Method and device for preparing ultrapure acetone

A kind of technology of acetone and materials, applied in the field of preparation of ultra-pure acetone, can solve the problems of cumbersome unit operation process, difficult process control, high energy consumption, etc., and achieve the effect of convenient operation process, stable product quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

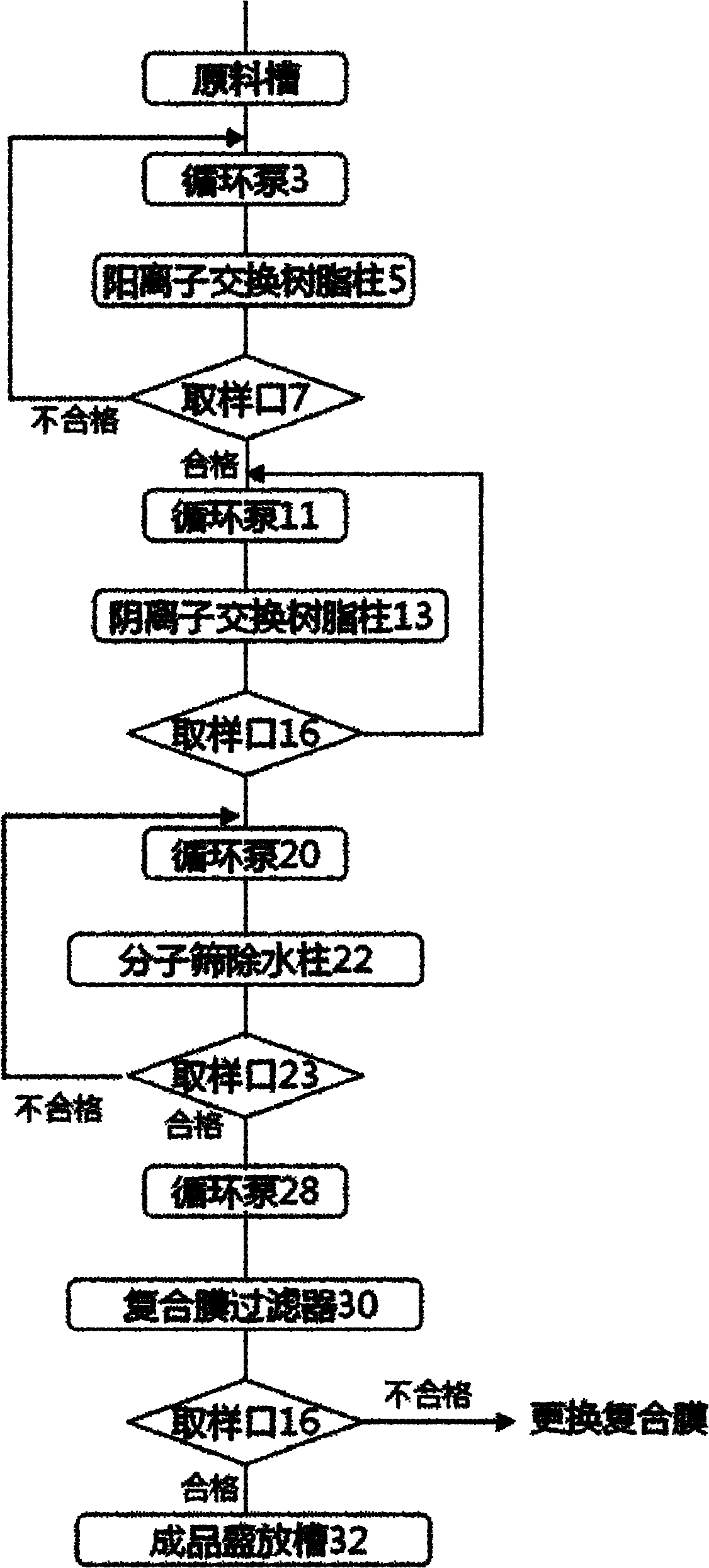

Method used

Image

Examples

Embodiment 1

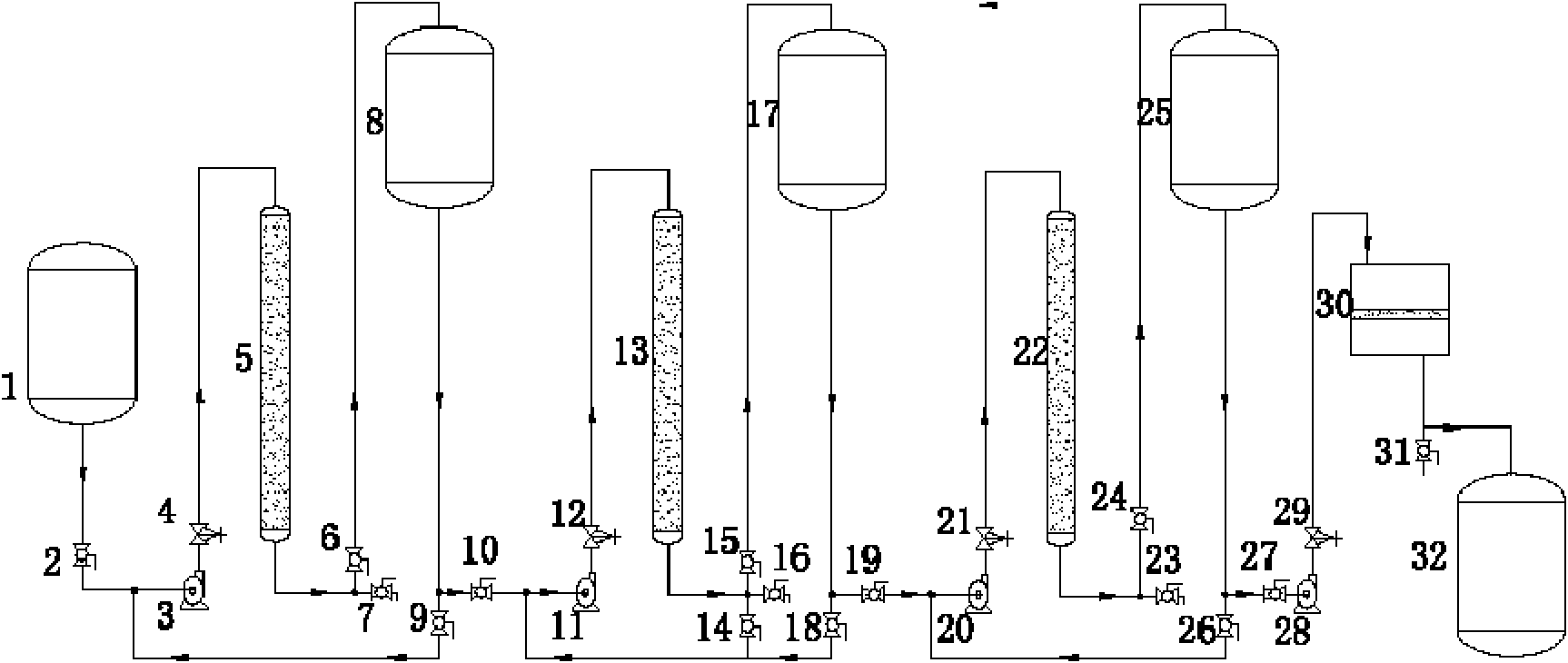

[0027] Put 15L of industrial grade acetone in the raw material tank 1 at normal temperature, and control the flow rate to be 200ml / min into the cation exchange column 5 with a size of 80cm×8cm for cation exchange. After 1 hour, take a sample through the 1# sampling port 7 to detect the cation of the acetone material content, the test results are shown in Table 1 (if the cation content of the test result acetone material does not meet the standard, the material is returned to the cation exchange material storage tank 8 by the circulation pump 3, and then circulated to the cation exchange column 5 for ion exchange, and the test result The acetone material after the cation content meets the standard carries out anion exchange).

[0028] The acetone material for removing cations enters the anion exchange column 13 with a size of 80cm × 8cm by the anion exchange circulation pump 11, and after 1 hour, the anion content of the acetone material is sampled and detected through the 2# sa...

Embodiment 2

[0032] Put 30L of industrial grade acetone in the raw material tank 1 at normal temperature, and control the flow rate to be 400ml / min into the cation exchange column 5 with a size of 80cm×8cm for cation exchange. After 2 hours, take a sample through the 1# sampling port 7 to detect the cation of the acetone material content, the test results are shown in Table 1 (if the cation content of the test result acetone material does not meet the standard, the steps of Example 1 are used to process.

[0033] The acetone material for removing cations enters the anion exchange column 13 with a size of 80cm × 8cm by the anion exchange circulation pump 11, and after 1 hour, the anion content of the acetone material is sampled and detected through the 2# sampling port 16, and the test results are shown in Table 1 (if the test results The anion content of the acetone material does not meet the standard,

[0034] The acetone material from which cations and anions have been removed enters the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com