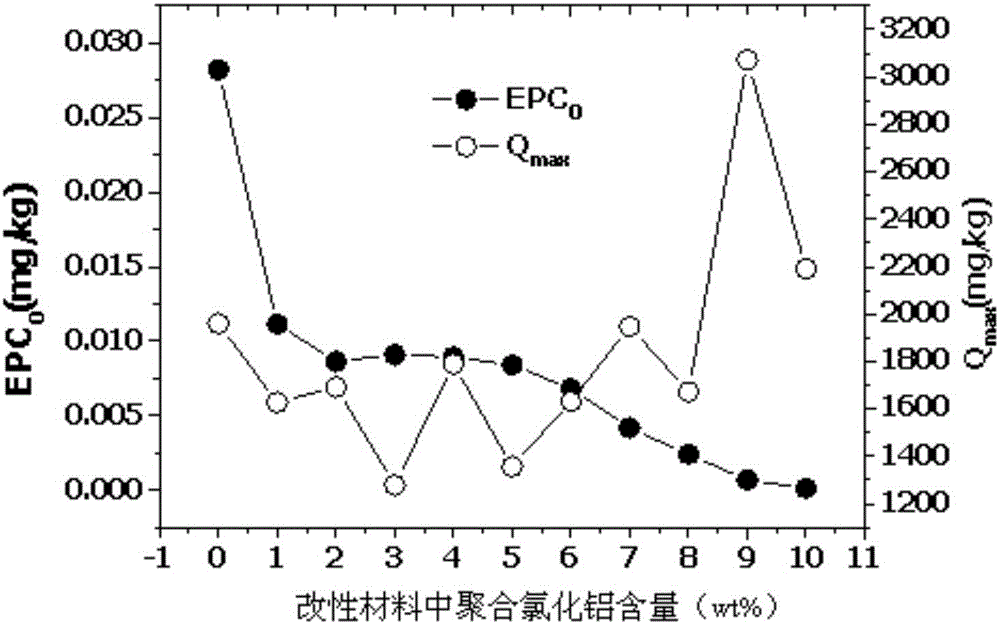

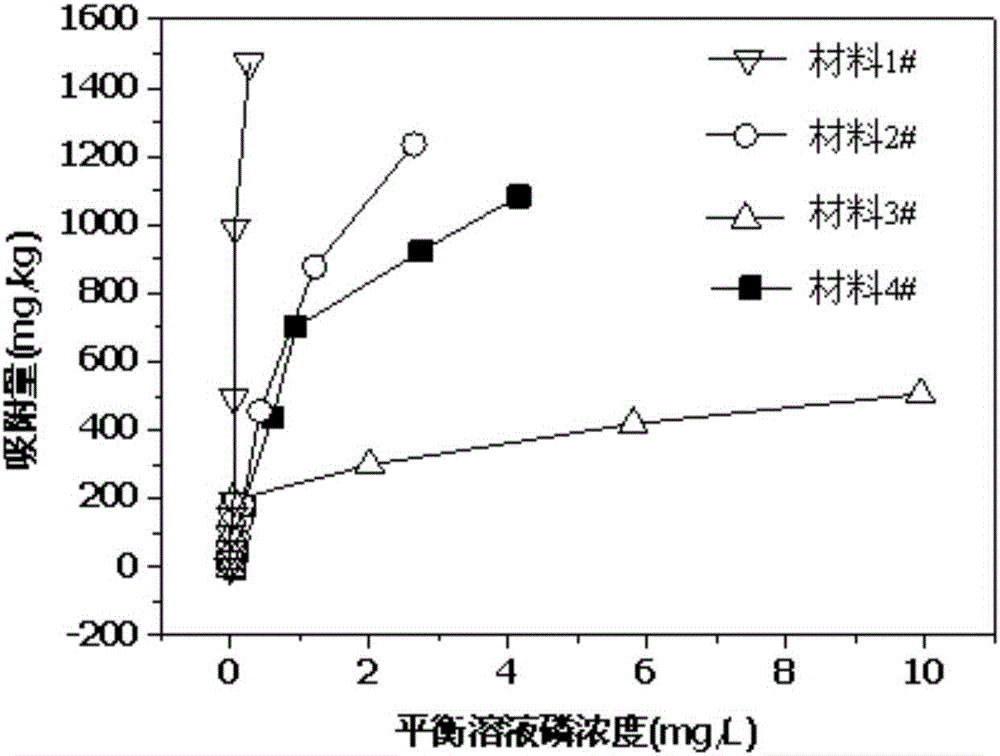

Preparation method and application of sediment endogenous phosphorus load control bottom sediment modified material

ActiveCN106277673ADesorption does not occur easilyIncrease the adsorption-desorption equilibrium concentrationSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningPhosphateWater quality

The invention provides a preparation method and application of a sediment endogenous phosphorus load control bottom sediment modified material. With creatively lake sediments being basic materials, by the utilization of the processes of modifying, granulating, calcining and others of zeolite and aluminum polychlorid, the adsorption-desorption balance concentration of the material for phosphate is obviously reduced, and the maximum adsorbing quantity of the material is increased. By in-situ simulation of a sediment-water interface phosphate release process, it is proved that the material can effectively restrain release of sediment-water interface phosphate; because the desorption capacity of the material for the phosphate is low, and the adsorption capacity is large, the material can really achieve sediment endogenous phosphorus load control, and the purpose of improving the water quality of a lake / reservoir is achieved. Taken materials are cheap, and the material has good economic benefits and high safety and has no ecological risks for a water body of the lake, saves energy, is environmentally-friendly and achieves an obvious control effect on sediment-water interface phosphorus release at different lake regions of the Dian lake during application.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Application of scale inhibitor containing sodium gluconate to salt-draining closed conduit

InactiveCN106082456ANo cloggingGood anti-scaling effectTreatment using complexing/solubilising chemicalsGluconic acidSodium sulfate

The invention relates to a scale inhibitor containing sodium gluconate. The scale inhibitor comprises the following components by weight parts: 15-19 parts of amino trimethylene phosphonic acid, 10-14 parts of polyaspartic acid, 8-12 parts of hexapotassium salt, 6-10 parts of zinc sulfate, 6-10 parts of tartaric acid, 1-5 parts of aluminum polychlorid, 2-6 parts of dodecyl dimethyl benzyl ammonium chloride, 1-5 parts of butyl hydroxy anisd, 1-5 parts of lauric acid, 2-6 parts of lauryl sodium sulfate, 1-5 parts of sodium gluconate, 0.2-0.6 part of bladder-wrack extracts, 0.2-0.6 part of throatroot root extractives and 52-56 parts of deionized water. The scale inhibitor provided by the invention has excellent inhibiting function for the algae propagated in the salt-draining closed conduit, has excellent scale inhibition effect for the inorganic salt sediment in the salt-draining closed conduit and can prolong the service life of the salt-draining closed conduit for 10-12 years.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

Stable salt-free polyaluminum chlorosulfates

ActiveUS9611155B2Reduce moistureAluminium compoundsSedimentation separationAluminium sulfateSalt free

Owner:USALCO

Stable Salt-Free Polyaluminum Chlorosulfates

ActiveUS20150021514A1Less-prone to increaseReduce shipping costsAluminium compoundsWater treatment compoundsAluminium sulfateSalt free

Highly sulfated, high basicity polyaluminum chlorosulfate compositions that can be made by mixing dry aluminum hydroxychloride with a solution of aluminum sulfate or by diluting a dry mixture of aluminum hydroxychloride and aluminum sulfate with water.

Owner:USALCO

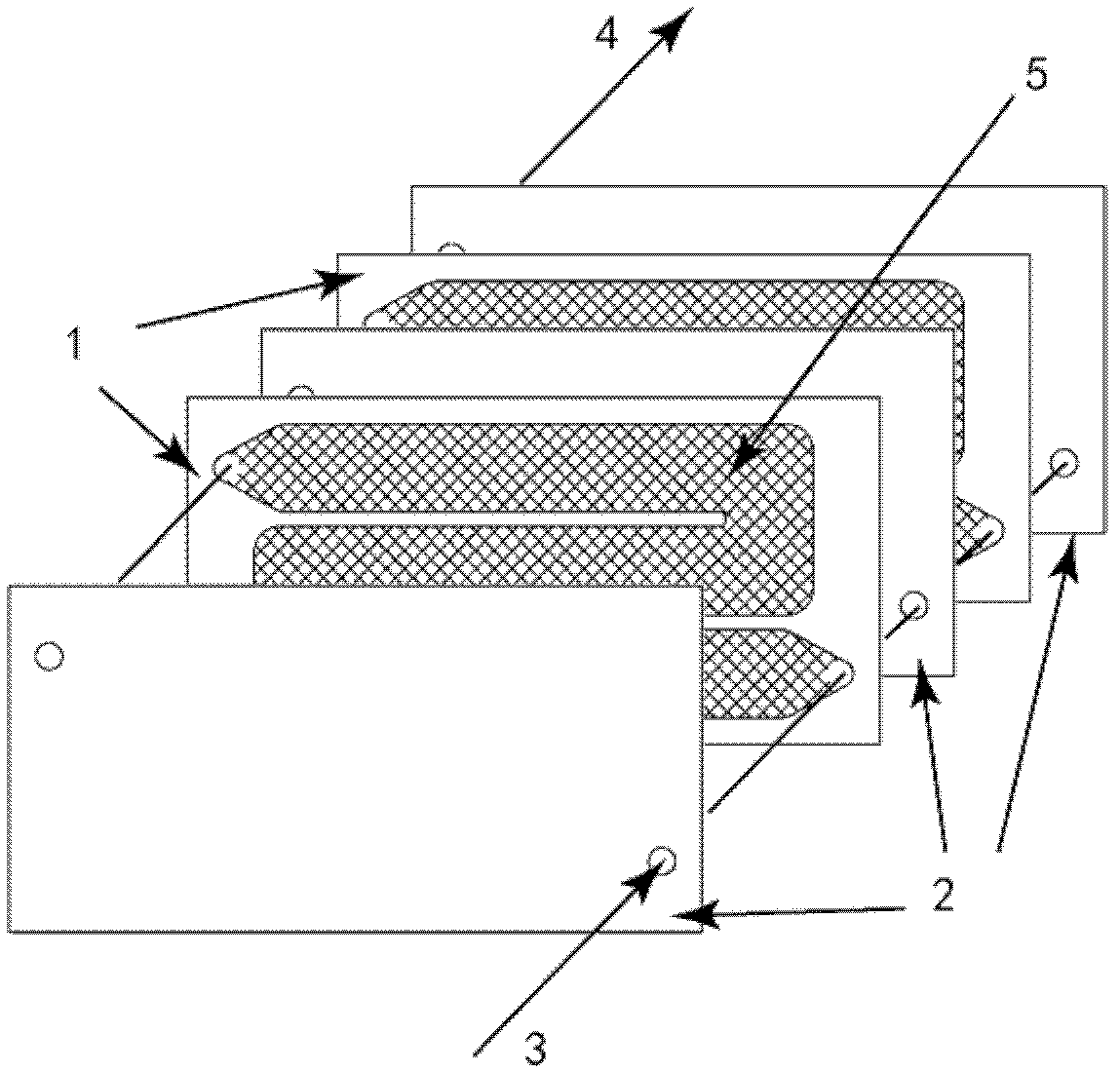

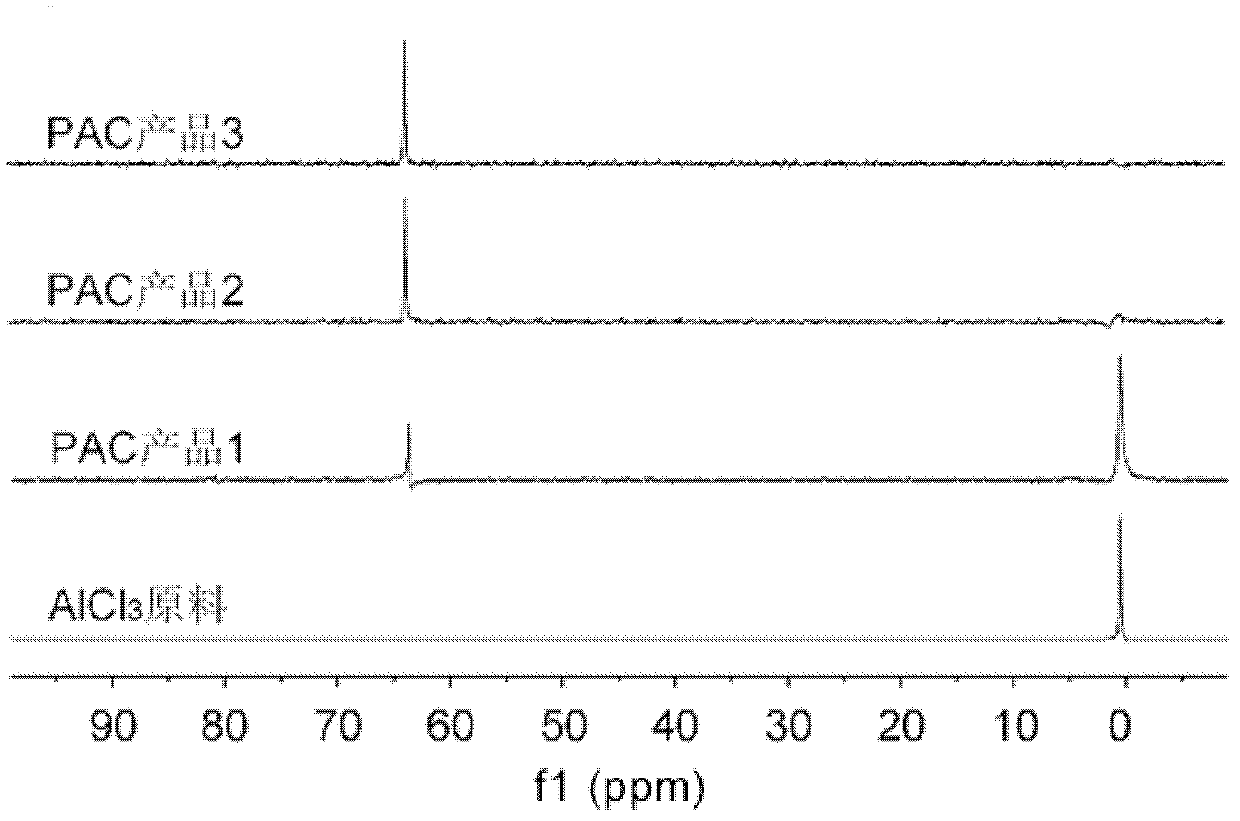

Electrochemical production device and manufacturing method of high-alkalization-degree aluminum polychlorid and Al13 chloride

The invention provides an electrochemical production device of high-alkalization-degree aluminum polychlorid and Al13 chloride. The electrochemical production device comprises a reaction container, a pump, an electrolytic cell stack and a flow rate indicator, which form a closed loop and are sequentially connected with one another, wherein the electrolytic cell stack consists of a plastic partition plate and an electrolytic cell group which are clamped, the electrolytic cell group consists of two inert electrodes which are adjacent to two sides of the plastic partition plate, both the plastic partition plate and each inert electrode are provided with a raw material liquid inlet and a product and half-finished product liquid outlet, respectively, and the inlet is connected with the outlet through a runner which is provided with a turbulence promotion grid. The invention also provides a manufacturing method of the high-alkalization-degree aluminum polychlorid and Al13 chloride by utilizing the production device. By adopting the device and the method, the distance between the electrodes and the polarization in an electrolysis process can be greatly reduced, the voltage loss in the electrolysis process can be reduced, and the energy consumption is reduced; rubber partitions such as aluminum hydroxide can be eliminated, and the aluminum polychlorid with high purity and alkalization degree and even the pure Al13 chloride can be directly produced.

Owner:WENZHOU UNIVERSITY

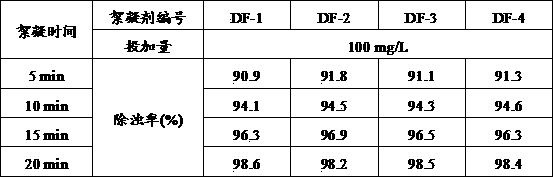

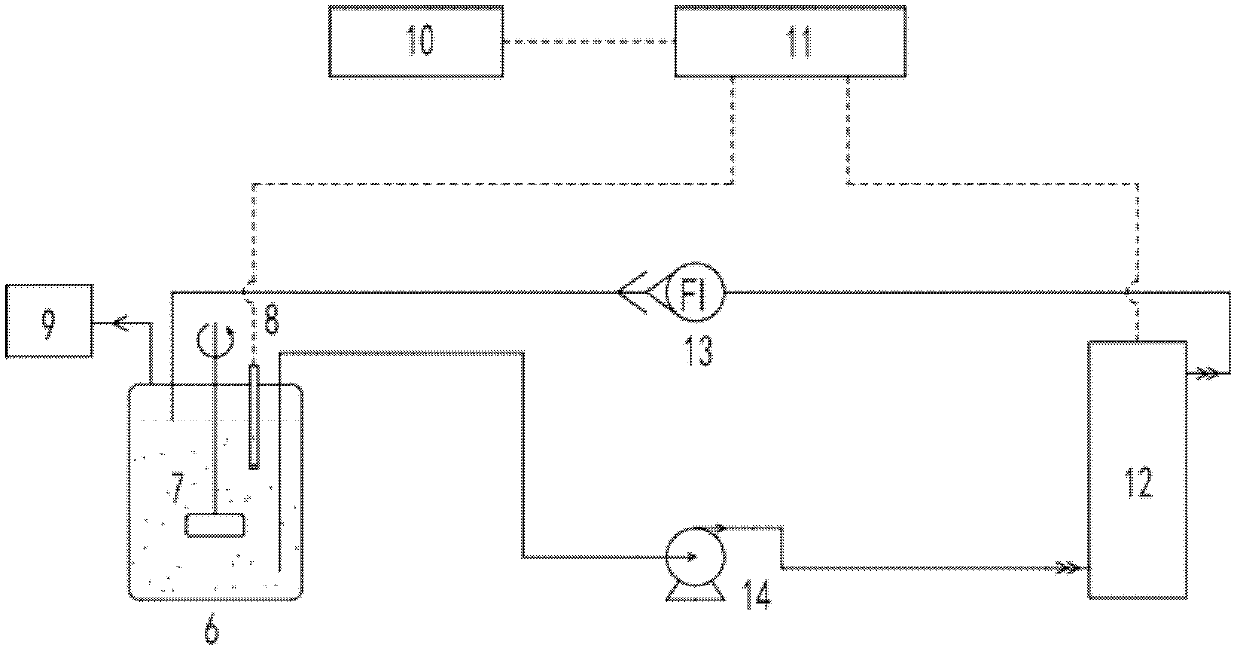

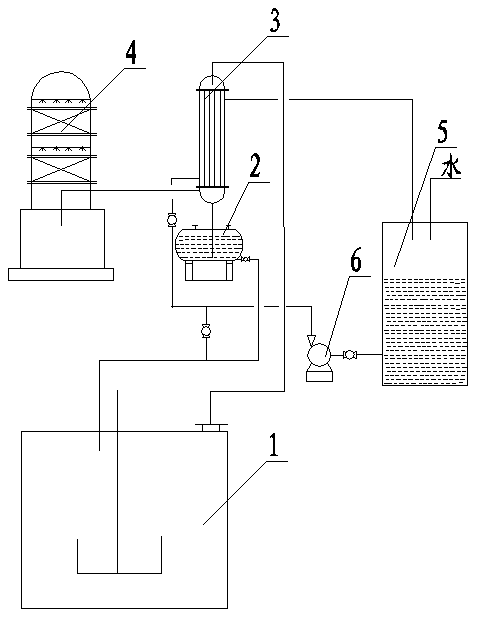

Acid mist condensing water-saving method of reaction kettle for producing aluminum polychlorid and system thereof

InactiveCN102698462AReduce consumptionEliminate the accumulation ofDispersed particle separationVapor condensationWater savingAluminium chlorohydrate

The invention discloses an acid mist condensing water-saving method of a reaction kettle for producing aluminum polychlorid and a system of the acid mist condensing water-saving method. The acid mist of the reaction kettle for producing the aluminum polychlorid is recycled after being condensed by a condenser, the condenser is cooled by using circulating water, wherein the cooling water temperature is 5-40 DEG C; the circular cooling water is conveyed to the reaction kettle for producing the aluminum polychlorid so as to produce water; liquid after being condensed by the acid mist is delivered into the reaction kettle for producing the aluminum polychlorid to replace the hydrochloric acid; the system is provided with the condenser, a condensing liquid collecting tank, a circulating water tank and a circular water pump; a gas outlet of the condenser is connected with the reaction kettle through a pipeline, a non-condensable gas outlet of the condenser is connected with the acid mist absorbing tower through the pipeline; a condensate outlet is connected with a condensate collecting tank through the pipeline; and the cooling water pipe is orderly connected with the circulating water tank, the circular water pump and the condenser.

Owner:HUAIHUA JUNYUAN FINE CHEM

Material for improving chemical wastewater

InactiveCN104326546ARaise the pHImprove decomposition abilityWater/sewage treatment by neutralisationCelluloseAluminium chloride

The invention relates to a material for improving chemical wastewater. The material is prepared from the following raw materials in parts by weight: 6-11 parts of decanal, 5-9 parts of sodium carboxymethylcellulose, 2-6 parts of polyacrylamide, 3-8 parts of surface active agent, 2-6 parts of calcium oxide, 5-9 parts of ion exchange resin, 5-8 parts of oyster shell powder, 1-5 parts of ferric oxide, 5-10 parts of polymeric aluminum, 4-7 parts of diammonium hydrogen phosphate, 2-6 parts of nanometer calcium sulfate, 1-4 parts of titanate coupling agent, 4-9 parts of zinc sulfate, and 6-10 parts of barium hydroxide. The material for improving chemical wastewater can improve the acidity-basicity of the wastewater, can absorb heavy metal ions, has strong decomposition capacity for suspended substances, and is safe and efficient.

Owner:QINGDAO TOPLINK INFORMATION TECH

Strong oxidant for papermaking waste water CODcr degradation and method for degrading CODcr in waste water

InactiveCN103708600AImprove compactnessReduce complexationWaste water treatment from plant processingWater/sewage treatment by flocculation/precipitationIron sulfateAluminium chloride

The invention aims to provide a strong oxidant for papermaking waste water CODcr degradation and a method for degrading CODcr in waste water, wherein the requirements on equipment operation and management are low, the equipment operating cost is low, the processing treatment efficiency is high, and secondary pollution can be prevented. The strong oxidant comprises the following components in parts by weight: 1 part of potassium permanganate, 10-60 parts of aluminum sulfate, 10-50 parts of ferric sulfate, and 10-50 parts of aluminum polychlorid. The method for degrading CODcr in waste water by utilizing the strong oxidant comprises the following steps: dissolving the strong oxidant in water in a proportion of 1: (5-20), then feeding in a coagulating basin for waste water treatment so as to carry out oxidation treatment, controlling the stirring speed at 50-100 rpm during the process and the reaction time to be 15-60 min, then feeding polyacrylamide as an auxiliary to complete the process of oxidation separation, and keeping the control time of the oxidant after dissolution within 1-12 hours. The strong oxidant and the method can be applied to the field of papermaking waste water treatment.

Owner:珠海市德莱环保科技有限公司

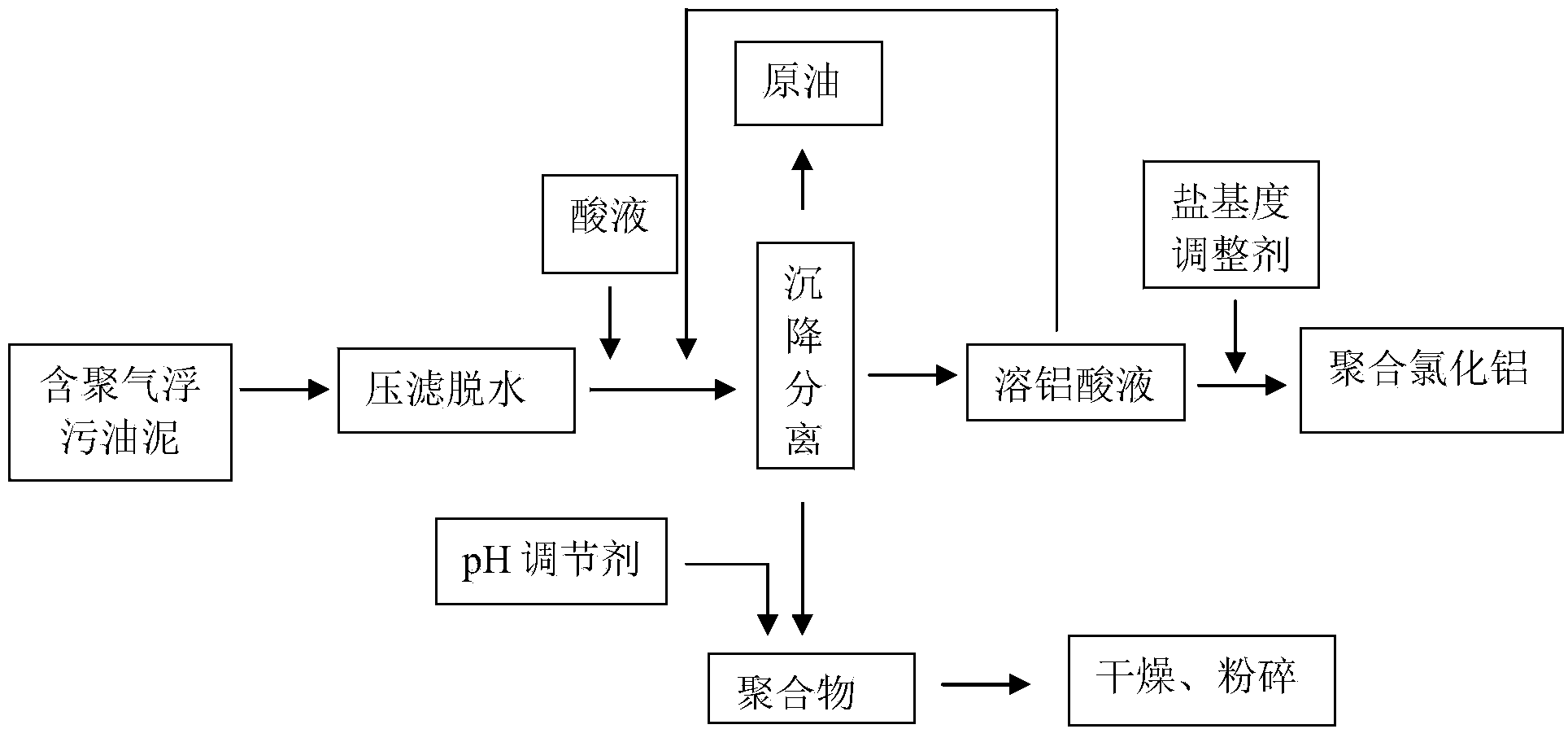

Method for recycling polymer-containing air flotation oil sludge

InactiveCN103626367AAchieve mutual separationReduce thicknessSludge treatmentLiquid hydrocarbon mixture productionAluminium chlorideEnvironmental engineering

The invention relates to treatment of oil sludge in oil fields and in particular relates to a method for recycling polymer-containing air flotation oil sludge. Through the method, a mutual effect between hydroxy-aluminium and a polymer is released due to an acid-soluble aluminum effect, and the thickness and stability of a water-in-oil emulsification colloidal particle interface membrane are reduced due to compression and curling effects on a double electric layer of the polymer of hydrogen ions, so that soluble aluminum, broken emulsion, the hydroxy-aluminium, the polymer and crude oil can be separated from one another; the separated crude oil is purified and then recycled; after the pH of the polymer is adjusted, the polymer is dried and crushed, and then can be taken as an additive of oil well cement; an acid solution with dissolved aluminum is taken as an aluminum source and applied to synthesis of aluminium polychlorid. Through the method, the environmental pollution caused by the polymer-containing air flotation oil sludge can be avoided, the crude oil can be recycled, the waste polymer and an aluminium-containing flocculating agent can be recycled, and the waste is changed into wealth.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

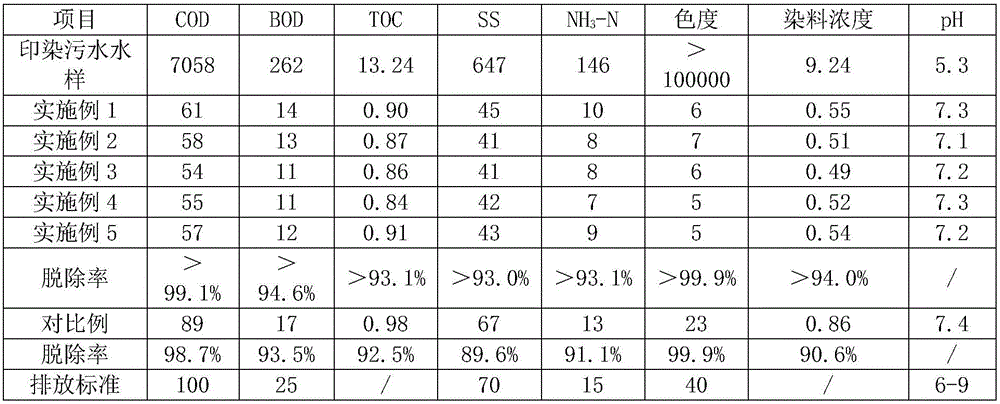

Sewage treatment agent for printing and dyeing industry and preparation method of sewage treatment agent

ActiveCN105731562AEasy to handleNo secondary pollutionWater/sewage treatmentWaste water treatment from textile industrySodium bicarbonateTreatment effect

The invention discloses a sewage treatment agent for the printing and dyeing industry. The sewage treatment agent consists of the following raw materials in parts by weight: 16-20 parts of ethylenediaminetetraacetic acid disodium, 10-15 parts of sodium bicarbonate, 25-30 parts of sodium laurylsulfate, 22-25 parts of modified kieselguhr, 32-38 parts of polymeric aluminum, 14-16 parts of aluminum sulfate, 30-35 parts of medical stone, 23-25 parts of activated carbon, 10-14 parts of perlite, 8-13 parts of molybdenum sulfide, 14-17 parts of tin oxide powder and 22-27 parts of propylene glycol. The invention further provides a preparation method of the sewage treatment agent for the printing and dyeing industry. The sewage treatment agent disclosed by the invention can play a coordination function due to compounding of raw materials and has a very good treatment effect on sewage of the printing and dyeing industry, treated sewage can meet the national emission effect, the environment can be prevented from secondary pollution, and in addition, the treated sewage can also be recycled, so that the purpose of water resource conservation can be achieved.

Owner:江门市金松印染纺织有限公司

Method for performing decoloration treatment on printing and dyeing wastewater by compounding magnesia powder and aluminum polychlorid

InactiveCN102674586AReduce dosageGood decolorization effectMultistage water/sewage treatmentWaste water treatment from textile industryFlocculationHigh concentration

The invention relates to a method for performing decoloration treatment on printing and dyeing wastewater by compounding magnesia powder and aluminum polychlorid and belongs to the technical field of wastewater treatment. According to the method, magnesia powder is fed for adsorption, and then aluminum polychlorid is fed for flocculation, and the method is used for treating the printing and dyeing wastewater of which pH value is greater than 10. The synergistic effect of the magnesia powder and the aluminum polychlorid is effectively exerted by compounding the magnesia powder and the aluminum polychlorid, and the method has the advantages of small feeding amount, good decoloration effect, and low treatment cost, and can be directly applied to decoloration treatment of alkaline high-concentration printing and dyeing wastewater.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Sewage processing agent

ActiveCN108751294AReduce COD valueThe preparation process steps are simpleWater/sewage treatmentSludgePolyacrylamide

The invention belongs to the field of sewage processing, and concretely relates to preparation and usage methods of a sewage processing agent. The sewage processing agent comprises the following raw materials in parts by weight: 40-50 parts of river sludge, 25-35 parts of corn straw, 1-5% of ginkgo leaf, 15-20 parts of cactus, 5-10 parts of grape leaf, 15-20 parts of reed leaf, 5-8 parts of whitesugar, 20-25 parts of bentonite, 3-5 parts of plant ash, 1-2 parts of oxalic acid, 15-20 parts of graphite powder, 20-25 parts of polyacrylamide, 25-30 parts of polymeric aluminium, and 3-5 parts of sodium alginate.

Owner:BINZHOU UNIV

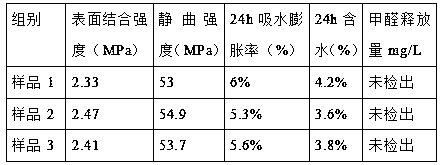

Bamboo-wood fiber board using bio-based non-formaldehyde adhesive and preparation method thereof

PendingCN111216212AHigh reactivityFast curingInorganic material artificial filamentsWood working apparatusAluminium chlorideXylylene

The invention discloses a bamboo-wood fiber board using bio-based non-formaldehyde adhesive and a preparation method thereof. The fiber board comprises the raw materials of, by weight, 60-70 parts offirst fiber, 6-10 parts of second fiber, 10-20 parts of adhesives, 25-35 parts of hydrophobic auxiliary agents, 6-8 parts of additives and 6-8 parts of modifiers. The second fiber is prepared from anhydrous aluminum chloride, aluminum powder, water, magnesium lactate and acetic acid, a sol-gel method is adopted during preparation, and the anhydrous aluminum chloride, the aluminum powder and the water are polymerized under a reaction condition to form a linear polymer to obtain polyaluminium chloride sol; and the magnesium lactate is added, the acetic acid is used as a stabilizer, and a spinning solution is obtained by stirring and reduced pressure distillation. According to the fiber board and the preparation method, the bamboo-wood fiber board is reasonable in component design and simplein process operation, the prepared bamboo-wood fiber board does not contain formaldehyde, benzene and xylene toxic substance release, formaldehyde pollution is effectively avoided, and the bamboo-woodfiber board has excellent mechanical property, high strength, excellent hydrophobic property and high practicability.

Owner:杨晨露

Treatment method of copper-containing etching liquid

ActiveCN103803737AAchieving zero emissionsNo secondary pollutionMultistage water/sewage treatmentCopper oxides/halidesAluminium chloridePhysical chemistry

The invention provides a treatment method of a copper-containing etching liquid. The treatment method is characterized by comprising the following steps: the copper content of the etching solution is 130 g / L-150 g / L, the pH is adjusted to 2.0-3.0, a reaction is carried out by adding 60-80 g / L of aluminum, the temperature is 75-85 DEG C, air is introduced during the reaction process, after the reaction, a precipitate is an electronic-grade copper powder, and a solution is a polymeric aluminum chloride flocculant. Substances contained in the etching liquid and characteristics thereof are fully utilized, the effects of the substances are all fully utilized, finally the wastewater treatment is achieved, the high-quality products extremely having application value are obtained, the waste of resources is avoided, and the raw material cost and the reagent cost are saved.

Owner:CHONGQING LONGJIAN METAL MFG

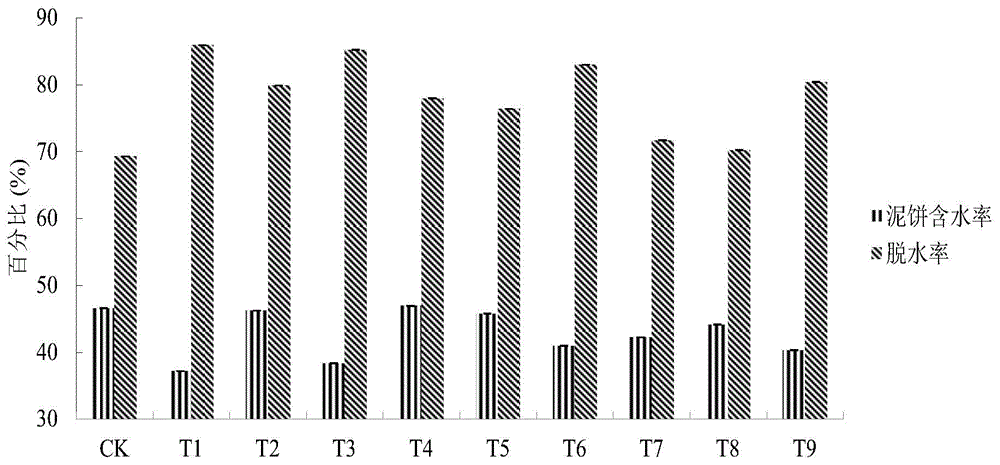

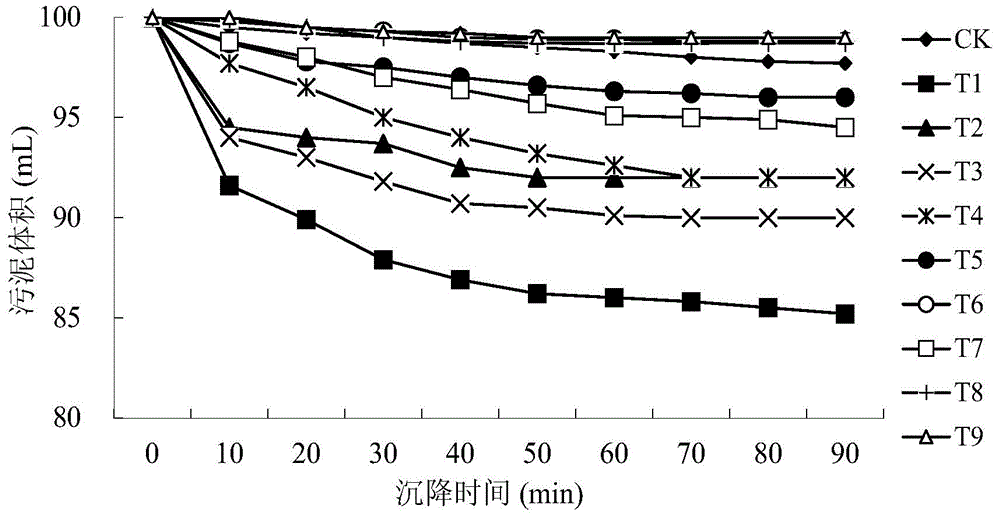

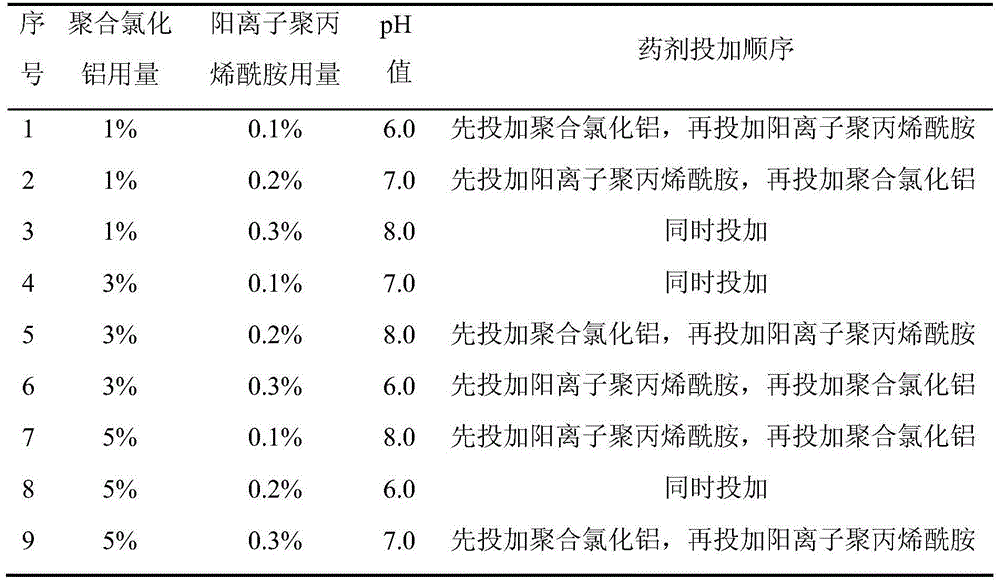

Method for improving dehydration performance of anaerobic digestion substrate of papermaking sludge by virtue of combination of two flocculants

InactiveCN104909538ASimple processEasy to operateSludge treatment by de-watering/drying/thickeningWaste water treatment from plant processingAluminium chlorohydrateFiltration

The invention belongs to the field of sewage treatment techniques and environmental protection and discloses a method for improving the dehydration performance of an anaerobic digestion substrate of papermaking sludge by virtue of combination of two flocculants. The method comprises the following steps: regulating the pH value of the anaerobic digestion substrate of the papermaking sludge to 6.0; firstly feeding 1% aluminum polychlorid solution (counted by dry basis), stirring, feeding 0.1% organic polymer flocculant cationic polyacrylamide solution (counted by dry basis) for chemical conditioning; carrying out a vacuum filtration dehydration process. According to the method, the moisture content of the anaerobic digestion substrate of the papermaking sludge is decreased from 75% to be about 37%, and the dehydration rate reaches 85% or above; the application process is simple, and the operability is strong; by virtue of simple suction filtration dehydration on the conditioned anaerobic digestion substrate of the papermaking sludge, relatively low moisture content can be achieved, efficient solid-liquid separation can be realized, and a foundation is laid for the duly treatment of the anaerobic digestion substrate of the papermaking sludge, so that the method has an important engineering application value.

Owner:SOUTH CHINA AGRI UNIV

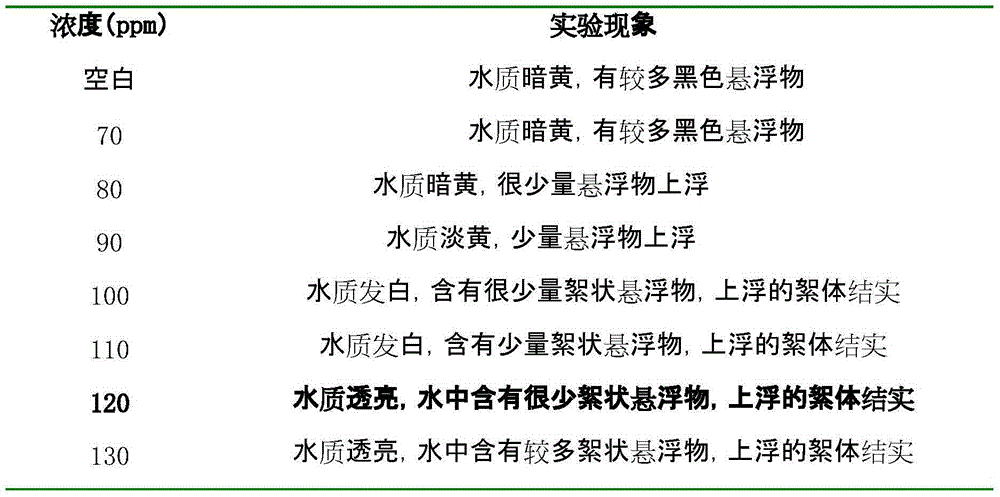

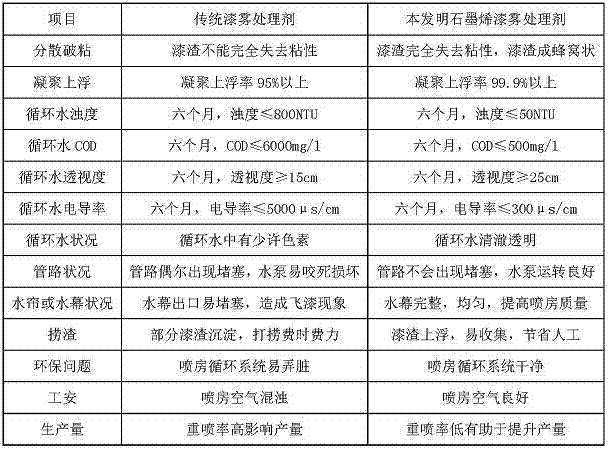

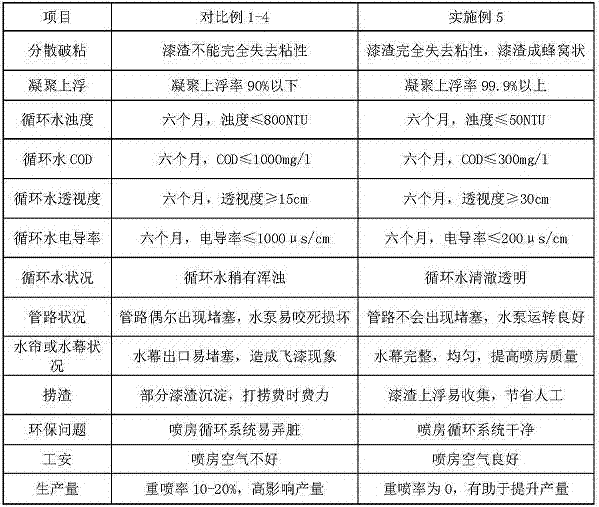

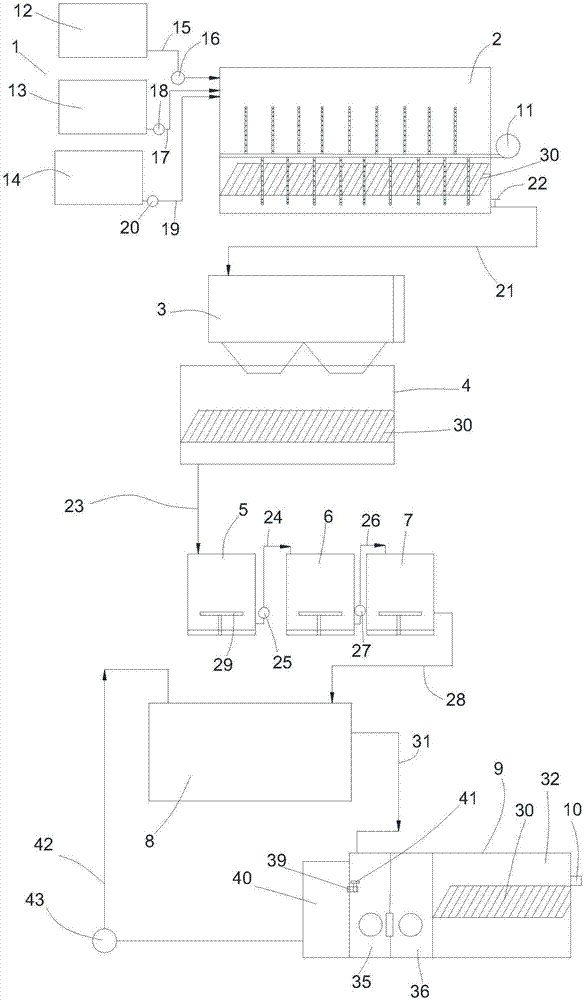

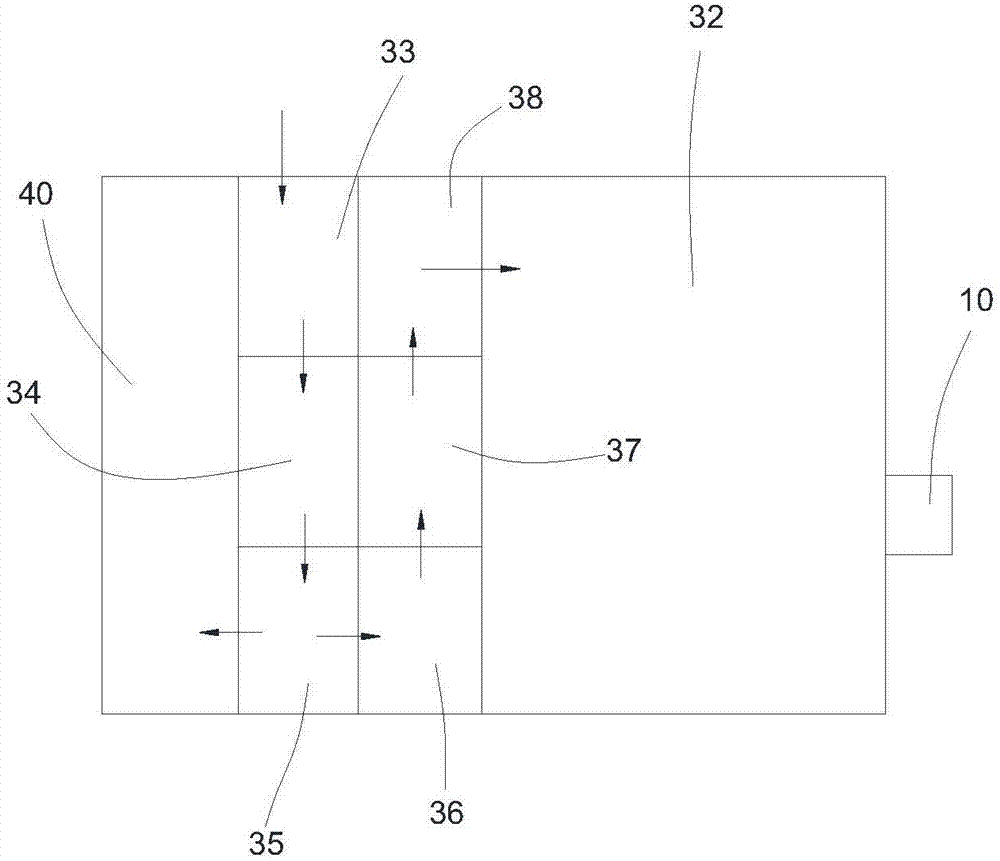

Graphene painting mist treating agent, preparation method and use method thereof

ActiveCN107021532AEasy to salvageSolve the real problemGrapheneMultistage water/sewage treatmentWater basedSodium Bentonite

A graphene painting mist treating agent comprises an A agent and a B agent; wherein the A agent is prepared from the following raw materials in percentage by weight: 0.02-0.08% of modified graphene, 1.6-2.6% of water-soluble melamino-formaldehyde resin, and 0.2-0.6% of sodium hydroxide; the B agent is prepared from the following raw materials in percentage by weight: 0.06-0.12% of water-based sodium bentonite, 0.2-0.5% of water-soluble acrylic resin, 5-10% of aluminium polychlorid and the balance of water. By using the graphene painting mist treating agent, adhesion of paint slag is completely eliminated, so that the paint slag is not adhered to a water screen or water curtain, air quality in a spraying room is increased, and no flying paint phenomenon exists in a factory; the paint slag completely flocculates and floats upwards, so that the paint slag is convenient and simple to fish out cleaning the bottom of a groove is not affected, and the cost for cleaning the groove is not increased; recycled water is clear and transparent; and the addition amount of drugs is small, so that costs are reduced and discharge is reduced.

Owner:HUNAN JINYU ENVIRONMENTAL PROTECTION TECH CO LTD

Metal anode oxidation sewage multilevel treatment system and treatment method thereof

PendingCN107324541AAvoid influenceIncrease the reaction areaWater treatment parameter controlTreatment involving filtrationAluminium chlorideSludge

The invention relates to a metal anode oxidation sewage multilevel treatment system and treatment method thereof. The metal anode oxidation sewage multilevel treatment system comprises a waste water collection pond for collecting metal anode oxidation waste water, a comprehensive reaction pond for adding a COD removal agent, lime, sodium pyrosulfite and a decoloring agent to react with the waste water, a press filter apparatus for separating the sewage from the water, a press filter water collection pond for collecting the water press filtered by the press filter apparatus, a level-l stirring pond for adding aluminum polychlorid to react with the press filtered water, a level-II stirring pond for adding polyacrylamide to react with the water treated by the level-I stirring pond, a level-III stirring pond for receiving the water in the level-II stirring pond, a level-I settling pond for settling the water in the level-III stirring pond, and a level-II settling pond for settling the water in the level-I settling pond. By adopting the metal anode oxidation sewage multilevel treatment system and method, reagents added in the metal anode oxidation process can be removed pointly. The comprehensive reaction pond is provided with an air blowing apparatus for stirring, so that the reaction area and efficiency can be effectively increased.

Owner:SANMING FOCTEK PHOTONICS INC

Treatment method of aluminum trichloride wastewater

PendingCN113247996AThe processing method is economicalQuality improvementAluminium chloridesIron halidesAluminium chlorideChlorobenzene

The invention discloses a treatment method of aluminum trichloride wastewater, which comprises the following steps: adding a solvent A into the aluminum trichloride wastewater generated in the production process of 2-chloro-4-(4-chlorophenoxy)acetophenone for first extraction, and removing a solvent layer to obtain a first extraction solution; adding a solvent B into the first extraction solution for second extraction, and obtaining a second extraction liquid after a solvent layer is removed; rectifying and separating out a small amount of fatty alcohol contained in the secondary extracting liquid, and then conducting evaporating, dehydrating and concentrating to obtain a concentrated solution; adding an alkaline substance into the concentrated solution in a stirring state to obtain a neutralized solution; raising the temperature of the neutralized solution to 30-150 DEG C, preserving heat for 1-48 hours, and then reducing the temperature to -10 DEGC to 40 DEG C to obtain a cured solution; and filtering the cured solution, wherein the filtrate is a polyaluminum chloride flocculant. The treatment method of the aluminum trichloride wastewater provided by the invention is economical and simple and convenient to operate, and the aluminum trichloride wastewater can finally become a high-quality polyaluminum chloride flocculant.

Owner:JIANGSU YANGNONG CHEM +1

Preparation method of alumina-zirconia composite staple fibers and preparation method thereof

ActiveCN111074379AImprove stabilityGuaranteed stabilityInorganic material artificial filamentsAluminium chlorideFiber

The invention provides a preparation method of alumina-zirconia composite staple fibers. The preparation method comprises the following steps of A) preparing poly aluminum chloride sol; mixing a zirconium oxychloride solution and the poly aluminum chloride sol to obtain zirconium-aluminum gel; B) peptizing the zirconium-aluminum gel to obtain a zirconium-aluminum solution; C) mixing the zirconium-aluminum solution with an aqueous solution of a spinning auxiliary agent, and performing distilling and concentrating to obtain a zirconium-aluminum composite spinning solution; D) aging the zirconium-aluminum composite spinning solution, and then throwing threads to form fibers to obtain precursor fibers; and E) carrying out heat treatment on the precursor fibers to obtain the alumina-zirconia composite staple fibers. According to the preparation method of the alumina-zirconia composite staple fibers in the invention, a single inorganic aluminum source and an inorganic zirconium salt are usedfor reaction, and the characteristics of firstly gelling and then peptizing are utilized, so that the stability of the sol spinning solution is improved without the need of adding an additional stabilizing auxiliary agent an crystal grain inhibitor, and the method is simple and safe and is suitable for preparing the alumina-zirconia composite staple fibers in industrial production.

Owner:山东鲁阳浩特高技术纤维有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com