Patents

Literature

52results about How to "Reduce complexation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

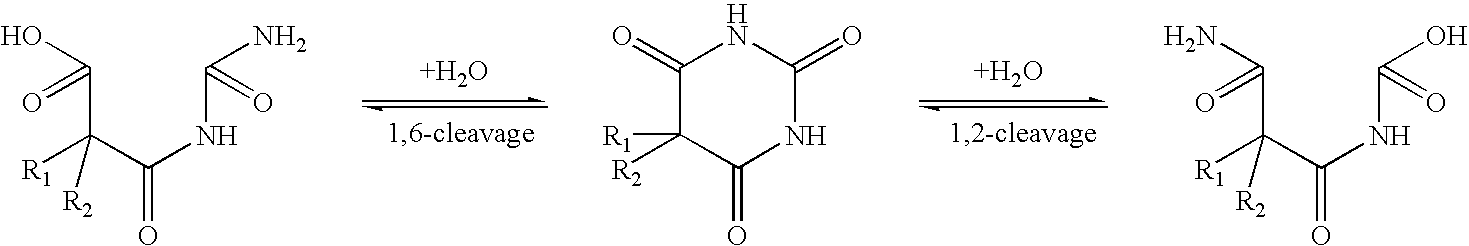

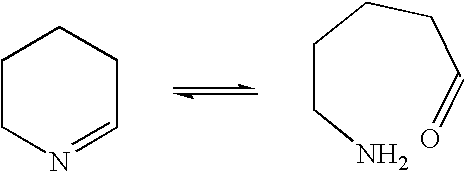

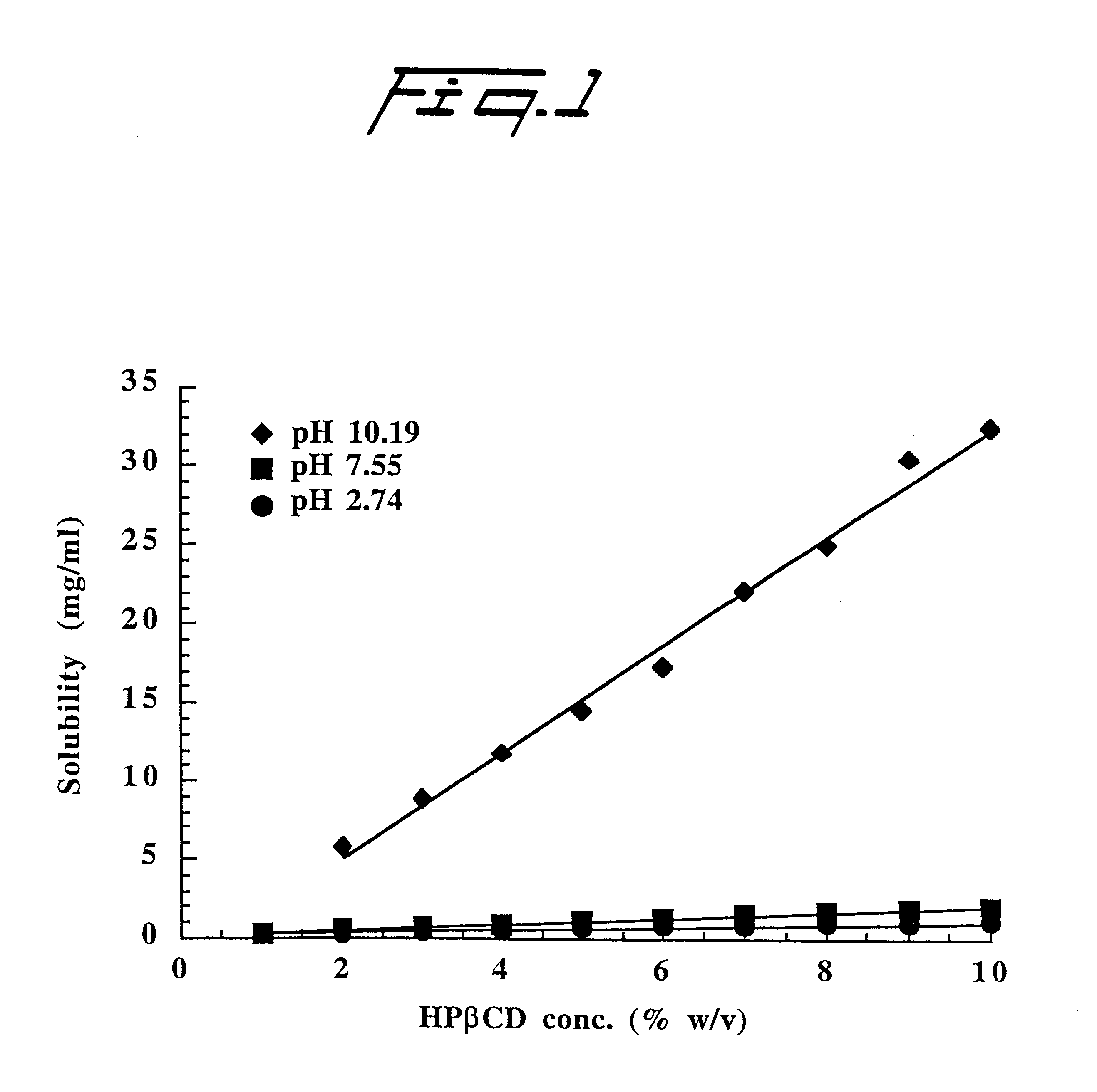

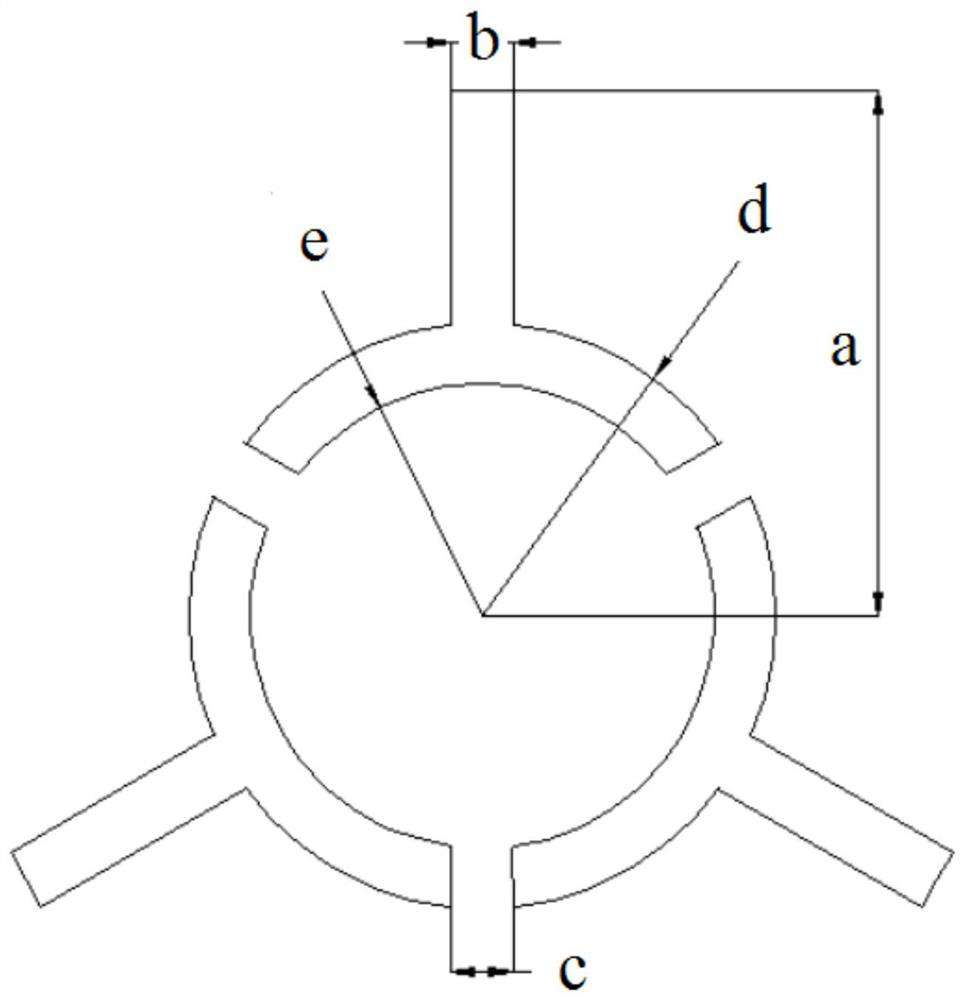

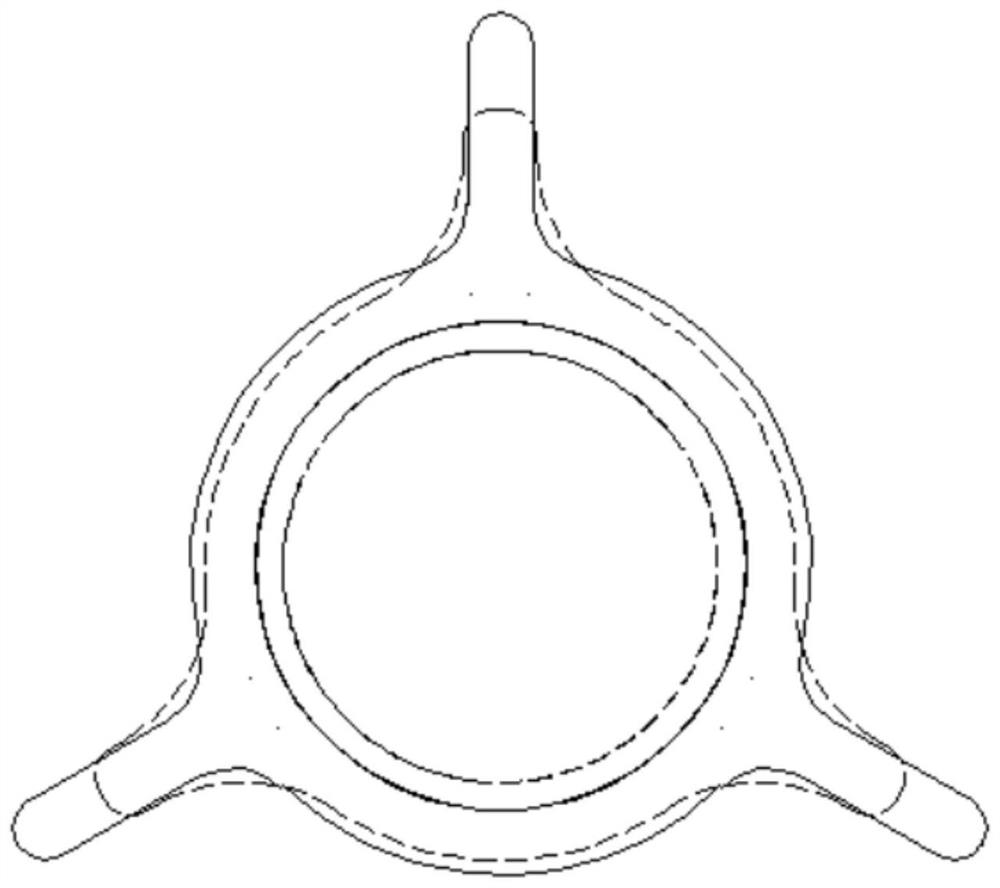

Cyclodextrin complexes of benzodiazepines

InactiveUS6699849B1Improve complexation efficiencyReduce complexationBiocideOrganic chemistryBenzodiazepineCyclodextrin

Methods for enhancing the complexation efficiency of a drug with cyclodextrin and for enhancing the availability of a drug following administration of a cyclodextrin-drug complex.

Owner:CYCLOPS EHF

Preparation method of cationic dyeable polyester fiber

ActiveCN107604463AReduce pressure riseLess impuritiesFilament/thread formingMonocomponent polyesters artificial filamentPressure risePolymer science

The invention relates to a preparation method of cationic dyeable polyester fiber, first, dimethyl isophthalate-5-benzenesulfonate sodium, ethylene glycol and a catalyst are mixed for ester exchange reaction, after completion of the reaction, ethylene glycol, a complex ion regulator and sulfuric acid are added for adjusting, terephthalic acid, ethylene glycol, a catalyst and a flatting agent are mixed for esterification reaction, a product obtained by adjusting after the ester exchange reaction is added into the reaction system with esterification reaction end point is reached for polycondensation to obtain spinning melt, and finally the cationic dyeable polyester fiber is obtained by metering, extrusion, cooling, oiling, stretching, heat setting and winding of the spinning melt. The method reduces the production of impurities in the fiber production process, thereby reducing the pressure rise of a spinning assembly and a filter, prolonging the service life, reducing the production cost and ensuring the continuity and safety of the whole production process, and the method has good economic value and popularization value.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

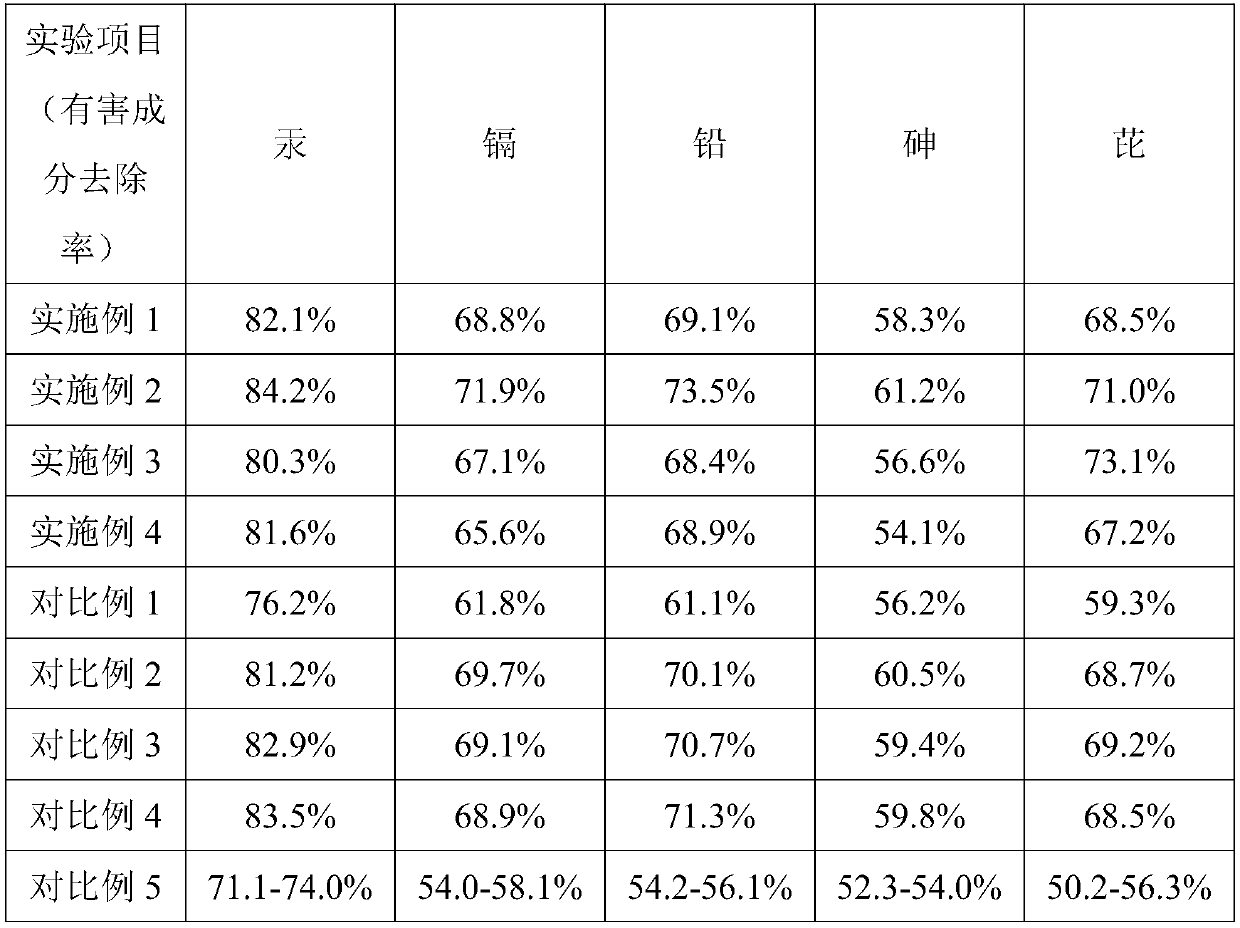

Restoration agent and preparation method thereof and method using restoration agent to restore heavy metal-polluted soil

InactiveCN107815316AThe comprehensive effect of the removal rate is goodImprove adsorption capacityContaminated soil reclamationOrganic fertilisersPotassiumMonocalcium phosphate

The invention discloses a restoration agent and a preparation method thereof and a method using the restoration agent to restore heavy metal-polluted soil, and belongs to the technical field of restoration of heavy metal soil pollution. The restoration agent is prepared from the following raw materials of biochar, sepiolite, monocalcium phosphate, sugarcane residues, lime powder, longan peel, tartaric acid, hydroxyethyl triphosphate, potassium lignosulphonate, malic acid, chitosan and soybean straw. The restoration agent is prepared by the following steps of powder preparing, fermenting, powder drying and the like. The restoration agent has the advantages that the preparation technology is simple; when the restoration agent is used for restoring the heavy metal-polluted soil, the removal rate of mercury, cadmium, lead, arsenic and pyrene is increased.

Owner:CHANGSHA QIUDIANBING INFORMATION TECH CO LTD

Preparing method for ordinary-pressure positive-ion dyeable polyester fiber

ActiveCN107541803ALess impuritiesReduce pressure riseMonocomponent polyetheresters artificial filamentMelt spinning methodsPressure risePolyethylene glycol

The invention relates to a preparing method for an ordinary-pressure positive-ion dyeable polyester fiber. The preparing method includes the steps that dimethyl isophthalate-5-sodium benzenesulfonate,ethylene glycol, a catalyst and an anti-ether agent are mixed to be subjected to an ester exchange reaction, the reaction is end, then ethylene glycol and sodium ethylene glycol are added, modulationis carried out, then terephthalic acid, ethylene glycol and a catalyst are mixed, and the mixture is subjected to an esterification reaction; the modulated product after the ester exchange reaction is end and polyethylene glycol are added into an esterification reaction system reaching the end point of the esterification reaction, condensation polymerization is carried out, and spinning melt is obtained; the spinning melt is measured, extruded, cooled, subjected to oil applying, stretched, subjected to heat setting and wound, and the ordinary-pressure positive-ion dyeable polyester fiber is prepared. According to preparing method, generation of impurities in the polyester-fiber production process is reduced, pressure rising of a spinning assembly and a filter is reduced accordingly, the service cycle of the polyester fiber is prolonged, the continuity and the safety of the whole production process are guaranteed, and the preparing method has the good economic value and popularizationvalue.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

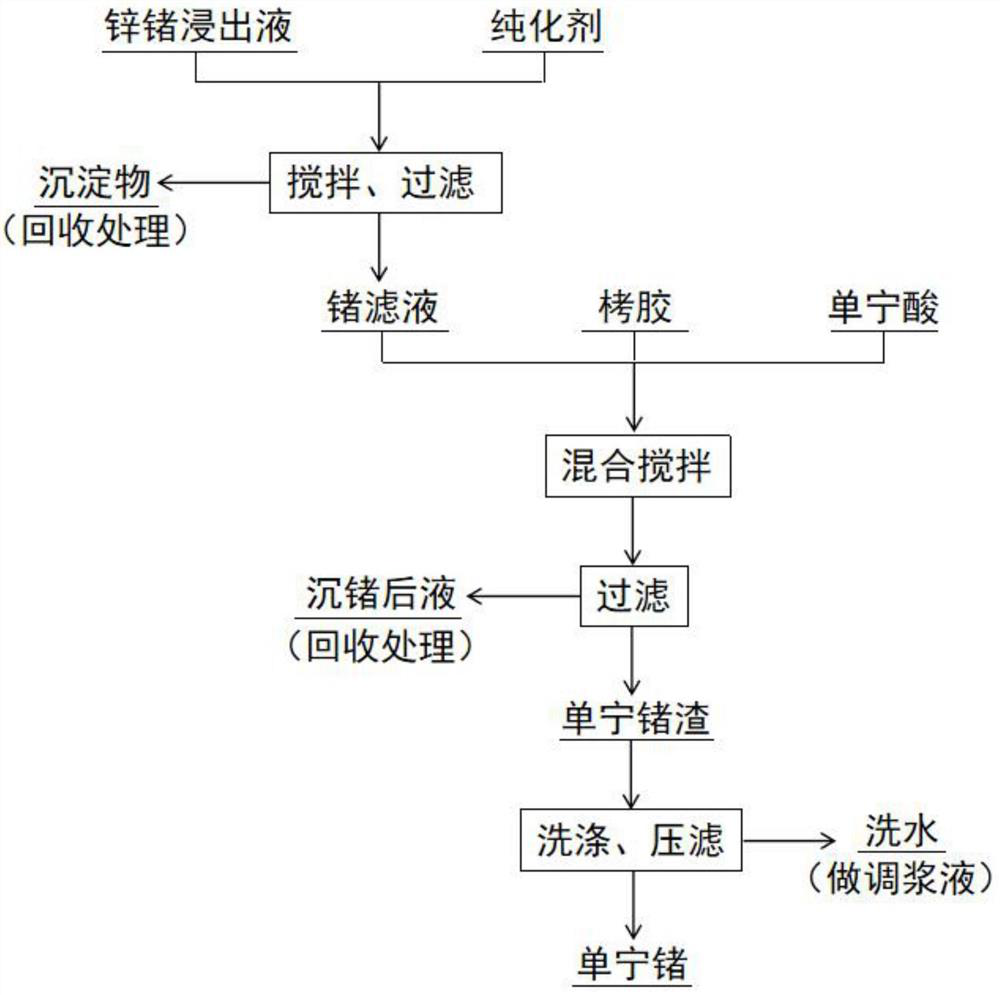

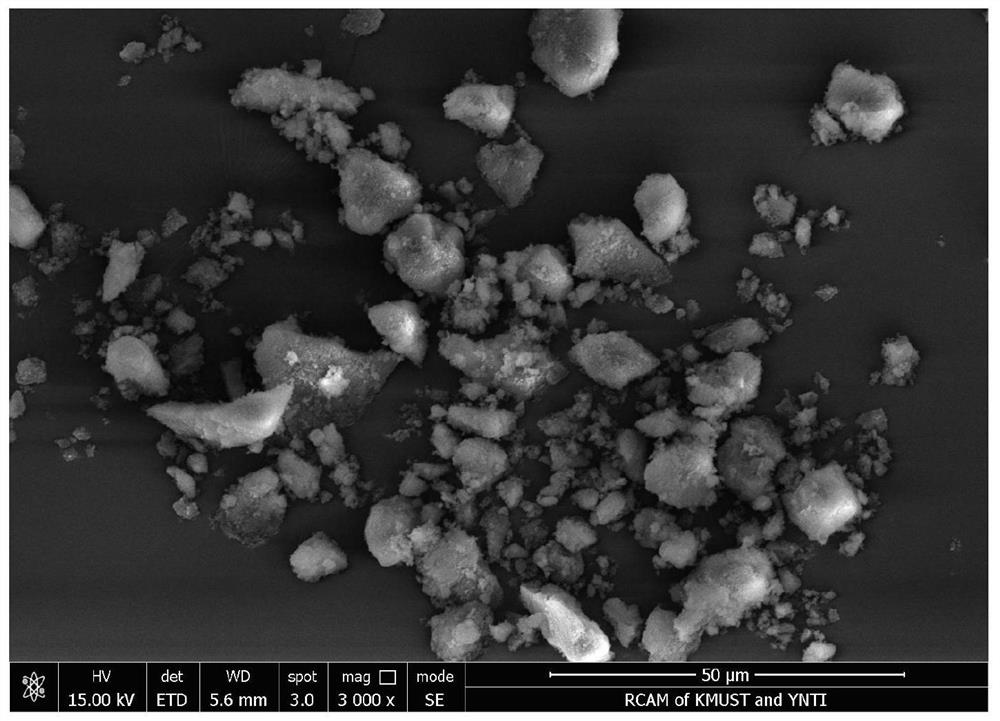

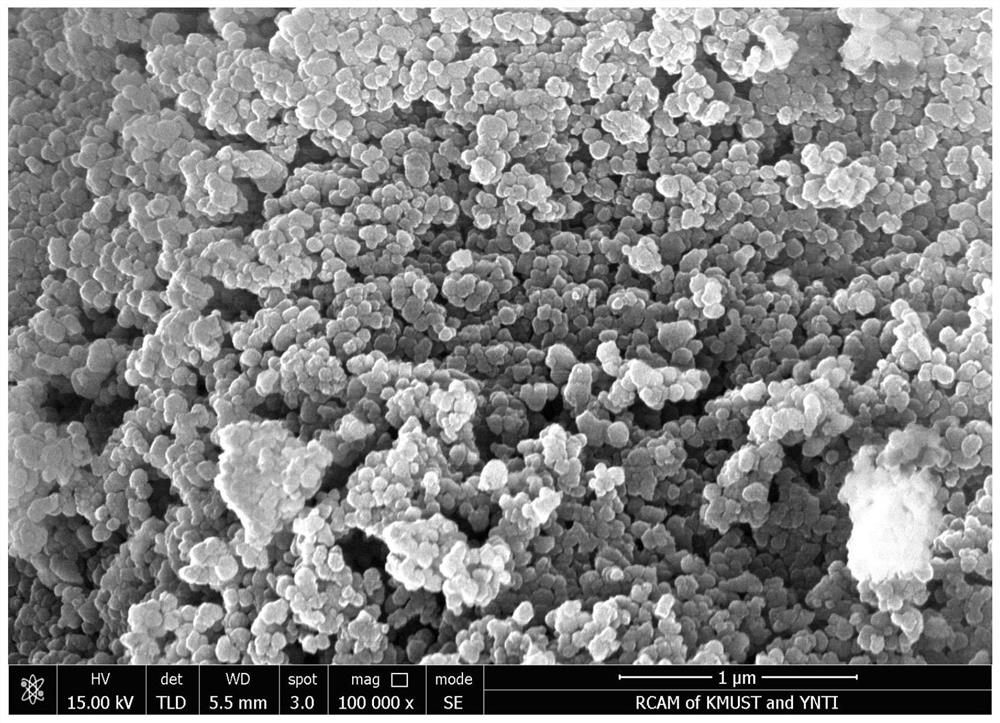

Method for efficiently extracting germanium from zinc-germanium leaching solution

PendingCN112662898ALow ion contentReduce complexationSugar derivativesProcess efficiency improvementSlagFiltration

The invention relates to a method for efficiently extracting germanium from a zinc-germanium leaching solution, and belongs to the technical field of hydrometallurgy in nonferrous metallurgy. The method comprises the following steps of adding a purifying agent into the zinc-germanium leaching solution, reacting for 10-20 minutes under a stirring condition so as to obtain a solution system A, and carrying out solid-liquid separation so as to obtain a solution B; and adding a tannin extract into the solution B, reacting for 1-10 minutes under a stirring condition, then slowly adding tannic acid, reacting for 10-20 minutes so as to obtain a system C, carrying out solid-liquid separation so as to obtain germanium-precipitated liquid and tannin germanium slag, and washing the tannin germanium slag so as to obtain tannin germanium. According to the method, the purifying agent is added to react with impurity ions so as to generate insoluble substances, a filtrate with high germanium content and low impurity element content is obtained through filtration, then germanium precipitation is carried out in sequence after the tannin extract and the tannic acid are added, the germanium precipitation rate reaches 98.9%, the germanium content in the tannin germanium reaches 5%, the purity of the tannin germanium is improved, the tannin extract is lower in price and lower in production cost compared with the tannic acid, and an existing germanium precipitation process can be obviously optimized. The method has the characteristics of low labor intensity, high germanium extraction rate and low production cost.

Owner:KUNMING UNIV OF SCI & TECH

Strong oxidant for papermaking waste water CODcr degradation and method for degrading CODcr in waste water

InactiveCN103708600AImprove compactnessReduce complexationWaste water treatment from plant processingWater/sewage treatment by flocculation/precipitationIron sulfateAluminium chloride

The invention aims to provide a strong oxidant for papermaking waste water CODcr degradation and a method for degrading CODcr in waste water, wherein the requirements on equipment operation and management are low, the equipment operating cost is low, the processing treatment efficiency is high, and secondary pollution can be prevented. The strong oxidant comprises the following components in parts by weight: 1 part of potassium permanganate, 10-60 parts of aluminum sulfate, 10-50 parts of ferric sulfate, and 10-50 parts of aluminum polychlorid. The method for degrading CODcr in waste water by utilizing the strong oxidant comprises the following steps: dissolving the strong oxidant in water in a proportion of 1: (5-20), then feeding in a coagulating basin for waste water treatment so as to carry out oxidation treatment, controlling the stirring speed at 50-100 rpm during the process and the reaction time to be 15-60 min, then feeding polyacrylamide as an auxiliary to complete the process of oxidation separation, and keeping the control time of the oxidant after dissolution within 1-12 hours. The strong oxidant and the method can be applied to the field of papermaking waste water treatment.

Owner:珠海市德莱环保科技有限公司

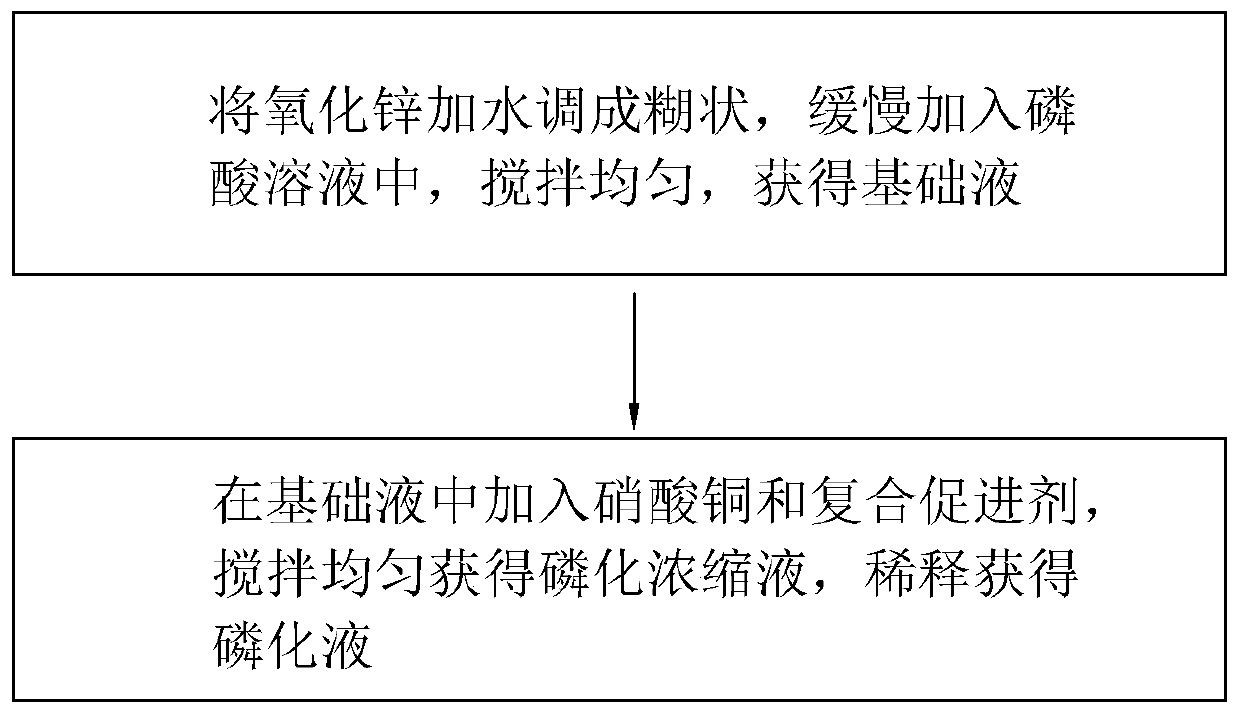

Anti-seismic prefabricated house

InactiveCN109778161AImprove film qualityPromotes electrochemical reactionsMetallic material coating processesElectrode potentialElectrochemical response

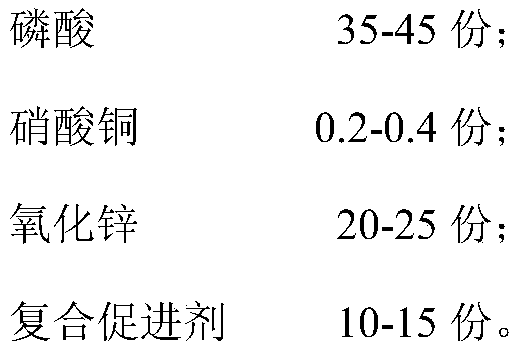

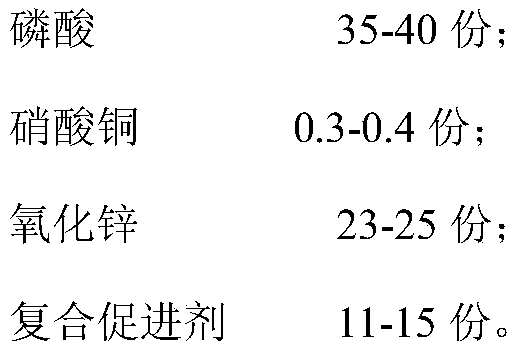

The invention discloses an anti-seismic prefabricated house, comprising a plurality of steel plates, wherein the outer side of each steel plate is treated by a phosphating solution to form a phosphating film, and the phosphating solution comprises the following components in parts by weight: 35-45 parts of phosphoric acid, 0.2-0.4 parts of copper nitrate, 20-25 parts of zinc oxide, and 10-15 partsof compound accelerant. The anti-seismic prefabricated house provided by the invention has the advantages: as the main film-forming materials, the phosphoric acid and zinc oxide can form a continuous and uniform phosphating film on the surface of the processed. Meanwhile, the addition of the compound accelerator further improves the film forming speed and film forming quality of the phosphatingfilm. In addition, because the electrode potential of copper is higher than that of iron, copper ions are reduced and deposited on the surface of a phosphated hinge body, so the cathode area on the surface is increased; the electrochemical reaction of phosphating is further promoted, the formation of phosphating crystal nucleus is accelerated, crystal grains are refined, and the phosphating film is compact and uniform; meanwhile, the phosphating speed is improved, the phosphating temperature is reduced, and finally the phosphating film has the advantages of compact film formation and strong adhesive force.

Owner:浙江华锦建筑装饰设计有限公司

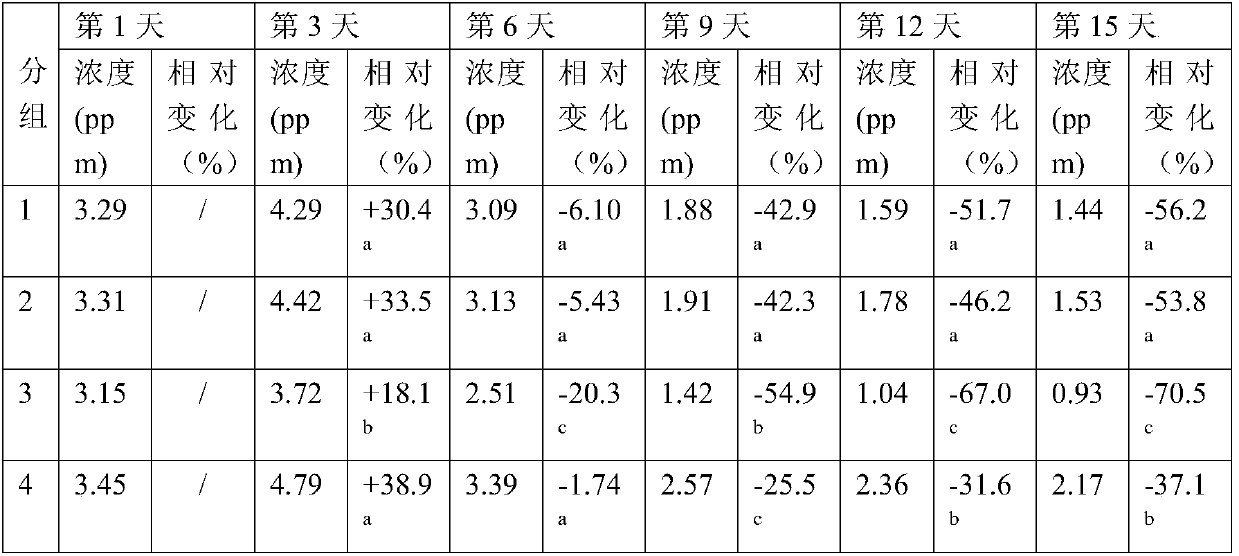

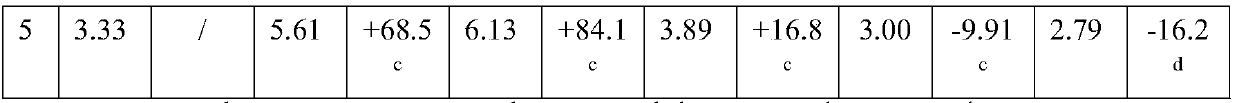

Compound preparation for deodorizing farm and reducing mycotoxins in livestock feed

The invention discloses a compound preparation for deodorizing a farm and reducing mycotoxins in a feed. The compound preparation is characterized by being prepared by mixing cinnamaldehyde and sodiumhumate in a weight ratio of 1:(2-5), and conducting stirring and sieving. The compound preparation of the invention has the advantages of reducing an odor caused by ammonia gas, hydrogen sulfide andindole in a livestock farm, reducing the mycotoxin content in the feed and promoting growth of livestock, wherein the sodium humate has the efficacy of regulating the acid-base balance in the livestock, promoting digestion and reducing the odor of livestock manure, and also has the efficacy of reducing mycotoxins in the feed, and the cinnamaldehyde exerts a synergistic effect by inhibiting growthof fungi in the feed and reducing production of mycotoxins.

Owner:何诚 +2

Formula feed for pig fattening period and preparation method thereof

PendingCN109874940AImprove digestibilityPromote degradationFood processingAnimal feeding stuffAnimal scienceRapeseed

The invention discloses a formula feed for the pig fattening period.The formula feed is prepared from, by weight, 40-50 parts of fermented corn germ meal, 20-30 parts of rice bran, 15-20 parts of drydistiller's grains, 10-15 parts of rapeseed cake, 10-15 parts of bean cake, 12-16 parts of a Chinese herbal medicine preparation, 5-8 parts of fish meal, 4-6parts of meat and bone meal, 7-10 parts ofcorn oil, 1-2 parts of salt, 1-2 parts of green tea powder, 0.8-1.2 parts of fermented polysaccharides and a trace amount of additives.The invention further disclosesa preparation method of the formula feed for the pig fattening period.Accordingly, the fermented corn germ meal serves as the main feed material, the fermented corn germ meal has the functions of achieving digestion and absorption easily and promoting growth, the surface of the feed is wrapped with a layer of Chinese herbal medicine preparation,the obtained feed has the effects of achieving the anti-bacterial property, diminishinginflammation, enhancing immunity, maintaining the balance of gastrointestinal microflora and the like, the nutritional requirements of fattening pigs in the growth period can be fully met, the fattening pigs can grow rapidly, the meat quality is obviously improved, and the disease resistance is high.

Owner:新昌县大船畈生物科技有限公司

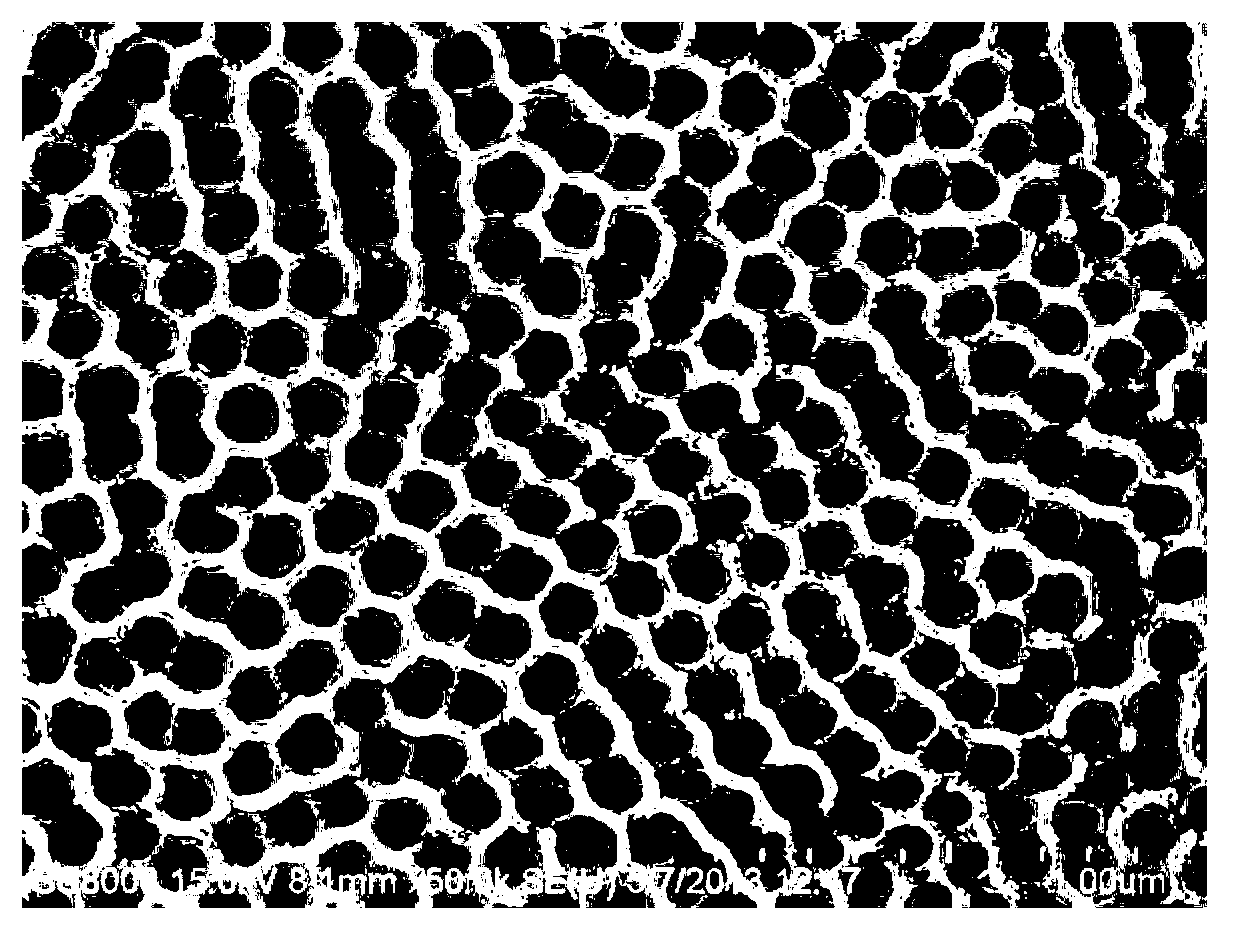

Method for eliminating nano porous layer on surface of titanium dioxide nano tube array

InactiveCN103303972AReduce complexationEfficient removalMaterial nanotechnologyTitanium dioxideElectrochemical anodizationWater treatment

The invention discloses a method for eliminating a nano porous layer on the surface of a titanium dioxide nano tube array, and relates to a method for eliminating a titanium dioxide nano porous layer. The invention provides a method for eliminating a nano porous layer covering the surface of a titanium dioxide nano tube array which is prepared by using an electrochemical anode oxidation method. The method comprises the following steps of: firstly, preparing a soaking liquid by using deionized water, hydrofluoric acid and nitric acid; and secondly, soaking the titanium dioxide nano tube array of which the surface is covered by the nano porous layer into the soaking liquid, taking out after soaking, washing by using the deionized water so as to eliminate the nano porous layer covering the surface of the titanium dioxide nano tube array. By utilizing the method, not only is the nano porous layer on the surface effectively eliminated, but also the structure of the titanium dioxide nano tube array is kept, and the operation that other nano materials of nano points, nano wires, nano rods and the like are assembled in nano tubes can be successfully carried out. The treated titanium dioxide nano tube array can be applied to the field of water treatment.

Owner:HARBIN INST OF TECH

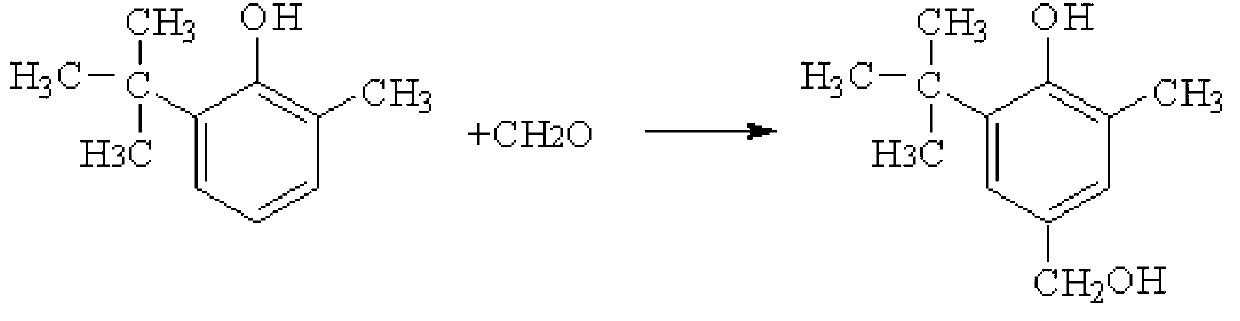

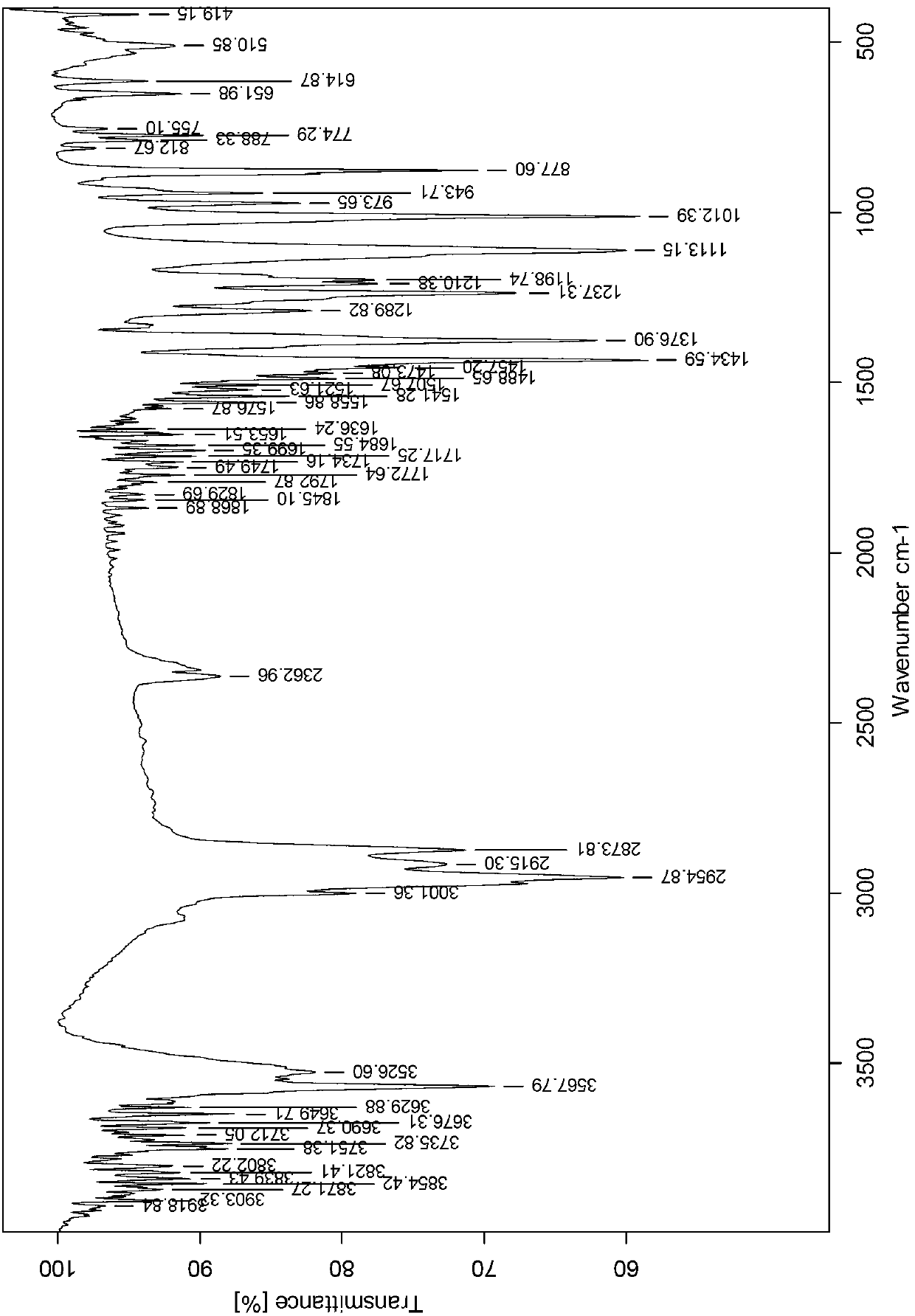

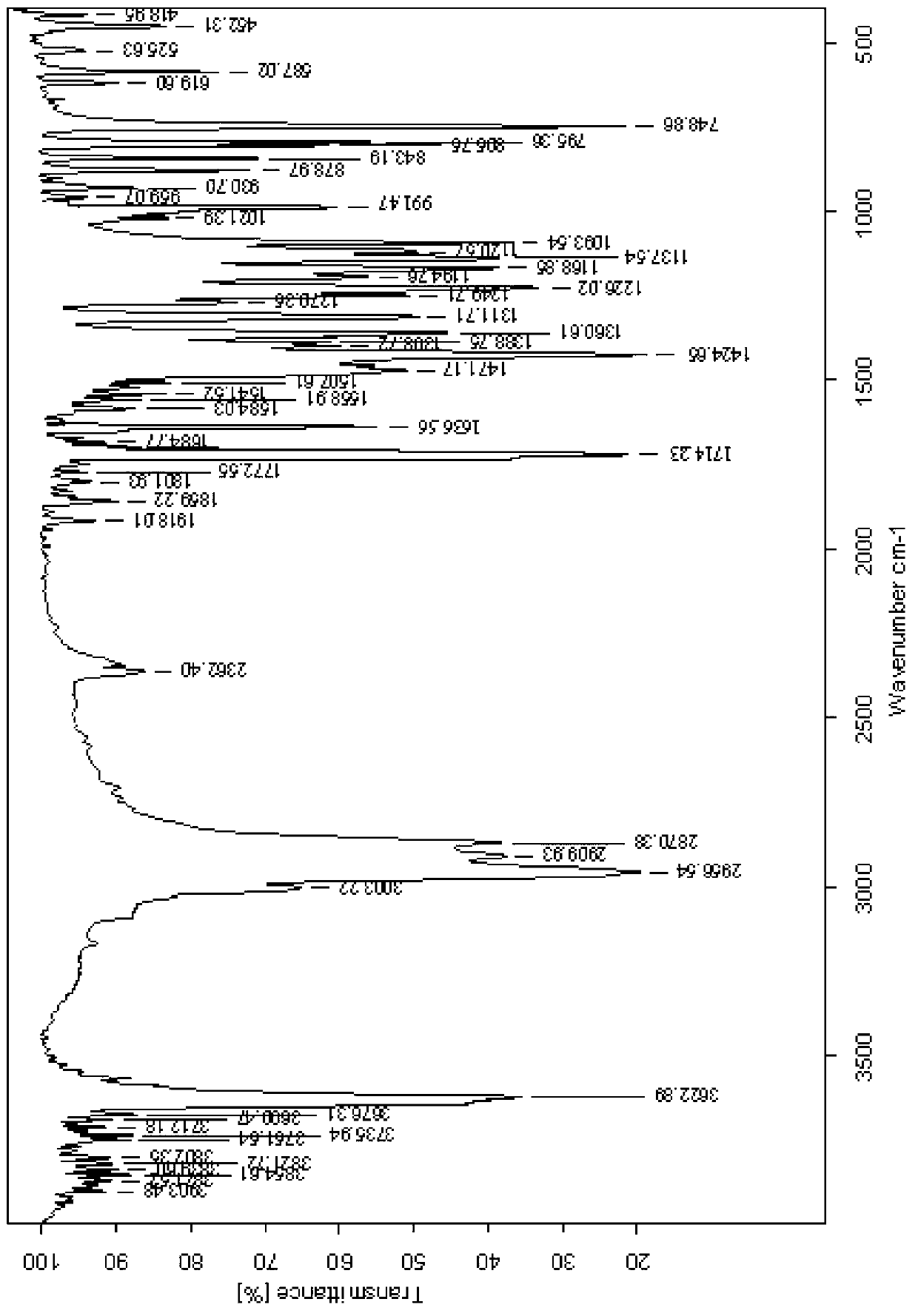

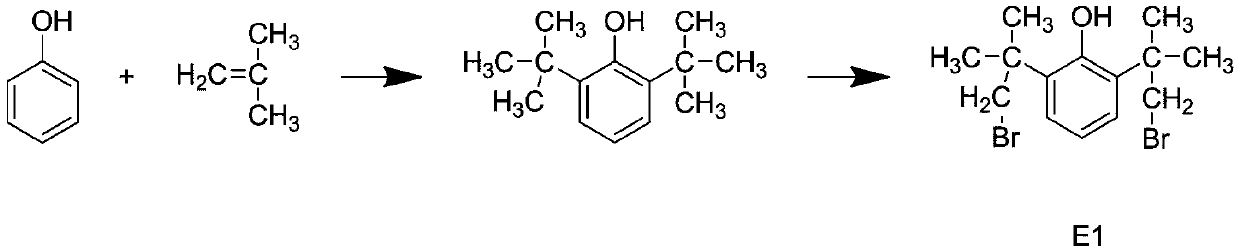

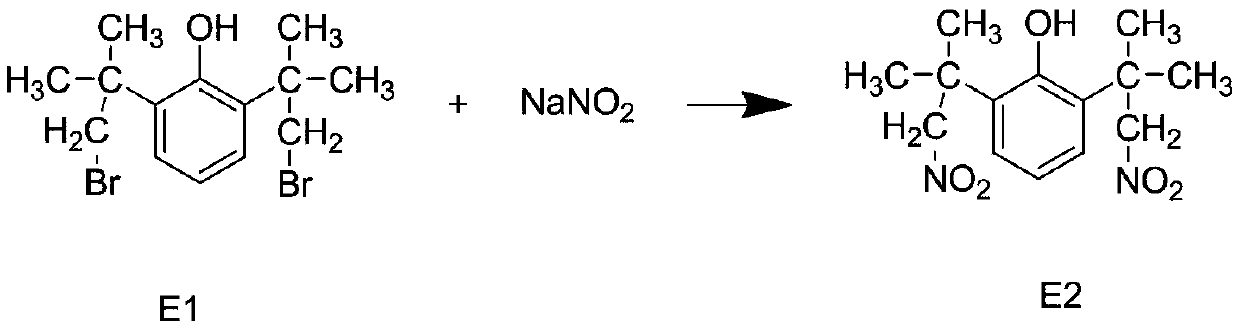

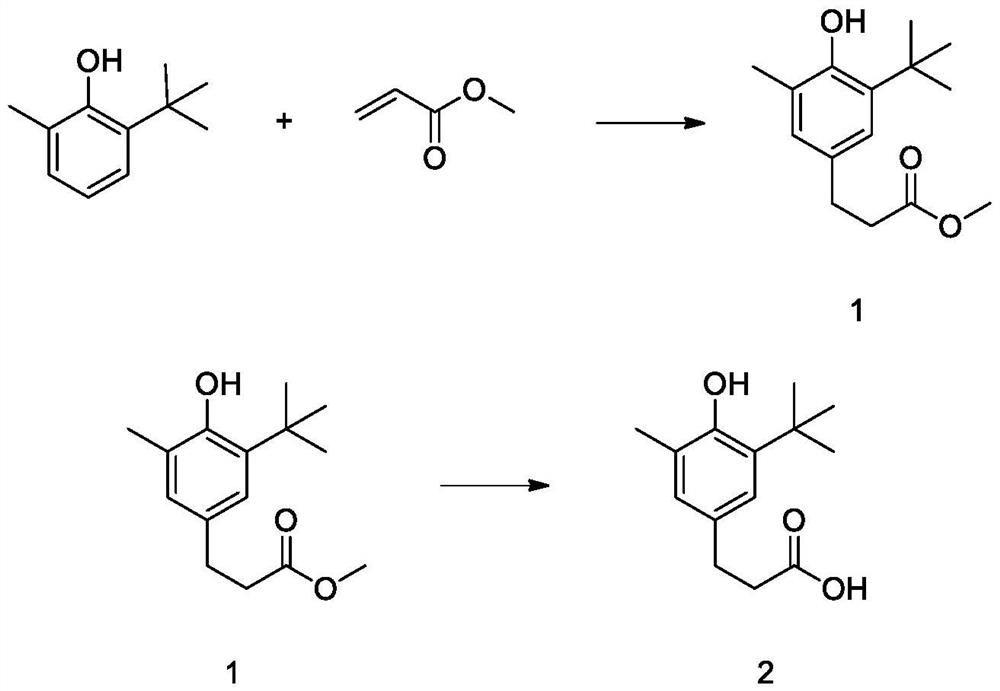

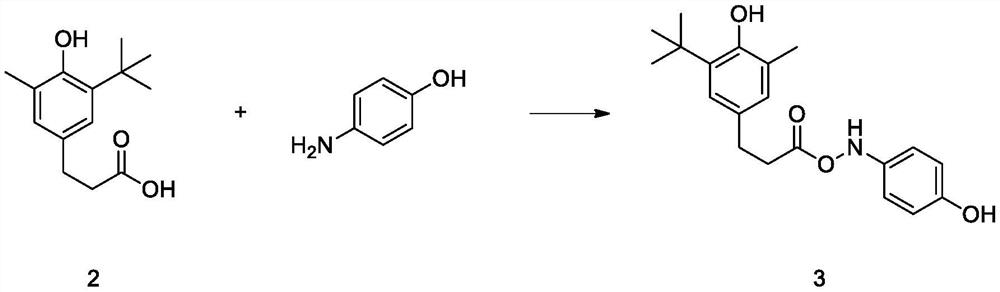

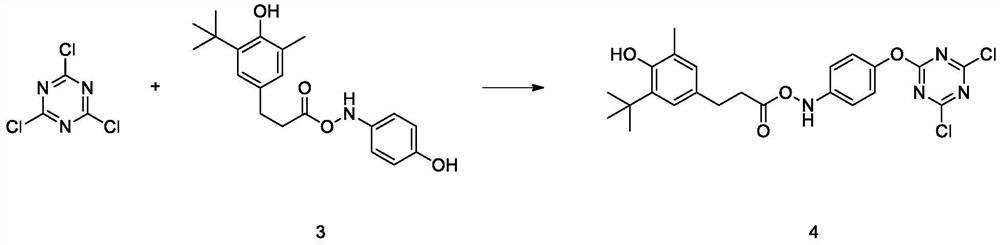

Preparation method of hindered phenol antioxidant 2-methyl-4-hydroxymethyl-6-tert-butyl phenol

InactiveCN103274907AReduce volatilityImprove heat resistanceOrganic chemistryOrganic compound preparationTert butyl phenolDistillation

The invention discloses a preparation method of hindered phenol antioxidant 2-methyl-4-hydroxymethyl-6-tert-butyl phenol. The preparation method comprises the following steps of: mixing raw materials, a solvent and a catalyst so as to obtain a mixture, introducing nitrogen and blowing, subsequently heating and stirring the mixture to be reacted, adding distilled water after the reaction is accomplished, carrying out pressure reduction and distillation so as to obtain a rough product; and recrystallizing the rough product by using isopentane so as to obtain the 2-methyl-4-hydroxymethyl-6-tert-butyl phenol, wherein the raw materials are multi-polyformaldehyde and 2-methyl-6-tert-butyl phenol; the solvent is tert-butyl alcohol; and the catalyst is potassium hydroxide. By utilizing the method, novel hindered phenol antioxidant 2-methyl-4-hydroxymethyl-6-tert-butyl phenol is prepared by utilizing active groups of end groups through simple chemical modification; the antioxidant comprises a methyl and a substituent tert-butyl which is large in size, so that the phenolic hydroxyl group is prevented from oxidation consumption, the complexation in charge transfer is reduced, and the oxidation resistance efficiency of the antioxidant is improved.

Owner:PETROCHINA CO LTD

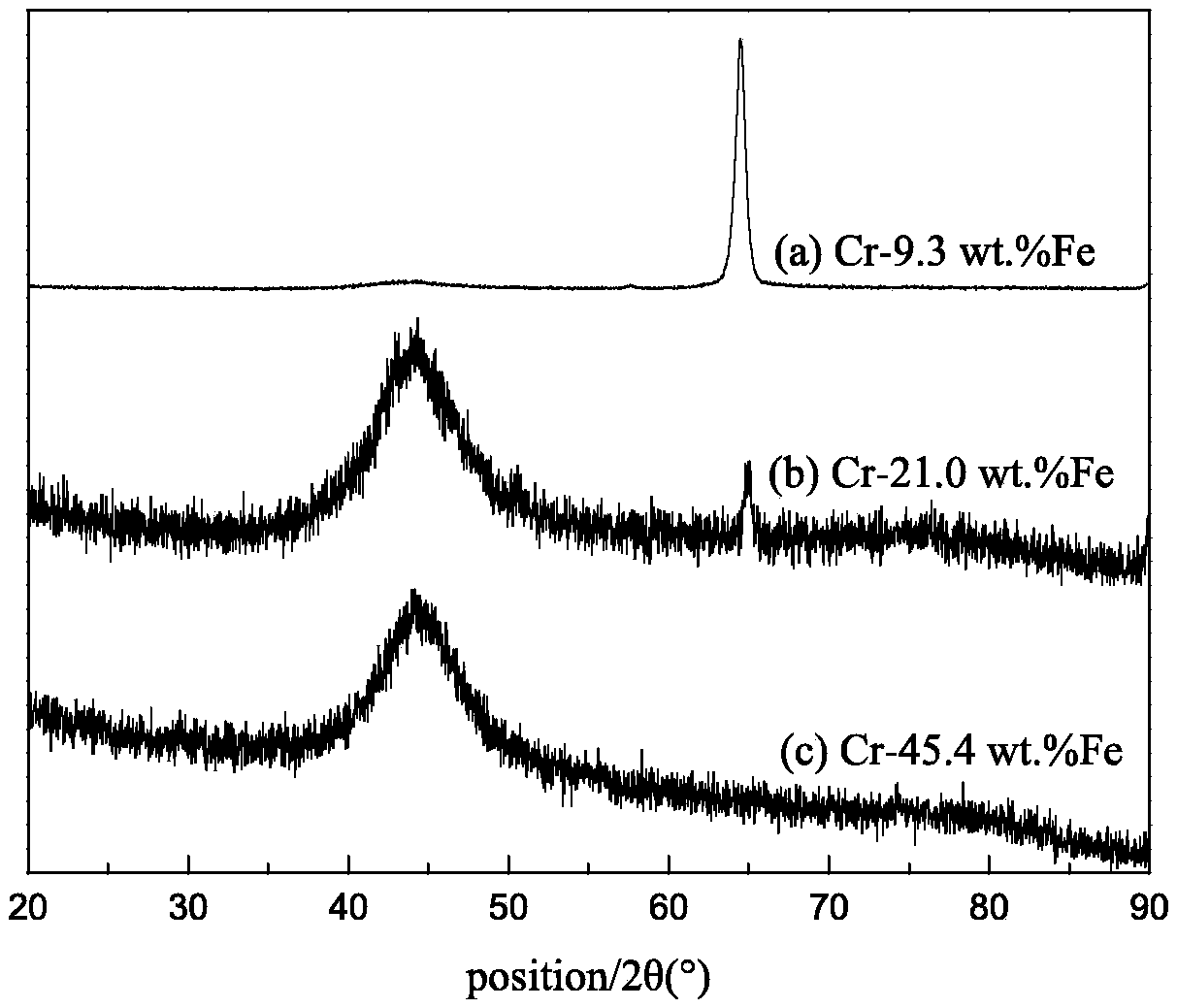

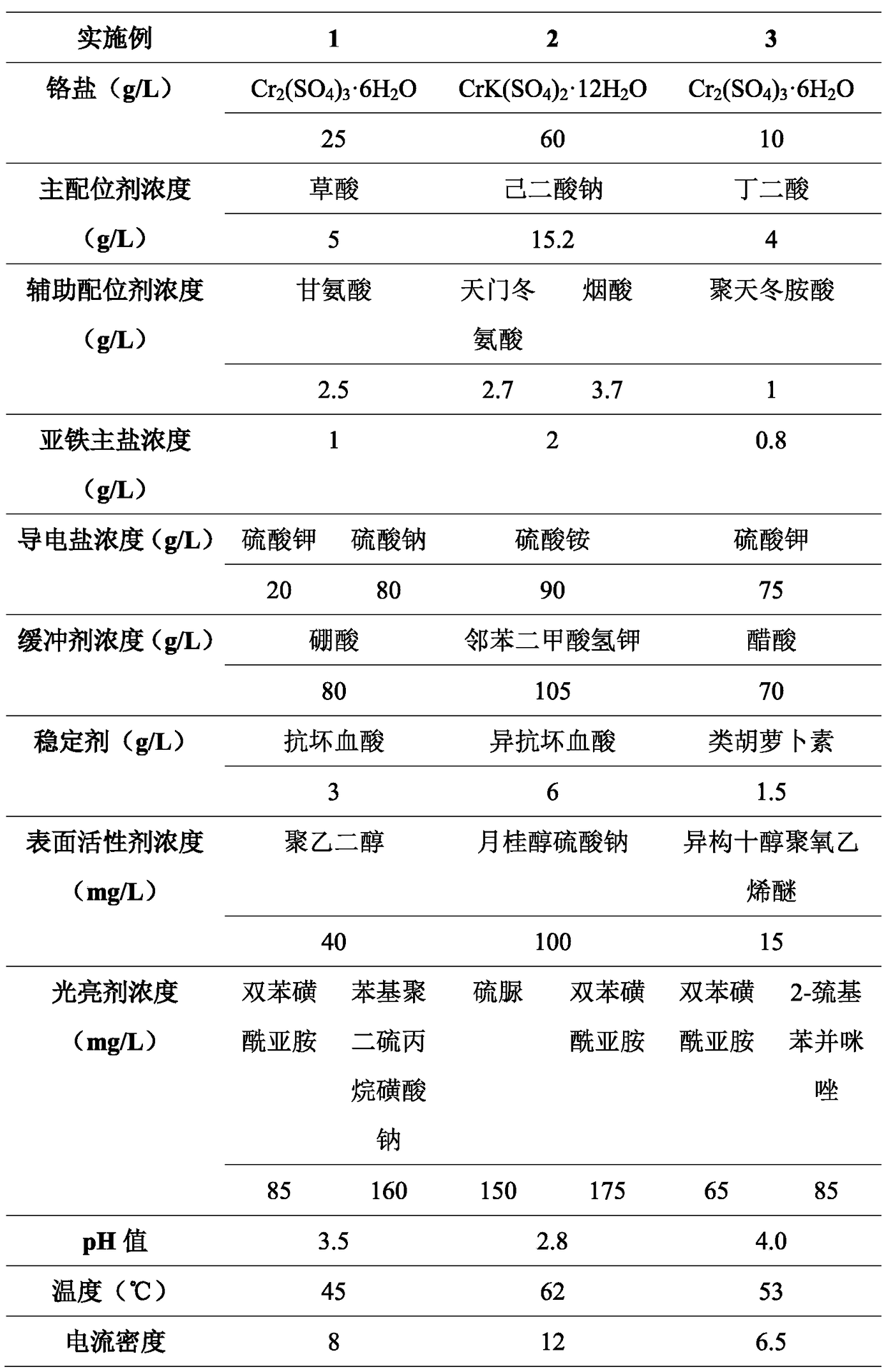

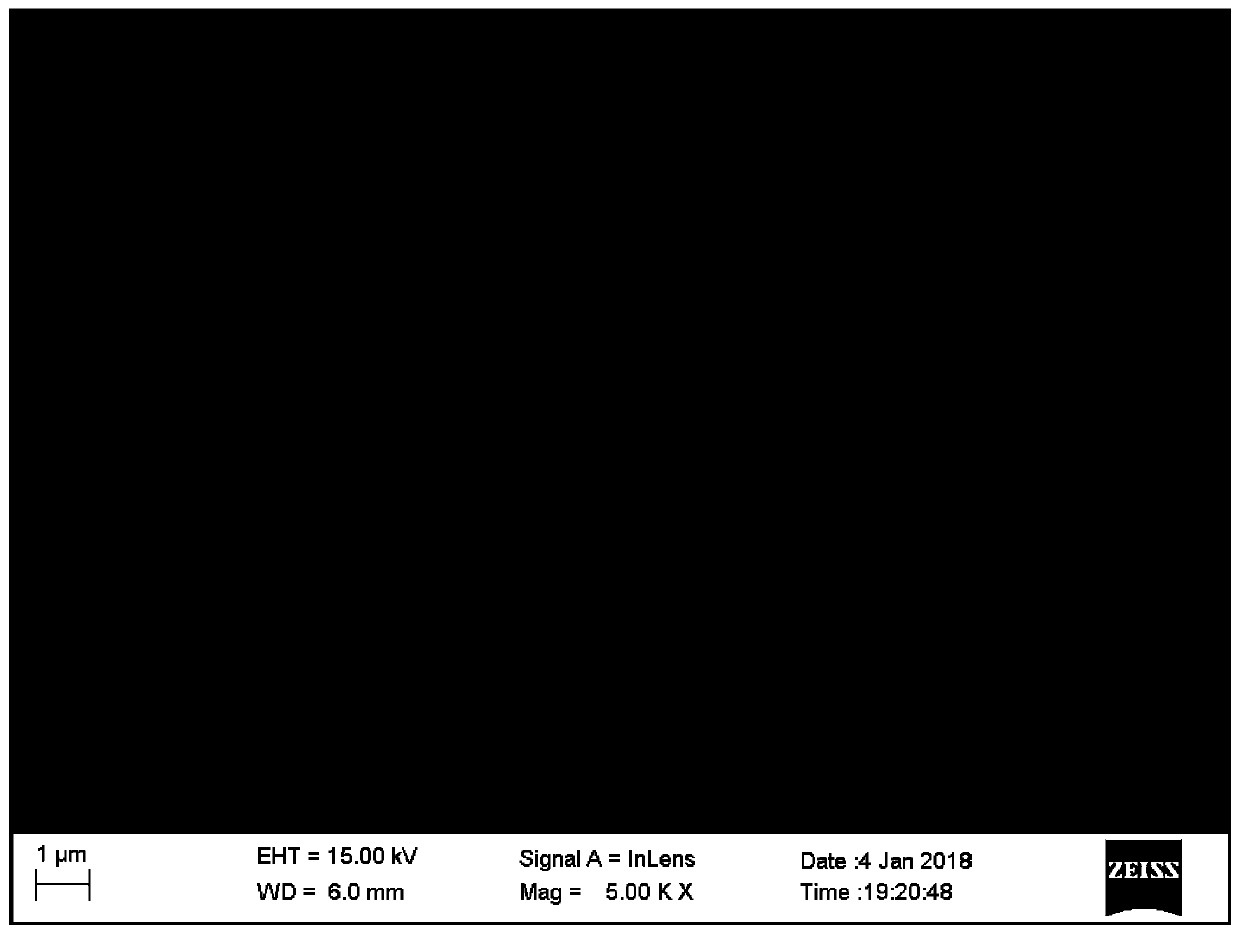

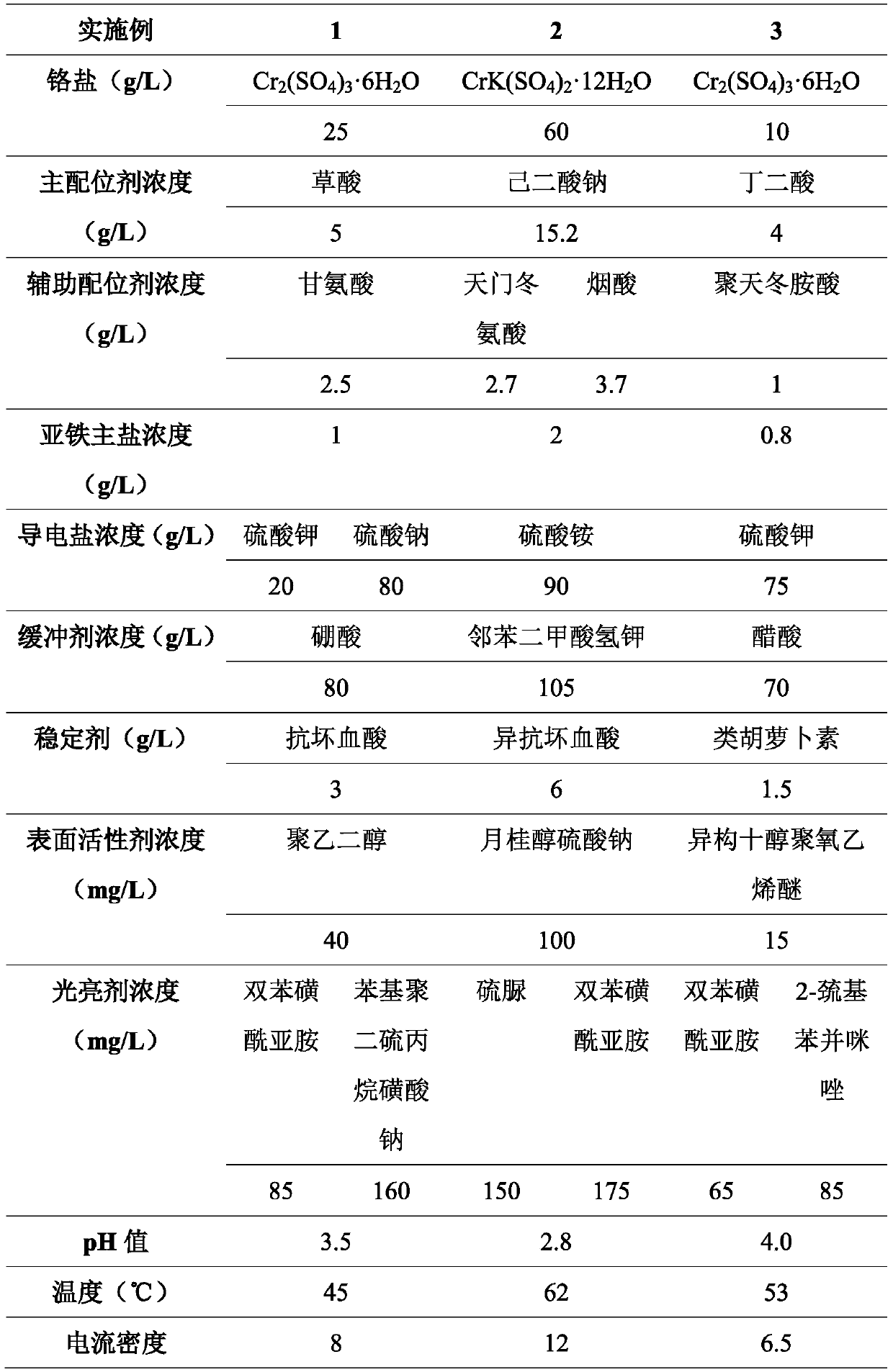

Electroplating liquid of trivalent chromium system for ferrochrome electrodeposition and preparation method thereof

The invention discloses electroplating liquid of a trivalent chromium system for ferrochrome electrodeposition and a preparation method thereof. A solvent of the electroplating liquid is water, and pHis 2.7-4.5. Solutes comprise trivalent chromium main salt, a trivalent chromium main complexing agent, a trivalent chromium auxiliary complexing agent, ferrous main salt, conducting salt, a buffer agent, a stabilizer, a surface active agent and a composite brightening agent. Trivalent chromium is coordinated in a composite coordinating mode, the coordinating capacity of water molecules on the trivalent chromium is lowered, and thus the deposition efficiency of chromium on the surface of a cathode is improved. The specific main complexing agent is micromolecular carboxylic acid and salt of themicromolecular carboxylic acid and can replace the water molecules to be complexed with the trivalent chromium, trivalent chromium electroreduction is promoted, the main complexing agent and the specific auxiliary complexing agent are complexed with trivalent chromium ions jointly to form a combined composite complex, and trivalent chromium electroreduction is further promoted.

Owner:XIAMEN UNIV

Archaistic bamboo joint resin tile and preparation method thereof

ActiveCN111333979AProtects from being consumed by oxidationIncrease the relative molecular massPolymer sciencePlasticizer

The invention discloses an archaistic bamboo joint resin tile and a preparation method thereof. The archaistic bamboo joint resin tile is prepared from the following raw materials, by weight: 100-120parts of PVC resin, 5-10 parts of engineering plastic, 30-50 parts of light calcium carbonate, 0.5-1 part of an antioxidant, 0.1-1 part of an anti-aging agent, 3-5 parts of a plasticizer and 2-3 partsof a flame retardant. The antioxidant belongs to a hindered phenol antioxidant and the relative molecular mass of antioxidant molecules is large, so tht the volatility of antioxidant molecules is further reduced; active double bonds contained in molecules of the anti-aging agent can be copolymerized with macromolecular monomers in the resin tile, so that precipitation of the anti-aging agent is prevented; and the antioxidant and the anti-aging agent are mixed for use, so that the resin tile still has good oxidation resistance and aging resistance after being used for a long time, and the service life of the archaistic bamboo joint resin tile is prolonged.

Owner:安徽金喜龙新型建材有限公司

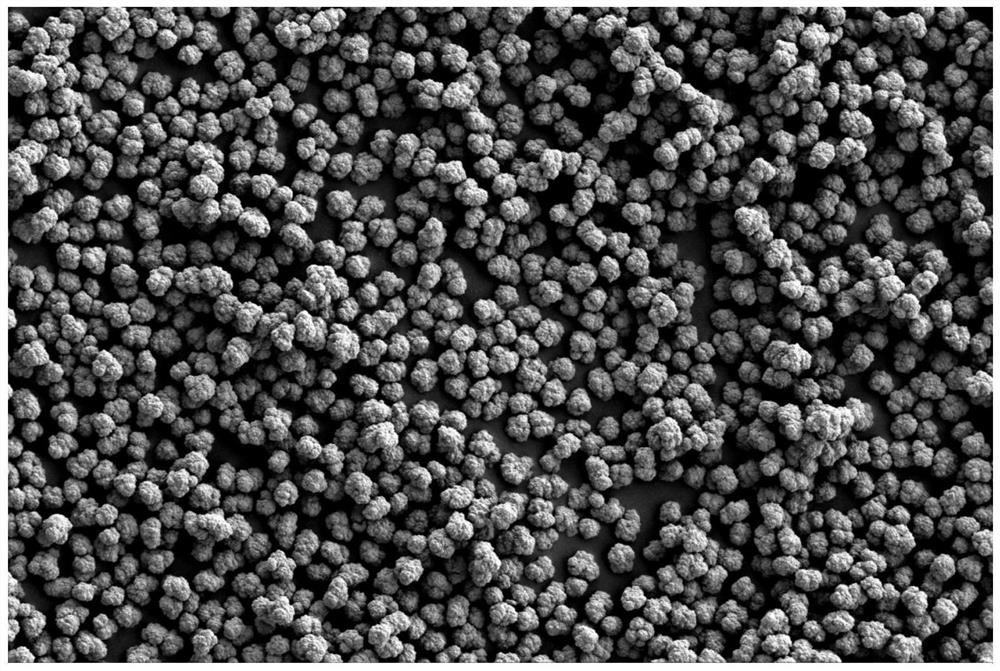

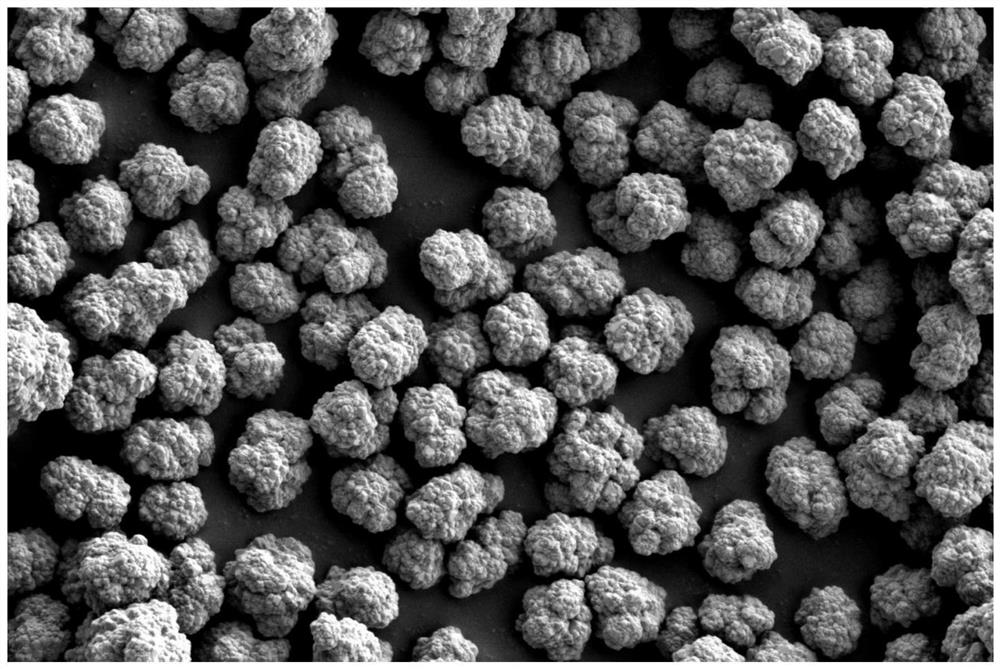

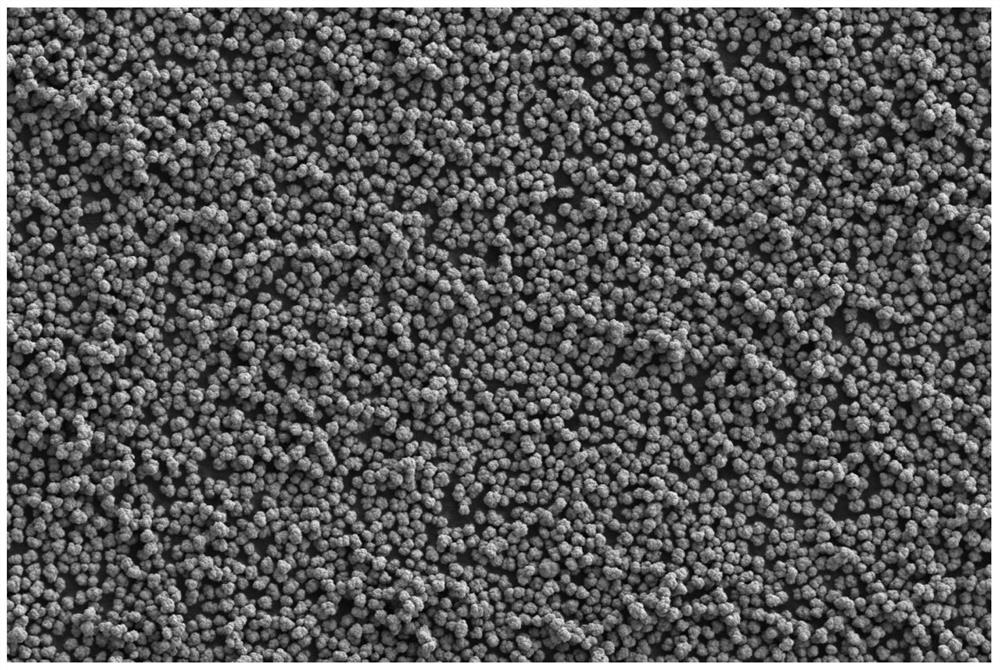

Preparation method of homogeneous-phase aluminum-doped small-particle-size cobaltosic oxide

ActiveCN112357970AReduced activityEffectively control the degree of bindingCell electrodesSecondary cellsCobalt(II,III) oxidePhysical chemistry

The invention relates to the technical field of preparation of lithium ion battery precursor cobaltosic oxide, in particular to a preparation method of homogeneous-phase aluminum-doped small-particle-size cobaltosic oxide. According to the method, a composite complexing agent is adopted to balance the reaction rate of Co <2+> and Al <3+> in the system, so that Co <2+> and Al <3+> can be subjectedto homogeneous coprecipitation, and the purpose of uniformly doping aluminum is achieved, by adopting the composite complexing agent, the combination degree of the complexing agent and metal ions canbe effectively controlled, so that the concentration of the metal ions in the tail liquid is reduced. The particle size of the aluminum-doped cobaltosic oxide prepared by the method is 2.0-6.0 [mu]m,the morphology of the aluminum-doped cobaltosic oxide is spherical, the tap density of the aluminum-doped cobaltosic oxide is 2.6-3.0 g / cm <3>, and the mass percent of Al is 0.1-1.2%.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드 +1

Thiorhodanine reagent and application thereof in solid-phase extraction of palladium

InactiveCN102505072AHigh enrichment factorHigh extraction recoveryOrganic chemistryProcess efficiency improvementCarboxyl radicalThiourea

The invention discloses a novel thiorhodanine reagent 5-(2-methyl-4-carboxylphenyl)-azo-thiorhodanine a method for preparing a graphitized carbon black solid-phase extraction column loaded with the thiorhodanine reagent, and the use of the solid-phase extraction column for solid-phase extraction of palladium. In solid-phase extraction, a palladium-containing solution flows through the solid-phase extraction column, palladium can react with the reagent loaded on the solid-phase extraction column to produce a stable complex compound so that palladium is adsorbed on the solid-phase extraction column, palladium is enriched on the solid-phase extraction column until saturated, and then palladium on the solid-phase extraction column is eluted with 0.5 to 2% thiourea as eluent. The solid-phase extraction column has high palladium enrichment factor and large extraction capacity, and the reagent can be repeatedly used. The single-extraction rate of palladium can exceed 96.8%, the enrichment factor exceeds 400, and the palladium extraction capacity of the reagent is more than 23.4 mg / g.

Owner:YUNNAN MINZU UNIV

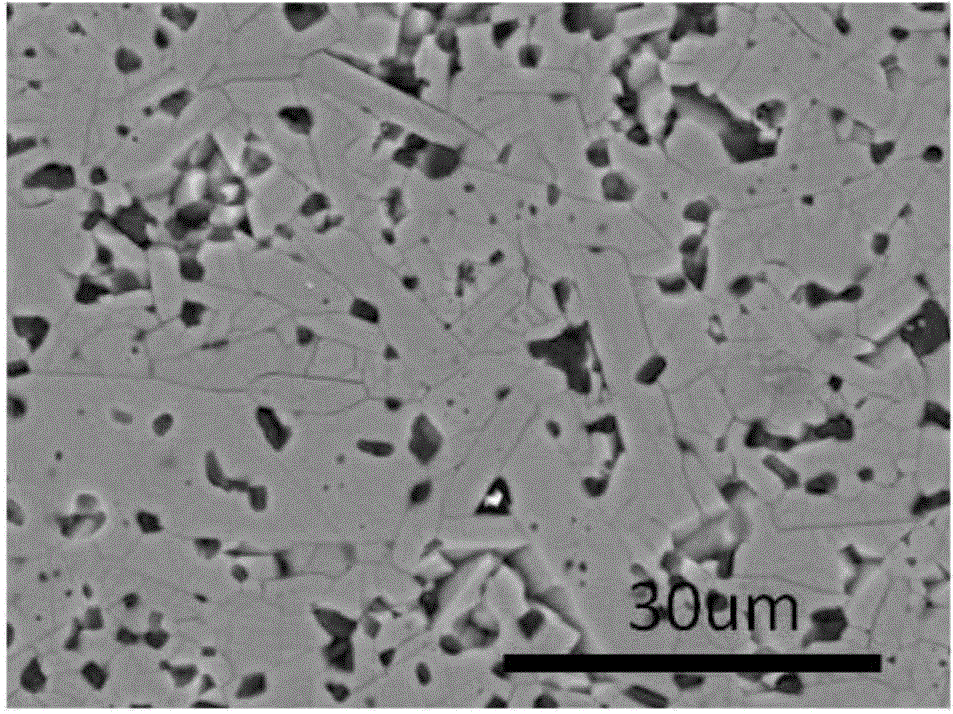

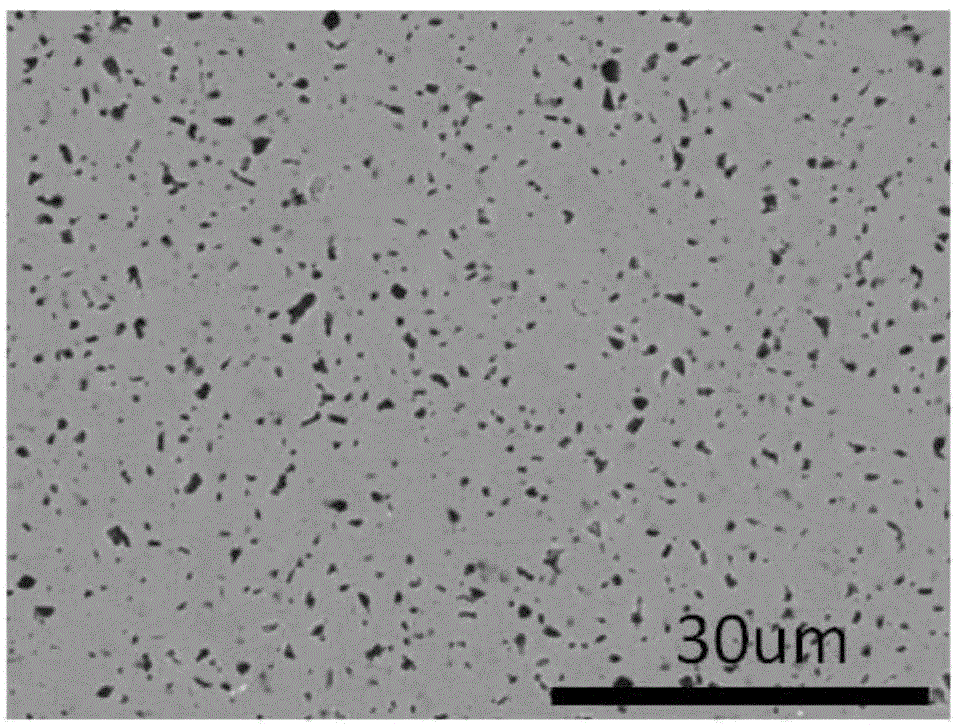

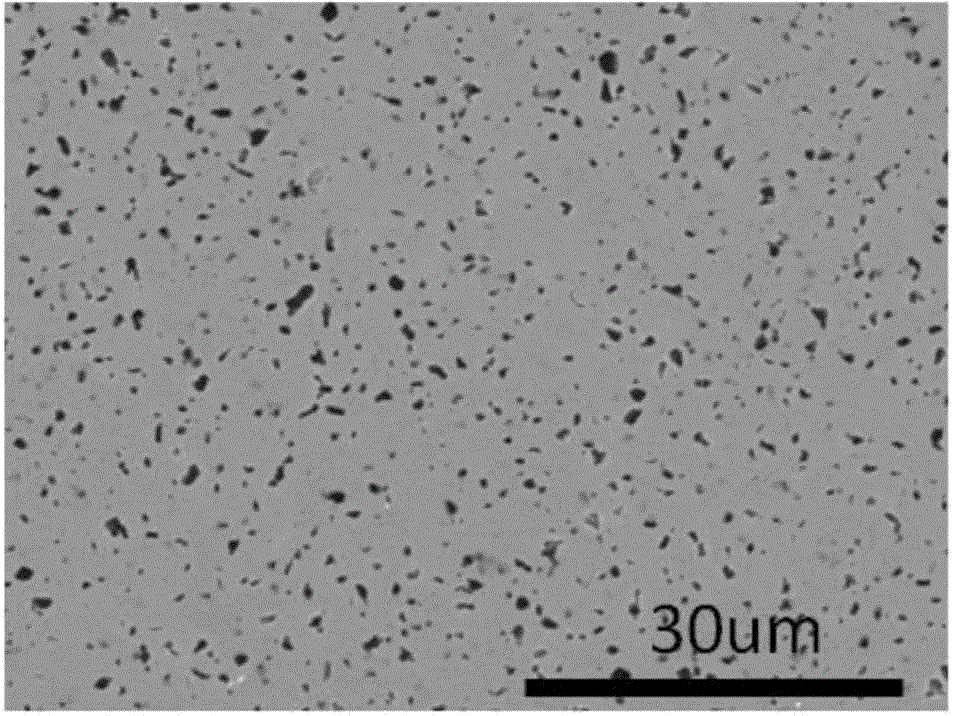

Method for corroding silicon carbide ceramics

The invention relates to a method for corroding silicon carbide ceramics, comprising: firstly adding concentrated hydrofluoric acid into a reaction vessel, then slowly adding concentrated nitric acid, stirring evenly, sealing and standing for 10-30 minutes to obtain an etching solution; The samples were immersed in the obtained etching solution and etched at 150-200°C for 12-24 hours. The method corrodes the solid-phase sintered silicon carbide ceramics at low temperature, so that the grain contrast after corrosion is obvious, and the grain boundary is cleaned, and at the same time, thermal defects introduced by high-temperature corrosion and defects introduced by high-energy etching are avoided.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Petroleum drilling auxiliary agent and preparation method thereof

PendingCN111500267AImproved heat and salt resistanceImprove heat and salt resistanceDrilling compositionMicrocrystalline waxDioxyethylene Ether

The invention discloses a petroleum drilling auxiliary agent and a preparation method thereof, and belongs to the technical field of petroleum auxiliary agent preparation. The petroleum drilling auxiliary agent is prepared from the following raw materials: modified humic acid, 4-hydroxy-6-acetamido-2-naphthalene sulfonic acid, maleic anhydride acylated chitosan, modified potassium hexatitanate whiskers, nonylphenol polyoxyethylene ether, linear polysiloxane, microcrystalline wax, hydroxyl aluminum and water. The petroleum drilling auxiliary agent is prepared through high-speed dispersion. By improving the prior art of the petroleum drilling auxiliary agent, the high-temperature and low-temperature filtration losses are remarkably reduced, and the application requirements are met.

Owner:粤久久食品科技(江门)有限公司

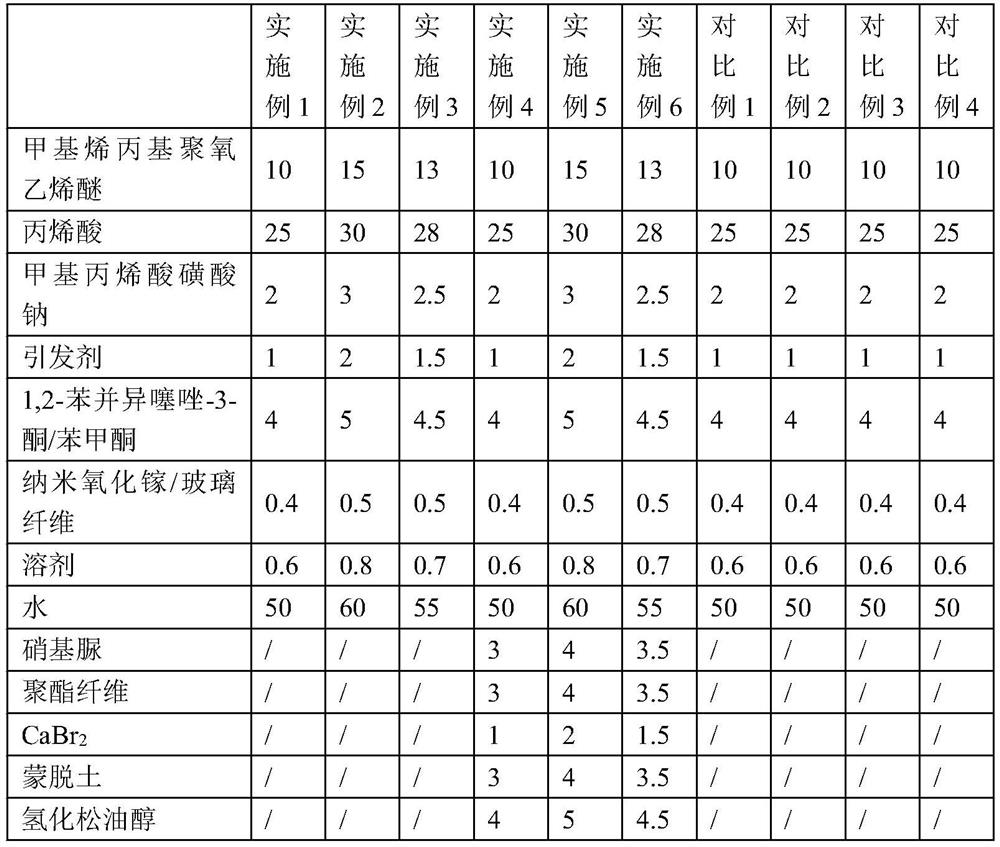

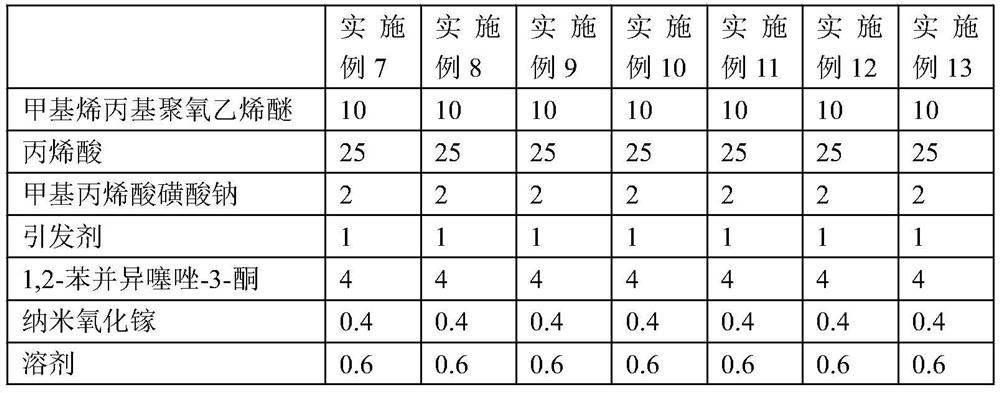

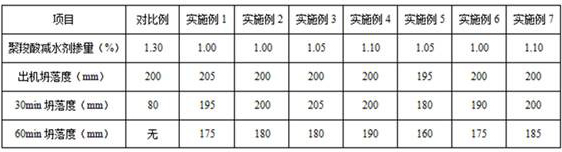

Early-strength polycarboxylate superplasticizer and preparation method thereof

The invention relates to the field of water reducing agents, and discloses an early-strength polycarboxylate superplasticizer and a preparation method thereof. The early-strength polycarboxylate superplasticizer is prepared from 10 to 15 parts of methylallylpolyoxyethylene ether, 25-30 parts of acrylic acid, 2-3 parts of sodium sulfonate methacrylate, 1-2 parts of an initiator, 4-5 parts of 1,2-benzisothiazole-3-one, 0.4-0.5 part of nanometer gallium oxide, 0.6-0.8 part of a solvent, and 50-60 parts of water. The preparation method comprises the following steps: mixing nanometer gallium oxide and a solvent, adding 1,2-benzisothiazole-3-one, and adding the mixture into a polycarboxylic acid polymer synthesized by other components to obtain the polycarboxylate superplasticizer. The preparation method has the advantages that the nanometer gallium oxide contains a microcosmic porous structure and can be better blended with 1,2-benzisothiazole-3-one after being mixed with a solvent, so a product adsorbing free carboxyl groups is obtained, the content of the free carboxyl groups capable of being complexed with calcium ions in a liquid phase is reduced, hydration is accelerated, coagulation time is shortened, water consumption is reduced, water film layers are decreased, and aggregate-cement interface structure is changed, so the early strength of concrete is better improved.

Owner:唐山冀东水泥外加剂有限责任公司 +1

A kind of electroplating solution and preparation method of trivalent chromium system electrodeposition chromium ferroalloy

The invention discloses electroplating liquid of a trivalent chromium system for ferrochrome electrodeposition and a preparation method thereof. A solvent of the electroplating liquid is water, and pHis 2.7-4.5. Solutes comprise trivalent chromium main salt, a trivalent chromium main complexing agent, a trivalent chromium auxiliary complexing agent, ferrous main salt, conducting salt, a buffer agent, a stabilizer, a surface active agent and a composite brightening agent. Trivalent chromium is coordinated in a composite coordinating mode, the coordinating capacity of water molecules on the trivalent chromium is lowered, and thus the deposition efficiency of chromium on the surface of a cathode is improved. The specific main complexing agent is micromolecular carboxylic acid and salt of themicromolecular carboxylic acid and can replace the water molecules to be complexed with the trivalent chromium, trivalent chromium electroreduction is promoted, the main complexing agent and the specific auxiliary complexing agent are complexed with trivalent chromium ions jointly to form a combined composite complex, and trivalent chromium electroreduction is further promoted.

Owner:XIAMEN UNIV

Methylene rhodanine reagent and application thereof in solid phase extraction of platinum

InactiveCN102659711AGood choiceReduce complexationOrganic chemistryProcess efficiency improvementPlatinumAcetic acid

The invention discloses a methylene rhodanine reagent and application thereof in solid phase extraction of platinum, belongs to the field of hydrometallurgy, and in particular relates to a new methylene rhodanine reagent and application thereof in solid phase extraction of platinum. The extracting reagent has a structural formula shown as the specifications, and is named 2,4-dimethyl benzol-methylene rhodanine. The reagent is prepared by condensing 2,4-dimethylbenzylidene and rhodanine in a glacial acetic acid medium. A solid phase extraction column prepared from the reagent can be used for the solid phase extraction of platinum, has high selectivity and high enrichment factor, and has high extraction capacity for the platinum, and the material can be repeatedly used. The primary extraction rate for the platinum is over 95.3 percent, and the enrichment factor is more than 500; and the material has the extraction capacity of 28.5mg / g for the platinum.

Owner:YUNNAN MINZU UNIV

Regeneration method of deactivated hydrogenation catalyst

PendingCN111729689AReduce utilizationIncrease profitOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst regeneration/reactivationCarboxyl radicalPtru catalyst

The invention provides a regeneration method of an deactivated hydrogenation catalyst. The regeneration method comprises the following steps: carrying out charking treatment on the inactivated hydrogenation catalyst; dipping the charked deactivated hydrogenation catalyst in a solution containing a hydroxyl and / or carboxyl chelated ligand compound; and carrying out microwave vacuum drying on the catalyst subjected to dipping treatment so that the deactivated hydrogenation catalyst then recovers the activity. According to the technical scheme, microwave vacuum drying is adopted, due to the factthat operation is carried out under the condition of air isolation, oxygenolysis cannot occur in the drying process even if the decomposition temperature of an organic additive is high, and the utilization rate of the organic additive is remarkably increased.

Owner:湖北中超化工科技有限公司

Method for treating alkaline zinc-nickel alloy electroplating wastewater

PendingCN112429884AReduce complexationReduce adverse effects on adsorption performanceSludge treatmentWaste water treatment from metallurgical processMetallurgyZinc ion

The invention provides a treatment method of alkaline zinc-nickel alloy electroplating wastewater, which comprises the following steps: (1) mixing an acid solution and electroplating wastewater, and regulating the pH value of the electroplating wastewater to be less than or equal to 2.5; and (2) removing zinc ions and nickel ions in the electroplating wastewater obtained in the step (1) by using an ion exchange method. According to the treatment method provided by the invention, the treatment process is simplified, the treatment speed is increased, the treatment cost is reduced, and the treatment method is particularly suitable for treating the electroplating wastewater rich in an EDTA complexing agent.

Owner:淮安中顺环保科技有限公司

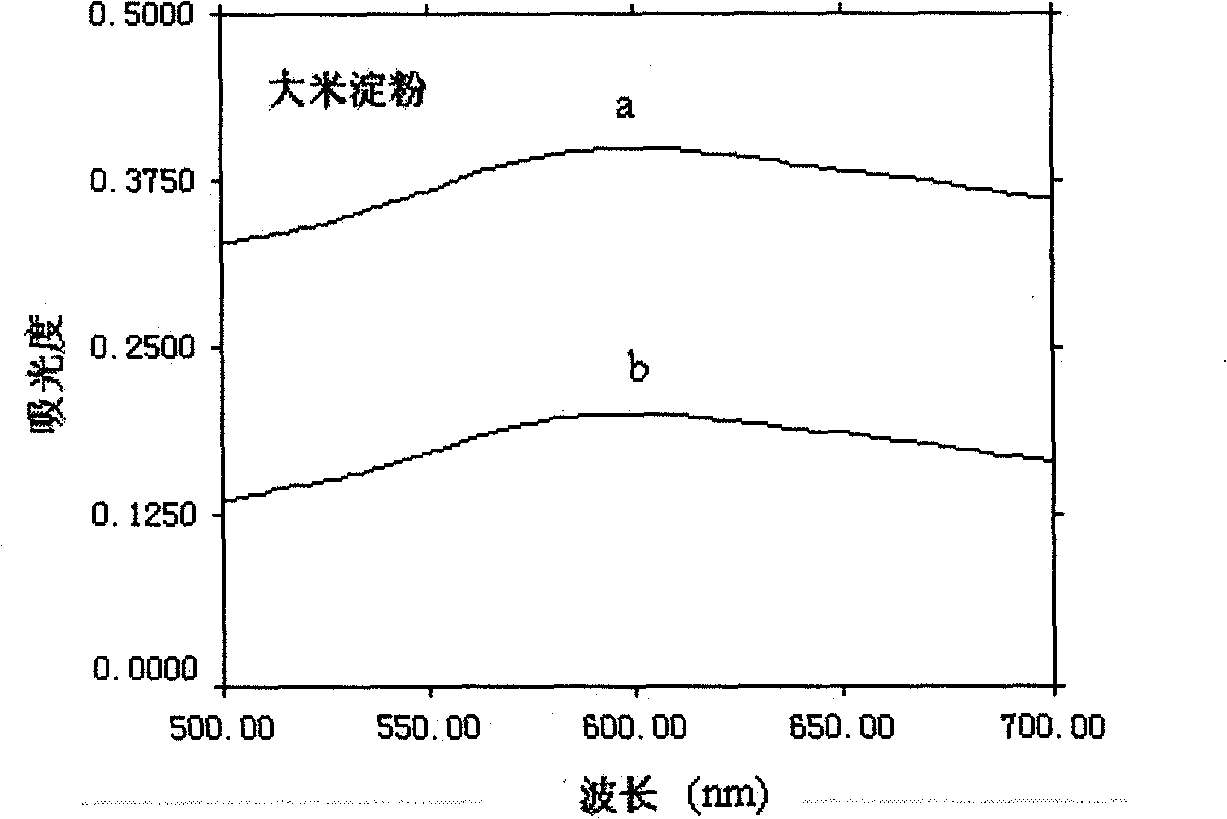

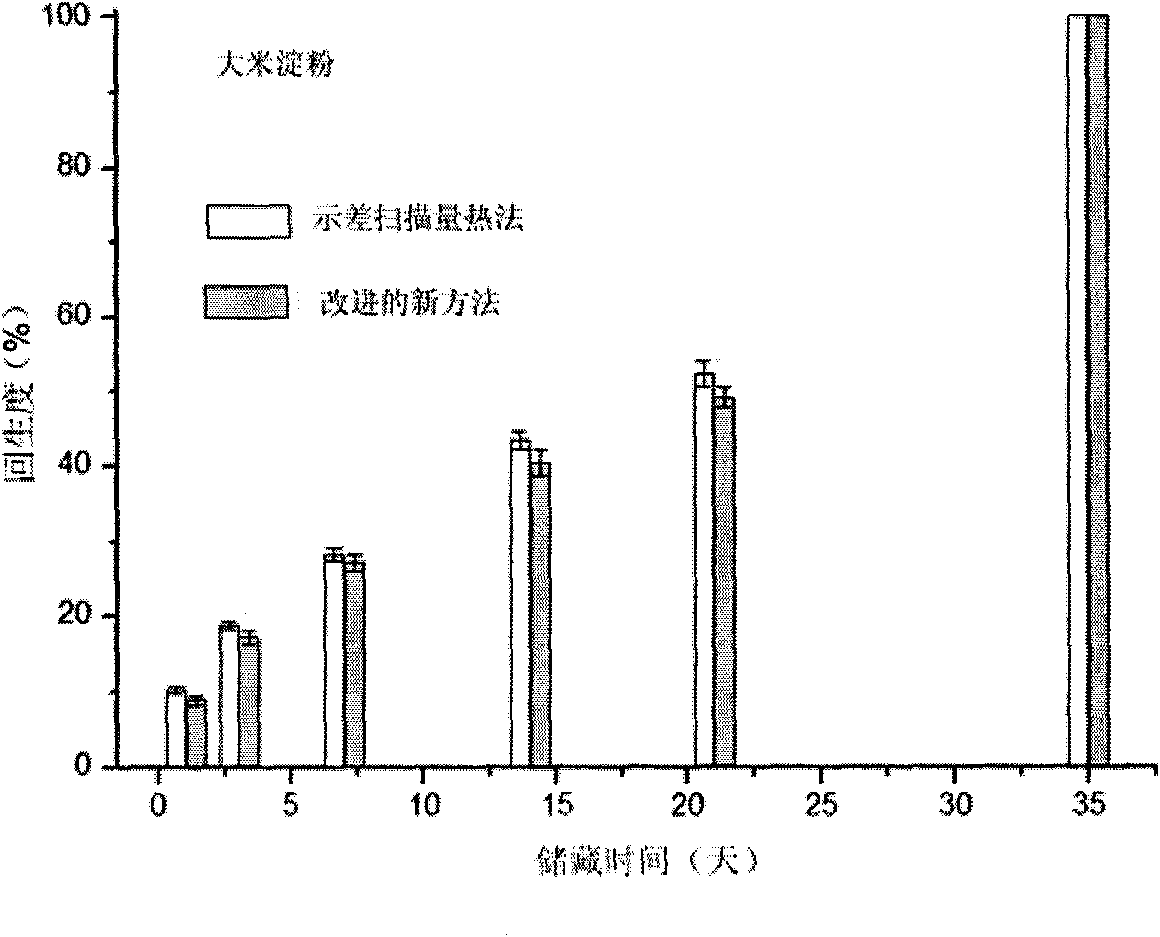

Simple method for measuring starch retrogradation degree

InactiveCN101839852AReduce complexationEasy to operateColor/spectral properties measurementsIodineRetrogradation

The invention discloses a simple method for measuring starch retrogradation degree, which belongs to the technical field of starch retrogradation degree measurement. Based on the principle that the retrograded starch has a lower iodine complexing capacity, the method comprises: firstly, drying a retrograded sample at a low temperature, dissolving and dispersing the retrograded starch in alkaline solution, and adjusting the pH value of the complexation reaction solution of the starch solution and iodine; and secondly, measuring the absorbancy of the measured sample at a wavelength of 600 nanometers, and converting the absorbancy into the starch retrogradation degree. Compared with the classic starch retrogradation degree measuring method, the method established by the invention has the advantages of simple and easy-to-implement operation, short measurement time and high accuracy. The method is suitable for measuring the retrogradation degrees of grain foods with high content such as rice and wheat and indirectly evaluating the shelf life of related foods with high starch content.

Owner:JIANGNAN UNIV

Oil shale semicoke adsorption inhibitor and application thereof in concrete preparation

ActiveCN114057428ARealize large-volume resource utilizationReduce dosageSolid waste managementWaste oilStearic acid

The invention discloses an oil shale semicoke adsorption inhibitor and application thereof in concrete preparation. The adsorption inhibitor is prepared by the following steps: sequentially adding 50-52.5 parts by weight of an anti-corrosion rheological agent, 5-20 parts by weight of methanol, 0.5-2 parts by weight of sulfonated melamine, 2-5 parts by weight of EDTA, 20-30 parts by weight of an organosilicon compound and 5-10 parts by weight of stearate into a mixing container, and fully and uniformly stirring, wherein the anti-corrosion rheological agent is a 'microbead' water-reducing active micro aggregate. The adsorption inhibitor is doped into the industrial solid waste oil shale semi-coke powder, so that the problems of strong water absorption, high water reducing agent adsorption and the like of the oil shale semi-coke are solved, the use amount of the water reducing agent is reduced in concrete production, and the obtained concrete is good in workability and workability; and due to a certain dispersing and grinding-aiding effects, the power consumption during grinding can be reduced; and finally, large-dosage resource utilization of the oil shale semi-coke in the cement-based concrete is realized, and high-value resource utilization of the oil shale semi-coke is realized.

Owner:GANSU ZHITONG TECH ENG DETECTION CONSULTING CO LTD

A kind of preparation method of wool-like polyester fiber

ActiveCN107460560BLess impuritiesReduce pressure riseHollow filament manufactureMelt spinning methodsFiberForeign matter

The invention relates to a preparation method of wool-imitating polyester fiber. The preparation method comprises the following steps of firstly, mixing dimethyl isophthalate-5-sodium benzenesulfonate, ethylene glycol and a catalyst, and performing ester exchange reaction; after reaction is finished, adding ethylene glycol and sulfuric acid for preparation; mixing terephthalic acid, the ethylene glycol, the catalyst, a stabilizer and calcium oxide-coated titanium dioxide particles, and performing etherifying reaction; then, adding a prepared product after finishing of the ester exchange reaction into an etherifying reaction system which has reached the end point of etherifying reaction, and performing condensation reaction, so as to obtain a spinning melt; finally, weighing the spinning melt, extruding, cooling, applying oil, tensioning, thermally shaping, and coiling, so as to obtain the wool-imitating polyester fiber. The preparation method has the advantages that the production of foreign matters in the polyester fiber production process is reduced, so that the pressure rise of a spinning assembly and a filter is reduced, the service cycle is extended, the continuity and safety in the whole production process are guaranteed, and the good economic value and popularizing value are realized.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

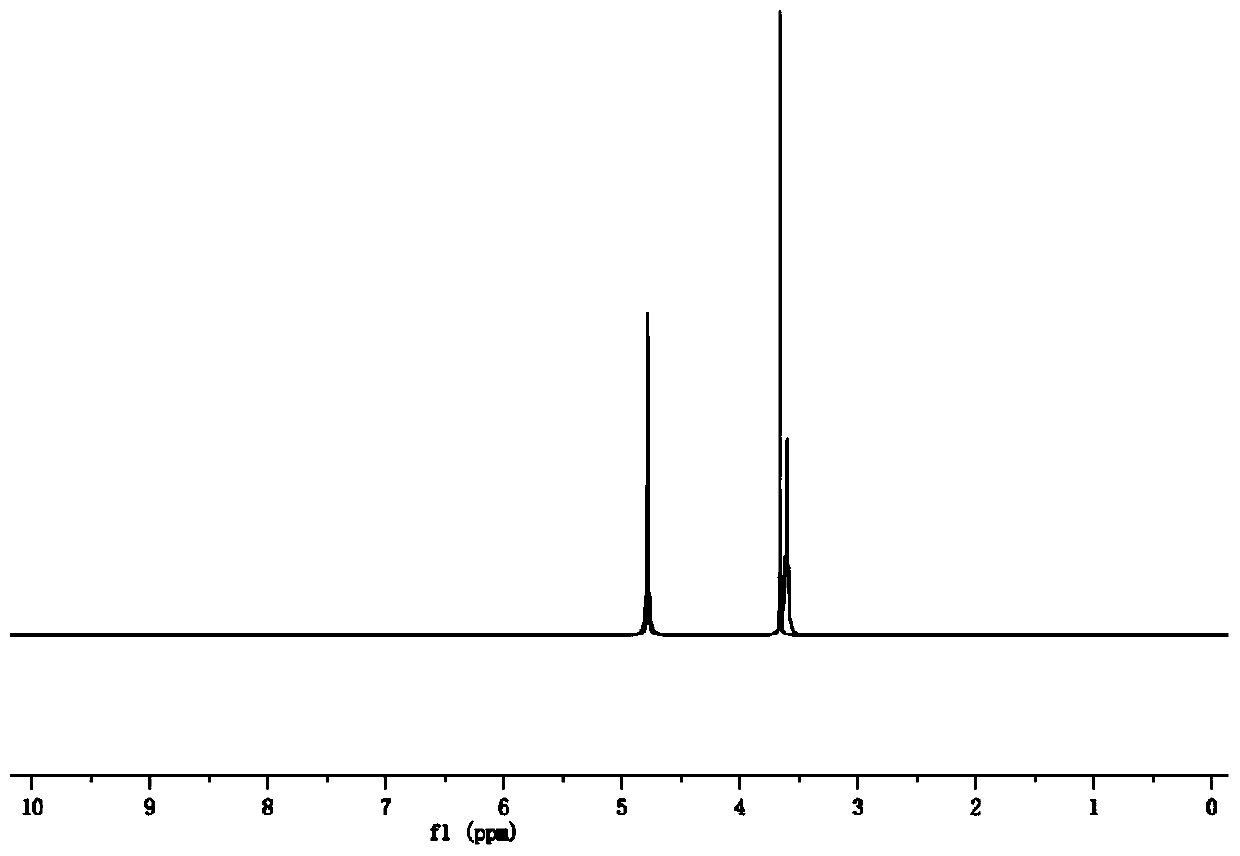

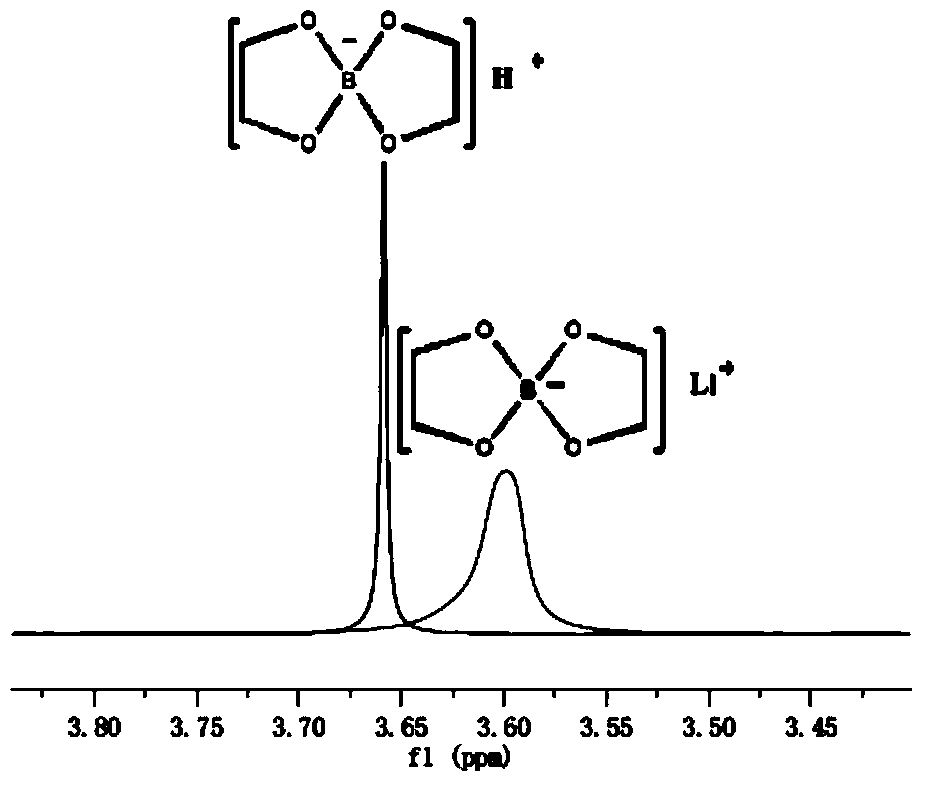

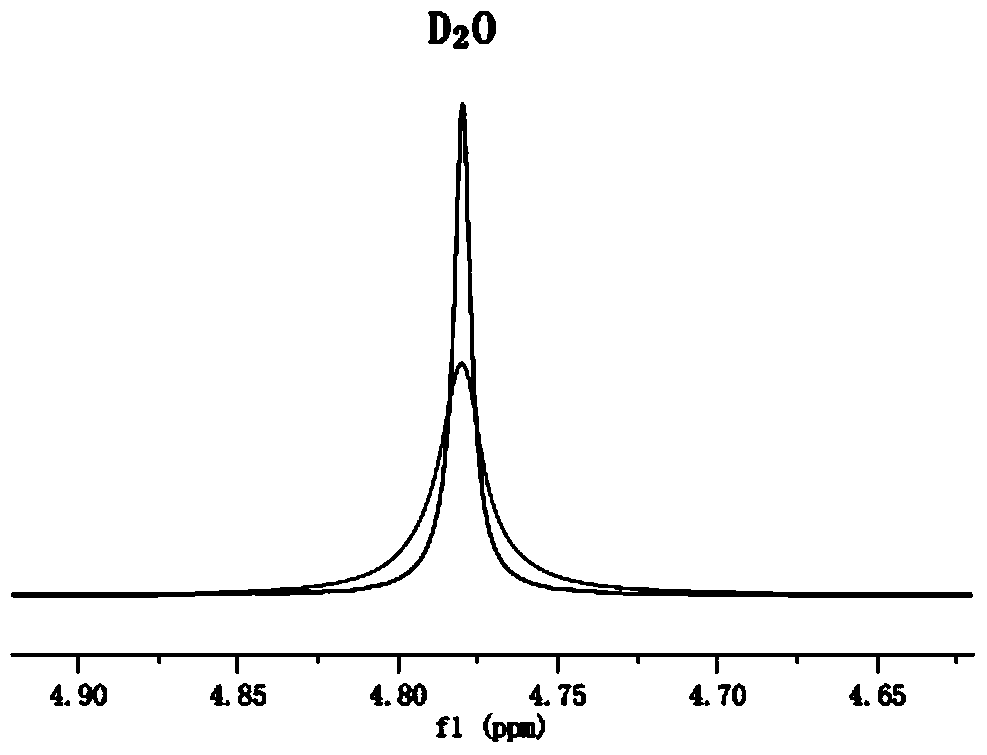

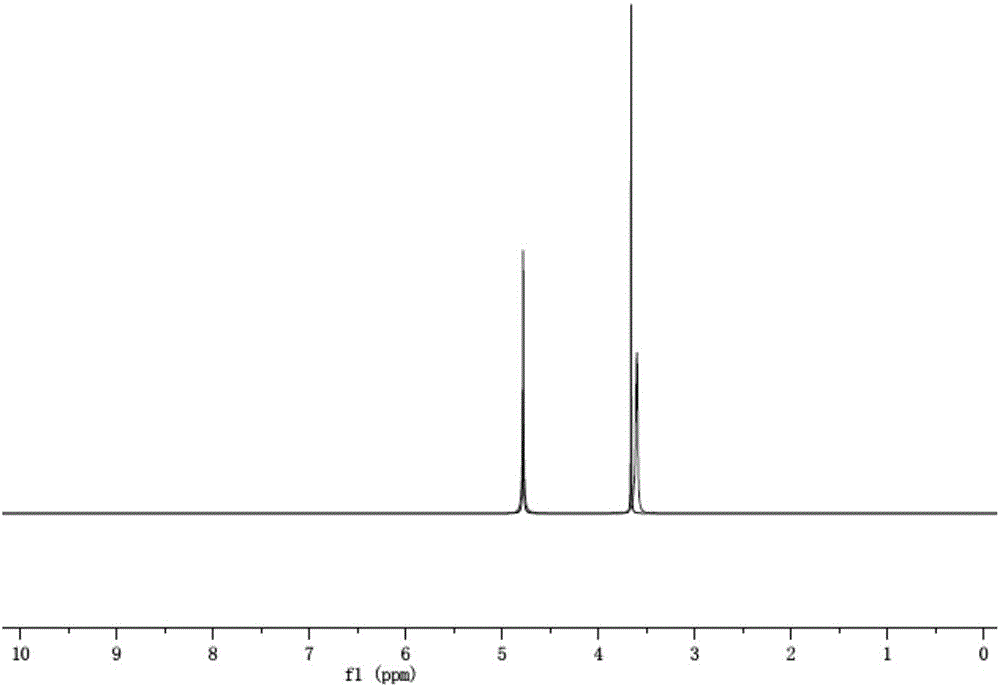

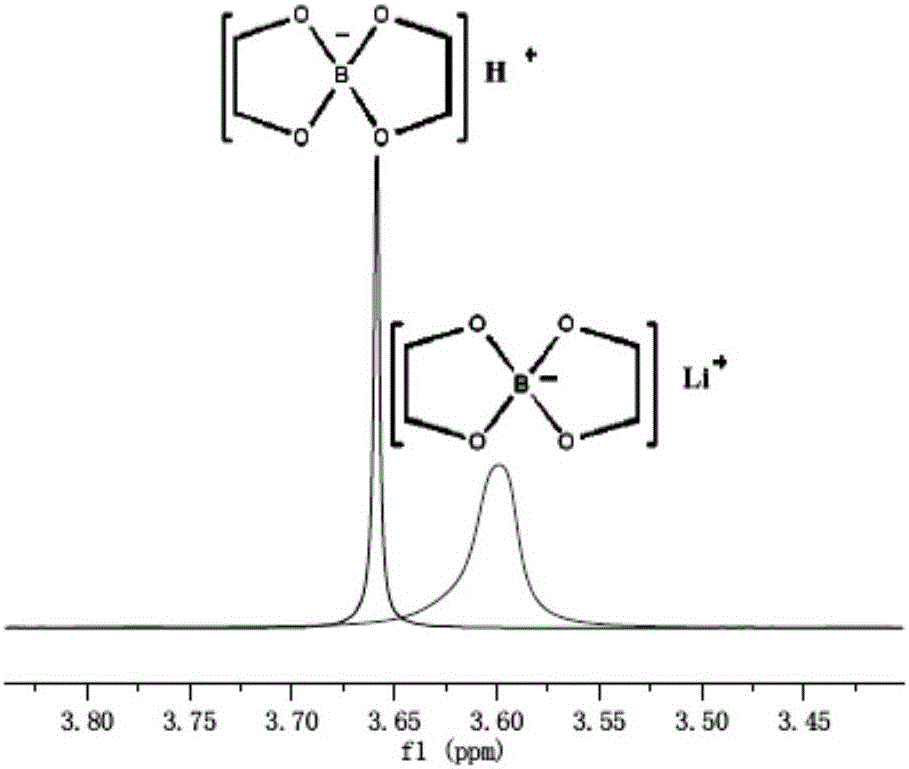

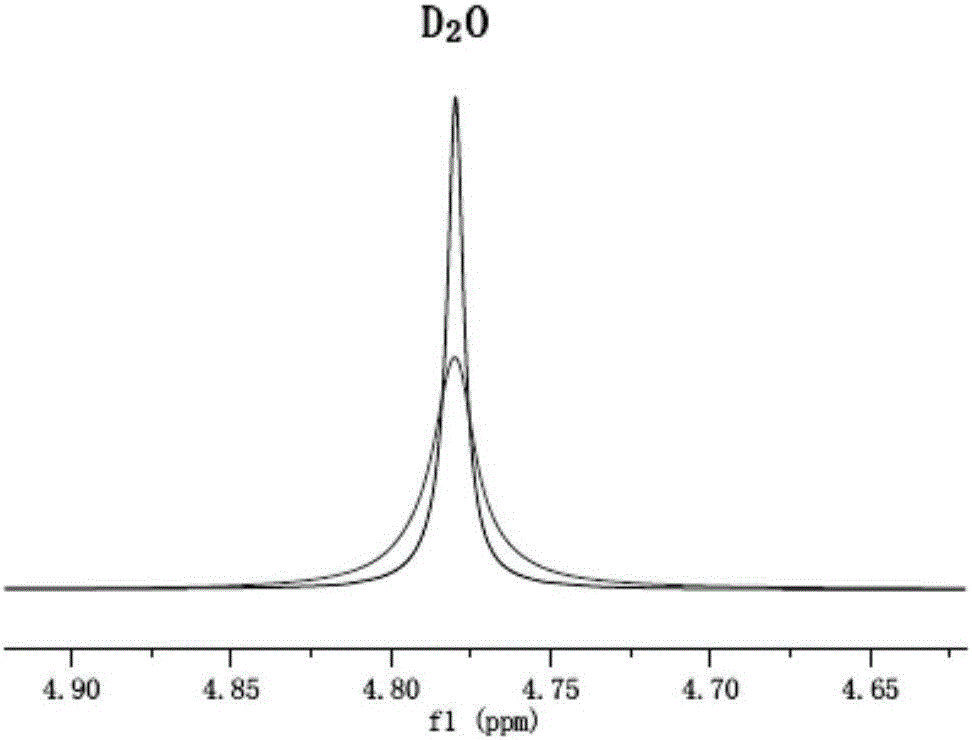

A kind of electrolytic solution and lithium ion battery

ActiveCN105870504BAvoid the risk of gas productionImprove cycle performanceSecondary cellsOrganic electrolytesOrganic solventHigh voltage battery

The invention relates to the field of lithium ion batteries, in particular to an electrolyte and a lithium ion battery. The electrolyte contains electrolyte salt, an organic solvent and an additive. The additive contains a boron salt additive. The additive further contains an SEI film-forming additive. The anion part of the boron salt additive can effectively disperse the negative charge density of anions, a negative charge center is shielded by a ligand with a large structure, therefore, an anode is effectively protected during circulation, and the circulation performance of the high-voltage battery is improved.

Owner:NINGDE AMPEREX TECH

A kind of preparation method of cationic dyeable polyester poy yarn

ActiveCN107557902BReduce pressure riseLess impuritiesMelt spinning methodsMonocomponent polyesters artificial filamentYarnPolymer science

The invention relates to a preparation method of cation dyeable POY (Polyester Pre-Oriented Yarn). The method comprises the following steps: firstly, mixing dimethyl isophthalate-5-sodium benzenesulfonate, ethylene glycol, a catalyst and an anti-ether agent, performing transesterification, and adding the ethylene glycol and a complex ion modifier for preparation after the transesterification is ended; secondly, mixing terephthalic acid, the ethylene glycol, the catalyst, a stabilizer and a delustering agent, performing esterification reaction, adding a product obtained by preparation after theesterification reaction into a reaction system already reaching a reaction endpoint of the esterification reaction, and performing condensation polymerization to obtain a spinning melt; finally, metering, extruding, cooling, oiling and winding the spinning melt to obtain the cation dyeable POY. The method reduces the generation of impurities in a production process, thereby reducing pressure riseof a spinning assembly and a filter, prolonging the service life, ensuring the continuity and safety of the whole production flow, and achieving a good economic value and promotion value.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

Electrolyte and lithium ion battery

ActiveCN105870504AAvoid the risk of gas productionImprove cycle performanceSecondary cellsOrganic electrolytesOrganic solventHigh voltage battery

The invention relates to the field of lithium ion batteries, in particular to an electrolyte and a lithium ion battery. The electrolyte contains electrolyte salt, an organic solvent and an additive. The additive contains a boron salt additive. The additive further contains an SEI film-forming additive. The anion part of the boron salt additive can effectively disperse the negative charge density of anions, a negative charge center is shielded by a ligand with a large structure, therefore, an anode is effectively protected during circulation, and the circulation performance of the high-voltage battery is improved.

Owner:NINGDE AMPEREX TECH

A preparation method of moisture-absorbing and sweat-wicking fiber with double special-shaped cross-section

ActiveCN107604464BReduce pressure riseLess impuritiesFilament/thread formingMonocomponent polyesters artificial filamentO-Phosphoric AcidSpinning

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

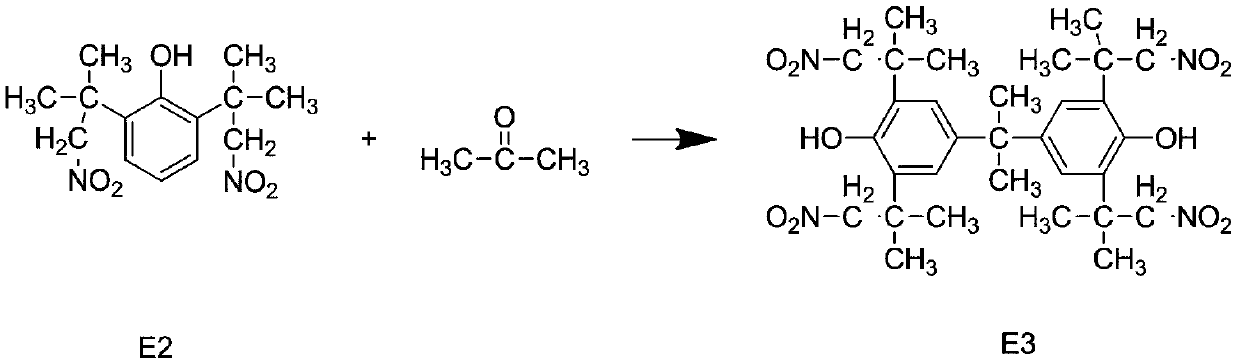

Production process of high-wear-resistance glass reinforced plastic pipe

PendingCN113429659AImprove antioxidant capacityReduce conjugation effectOrganic chemistryEpoxyCyclohexanone

The invention discloses a production process of a high-wear-resistance glass fiber reinforced plastic pipe, and belongs to the technical field of glass fiber reinforced plastic preparation processes. The method comprises the following steps: 1, weighing the following raw materials in parts by weight: 10-30 parts of polyethylene, 15-25 parts of epoxy resin, 5.6-11.6 parts of nano ceramic particles, 6-8 parts of glass fibers, 4-6 parts of a coupling agent, 5-10 parts of cyclohexanone, 5.5-7.5 parts of a corrosion-resistant agent and 12-14 parts of a wear-resistant agent; 2, mixing the raw materials in sequence; 3, adding a wear-resistant agent, and carrying out extrusion molding; and preparing and adding a corrosion-resistant agent, wherein the corrosion-resistant agent has two chloramine structures with antibacterial activity and an antioxidant semi-hindered phenol structure, and the corrosion-resistant agent can effectively reduce corrosion of microorganisms and oxidation on the prepared glass reinforced plastic pipe, so that the structural integrity of the glass reinforced plastic pipe is further maintained, and the wear-resistant function is further improved.

Owner:ANHUI RUIFENG PIPE IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com