Method for recycling polymer-containing air flotation oil sludge

A sewage sludge and recycling technology, applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of occupying large cultivated land, soil, water body air pollution, etc., and solve the problem of environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

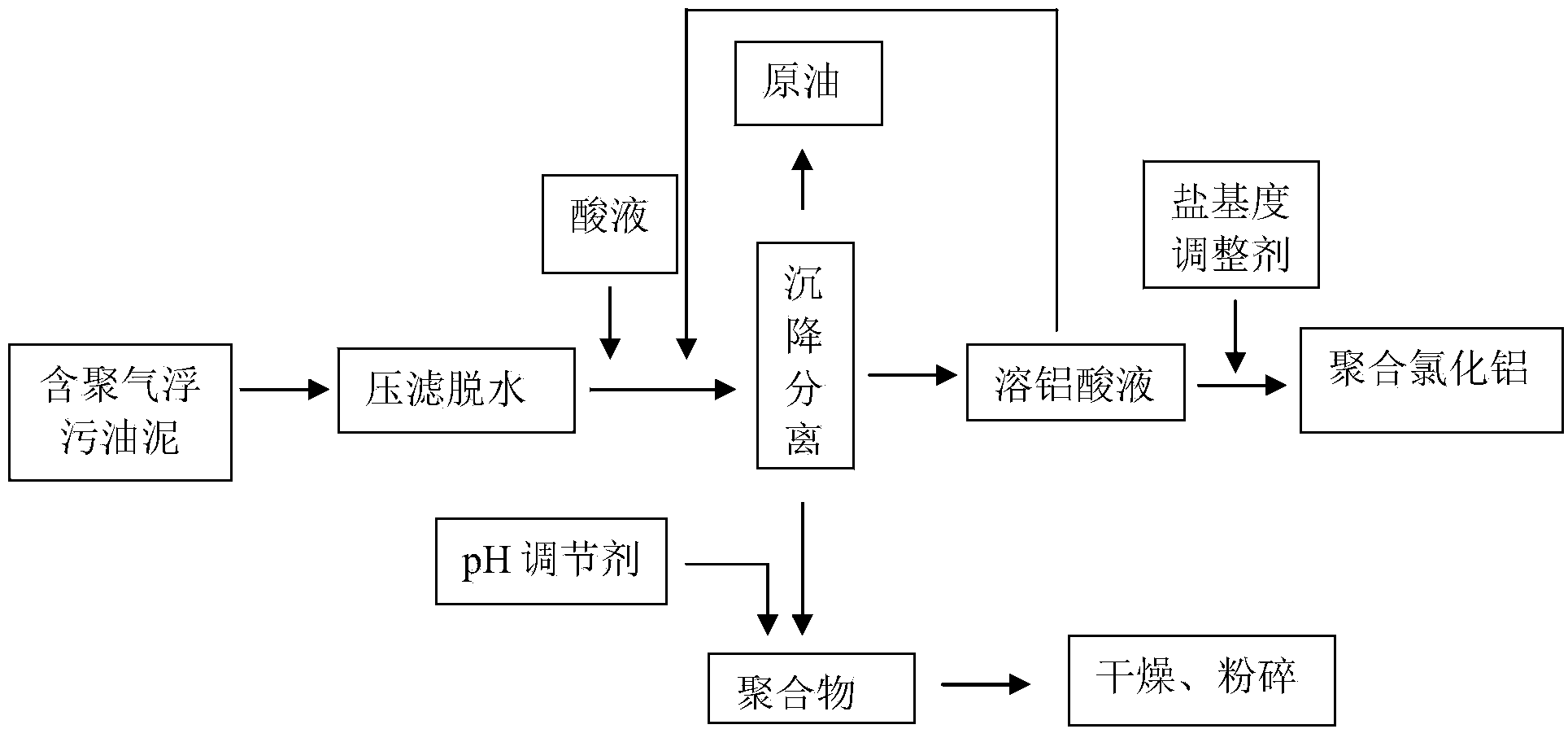

[0025] A method for resource recovery and reuse of air-accumulating flotation sludge, the specific steps are as follows:

[0026] 1) Mix 500g of air-accumulated flotation sludge with 500ml of 20% hydrochloric acid solution and stir evenly after pressure filtration and dehydration to less than 80%, and let it stand;

[0027] 2) Set the mixture in step 1) for 24 hours to separate crude oil, aluminum-containing acid liquid and polymer. If the polymer and crude oil cannot be completely separated, use solvent extraction oil for extraction and separation. The solvent extraction oil is 6 # Solvent oil;

[0028] 3) The polymer separated in step 2) is used as an admixture for oil well cement after adjusting the pH value, drying, and pulverization, and the pH value is adjusted to 7 as an admixture for preparing oil well cement. The addition amount is 1%; wherein, The regulator used to adjust the pH value is a mixture of sodium hydroxide and sodium carbonate;

[0029] 4) Recycle and re...

Embodiment 2

[0031] A method for resource recovery and reuse of air-accumulating flotation sludge, the specific steps are as follows:

[0032] 1) Mix 500g of air-accumulating flotation sludge with 500ml of 30% hydrochloric acid solution after pressure filtration and dehydration, stir evenly, and let stand;

[0033] 2) Set the mixture in step 1) for 24 hours to separate crude oil, aluminum-containing acid liquid and polymer. If the polymer and crude oil cannot be completely separated, use solvent extraction oil for extraction and separation. The solvent extraction oil is mixed Aromatics;

[0034] 3) The polymer separated in step 2) is used as an admixture for oil well cement after adjusting the pH value, drying, and crushing; the added amount of the admixture for preparing oil well cement is 5% after adjusting the pH value to 9, wherein, The regulator used to adjust the pH value is a mixture of magnesium oxide and calcium oxide;

[0035] 4) Recycle and reuse the aluminum-containing acid s...

Embodiment 3

[0037] A method for resource recovery and reuse of air-accumulating flotation sludge, the specific steps are as follows:

[0038] 1) Mix 250 grams of air-accumulated flotation sludge with 800ml of 10% hydrochloric acid solution after pressure filtration and dehydration, stir evenly, and let stand;

[0039] 2) Set the mixture in step 1) for 24 hours to separate crude oil, aluminum-containing acid liquid and polymer. If the polymer and crude oil cannot be completely separated, use solvent extraction oil for extraction and separation. The solvent extraction oil is 6 # A mixture of solvent naphtha and mixed aromatics;

[0040] 3) The polymer separated in step 2) is used as an additive for fly ash pavement cement after adjusting the pH value, drying, and crushing; wherein, the regulator for adjusting the pH value is sodium hydroxide, magnesium oxide mixture;

[0041] 4) Recycle and reuse the aluminum-containing acid solution separated in step 2) in step 1), stop recycling until t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com