Method for efficiently extracting germanium from zinc-germanium leaching solution

A leaching solution, zinc germanium technology, applied in chemical instruments and methods, improvement of process efficiency, sugar derivatives, etc., can solve the problems of high price of tannic acid, can not be recycled, expensive, etc., to improve the rate of germanium deposition and single The effect of improving the purity of germanium, reducing production costs and improving the rate of germanium deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

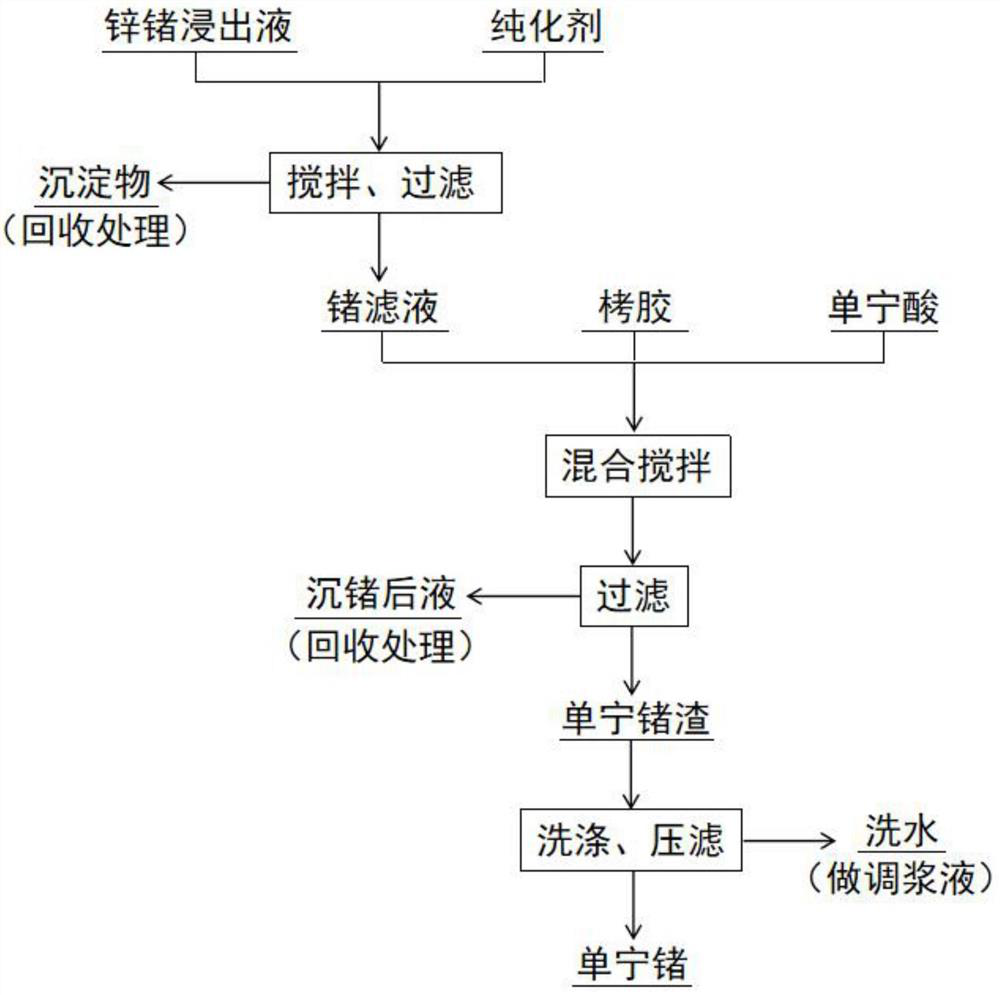

[0019] Embodiment 1: a kind of method (see figure 1 ),Specific steps are as follows:

[0020] (1) Add the purifying agent (catechol) to the zinc-germanium leaching solution, and react for 10 minutes under stirring conditions to precipitate and react impurity ions such as arsenic and iron with catechol to obtain the solution system A, and separate the solid and liquid to obtain the solution B; wherein zinc content is 100g / L in zinc-germanium leach solution, and Ge content is 50mg / L, and Fe content is 5g / L, and Mg content is 60g / L, and As content is 0.5g / L, purifying agent (catechol ) in an amount of 5g / L; the pH value of the solution system A is 1; the Zn content in the solution B is 98.9g / L, the Ge content is 49.5mg / L, the Fe content is 2.1g / L, and the Mg content is 59.3g / L, the As content is 0.2g / L, and the pH value of solution system B is 1;

[0021] (2) Add tannic acid extract (Vitex bark extract) to solution B in step (1), react for 1 minute under stirring conditions, t...

Embodiment 2

[0025] Embodiment 2: a kind of method (see figure 1 ),Specific steps are as follows:

[0026] (1) Add the purifying agent (biochar) into the zinc-germanium leaching solution, and react for 15 minutes under stirring conditions so that the impurity ions such as arsenic and iron are adsorbed and precipitated with the biochar to obtain the solution system A, and the solid-liquid separation obtains the solution B; wherein the zinc Zinc content is 150g / L in germanium leaching solution, and Ge content is 75mg / L, and Fe content is 7.5g / L, and Mg content is 80g / L, and As content is 0.75g / L, and the add-on of purification agent (biochar) is 7.5g / L; pH value of solution system A is 1.5; Zn content in solution B is 149.2g / L, Ge content is 74.5mg / L, Fe content is 3.8g / L, Mg content is 79.3g / L, As The content is 0.28g / L; the pH value of solution system B is 1.5;

[0027] (2) Add tannin extract (almond bark tannin extract) to solution B in step (1), react for 5 minutes under stirring condi...

Embodiment 3

[0031] Embodiment 3: a kind of method (see figure 1 ),Specific steps are as follows:

[0032] (1) Add the purifying agent (D001 resin) to the zinc-germanium leaching solution, and react for 20 minutes under stirring conditions to adsorb and precipitate impurity ions such as arsenic and iron with biochar to obtain solution system A, and separate solid-liquid to obtain solution B; The zinc content in the germanium leaching solution is 200g / L, the Ge content is 100mg / L, the Fe content is 10g / L, the Mg content is 100g / L, the As content is 1g / L, and the addition amount of the purifying agent (D001 resin) is 10.0g / L; the pH value of the solution system A is 3.0; the Zn content in the solution B is 199.3g / L, the Ge content is 99.5mg / L, the Fe content is 3.2g / L, the Mg content is 99.6g / L, and the As content is 0.23g / L; pH value of solution system A is 3.0;

[0033] (2) Add tannin extract (larch tannin extract) to solution B in step (1), react under stirring conditions for 10 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com