Production process of high-wear-resistance glass reinforced plastic pipe

A technology of glass steel pipe and production process, applied in the direction of organic chemistry, etc., which can solve the problems of short service life, poor corrosion resistance, poor wear resistance, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

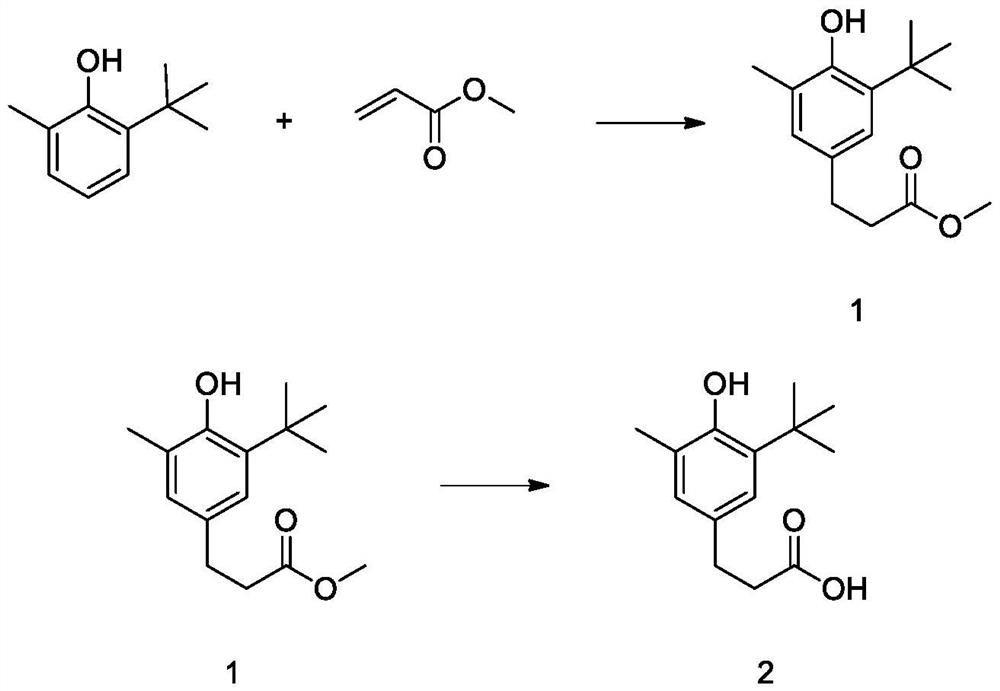

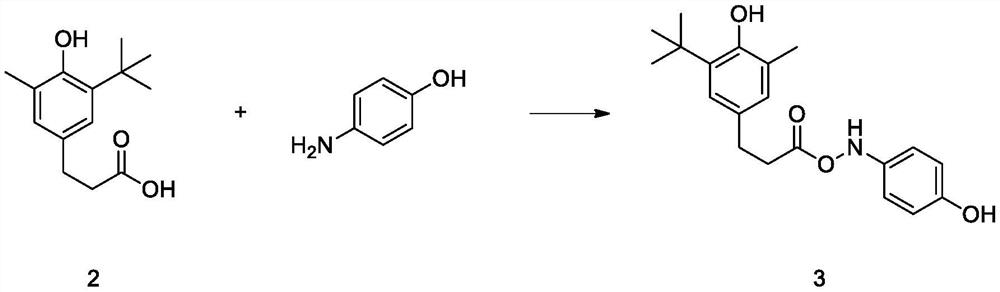

[0032] Prepare anti-corrosion agent, this anti-corrosion agent is made by following steps:

[0033] Step S1: Add 2-methyl-6-tert-butylphenol and potassium hydroxide into the flask, blow nitrogen, react at 55°C for 1 hour, then raise the temperature to 90°C, add methyl acrylate, and continue to heat up to 120°C ℃, reacted for 4 hours, and prepared intermediate 1; then intermediate 1 and absolute ethanol were added to the flask, nitrogen gas was introduced, and a sodium hydroxide solution with a mass fraction of 10% was added dropwise while stirring at a temperature of 20°C, and the After the addition, the temperature was raised to 40°C, and the reaction was continued for 3 hours to obtain intermediate 2;

[0034] Step S2: add p-aminophenol and intermediate 2 into the flask, then add toluene and p-toluenesulfonic acid, react at a temperature of 140° C. for 6 hours, and obtain intermediate 3 after the reaction;

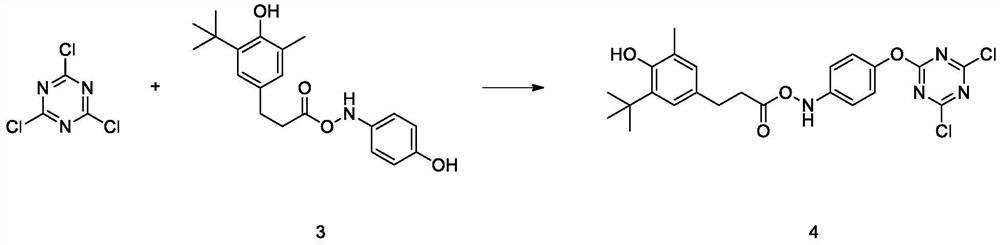

[0035] Step S3: Add cyanuric chloride to the flask, then add aceto...

Embodiment 2

[0039] Prepare anti-corrosion agent, this anti-corrosion agent is made by following steps:

[0040] Step S1: Add 2-methyl-6-tert-butylphenol and potassium hydroxide into the flask, blow nitrogen, react at 55°C for 1 hour, then raise the temperature to 90°C, add methyl acrylate, and continue to heat up to 120°C ℃, reacted for 4 hours, and prepared intermediate 1; then intermediate 1 and absolute ethanol were added to the flask, nitrogen gas was introduced, and a sodium hydroxide solution with a mass fraction of 10% was added dropwise while stirring at a temperature of 20°C, and the After the addition, the temperature was raised to 40°C, and the reaction was continued for 3 hours to obtain intermediate 2;

[0041] Step S2: Add p-aminophenol and intermediate 2 into the flask, then add toluene and p-toluenesulfonic acid, react at a temperature of 145°C for 6.5 hours, and obtain intermediate 3 after the reaction;

[0042] Step S3: Add cyanuric chloride to the flask, then add aceto...

Embodiment 3

[0046] Prepare anti-corrosion agent, this anti-corrosion agent is made by following steps:

[0047] Step S1: Add 2-methyl-6-tert-butylphenol and potassium hydroxide into the flask, blow nitrogen, react at 55°C for 1 hour, then raise the temperature to 90°C, add methyl acrylate, and continue to heat up to 120°C ℃, reacted for 4 hours, and prepared intermediate 1; then intermediate 1 and absolute ethanol were added to the flask, nitrogen gas was introduced, and a sodium hydroxide solution with a mass fraction of 10% was added dropwise while stirring at a temperature of 20°C, and the After the addition, the temperature was raised to 40°C, and the reaction was continued for 3 hours to obtain intermediate 2;

[0048] Step S2: add p-aminophenol and intermediate 2 into the flask, then add toluene and p-toluenesulfonic acid, react at a temperature of 150° C. for 7 hours, and obtain intermediate 3 after the reaction;

[0049] Step S3: Add cyanuric chloride to the flask, then add aceto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com