Combined electrofusion connecting pipe and pipe construction welding method

A technology for connecting pipe fittings and a welding method, which is applied in the field of combined electrofusion connecting pipe fittings and pipe fittings construction and welding, can solve the problems of inconvenient processing and mass production, high required operation level, and high product scrap rate, and achieves easy processing and mass production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

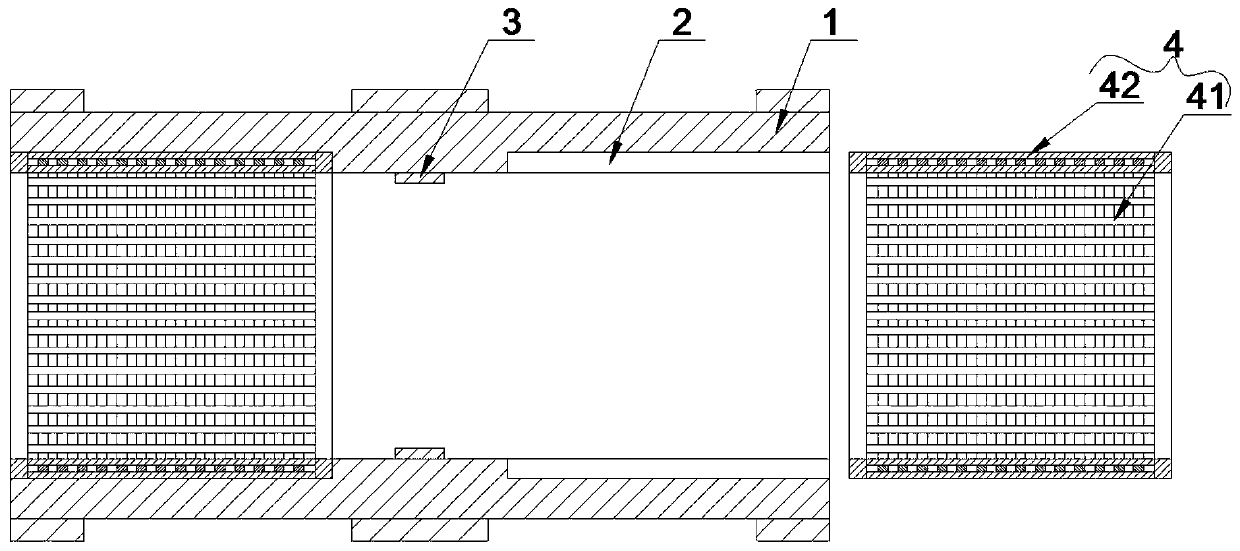

[0041] see Figure 1~5 , a combined electrofusion connection pipe fitting, including an electrofusion connection piece 1 for pipeline welding, a cylindrical electric heating element 4 is built in both ends of the electric fusion connection piece 1, and the electric heating element 4 is connected with the electric fusion The connecting piece 1 can be assembled and assembled in a detachable manner.

[0042] In this embodiment, the electrofusion connector 1 can be injection molded by an injection molding machine, and its structure can be figure 1 The straight cylindrical shape shown in , can also be Figure 4 Tee tubular in or Figure 5 Elbow tubes in the middle, or even other special-shaped tubes, as long as the opening end is cylindrical, the material can be polyolefins such as PE and PPR, and the finished electrical appliances can be made through specific molds or mechanical processing methods in the process of injection molding. The loading position of the electric heating e...

Embodiment 2

[0045] see Figure 1~3 , a combined electrofusion connection pipe fitting, including an electrofusion connection piece 1 for pipeline welding, a cylindrical electric heating element 4 is built in both ends of the electric fusion connection piece 1, and the electric heating element 4 is connected with the electric fusion The connecting piece 1 can be assembled and assembled in a detachable manner.

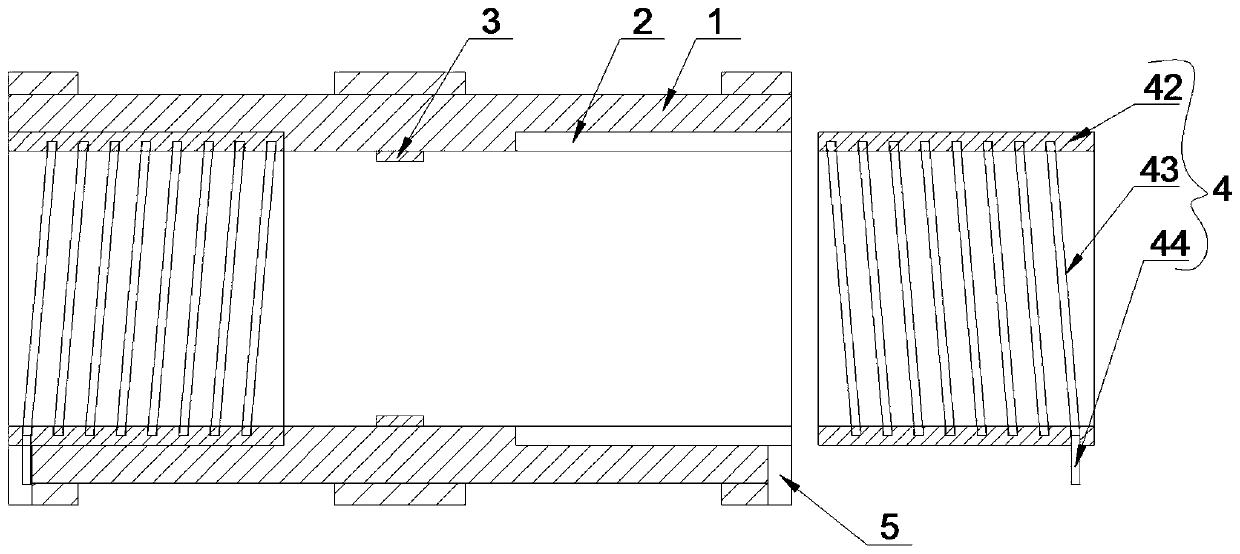

[0046] A retaining ring 3 is arranged in the inner hole of the electrofusion connector 1 , and the two electric heating elements 4 are respectively located at two ends of the retaining ring 3 .

[0047] In this embodiment, the inner diameter of the retaining ring 3 is smaller than the inner diameter of the electrofusion connector 1, and the pipe material to be taken over can move to conflict with the end face of the retaining ring 3 when it is loaded into the pipe fitting of the electrofusion connector 1. The limited position, that is, the connection position of the pipes to be con...

Embodiment 3

[0054] see Figure 1~3 , a combined electrofusion connection pipe fitting, including an electrofusion connection piece 1 for pipeline welding, a cylindrical electric heating element 4 is built in both ends of the electric fusion connection piece 1, and the electric heating element 4 is connected with the electric fusion The connecting piece 1 can be assembled and assembled in a detachable manner.

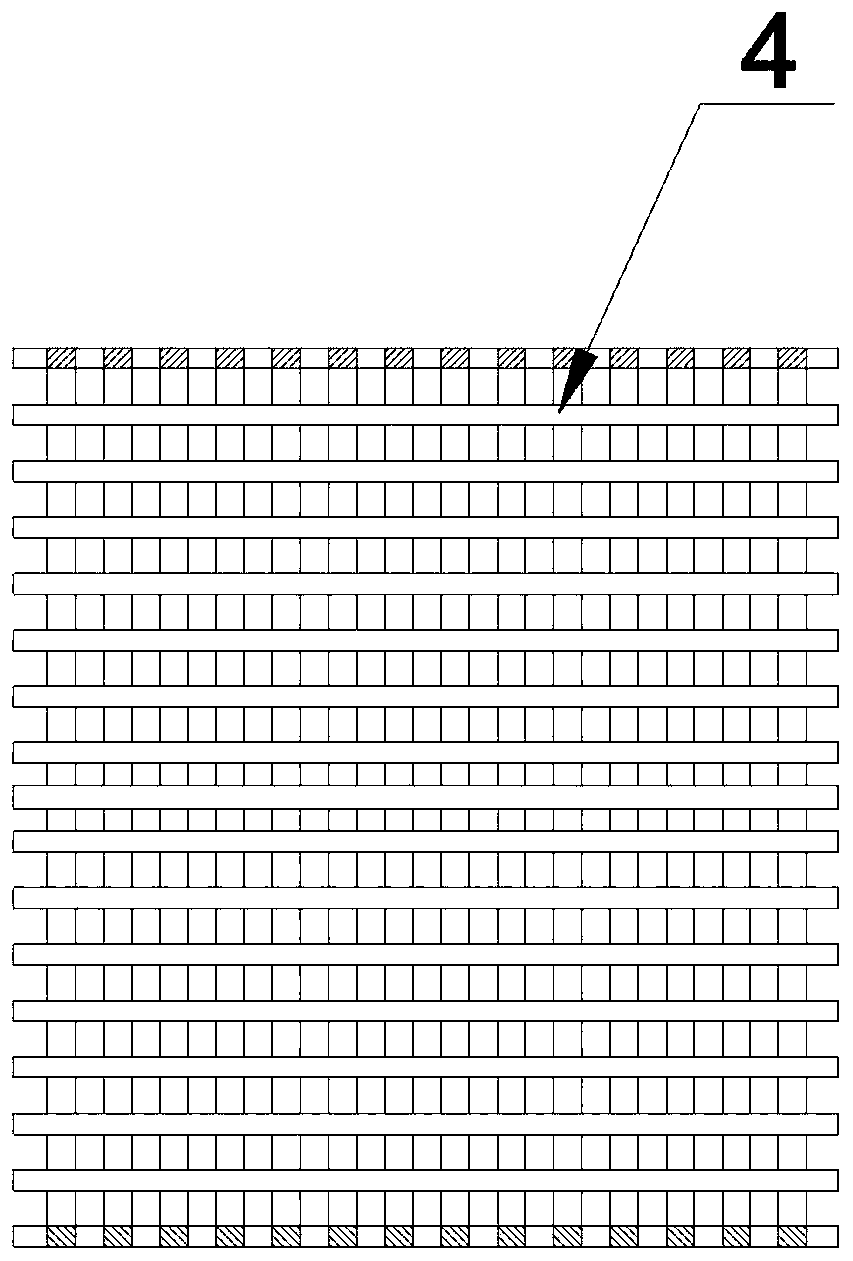

[0055] The heating element 4 is composed of a threaded resistance wire 43, one end of the resistance wire 43 is electrically connected to a copper electrode 44 longitudinally, and the two ends of the electrofusion connector 1 are provided with electrode grooves 5, and the copper electrode 44 is located at Inside the electrode tank 5.

[0056] In this embodiment, the electrofusion connection pipe fitting can be formed by putting the threaded resistance wire 43 into both ends of the electrofusion connector 1, and then the copper electrode 44 in the motor slot can be energized to make...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com