Sewage treatment agent for printing and dyeing industry and preparation method of sewage treatment agent

A kind of sewage treatment agent, industrial technology, applied in textile industry wastewater treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems such as the need to improve the treatment effect, high cost, cumbersome process flow, etc., to achieve easy Large-scale promotion, good treatment effect, good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

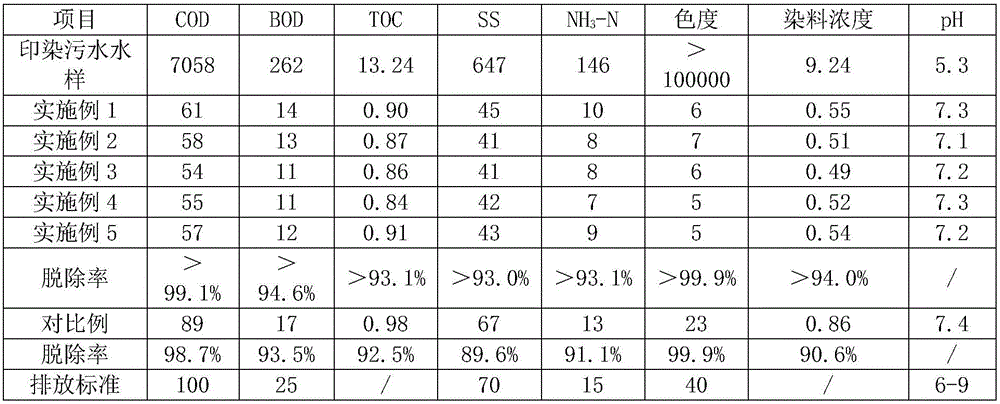

Examples

Embodiment 1

[0018] A sewage treatment agent for the printing and dyeing industry, consisting of the following raw materials in parts by weight: 16 parts of disodium edetate, 10 parts of sodium bicarbonate, 25 parts of sodium lauryl sulfate, and 22 parts of modified diatomite , 32 parts of polyaluminum chloride, 14 parts of aluminum sulfate, 30 parts of medical stone, 23 parts of activated carbon, 10 parts of perlite, 8 parts of molybdenum sulfide powder, 14 parts of tin oxide powder, 22 parts of propylene glycol.

[0019] The preparation method that is used for the sewage treatment agent of printing and dyeing industry described in the present embodiment, the steps are as follows:

[0020] 1) Weigh modified diatomite, medical stone and perlite, after crushing, pass through 80 mesh sieve to obtain mixed powder;

[0021] 2) Weigh disodium edetate and sodium lauryl sulfate, put them into a reaction kettle, add propylene glycol, heat up to 50°C, and stir and mix for 20 minutes;

[0022] 3) C...

Embodiment 2

[0027] A sewage treatment agent for the printing and dyeing industry, consisting of the following raw materials in parts by weight: 20 parts of disodium edetate, 15 parts of sodium bicarbonate, 30 parts of sodium lauryl sulfate, and 25 parts of modified diatomite , 38 parts of polyaluminum chloride, 16 parts of aluminum sulfate, 35 parts of medical stone, 25 parts of activated carbon, 14 parts of perlite, 3 parts of molybdenum sulfide powder, 17 parts of tin oxide powder, and 27 parts of propylene glycol.

[0028] The preparation method that is used for the sewage treatment agent of printing and dyeing industry described in the present embodiment, the steps are as follows:

[0029] 1) Weigh modified diatomite, medical stone and perlite, after crushing, pass through a 100-mesh sieve to obtain a mixed powder;

[0030] 2) Weigh disodium edetate and sodium lauryl sulfate, put them into a reaction kettle, add propylene glycol, heat up to 55°C, and stir and mix for 30 minutes;

[0...

Embodiment 3

[0036] A sewage treatment agent for the printing and dyeing industry, consisting of the following raw materials in parts by weight: 18 parts of disodium edetate, 13 parts of sodium bicarbonate, 27 parts of sodium lauryl sulfate, and 24 parts of modified diatomite , 35 parts of polyaluminum chloride, 15 parts of aluminum sulfate, 33 parts of medical stone, 24 parts of activated carbon, 12 parts of perlite, 11 parts of molybdenum sulfide powder, 16 parts of tin oxide powder, and 24 parts of propylene glycol.

[0037] The preparation method that is used for the sewage treatment agent of printing and dyeing industry described in the present embodiment, the steps are as follows:

[0038] 1) Weigh modified diatomite, medical stone and perlite, after crushing, pass through a 100-mesh sieve to obtain a mixed powder;

[0039] 2) Weigh disodium edetate and sodium lauryl sulfate, put them into the reaction kettle, add propylene glycol, heat up to 53°C, stir and mix for 25 minutes;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com