Metal anode oxidation sewage multilevel treatment system and treatment method thereof

A metal anode and treatment system technology, applied in the sewage treatment system and its treatment field, can solve the problems of direct sewage discharge, environmental pollution, etc., and achieve the effect of improving the reaction area and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

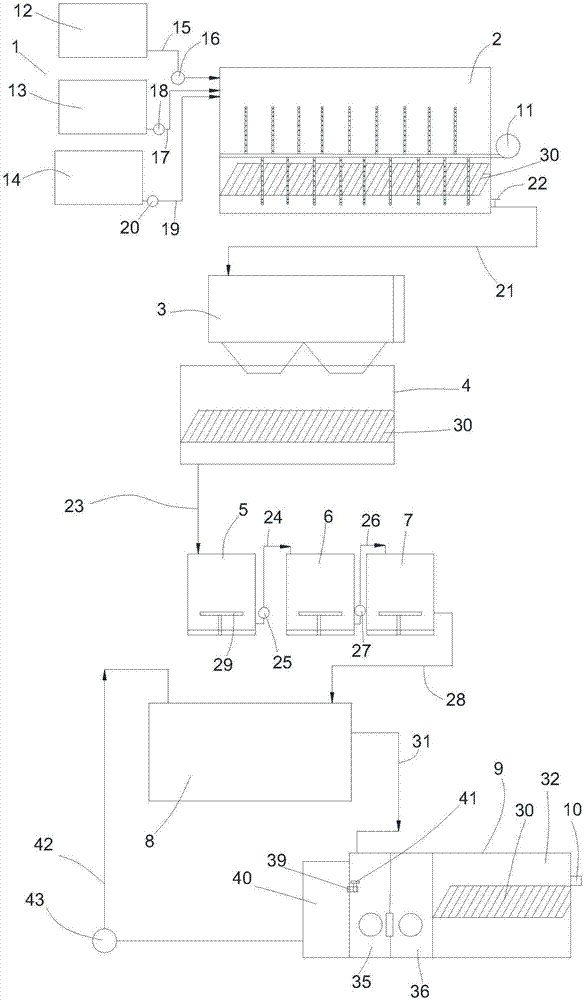

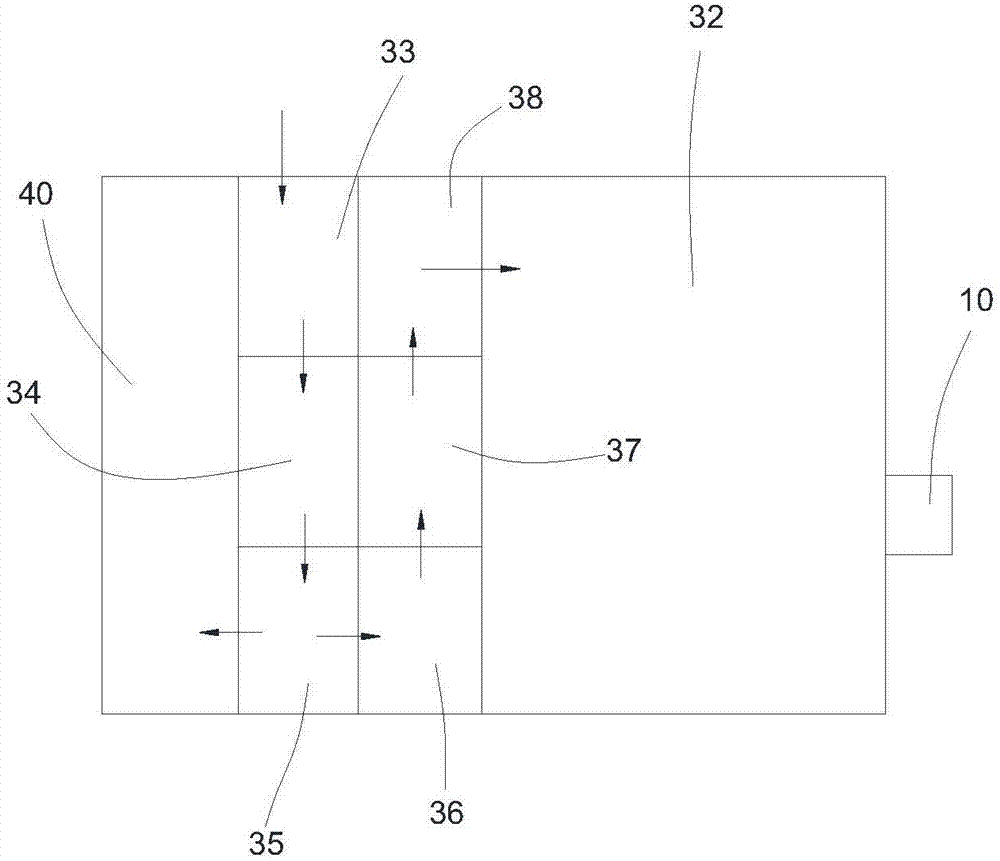

Embodiment 1

[0026] refer to figure 1 , figure 2 , a metal anodized sewage multi-stage treatment system, including a waste water collection pool for collecting metal anodized waste water 1, a comprehensive reaction for adding COD removal agent, lime, sodium pyrosulfite, and decolorizing agent to react with waste water Pool 2, filter press device for separating sludge from water 3, filter press water collection tank for collecting water after press filter press filter press device 4, for adding polyaluminum chloride and press filter water The primary stirring tank 5 for reaction, the secondary stirring tank 6 for adding polyacrylamide to react with the water treated in the primary stirring tank 5, and the tertiary stirring tank for receiving the water in the secondary stirring tank 6 7. A primary sedimentation tank 8 for settling the water in the tertiary stirring tank 6 , and a secondary settling tank 9 for settling the water in the primary settling tank 8 . The wastewater collection po...

Embodiment 2

[0044] refer to figure 1 , figure 2 , a metal anodized sewage multi-stage treatment system, including a waste water collection pool for collecting metal anodized waste water 1, a comprehensive reaction for adding COD removal agent, lime, sodium pyrosulfite, and decolorizing agent to react with waste water Pool 2, filter press device for separating sludge from water 3, filter press water collection tank for collecting water after press filter press filter press device 4, for adding polyaluminum chloride and press filter water The primary stirring tank 5 for reaction, the secondary stirring tank 6 for adding polyacrylamide to react with the water treated in the primary stirring tank 5, and the tertiary stirring tank for receiving the water in the secondary stirring tank 6 7. A primary sedimentation tank 8 for settling the water in the tertiary stirring tank 6 , and a secondary settling tank 9 for settling the water in the primary settling tank 8 . The wastewater collection po...

Embodiment 3

[0061] refer to figure 1 , figure 2 , a metal anodized sewage multi-stage treatment system, including a waste water collection pool for collecting metal anodized waste water 1, a comprehensive reaction for adding COD removal agent, lime, sodium pyrosulfite, and decolorizing agent to react with waste water Pool 2, filter press device for separating sludge from water 3, filter press water collection tank for collecting water after press filter press filter press device 4, for adding polyaluminum chloride and press filter water The primary stirring tank 5 for reaction, the secondary stirring tank 6 for adding polyacrylamide to react with the water treated in the primary stirring tank 5, and the tertiary stirring tank for receiving the water in the secondary stirring tank 6 7. A primary sedimentation tank 8 for settling the water in the tertiary stirring tank 6 , and a secondary settling tank 9 for settling the water in the primary settling tank 8 . The wastewater collection po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com