Electrochemical production device and manufacturing method of high-alkalization-degree aluminum polychlorid and Al13 chloride

A polyaluminum chloride and production device technology, which is applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of high energy consumption and low Al13 content in the inert electrode electrolysis method, and achieve the elimination of short circuit risks, reduction of ohmic drop, The effect of reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

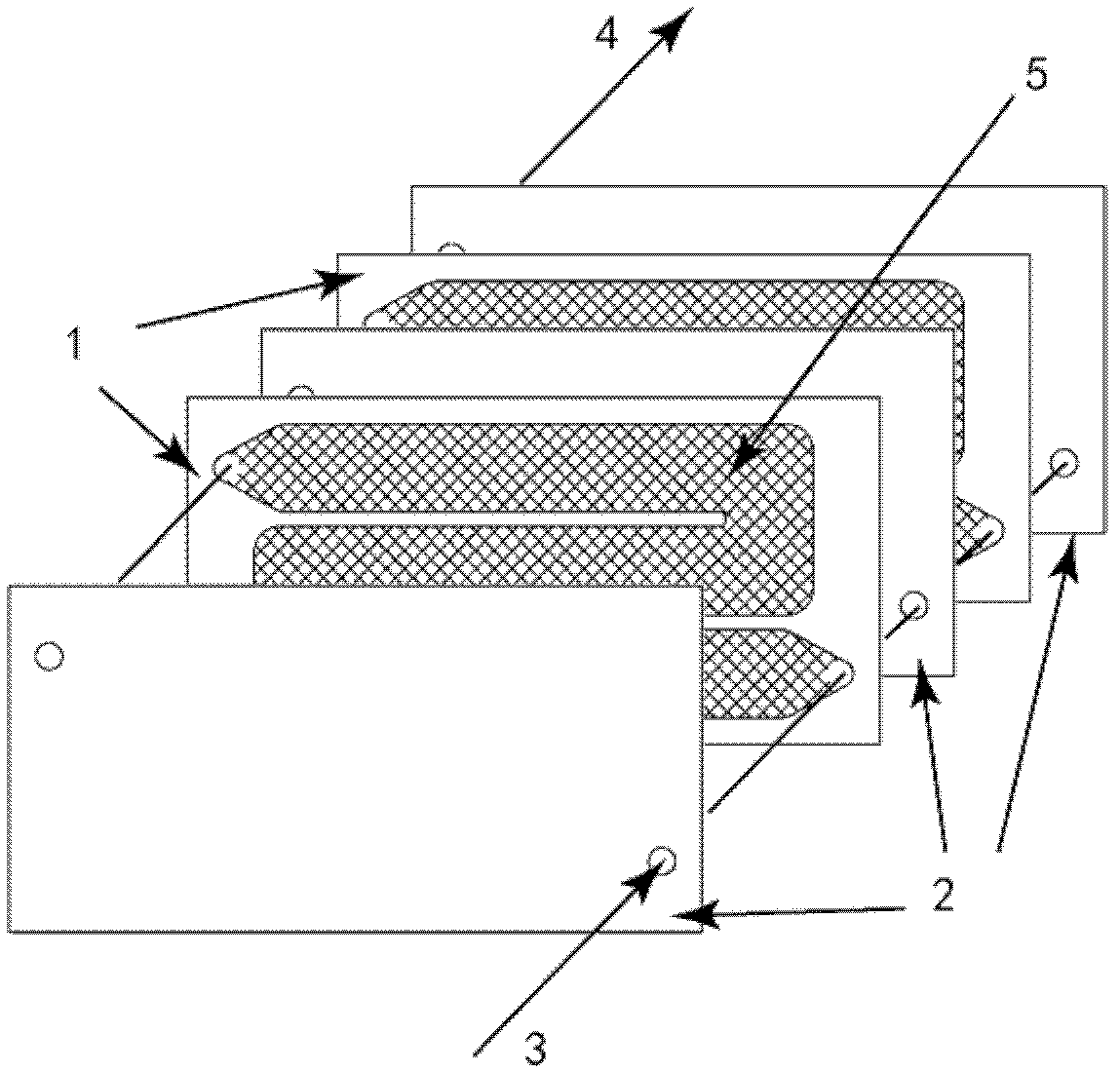

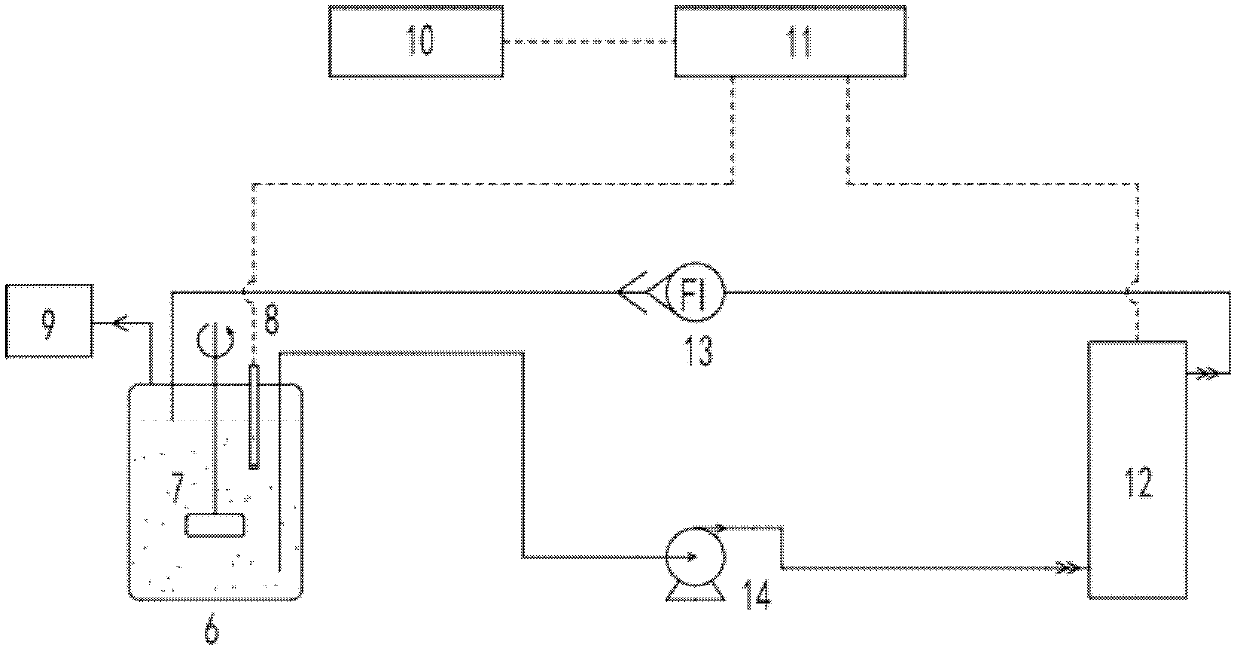

[0030] as attached Figure 1-2 Shown, a kind of high alkalization polyaluminium chloride of the present invention and Al 13 The electrochemical production device of chloride comprises a reaction vessel 6, a pump 14, an electrolytic cell stack 12, and a flow indicator 13 which form a closed loop and are connected in sequence, and a stirring device 7 and a pH and temperature composite probe 8 are arranged in the reaction vessel 6, The top of the reaction vessel 6 is also connected to the gas absorber 9, the controller 11 is connected to the pH and temperature composite probe 8, the DC power supply 10 is respectively connected to the electrolytic cell stack 12 through the controller 11, and the electrolytic cell stack 12 is composed of no less than one group of electrolytic cells. The cells are connected in parallel or in series, wherein each group of electrolytic cells is clamped by a plastic separator 1 and two adjacent inert electrodes 2 on both sides, and the plastic separato...

Embodiment 2

[0035] A 0.6 mm thick EVA material separator was used for the plastic separator, and the total electrolytic electricity was 3.0 mol electron electricity. Other devices and reaction conditions were the same as in Example 1. At this time, the PAC product solution 2 with a total aluminum concentration of 0.25mol / L was obtained.

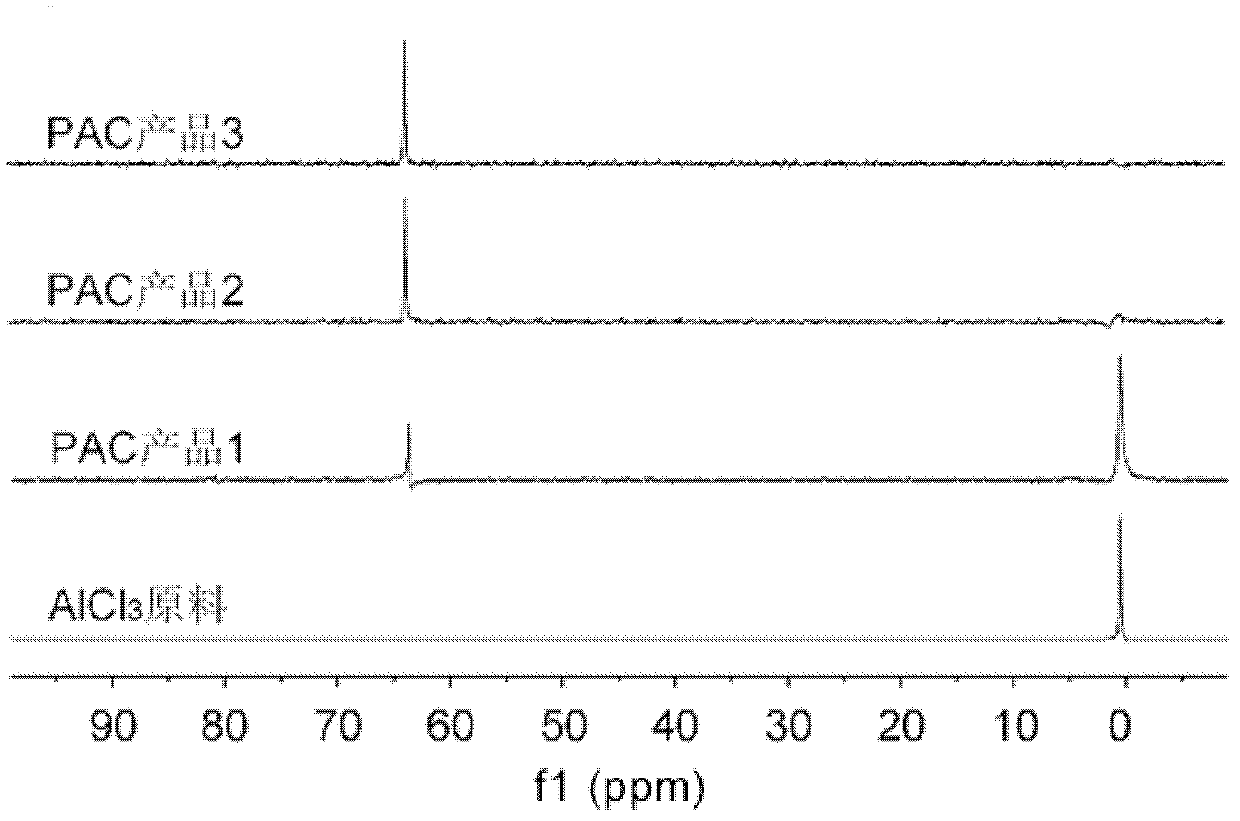

[0036] Gained PAC product solution 2 obtains through Ferron colorimetric analysis, and its dissolved total aluminum concentration is still 0.25mol / L; 27 AlNMR characterization shows that the six-coordinated monomeric aluminum ion and Keggin structure Al in dissolved aluminum 13 The ion ratio is 0.8%:99.2%; the anion in the product is mainly Cl - (0.154mol / L) and a small amount of ClO 3 - Ions (5.3×10 -3 mol / L), the degree of alkalization is 78.4%.

Embodiment 3

[0038] A 0.6 mm thick ABS material separator was used as the plastic separator, and the total electrolytic electricity was 4.0 mol electron electricity. Other devices and reaction conditions were the same as in Example 1. At this time, the PAC product solution 3 with a total aluminum concentration of 0.25 mol / L was obtained.

[0039] Gained PAC product solution 3 obtains through Ferron colorimetric analysis, and its dissolved state total aluminum concentration is still 0.25mol / L; 27 AlNMR characterization shows that the six-coordinated monomeric aluminum ion and Keggin structure Al in dissolved aluminum 13 The ion ratio is 0.2%: 99.8%; the anion in the product is mainly Cl - (0.124mol / L) and a small amount of ClO 3 - Ions (1.62×10 -2 mol / L), the degree of alkalization is 81.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com