Acid mist condensing water-saving method of reaction kettle for producing aluminum polychlorid and system thereof

A technology of polyaluminum chloride and water-saving system, applied in aluminum chloride, chemical instruments and methods, aluminum halide, etc., can solve the problems of reducing the heat exchange efficiency of the condenser, low cycle utilization rate, increasing alkali consumption, etc. Achieve the effect of saving dosage, reducing lye consumption and reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

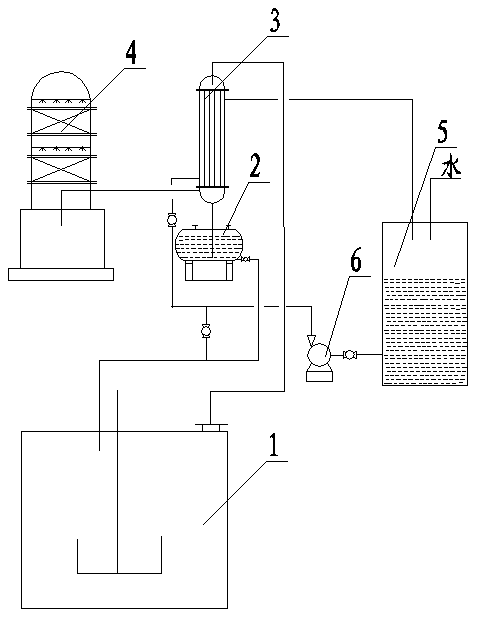

[0015] like figure 1 The acid mist condensation water-saving system of the reaction kettle for producing polyaluminium chloride shown has a reaction kettle 1, a condensate collection tank 2, a condenser 3, an acid mist absorption tower 4, a circulating water tank 5, a circulating water pump 6, and a condenser The air inlet of 3 is connected to the mist discharge port of reactor 1 through a pipeline, the uncondensed gas outlet of condenser 3 is connected to acid mist absorption tower 4 through a pipeline, and the condensate outlet of condenser 3 is connected to condensate collection tank 2 through a pipeline The outlet of the condensate outlet pipe is immersed below the liquid surface of the condensate to form a liquid seal. There is no need to install a valve on the condensate outlet pipe of the condenser 3. The acid mist is separated from the outside by the liquid seal, and the condensate relies on the condensate. The static pressure of the liquid column formed on the outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com