Preparation method and application of sediment endogenous phosphorus load control bottom sediment modified material

A technology of load control and modified materials, which is applied in the fields of temperature control sludge treatment, chemical instruments and methods, sludge treatment, etc. The effect of adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

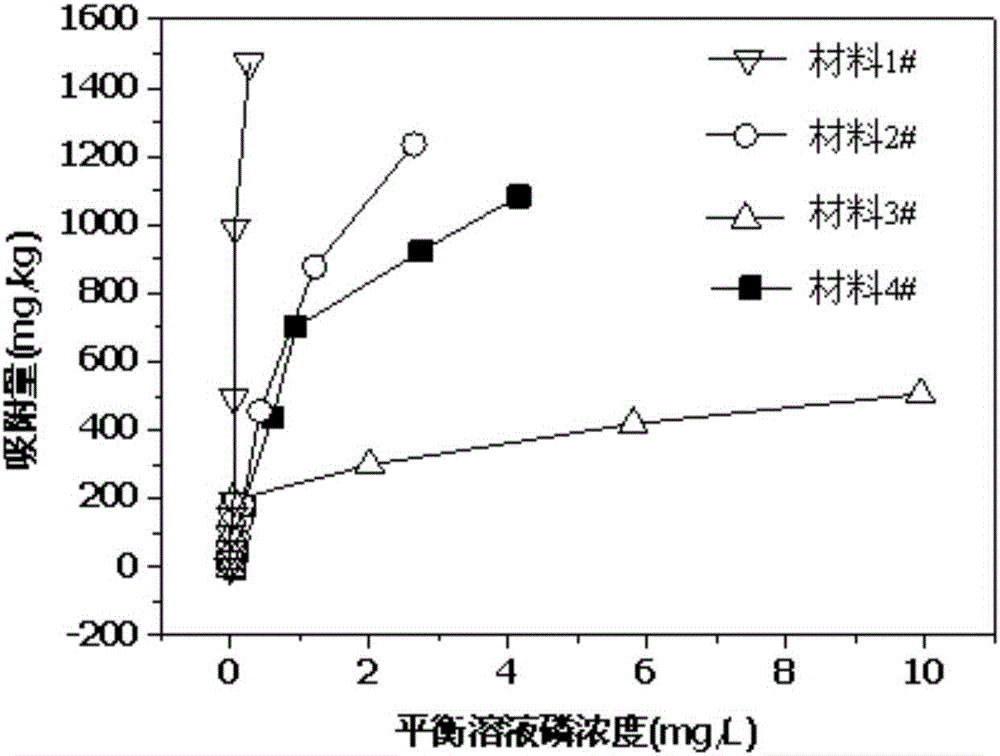

Embodiment 1

[0041] The endogenous phosphorus load control sediment modification material described in this example is prepared by the following method:

[0042] (1) Collect lake bottom mud as raw material, freeze-dry, grind and sieve to obtain sediment powder with particle size not less than 100 mesh, and set aside;

[0043] (2) Get zeolite, grind and sieve to obtain zeolite powder with particle size not less than 100 mesh, and set aside;

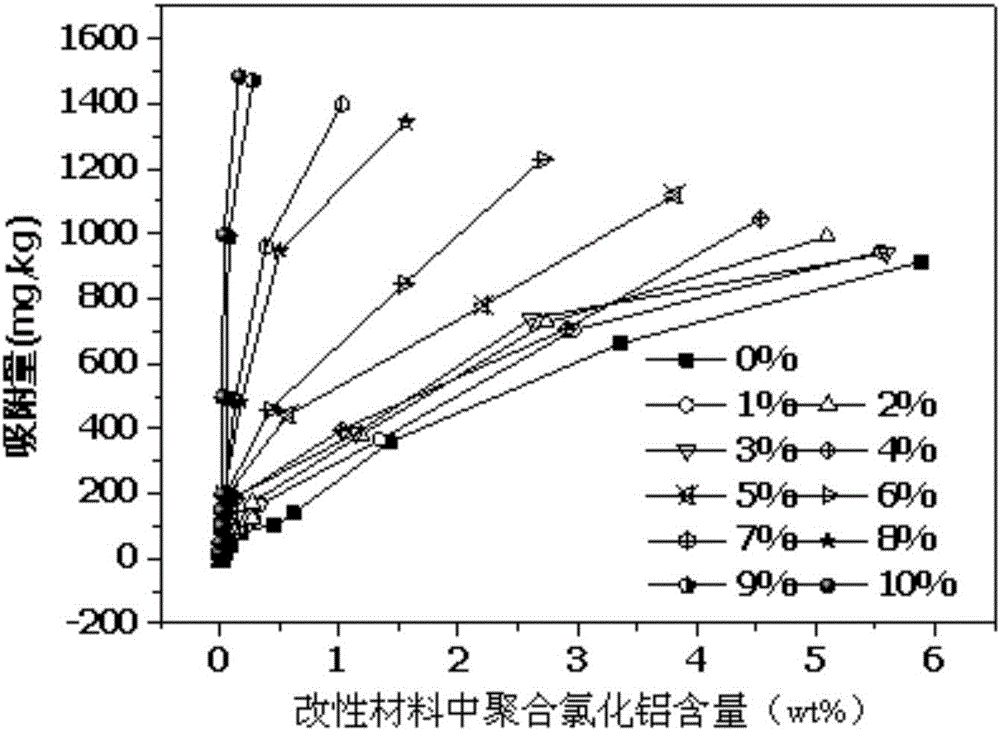

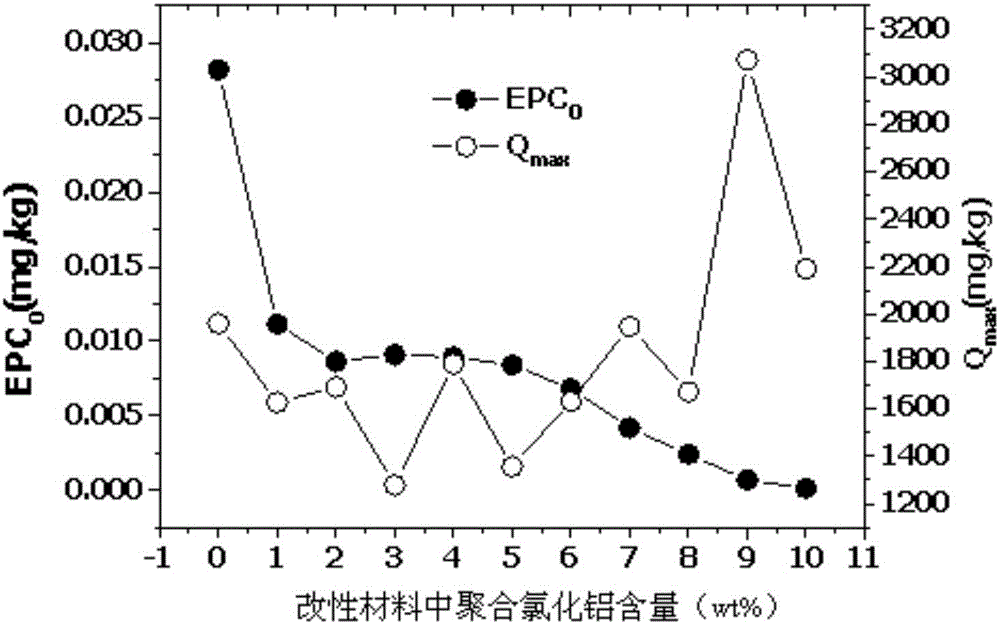

[0044] (3) Mix the sediment powder with the zeolite powder and polyaluminum chloride uniformly to form a mixed powder, the quality of the zeolite powder is 30% of the total mass of the mixed powder, and the polymer The quality of aluminum chloride is 8% of described mixed powder gross mass, standby;

[0045] (4) The mixed powder is soaked with water, the amount of water added accounts for 10wt% of the mixed powder mass, and then extruded into granules, and the molding material is roasted at 400 ° C for 3 hours to obtain a particle size of 3- 5mm of s...

Embodiment 2

[0047] The endogenous phosphorus load control sediment modification material described in this example is prepared by the following method:

[0048] (1) Collect lake bottom mud as raw material, freeze-dry, grind and sieve to obtain sediment powder with a particle size of 100 to 200 mesh, and set aside;

[0049] (2) Get the zeolite, grind and sieve to obtain a zeolite powder with a particle size of 100 to 200 meshes, and set aside;

[0050] (3) Mix the sediment powder with the zeolite powder and polyaluminum chloride uniformly to form a mixed powder, the quality of the zeolite powder is 50% of the total mass of the mixed powder, and the polymer The quality of aluminum chloride is 1% of the total mass of the mixed powder, for subsequent use;

[0051] (4) The mixed powder is soaked with water, the amount of water added accounts for 10wt% of the mixed powder mass, and then extruded into granules, and the molding material is roasted at 700 ° C for 2 hours to obtain a particle size...

Embodiment 3

[0053] The endogenous phosphorus load control sediment modification material described in this example is prepared by the following method:

[0054] (1) Collect lake bottom mud as raw material, freeze-dry, grind and sieve to obtain sediment powder with a particle size of 150-200 mesh, and set aside;

[0055] (2) Get the zeolite, grind and sieve to obtain a zeolite powder with a particle size of 150 to 200 meshes, and set aside;

[0056] (3) Mix the sediment powder with the zeolite powder and polyaluminum chloride uniformly to form a mixed powder, the quality of the zeolite powder is 40% of the total mass of the mixed powder, and the polymer The quality of aluminum chloride is 9% of described mixed powder gross mass, standby;

[0057] (4) The mixed powder is soaked with water, the amount of water added accounts for 10wt% of the mixed powder mass, and then extruded into granules, and the molding material is calcined at 600°C for 2h to obtain a particle size of 4- 5mm sediment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com