Method for improving dehydration performance of anaerobic digestion substrate of papermaking sludge by virtue of combination of two flocculants

A papermaking sludge and anaerobic digestion technology, which is applied in dehydration/drying/concentrated sludge treatment, processing wastewater treatment, etc., can solve the problems of high sediment, low moisture content of mud cake, high cost, etc., and achieve high efficiency solid-liquid Separation, strong operability, low water content effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

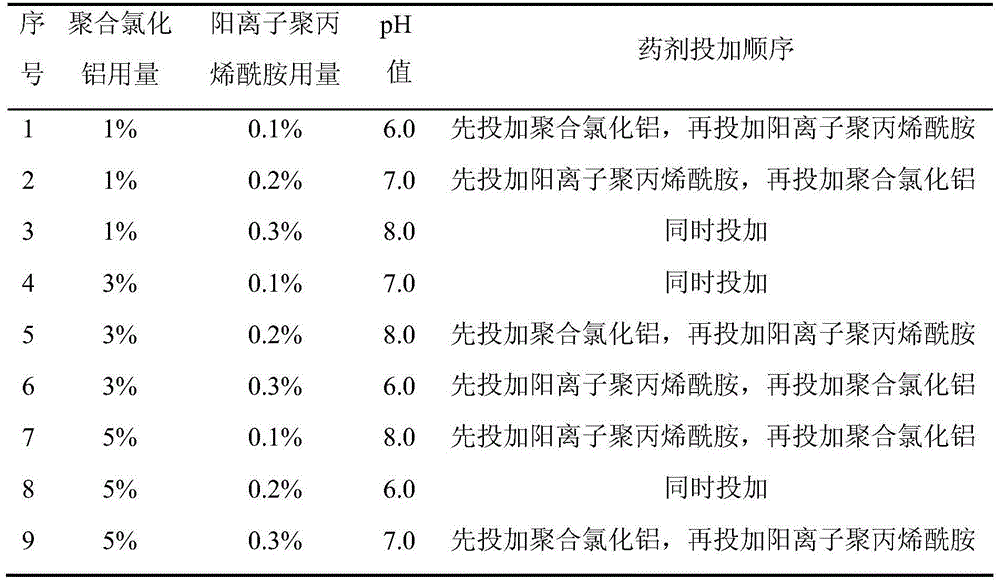

[0026] (1) Papermaking sludge (taken from Guangzhou Paper Mill, which is biochemical sludge obtained in the process of papermaking wastewater treatment, with a moisture content of 43 to 46%), monosodium glutamate waste liquid ( Taken from Guangzhou Aosang Monosodium Glutamate Factory, with a moisture content of 45-50%), inoculated sludge (referring to one or more of the anaerobic digested sludge from septic tank sludge, spoiled river sludge, or urban sewage treatment plant) The seed sludge obtained after domestication; the present invention adopts the domestication method to cultivate the seed sludge, and selects the domesticated papermaking sludge after 2 months of anaerobic fermentation as the inoculation sludge, with a moisture content of 87.07%) and distilled water for joint anaerobic fermentation. The fermentation condition is that the mass solid content of the fermentation material (papermaking sludge, monosodium glutamate waste liquid, inoculation sludge and distilled wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com