Patents

Literature

214results about How to "With industrial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

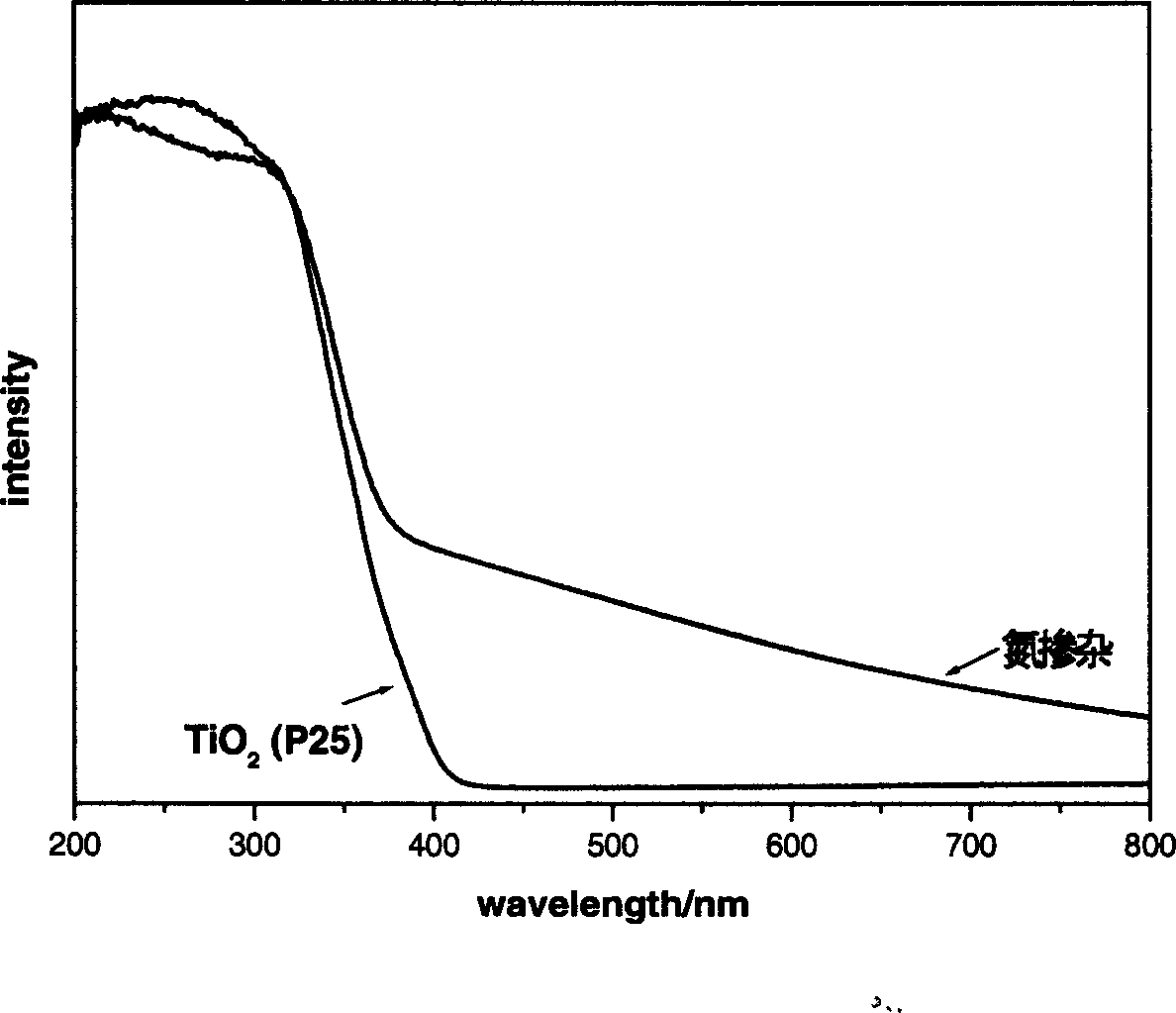

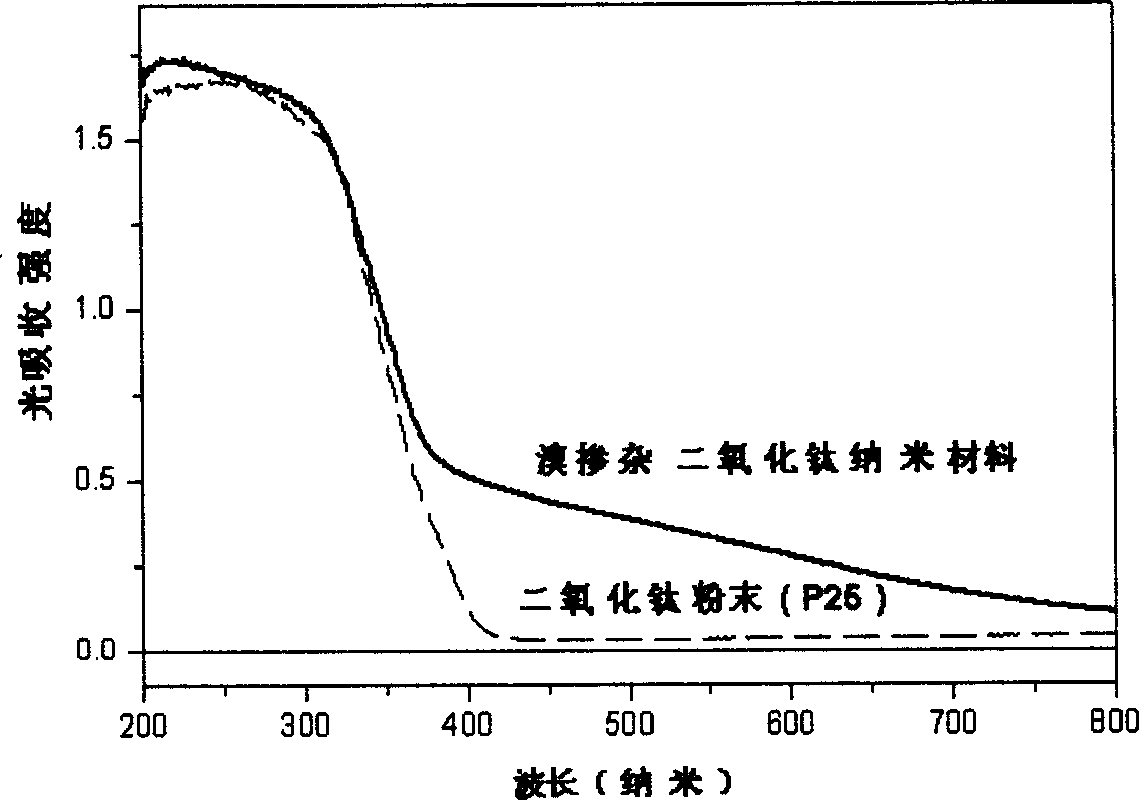

Preparaton method of photo catalytic active nitrogen adulterated titanium dioxide nano material

InactiveCN1555913AImprove photon quantum efficiencyAchieve full frequency absorptionCatalyst activation/preparationNano catalystQuantum efficiency

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of glycolide

ActiveCN103242287AShorten production timeReduce production processOrganic chemistryAcetic acidOligomer

The invention discloses a preparation method of glycolide. According to the preparation method, high purified glycolic acid crystal is taken as a raw material, and high-purity high-yield glycolide crystal can be synthetized through a series of steps such as dehydration polycondensation, melt phase polycondensation, depolymerization reaction and recrystallization purification. Glycolic acid oligomer is generated through glycolic acid polycondensation, and almost all the glycolic acid oligomers are depolymerized for preparing the glycolide under the action of a high efficient catalyst, the usage amount of the catalyst is low, the preparation technology is simple, the yield is high and the preparation method has industrial production potential.

Owner:WUHAN UNIV

Method for synthesizing anatase type crystallizing titanium dioxide nano nuclear-shell or shell structure material by water phase one-step method

InactiveCN101077792AThe method flow is simpleEasy to operateTitanium dioxidePhotonic crystalPolystyrene

The present invention relates to preparation process of core-shell material and hollow material, and is especially water phase one-step synthesis process for preparing nanometer crystallized anatase type titania material in core-shell and hollow structure. Water soluble titanium peroxide precursor is treated through a sol-gel process so as to coat a nanometer titania layer onto the surface of polystyrene, and the nanometer titania layer in the shell is crystallized directly at relatively low temperature to form nanometer anatase type titania without needing sintering. Furthermore, the precursor may be controlled properly, so that the polystyrene core serving as the template may be dissolved spontaneously after the shell is formed and crystallized and nanometer hollow titania may be obtained directly in water phase. The present invention is simple, easy to operate, low in cost and suitable for batch production, and may find wide application in different aspects.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Novel peptide with angiotonin transferase restraining liveness and method of producing the same

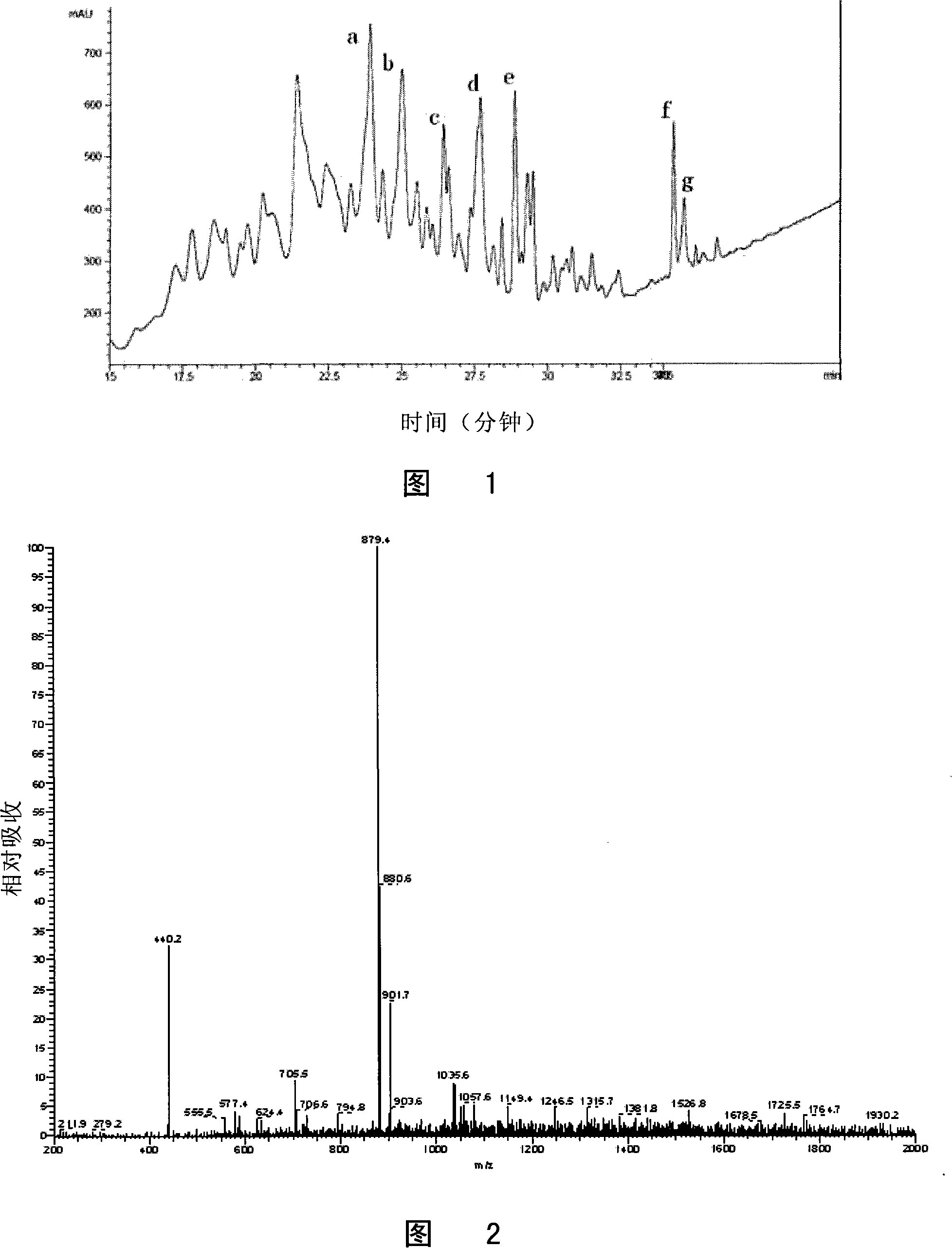

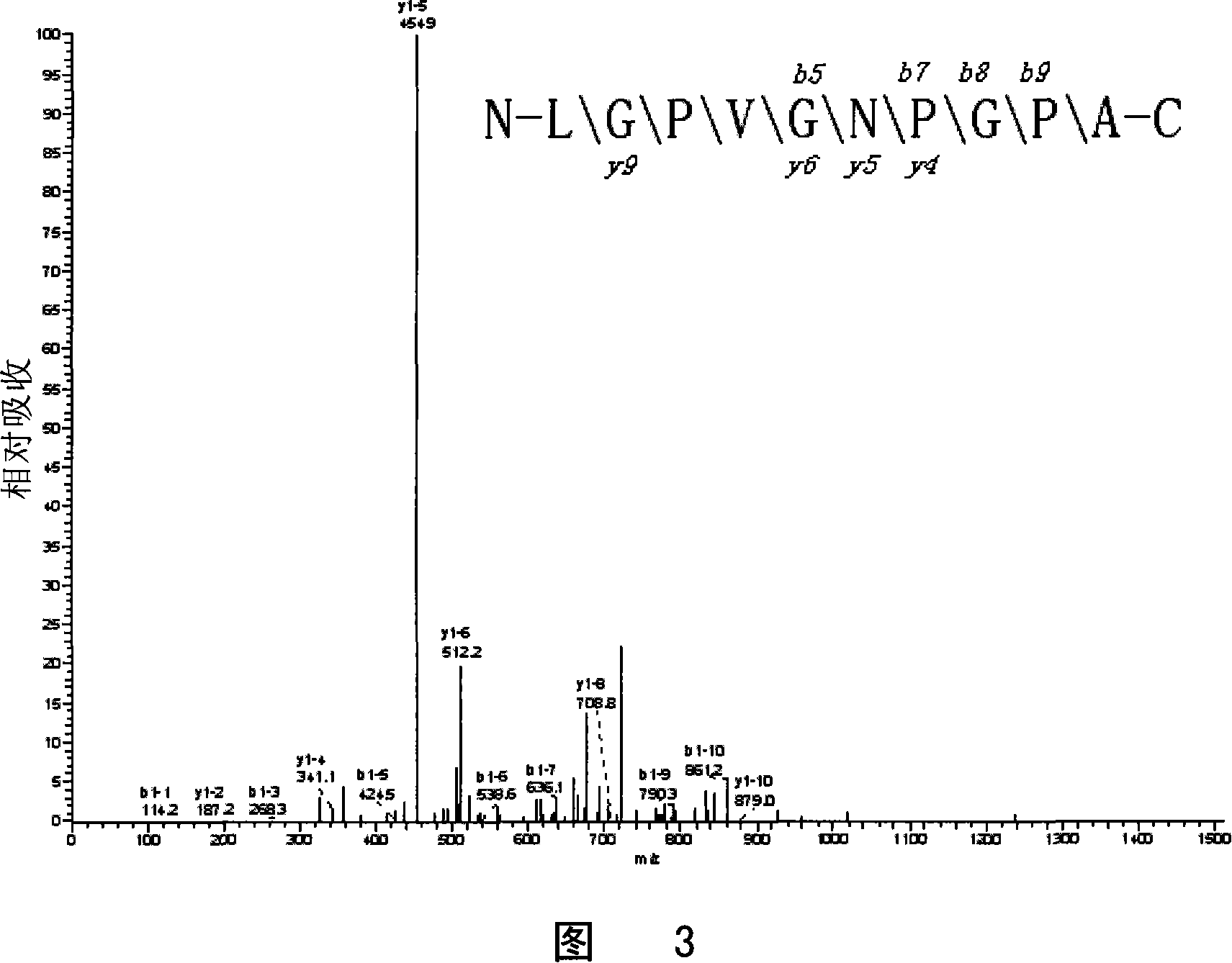

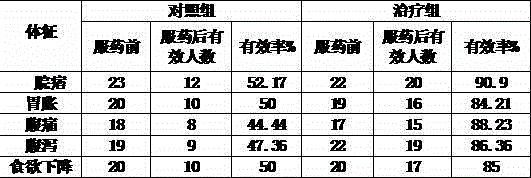

InactiveCN101153055AGood ACE inhibitory activityHigh prolinePeptide/protein ingredientsPeptidesUltrafiltrationDecomposition

The present invention discloses a method of using biological enzyme decomposition to prepare a hydrolysis compound containing peptide of angiotensin transfer enzyme inhibitory activity, and three novel peptides of high ACE inhibitory activity. For the hydrolysis compound containing peptide of angiotensin transfer enzyme inhibitory activity of the present invention, the oxhide rich in praline is used as the raw material; the product of ACE inhibitory activity IC50 equal to 0.168mg / m can be prepared through the compounding and hydrolysis of biological enzyme. After ultrafiltration, the IC50 is equal to 0.079mg / ml. The means of analysis and detection determines the peptides, ISVPGPM, LGPVGNPGPA and DLSFLPQPPQQ, containing high ACE inhibitory activity. The three peptide sections are novel peptide sections containing high ACE inhibitory activity. Therefore, the three peptides have potential function of lowering blood pressure. The compounding and decomposition of biological enzyme of oxhide is a peptide type hydrolysis product, has inhibitory effects on angiotensin transfer enzyme (ACE), and can be widely used for health food, functional food, auxiliary drugs for lowering blood pressure and other products; the peptide has broad market prospects.

Owner:EAST CHINA UNIV OF SCI & TECH +1

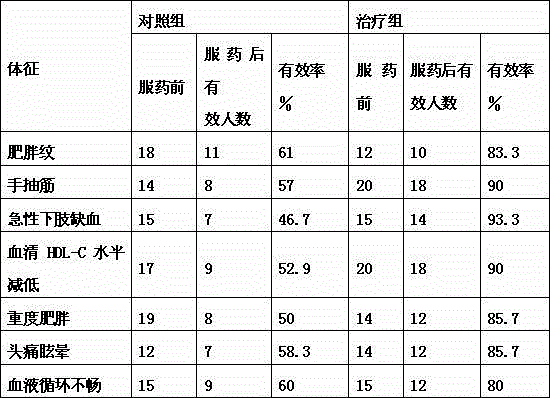

Yueju Baohe dispersible tablets and preparing method thereof

InactiveCN106728634AWith industrial productionImprove solubilityDigestive systemPill deliveryMaterials preparationTraditional medicine

The invention discloses Yueju Baohe dispersible tablets and a preparing method thereof. The Yueju Baohe dispersible tablets are prepared from, by weight, 10-50% of traditional Chinese medicine extract, 10-80% of filler, 5-50% of internally added disintegrant, 5-15% of externally added disintegrant, 0.1-10% of corrigent, 0.1-20% of wetting agent and 0.05-20% of lubricant. The traditional Chinese medicine extract comprises, by weight, 60-120 parts of ginger-processed fructus gardeniae, 60-120 parts of medicated leaven stir-fried with bran, 60-120 parts of vinegar-processed rhizoma cyperi, 60-120 parts of rhizoma chuanxiong, 60-120 parts of rhizoma atractylodis, 60-120 parts of radix aucklandiae and 60-120 parts of semen arecae. The preparing method comprises the steps of material preparation, extraction, tablet preparation and packaging. The Yueju Baohe dispersible tablets can soothe liver and dispel melancholy, whet the appetite and promote digestion, and are used for treating symptoms like dyspepsia, qi depression and stasis, poor appetite and thoracico-abdominal swelling pain.

Owner:HARBIN SHENGJI PHARMA

Ginkgo leaf extract and its extracting method

ActiveCN1586548AScientifically feasibleHigh extraction rateUnknown materialsCardiovascular disorderVascular diseaseGinkgo leaf extract

The present invention belongs to the field of Chinese medicine preparing technology. The ginkgo leaf extract has total flavone and total terpene lactone content over 80 %, total flavone content over 70 %, flavonoid glycoside content over 40 % and total terpene lactone content over 10 %. The extraction process includes the following steps: extracting, purifying and separating, concentration, drying, etc. Compared with available technology, the present invention has the advantages of reasonable technological path, being suitable for industrial production, low production cost, high extracting rate of effective components, etc. The present invention also discloses the infusion liquid and powder for injection with the ginkgo leaf extract and their preparation process. The ginkgo leaf extract has wide application in medicine for treating cardiac vascular diseases.

Owner:AOLING BODA MEDICINE SCI & TECH DEV BEIJING

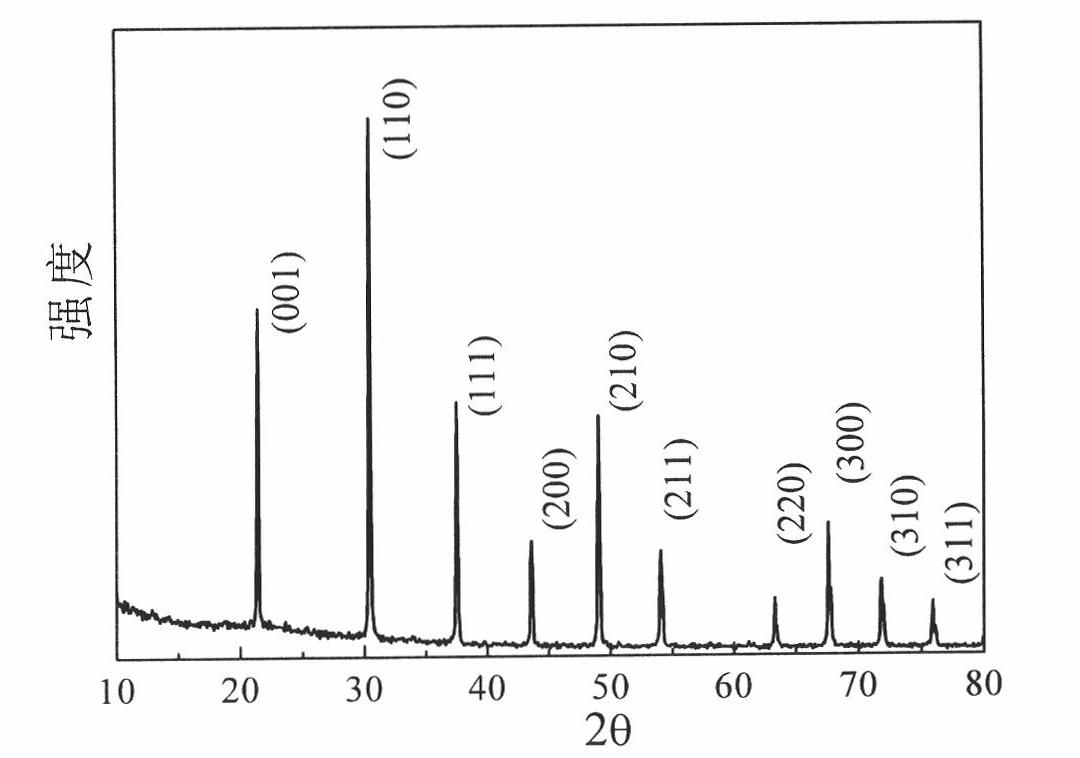

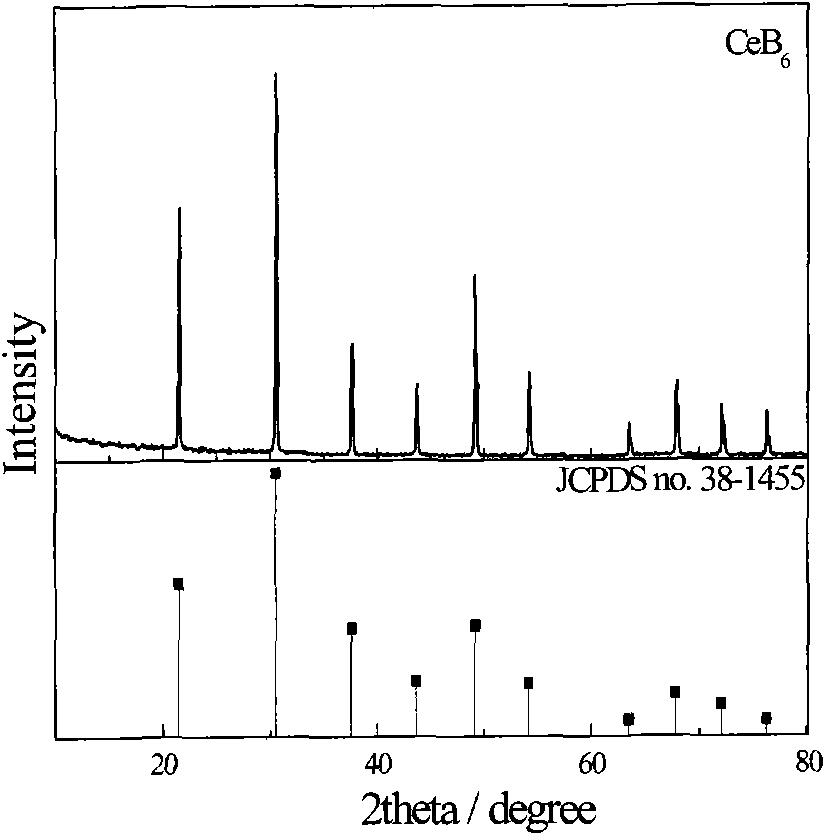

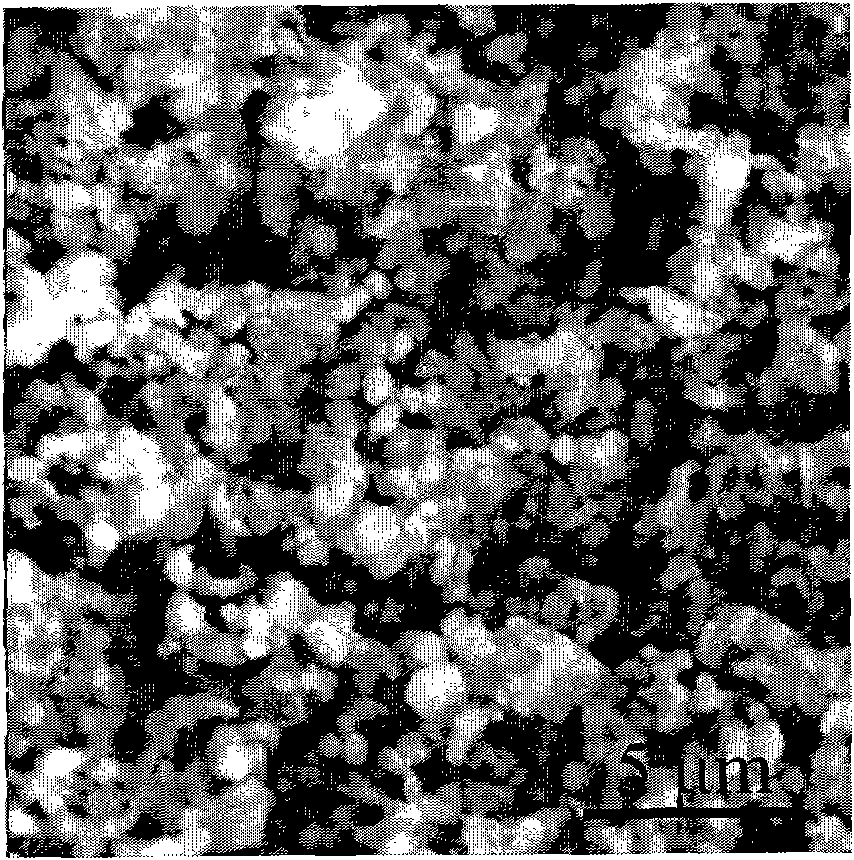

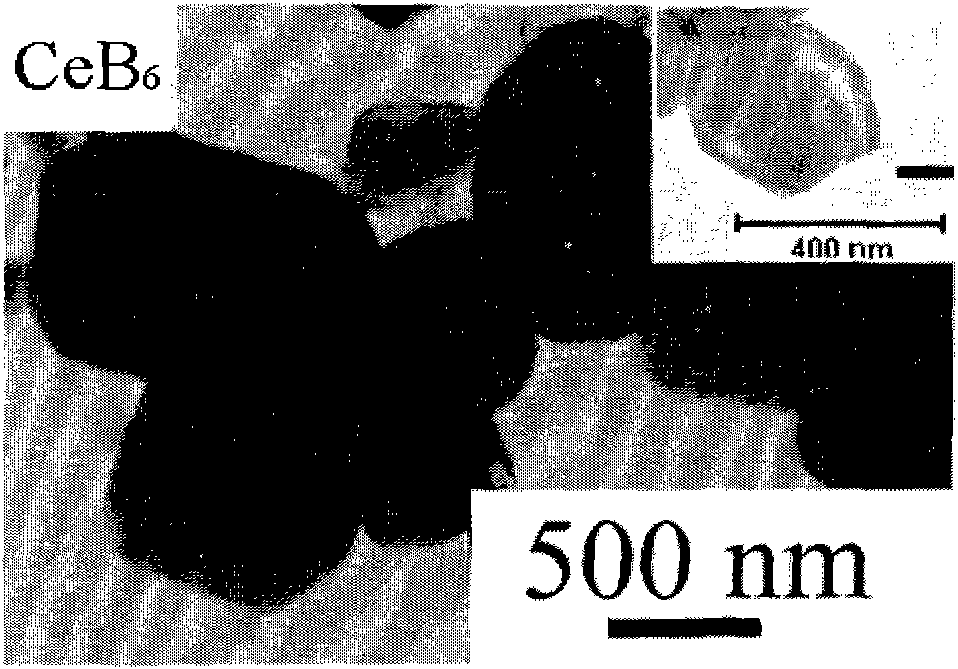

Method for preparing nano superfine rare-earth hexaboride powder

The invention relates to a method for preparing nano superfine rare-earth hexaboride powder. In the presence of a reducing agent, a metal resource raw material and a boron source raw material react in a reactor at the temperature of between 500 and 650 DEG C to form a product. In the method, the nano superfine rare-earth hexaboride powder is prepared by solid phase reaction under the conditions of lower temperature and no obvious pressure. Compared with the conventional boron thermal reduction and carbon thermal reduction technology, the method of the invention has the advantages of lower reaction temperature, no need of pressure, low raw material cost and probability of realizing mass production.

Owner:SHANDONG UNIV

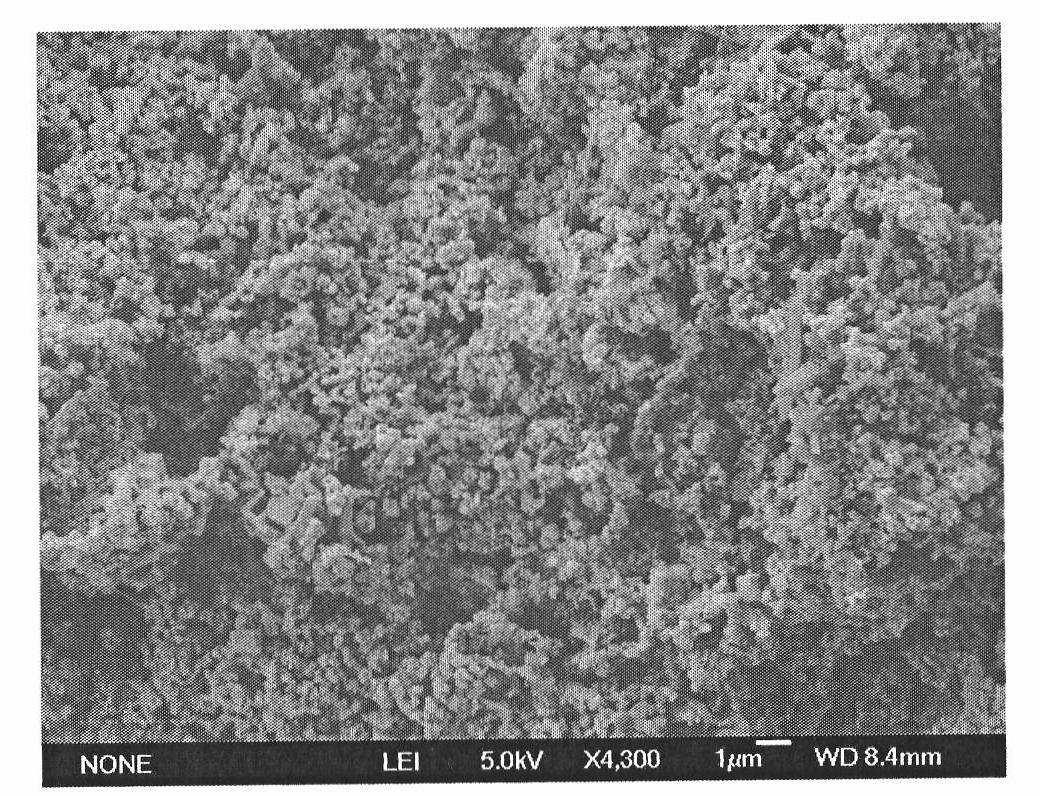

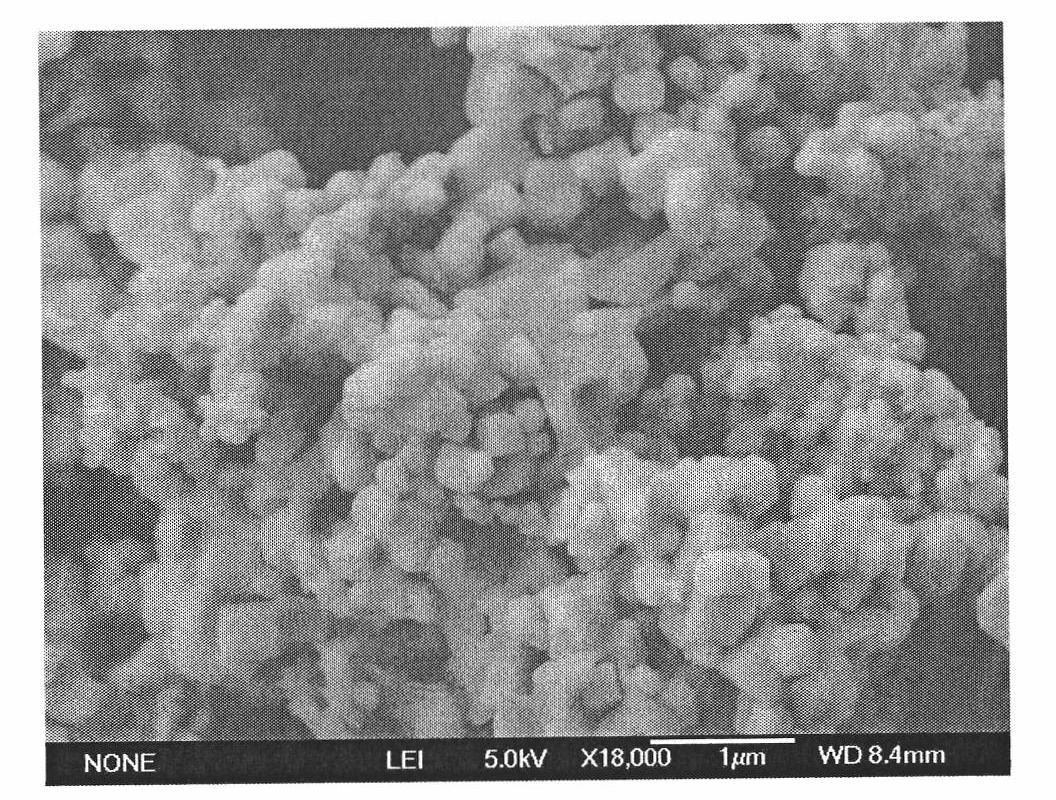

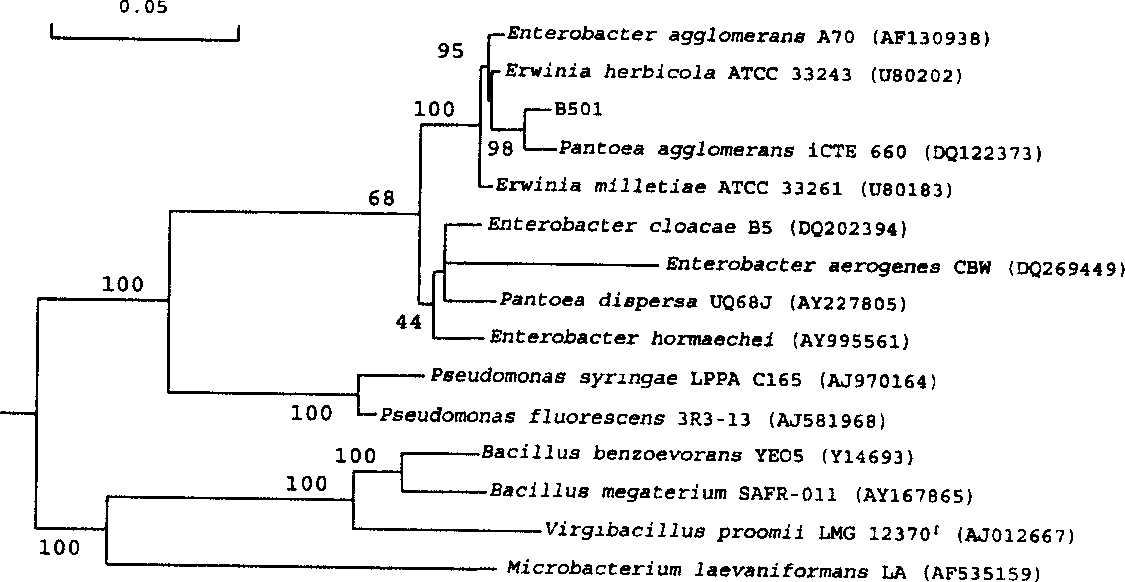

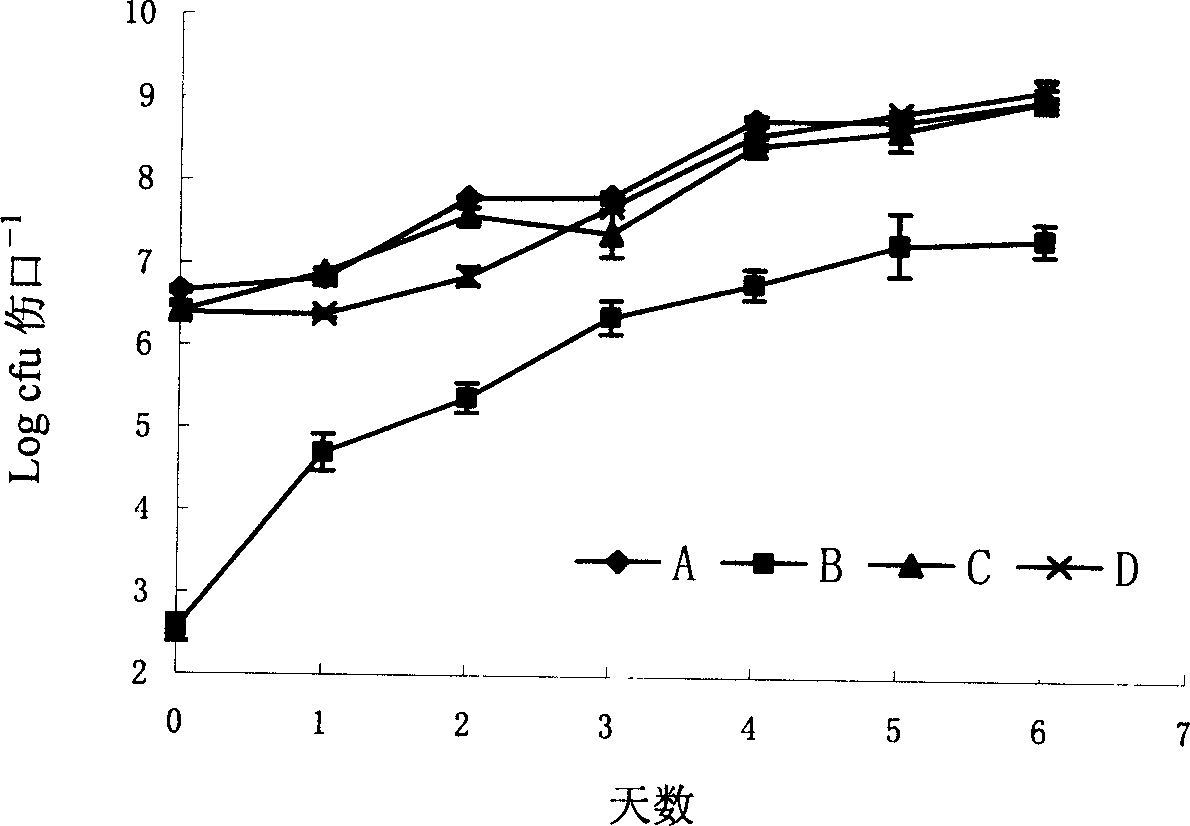

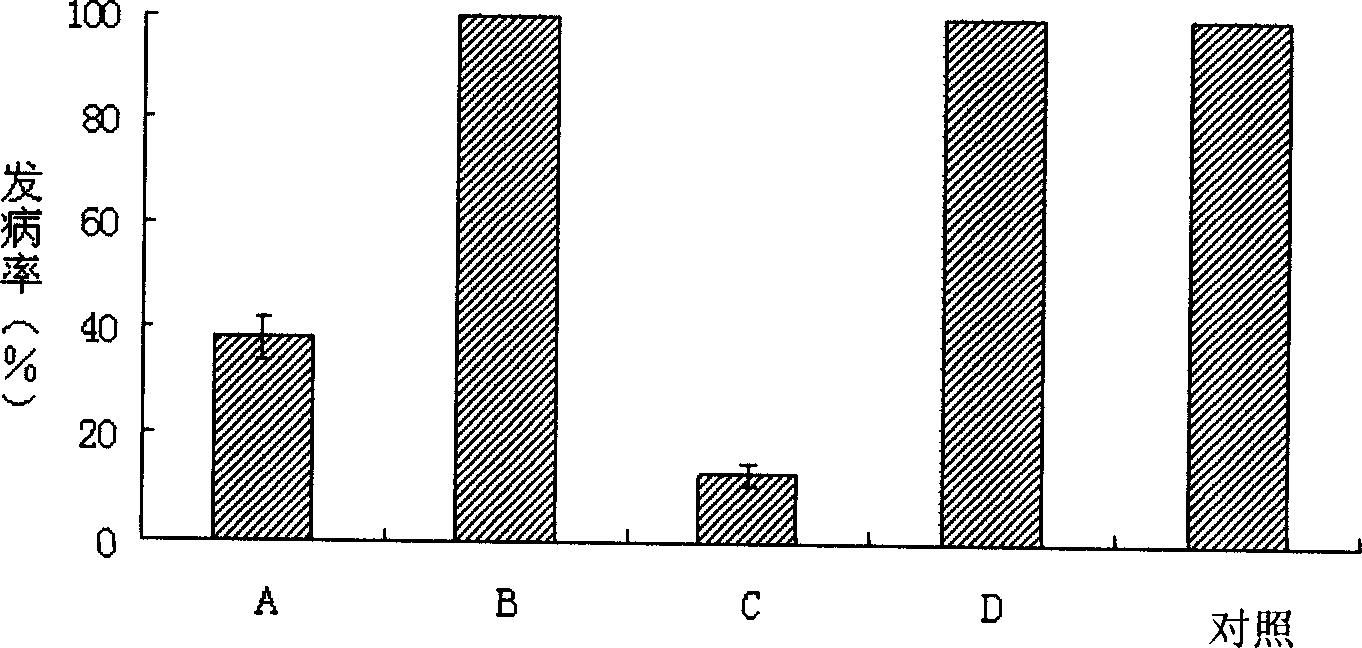

One strain forming a block type fanjun fungus, fermentation culturing method and application thereof

InactiveCN1831116AEffective controlSimple preparation processBiocideBacteriaDiseaseEnterobacter agglomerans

The invention discloses Pantoea agglomerans B50l CGMCC No.1655 and fermenting cultivating method and application. The method includes the following steps: inoculating the Pantoea agglomerans B50l CGMCC No.1655 into triangle bottle to gain seed liquid, inoculating the seed liquid into fermenting jar special cultivating medium for 48-96 hours. It has good effect to avoid disease, high effect efficiency, high biology safety and simple manufacture technology.

Owner:NORTHWEST A & F UNIV

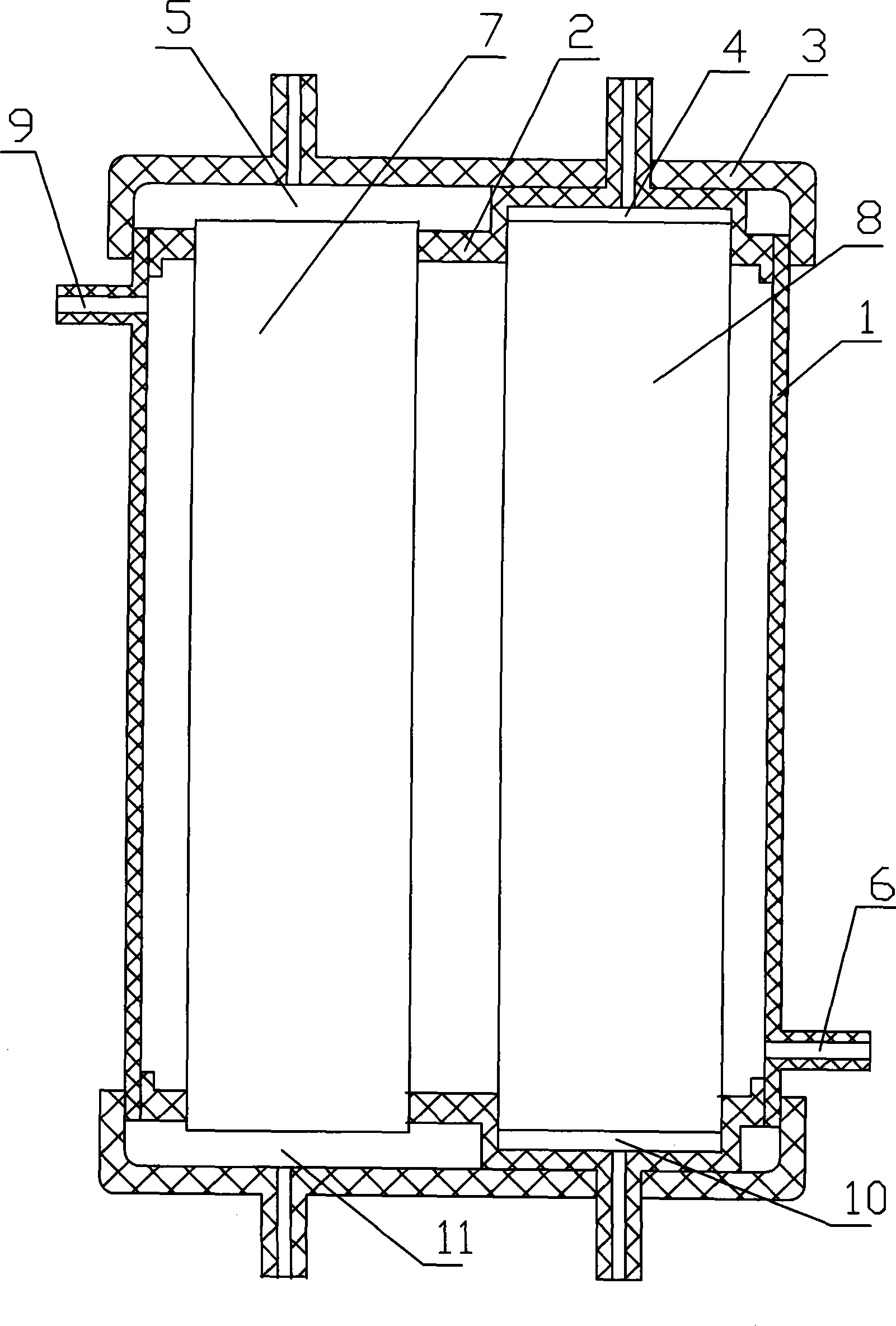

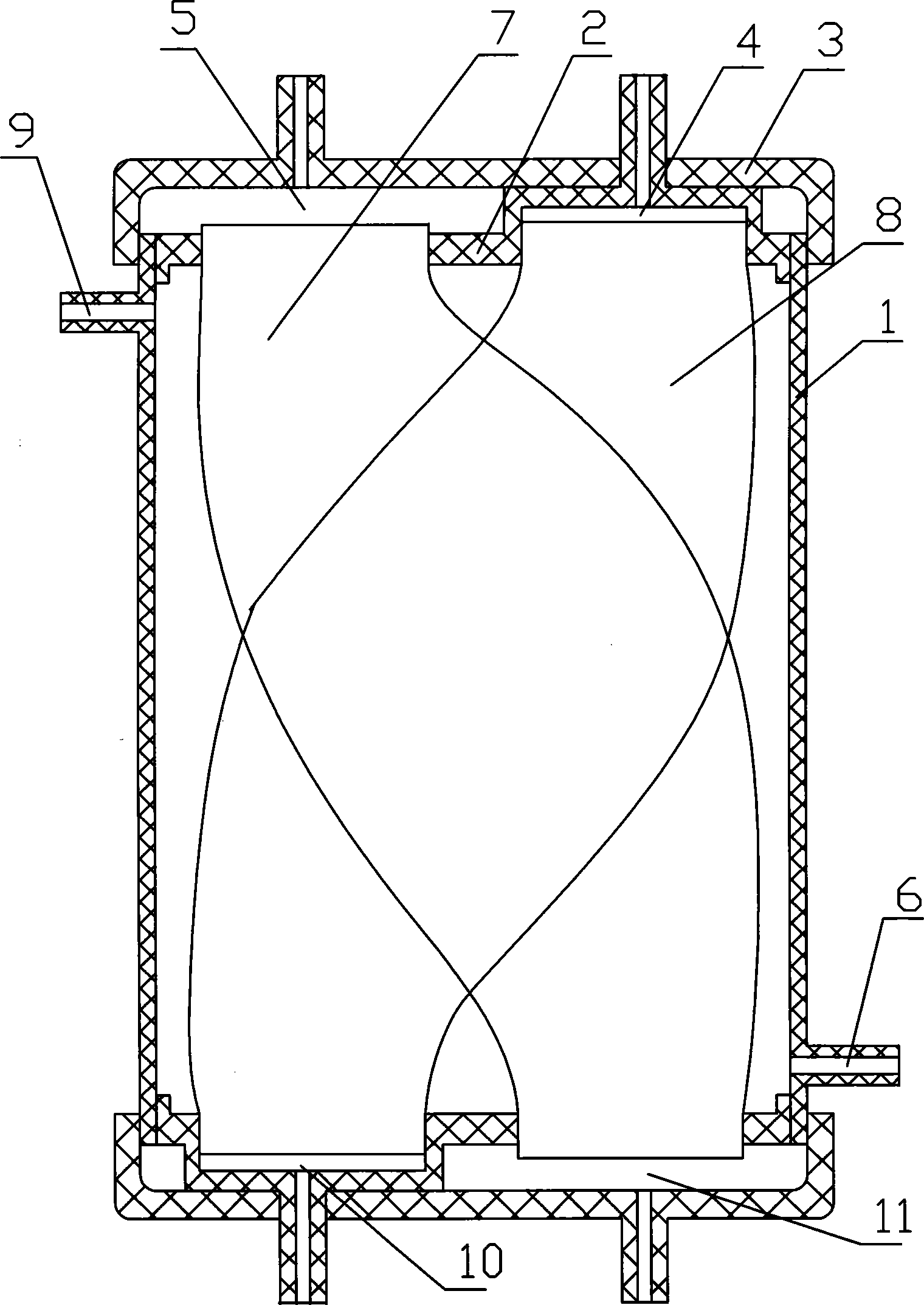

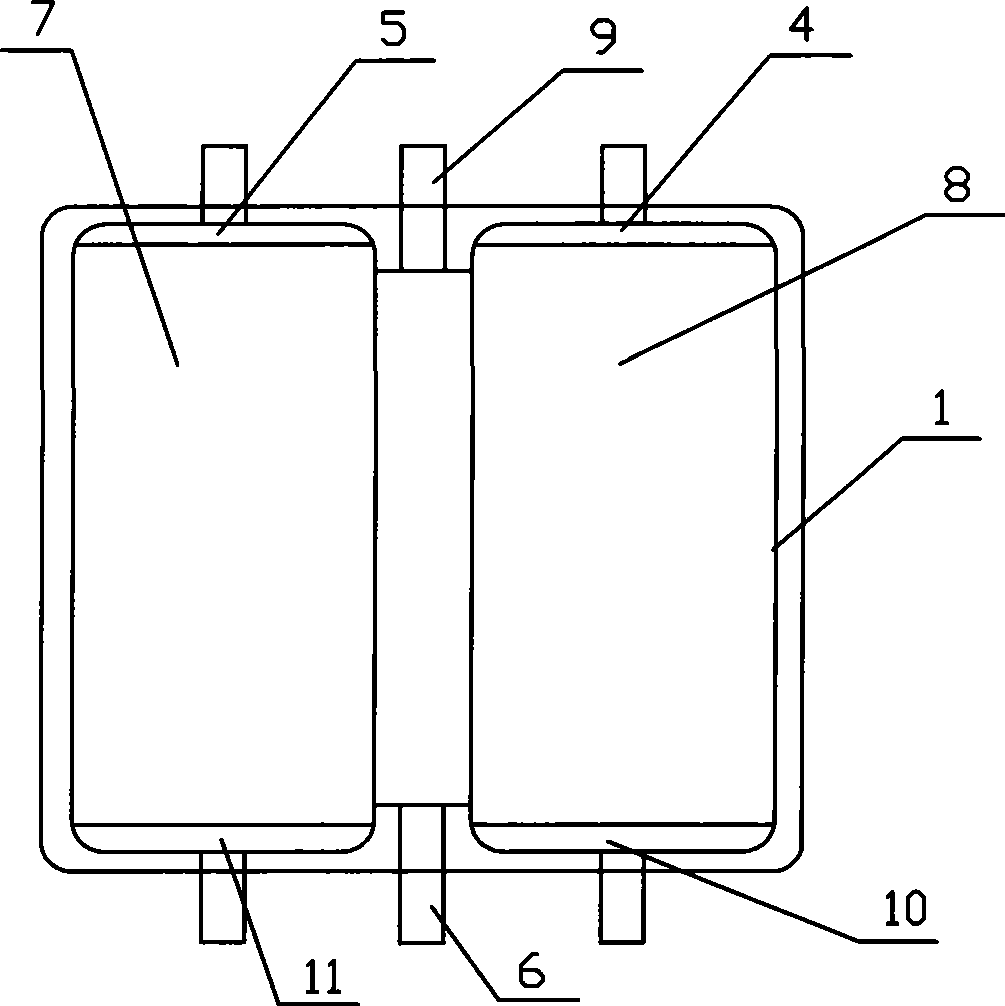

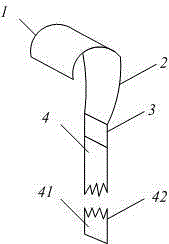

Culture fluid gas/liquid and liquid/liquid exchanger for tissue engineering tissue bionic cultivation

InactiveCN101486967AEasy to updateRealize pulsed cycle updateTissue/virus culture apparatusFiberCulture fluid

The invention discloses a culture fluid gas-to-fluid and fluid-to-fluid exchanger that is used for biomimetic tissue cultivation in tissue engineering, an inlet and an outlet of a circular culture fluid are arranged in the chamber of an exchanger shell, an inlet and an outlet of a fresh culture fluid are arranged on the shell, an inlet and an outlet that are used for the fresh culture fluid to pass through and for communicating a hydrophilic hollow fiber semi-permeable biomembrane bunch that implements fluid-to-fluid exchange of the circular culture fluid with the fresh culture fluid are arranged in the chamber, a gas outlet and a gas inlet are arranged on the shell, an inlet and an outlet that are used for gas to pass through and for communicating a hydrophobic hollow fiber semi-permeable biomembrane bunch that implements gas-to-fluid exchange of the circular culture fluid with the gas are arranged inside the chamber, and an airtight space is formed inside the chamber of the shell. Oxygen, carbon dioxide, the fresh culture fluid and the circular culture fluid can finish the gas-to-fluid and the fluid-to-fluid exchange and update inside the exchanger without opening the chamber, and the chamber is closed so as to ensure the pulse-typed circulation of the fresh culture fluid and the circular culture fluid and to support the biomimetic tissue cultivation in tissue engineering.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

Method for synthetizing synthetic metal boride nano-powder by iodine assisting magnesium co-reduction solid-phase reaction

InactiveCN101837987ALow priceWith industrial productionMetal boridesPhysical chemistryMaterials science

The invention relates to a method for synthetizing synthetic metal boride nano-powder by iodine assisting magnesium co-reduction solid-phase reaction, which utilizes the iodine assisting magnesium co-reduction solid-phase reaction to synthetize alkaline earth, rare earth metal six-boron compound and transition metal boride as well as ternary rare earth six-boron compound, is a common and universal method, and can prepare and obtain YB6, ScB6, CeB6, PrB6, PrB6, NdB6, SmB6, EuB6, CaB6, SrB6, BaB6 and the like, ternary rare earth six-boron compound and transition metal boride.

Owner:SHANDONG UNIV

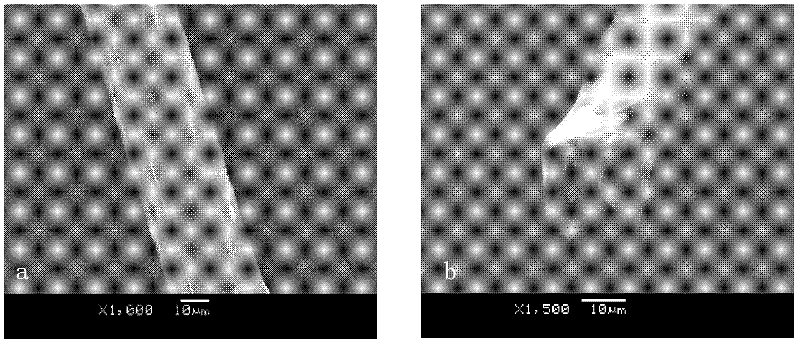

Process for preparing core-shell type polysiloxane composite particles

The invention discloses a process for preparing core-shell polysiloxane complex particles. It includes the following steps: adding organosilane into mixtures of water and / or organic solvent to perform hydrolytic reaction with alkali or acid; mixing the obtained hydrolysate solution with polymer particles as core materials of core-shell complex particle or its dispersion, then adding alkaline substances to produce core-shell polysiloxane complex particles. The method of this invention even can produce core-shell particles with polysiloxane as its shell layer without core materials treatment by coupling agents, and can adopt various polymer particles with grain diameter of 0.01-100ª–m as core materials, and can easily control the shell thickness of the complex particles. The invention can easily obtain the core-shell polysiloxane complex particles and has a high productivity, so it has an industrial production prospect.

Owner:EAST CHINA UNIV OF SCI & TECH

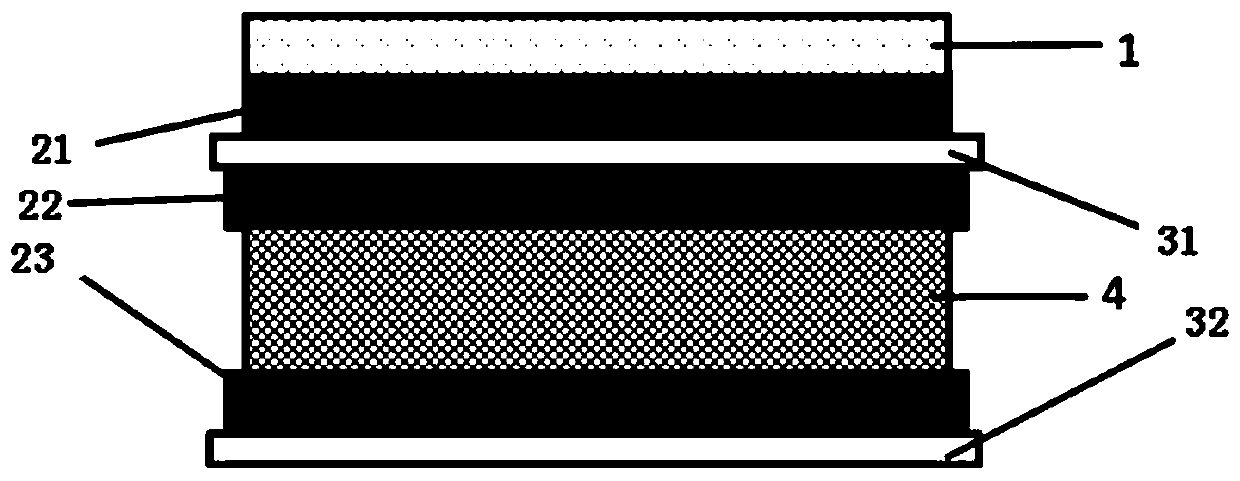

Piezoelectric-triboelectric hybrid self-driven electronic skin and preparation method thereof

ActiveCN110514326AHas shapeWith property sensingLiquid surface applicatorsFilament/thread formingHybrid typeFiber

The invention provides piezoelectric-triboelectric hybrid type self-driven electronic skin. The skin characterized in that the skin comprises a triboelectric sensing part and a piezoelectric sensing part arranged at the lower side of the triboelectric sensing part; the triboelectric sensing part comprises a flexible transparent porous electronegative film and a first flexible conductive fabric electrode arranged at the lower side of the flexible transparent porous electronegative film; the piezoelectric sensing part comprises a piezoelectric nanofiber film, a second flexible conductive fabricelectrode and a third flexible conductive fabric electrode, wherein the second flexible conductive fabric electrode and the third flexible conductive fabric electrode are arranged at the upper side and lower side of the piezoelectric nanofiber film respectively; the piezoelectric nanofiber film is obtained through an electrostatic spinning technology; and the flexible transparent porous electronegative film is of a porous structure prepared by taking a lotus leaf as a template. The multifunctional flexible self-driven electronic skin of the invention does not need to be driven by an external additional power source, and can ensure the accuracy of sensing and the wearing comfort of a human body.

Owner:DONGHUA UNIV

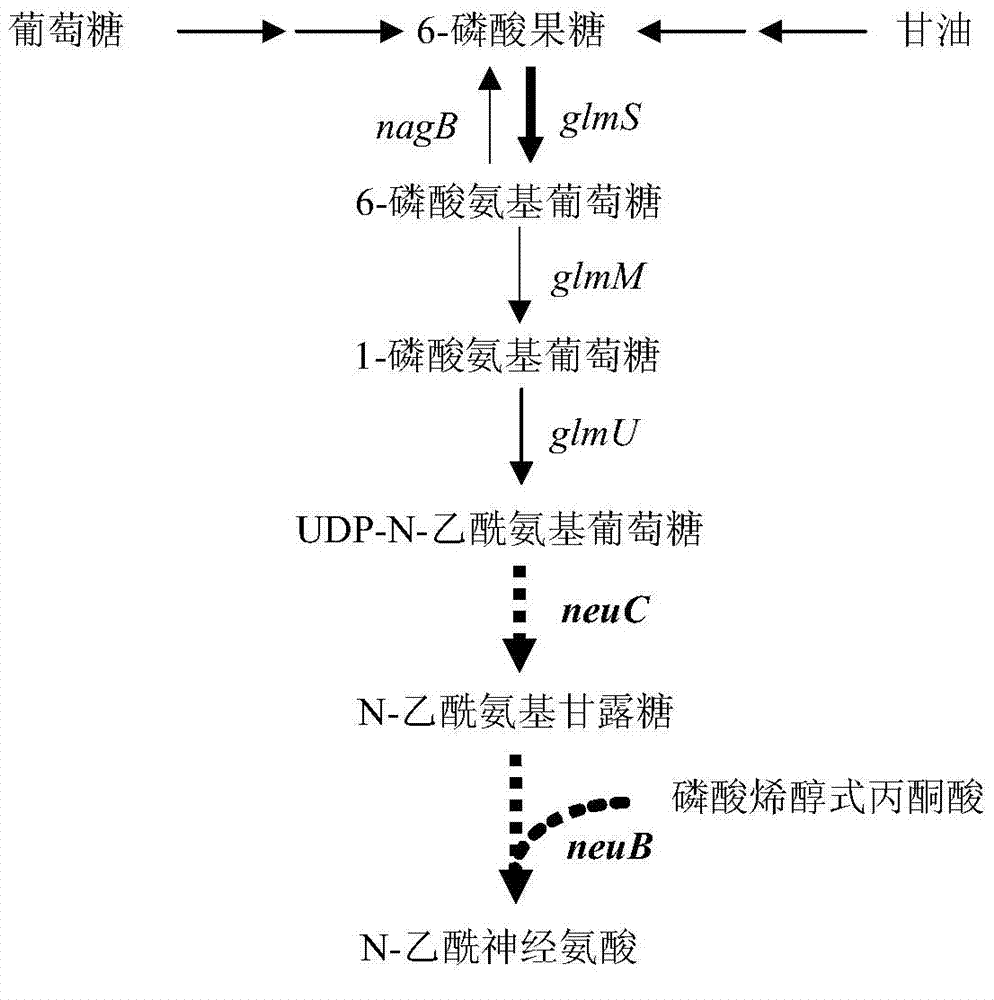

Bacillus subtilis gene engineering bacterial producing Neu5Ac, construction method and application thereof

InactiveCN103923869AWith industrial productionSimple production processBacteriaMicroorganism based processesFood industryGlycerol

The present invention discloses Bacillus subtilis gene engineering bacterial producing Neu5Ac, a construction method and an application thereof. According to the present invention, according to the gene engineering bacterial, genes for coding UDP-N-acetyl glucosamine epimerase and Neu5Ac synthetase are introduced into Bacillus subtilis so as to be expressed, and expression of glucosamine 6-phosphate synthetase of the Bacillus subtilis is enhanced to construct the complete metabolic pathway from glucose or glycerol to Neu5Ac in the Bacillus subtilis so as to utilize glucose or glycerol as a substrate to carry out fermentation culture so as to produce Neu5Ac; and the adopted Bacillus subtilis is widely used in the food industry, is safe and harmless, and is suitable for production of Neu5Ac required by food and health products.

Owner:武汉中科光谷绿色生物技术有限公司

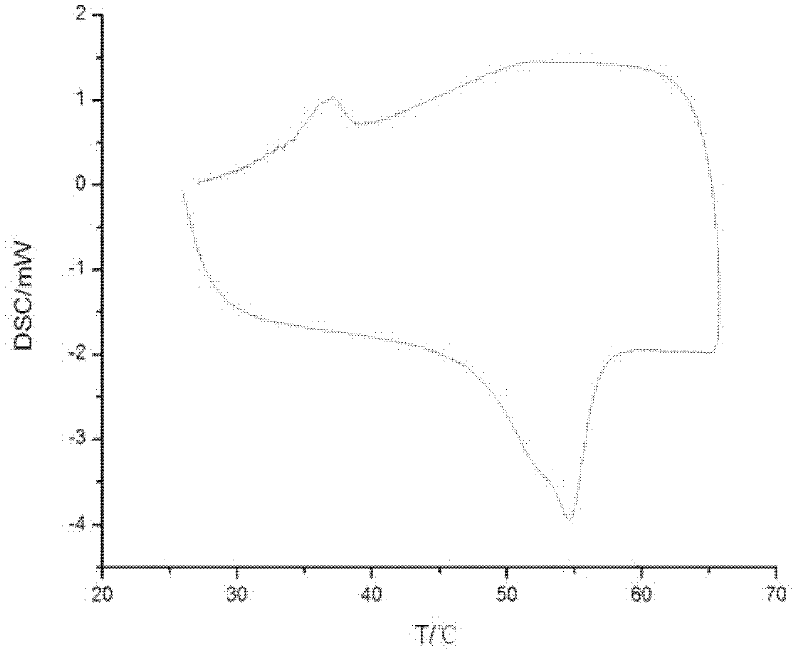

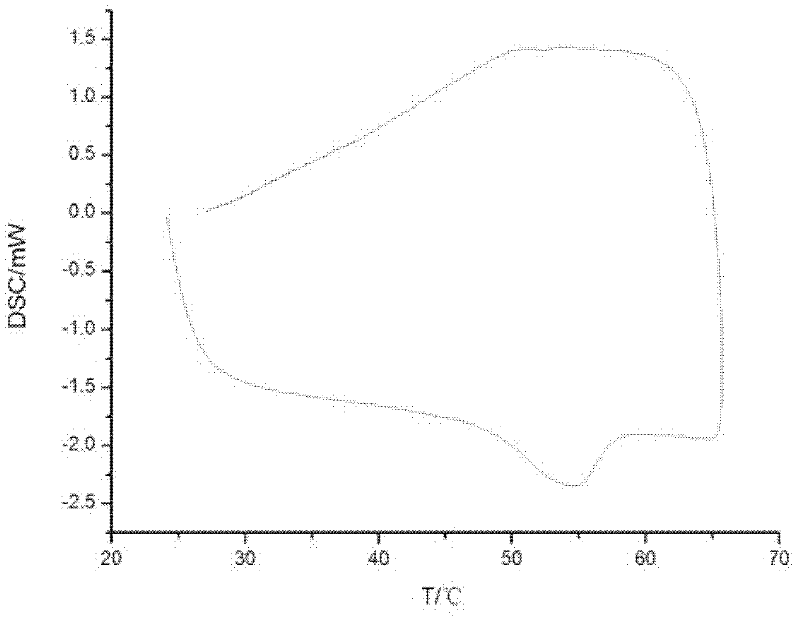

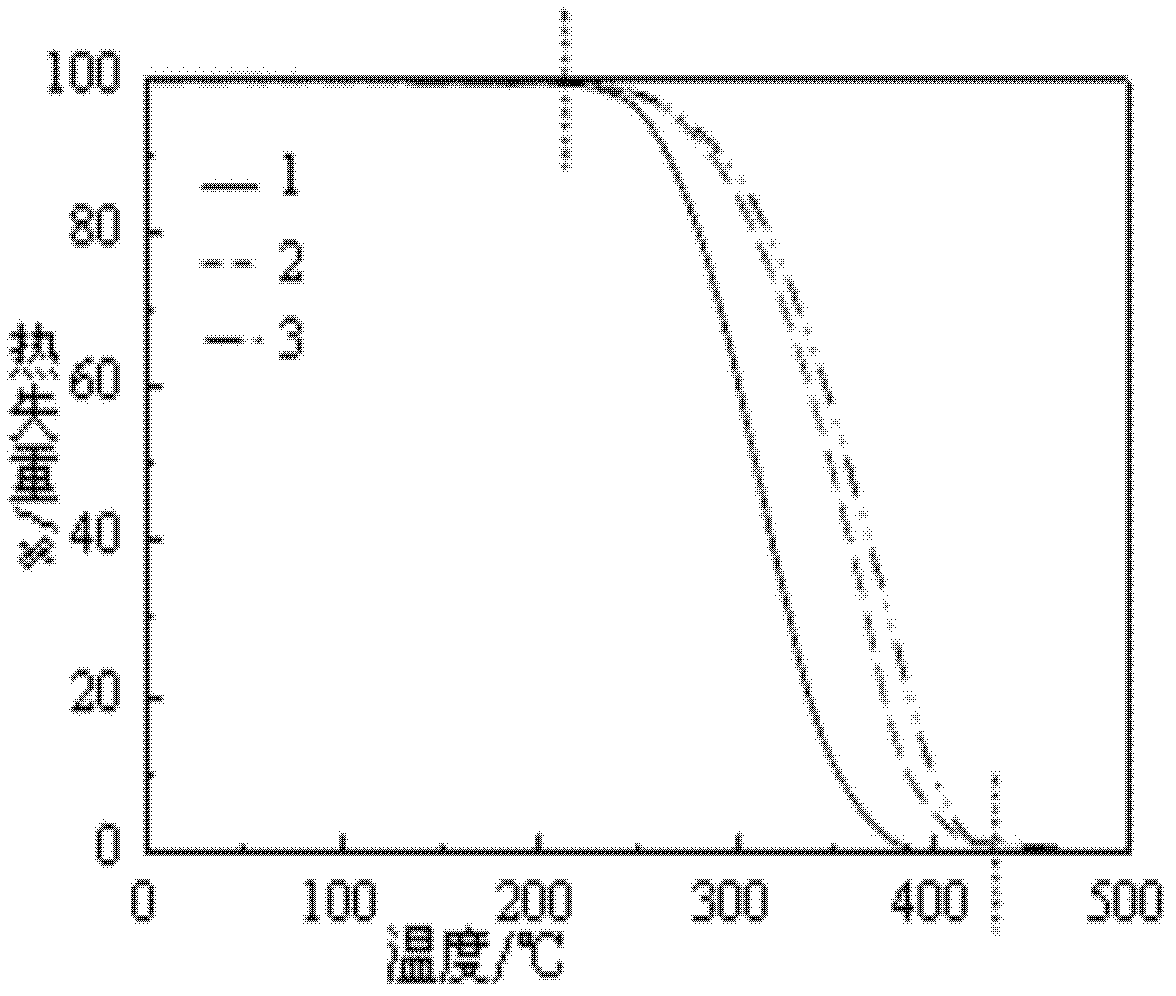

Multifunctional comfort fiber with functions of phase transition temperature regulation, moisture absorption and moisture wicking

InactiveCN102443878AStrong moisture wickingGood heat resistanceMelt spinning methodsConjugated synthetic polymer artificial filamentsMultiple functionPolymer

The invention relates to multifunctional comfort fiber with functions of phase transition temperature regulation, moisture absorption and moisture wicking. According to the fiber, an interpenetrating network composite phase transition material is adopted as a heat storage and temperature regulation material, a fiber-forming polymer is adopted as a matrix, a pore-forming agent and a compatibilizer are added to prepare a spinning raw material, and a melt spinning process is adopted to prepare the multifunctional comfort fiber. The spinning raw material preparation method comprises: mixing the interpenetrating network composite phase transition material and the fiber-forming polymer according to a mass ratio of (95-60):(5-40), then adding the pore-forming agent and the compatibilizer, and uniformly mixing, wherein the mass of the pore-forming agent is 0-10% of the total mass of the interpenetrating network composite phase transition material and the fiber-forming polymer, the mass of the compatibilizer is 1-5% of the total mass of the interpenetrating network composite phase transition material and the fiber-forming polymer, the pore-forming agent is the PEG with the molecular weight of 1000-2000, the compatibilizer is one or a plurality of materials selected from PP-g-PEGA, PP-g-PEG, PET-g-PEGA, PEGA, montmorillonite, and the like. The phase transition temperature range of the multifunctional comfort fiber is 30-55 DEG C, the melting phase transition enthalpy is 5.24-29.12 J / g, the breaking strength is 3.0-3.5 cN / dex, and the thermal decomposition temperature is more than 400 DEG C.

Owner:DALIAN POLYTECHNIC UNIVERSITY

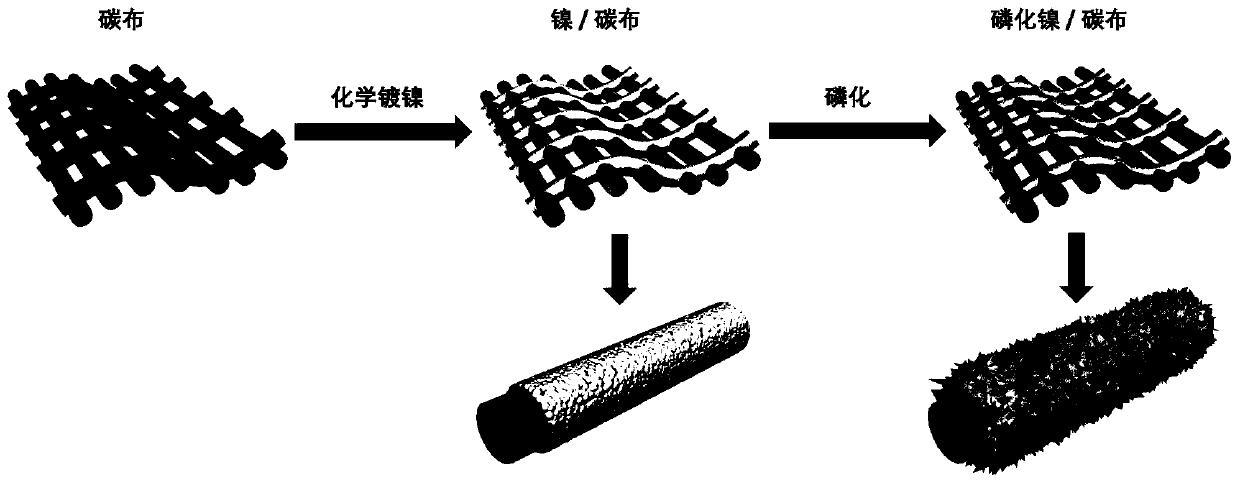

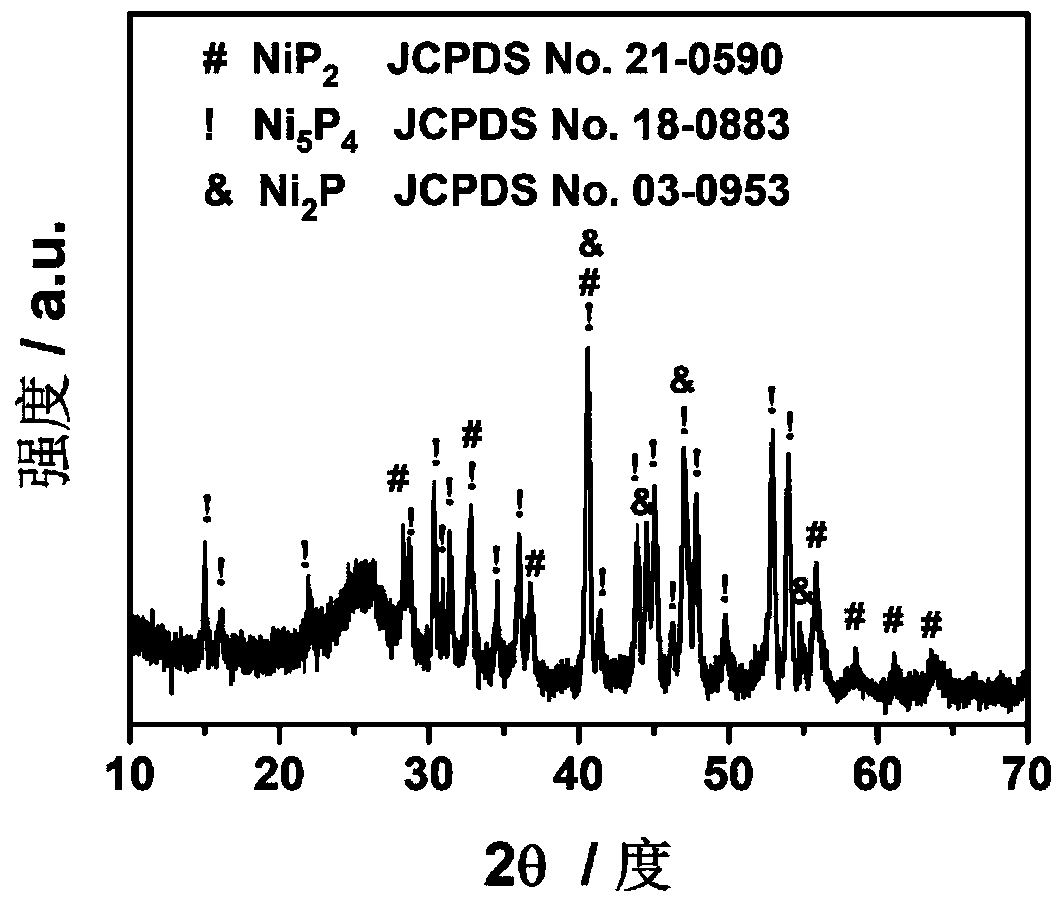

Preparation method of porous nano flaky nickel phosphide material loaded by multiple substrates

InactiveCN109876834ALarge specific surface areaImprove conductivityPhysical/chemical process catalystsElectrodesElectroless nickelOvervoltage

The invention discloses a preparation method of a porous nano flaky nickel phosphide material loaded by multiple substrates. The preparation method comprises the following steps: firstly, carrying outultrasonic cleaning on a substrate, putting the substrate into a catalyst solution to carry out loading of an electroless nickel plating catalyst, putting the substrate loaded with the catalyst intoan electroless nickel plating solution to carry out electroless nickel plating, and finally placing phosphorus at the bottom of a crucible, placing the nickel-plated substrate above the phosphorus, covering the crucible with a cover, and putting the crucible in a tubular furnace for phosphating so as to obtain the porous nano flaky nickel phosphide material loaded by the substrate. The method is simple in process, low in cost and short in period. The prepared nickel phosphide / conductive substrate material has high electrocatalytic hydrogen evolution activity in an acidic electrolyte, has verylow overvoltage potential and Tafel slope, has high stability, is good in mechanical property, can be directly used as a hydrogen evolution electrode to assemble an acidic electrolytic cell, and has avery high application value.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

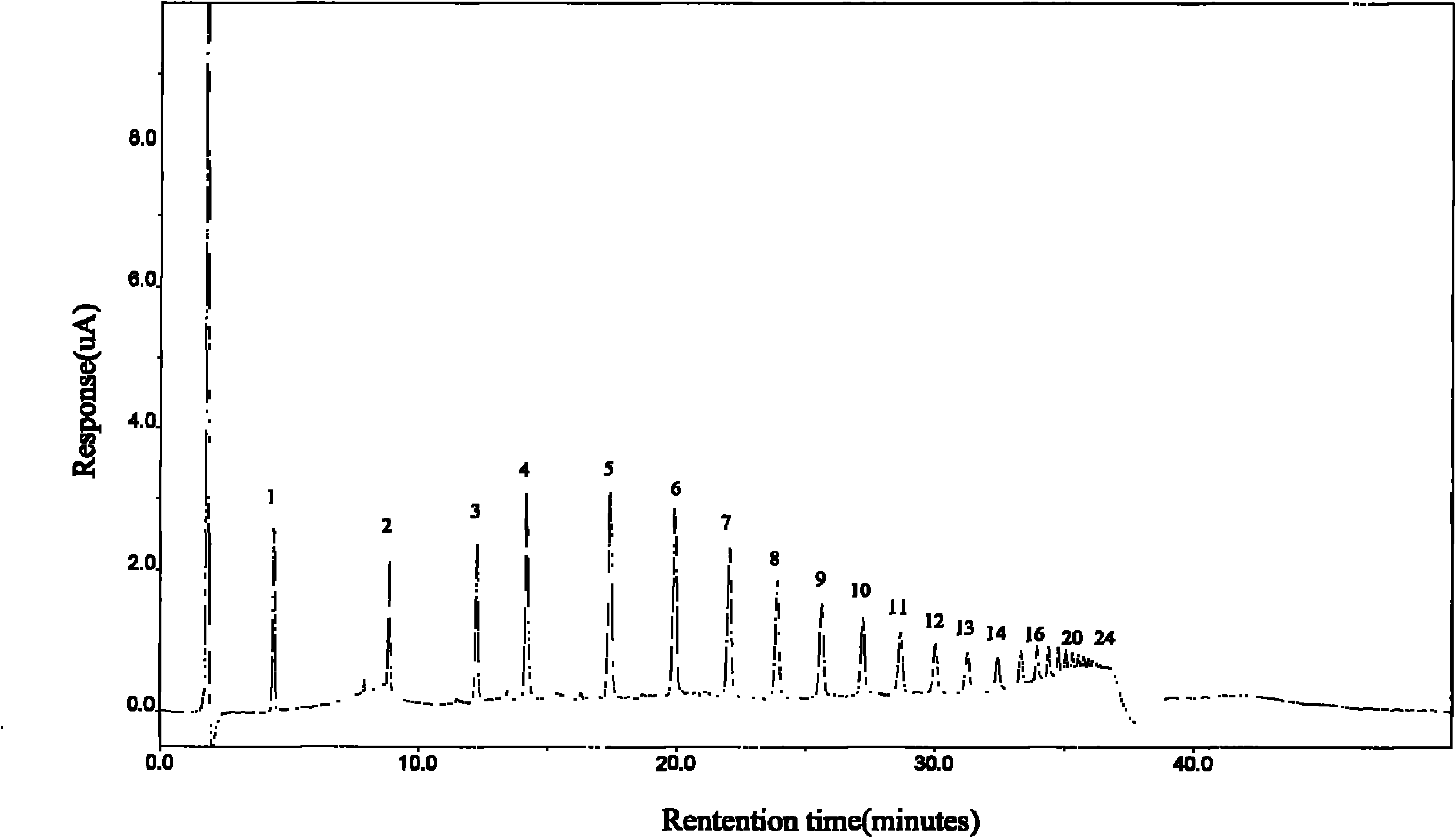

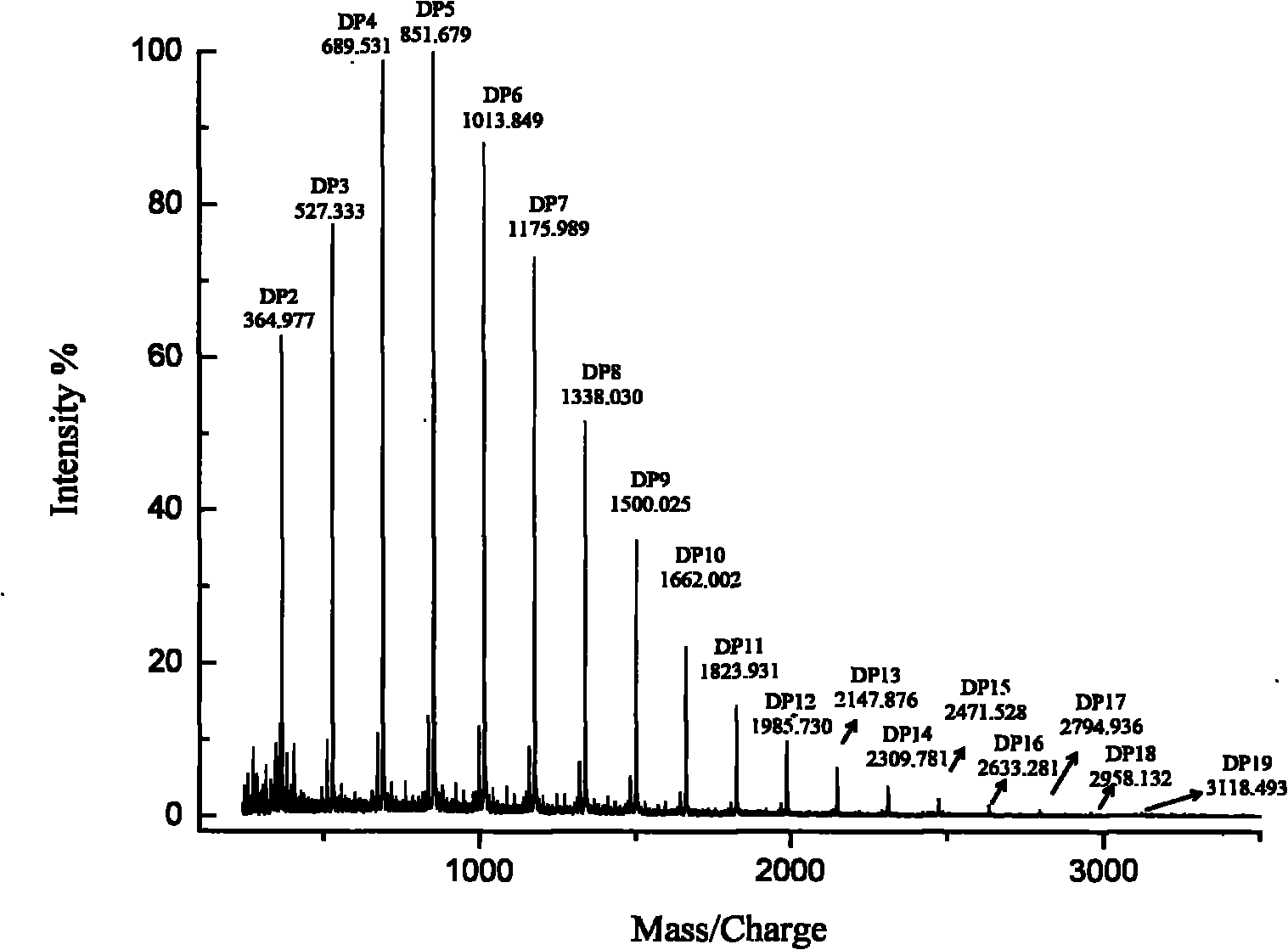

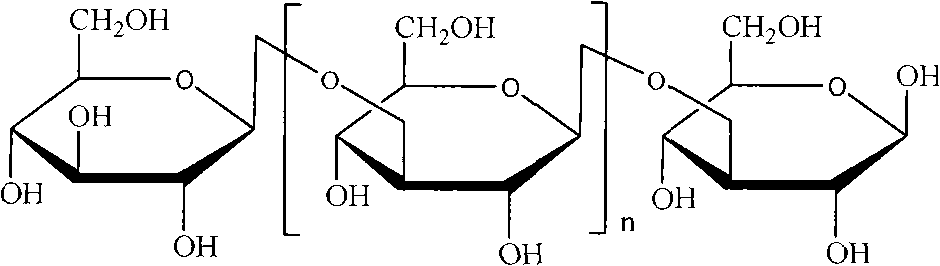

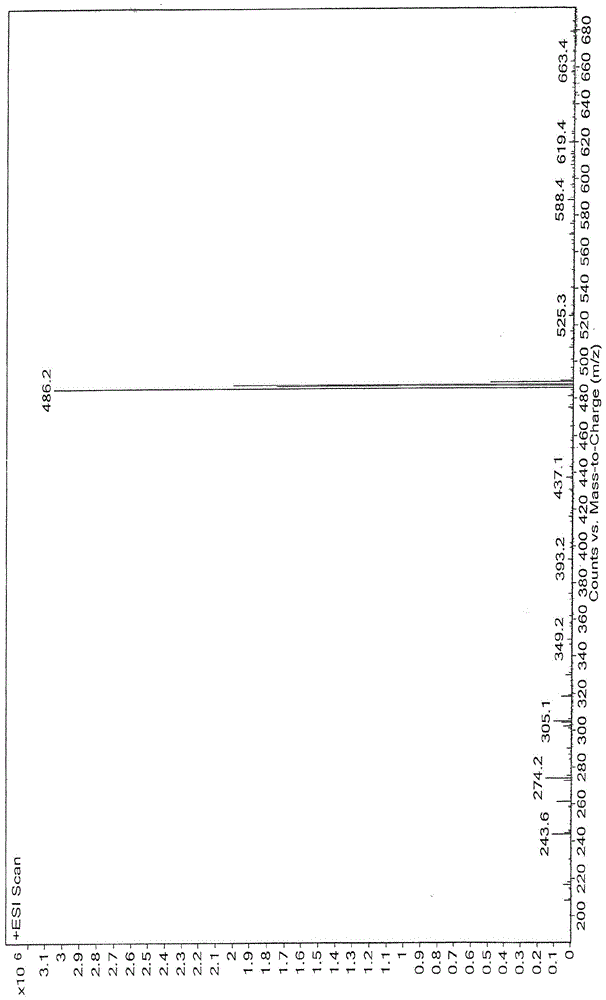

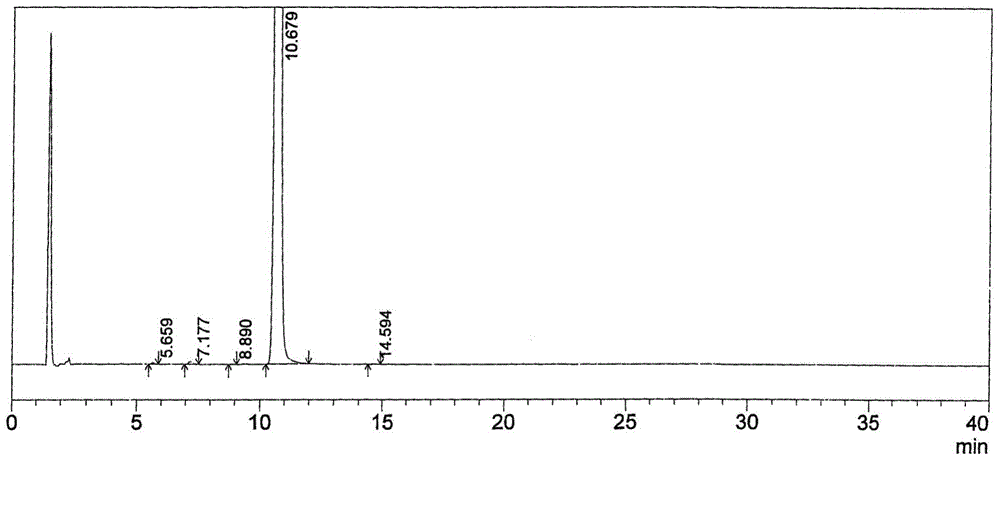

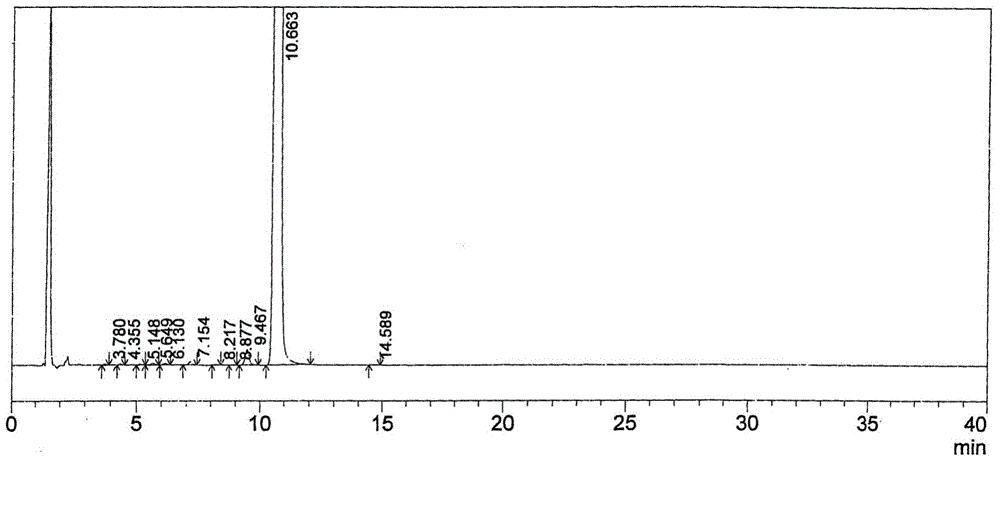

Preparation method of Curdlan oligomers

InactiveCN102312021AEasy to operateConditions are easy to controlSaccharides productionGlycosideOligomer

The invention discloses a preparation method of Curdlan oligomers. The method comprises the following steps of: fully dissolving Curdlan polysaccharide into a solvent to obtain a homogeneous solution; adding acid at a temperature in a range of 80-140 DEG C, wherein a final concentration of the acid in the solution is 0.1-10 M; reacting for 30-500 min; adding organic solvent sediments which are 3-5 times as much as the volume of reaction liquid and meanwhile, stirring and filtering to obtain a milky solid; washing the solid by the organic solvent 1-4 times to obtain the Curdlan oligomers with an average molecular weight of 340-4000 Da, which is measured by an efficient liquid phase detection after drying. The degradation efficiency of the preparation method reaches more than 85%. The Curdlan oligomers are oligomers formed by connecting glucose molecules through beta-(1->3) glucosidic bonds; the degree of polymerization (Degree of Polymerization, DP) of the Curdlan oligomers is 2-24; a molecular formula of the Curdlan oligomers is (C6H12O6)n, wherein n is equal to 2-24. The average molecular weight of the Curdlan oligomers is 340-4000 Da. The preparation method provided by the invention has a simple and controllable preparation process, short reaction time and good degradation efficiency, and is environmentally friendly and suitable for industrial production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of afatinib compound

The invention provides a novel preparation method of an afatinib compound. Raw materials and reagents used in the preparation method have the advantages of low cost, stable chemical property and convenience in long-term storage and the content of an impurity cis-isomer in the prepared afatinib compound is very low.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD +1

Jiangzhining dispersible tablets and preparation method thereof

InactiveCN104352594AImprove solubilityGood dispersionMetabolism disorderDigestive systemBlood lipidsTraditional medicine

The invention provides Jiangzhining dispersible tablets and a preparation method thereof. The Jiangzhining dispersible tablets are prepared from the following raw materials: 10-60% of traditional Chinese medicine extract, 15-70% of filling agent, 5-50% of internally added disintegrating agent, 5-15% of externally added disintegrating agent, 0.1-15% of flavoring agent, 0.1-12% of wetting agent, 0.05-5% of lubricating agent and 0.1-20% of flow aid, wherein the traditional Chinese medicine extract comprises the following raw materials: hawthorns, radix polygonum multiflorum preparata, semen cassiae and lotus leaves. The Jiangzhining dispersible tablets have the functions of reducing blood lipid and blood pressure, tonifying middle-Jiao and qi and strengthening and consolidating body resistance, have good solubility and dispersibility, high dissolution rate and good bioavailability, are fast in body distribution, have stable quality and good tastes, are convenient to take and can be swallowed and chewed.

Owner:HEILONGJIANG ZHICHENG MEDICAL TECH

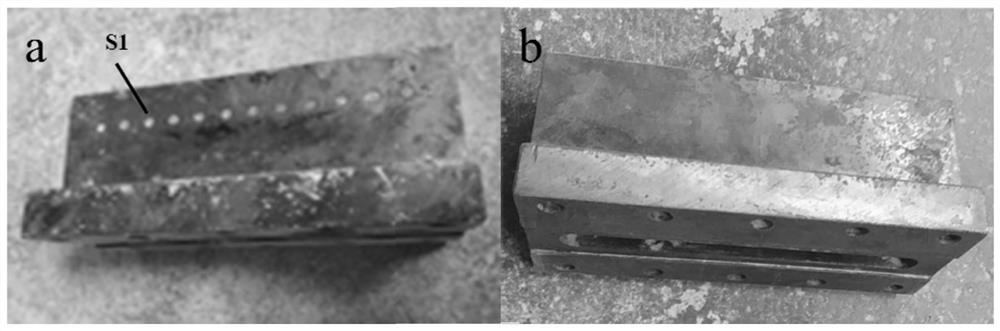

Preparation method for surface-reinforcing coating of copper crystallizer

InactiveCN104278269AWith industrial productionSolving Metallurgical Bonding ProblemsMetallic material coating processesCopperCoating

The invention discloses a preparation method for a surface-reinforcing coating of a copper crystallizer. The method employs a plasma powder built-up welding or spray welding technology. Plasma between a welding gun and the surface of the copper crystallizer is sent to an alloy powder, and the alloy powder and a copper base material are melt under the high temperature of plasma and form a molten pool, the technological parameters of built-up welding or spray welding are adjusted for enabling the copper-plate base material to be slightly molten, the welding gun moves forwards and forms a welding channel, and welding channels reciprocates and are overlapped for forming the metallurgy combined reinforcing coating on the surface of the copper crystallizer. The method helps to effectively solve the metallurgy combination problem between the coating and the copper crystallizer base body, possesses advantages of both production efficiency and cost, and makes industrialization of the metallurgy-combined copper-crystallizer surface reinforcing coating possible.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

Detoxication method for jatropha curcas and meal thereof

InactiveCN102090512ASimple processReduce manufacturing costFood processingAnimal feeding stuffWater contentSolvent

The invention discloses a detoxication method for jatropha curcas and meal thereof. The method comprises the following steps: husking, crushing and flaking the jatropha curcas, then adding 12%-18% of hot water for hardening and tempering, and steaming and stir-frying for 70-100 minutes at the temperature of 95-110 DEG C in a steaming and stir-frying pot; squeezing materials till the residual oil content is 14-17%, soaking a press cake in a No. 6 solvent or n-hexane for 3-5 times till the residual oil content is reduced to 0.3%-1.5%, and performing direct steaming and stir-frying on jatropha curcas meal for exsolution so as to reduce the water content to 5%-8%; and extracting extracted meal with ethanol, and performing the direct steaming and stir-frying on the ethanol extracted meal for exsolution so as to reduce the water content to 10%-12%, thus obtaining the detoxicated jatropha curcas meal. By adopting the method, the purpose of detoxicating the jatropha curcas can be simultaneously achieved while the oil making process is performed, the process is simple, the production cost is low, and the loss of the raw materials is low, thereby having value for industrial production. The detoxicated meal of the jatropha curcas, which is obtained by using the method, can be used in the feed industry as a feed protein additive.

Owner:CHINA NAT OFFSHORE OIL CORP +2

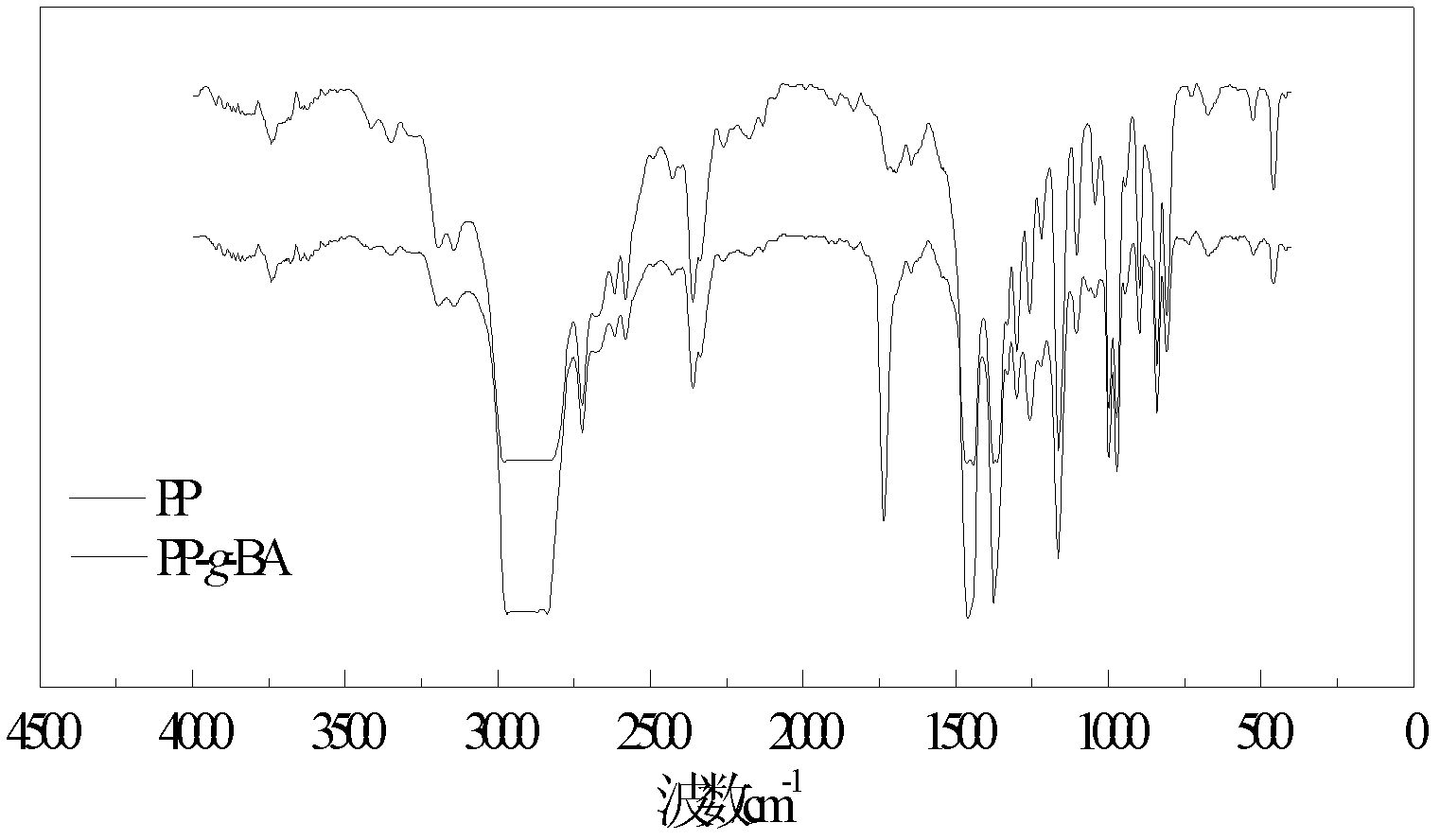

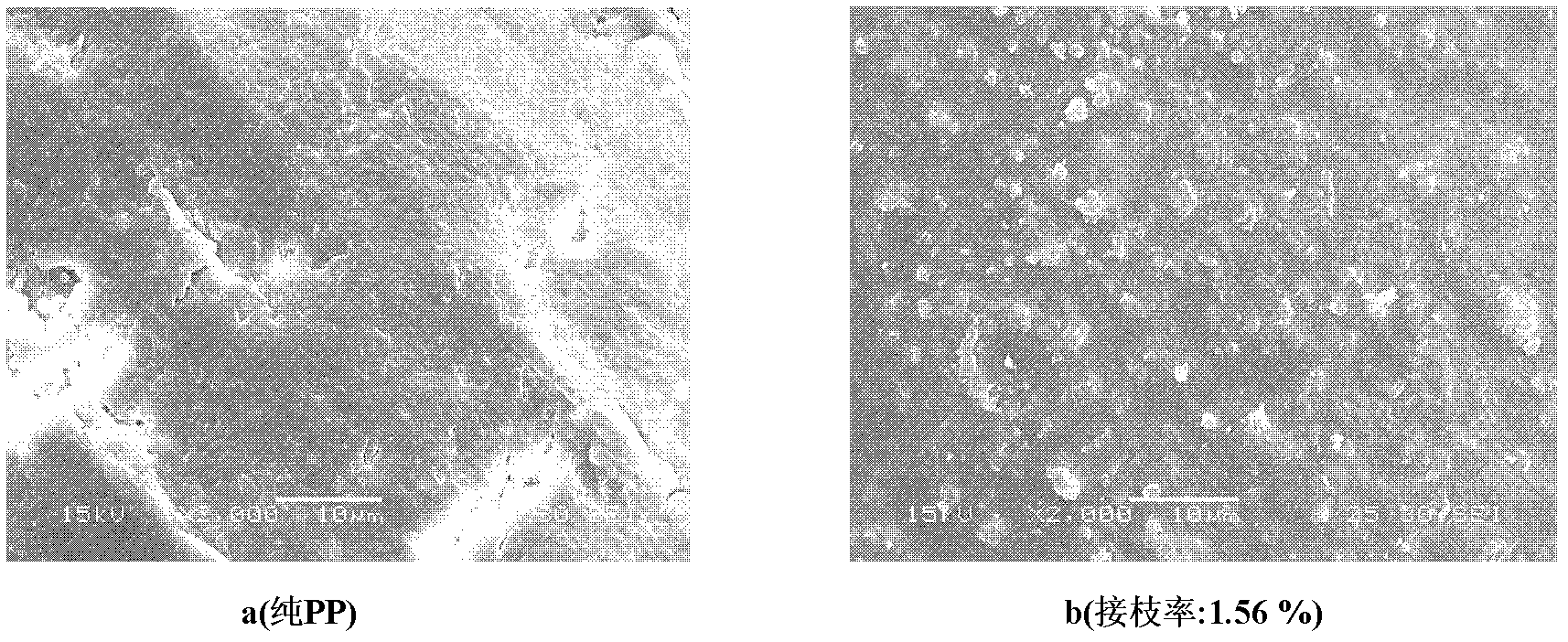

Method for carrying out solid-phase grafting modification on polypropylene by assistance of supercritical carbon dioxide

InactiveCN102863588AImprove thermal performanceIncrease polarityBulk chemical productionSwelling pressurePolypropylene

The invention relates to a method for carrying out solid-phase grafting modification on polypropylene by assistance of supercritical carbon dioxide. The method comprises the following steps of: swelling the polypropylene for 0.5-10 hours in the supercritical carbon dioxide dissolved with vinyl monomer and an initiating agent, and then slowly releasing pressure; transferring the swelled polypropylene into a reaction kettle, adding interfacial dimethylbenzene according to the mass ratio with the polypropylene of being 1%, rising the temperature to 65-165 DEG C under normal pressure, and reacting for 1-10 hours to obtain a target product, wherein the swelling and penetrating temperature in the swelling process is 31-60 DEG C, and the swelling pressure is 7.5-12MPa; the initiating agent is an azo compound or peroxide, and the mass of the initiating agent is 0.1-5.0% of the mass of the polypropylene; and the mass of the vinyl monomer is 0.2-20% of the mass of the polypropylene. According to the method, the grafting rate reached 5.40%, and the grafting efficiency is over 90%. According to the method, the thermal property, the polarity and the mechanical property and the like are obviously improved and the hydrophilcity is obviously improved.

Owner:PETROCHINA CO LTD

Preparation method and application of honeycomb type sulfur dioxide catalyst

InactiveCN102716756ALow costHigh strengthCatalyst carriersDispersed particle separationActive componentHoneycomb

The invention relates to a preparation method and application of a honeycomb type sulfur dioxide catalyst, particularly relates to a honeycomb type catalyst for oxidizing sulfur dioxide into sulfur trioxide and a preparation method of the honeycomb type catalyst, and belongs to the technical field of environmental purification. Silicon oxide or another substance such as silicon-aluminum oxide is used as a carrier, and a product is formed after active components and forming auxiliaries are added into the carrier and is dried and calcined to prepare the honeycomb type sulfur dioxide catalyst. The honeycomb type sulfur dioxide catalyst is prepared by the mixing preparation method, and the method includes dissolving the active components or dissolving the active components and cocatalyst compositions to obtain liquor; and mixing, kneading, ageing, drying and calcining the liquor, the carrier and the forming auxiliaries to form the catalyst. The catalyst has the advantages of wide application range, low cost, high strength, simplicity and feasibility in operation, and the like, and is applicable to industrial production. In addition, the honeycomb type sulfur dioxide catalyst can be widely used for oxidizing sulfur dioxide into sulfur trioxide and treating sulfur dioxide generated in various combustion processes and contained in industrial waste gas.

Owner:JIANGSU LONGYUAN CATALYST CO LTD

Method for purifying ethyl acetate

InactiveCN102731298AEfficient removalSafe and easy purification processOrganic compound preparationCarboxylic acid esters preparationChemical industryPurification methods

The invention discloses a method for purifying ethyl acetate, which comprises the steps of: sequentially adding 4-6wt% sodium sulfite solution and saturated calcium chloride solution into industrial-grade ethyl acetate serving as a raw material; stirring to remove organic impurities in ethyl acetate; then sequentially adding anhydrous potassium carbonate for drying and 4A molecular sieve for adsorbing and purifying; and finally collecting purified ethyl acetate by a rectification method, wherein the purity of ethyl acetate purified by the method is more than 99.5%. Compared with the prior art, the method is safe, simple and convenient in the purification process, and can save energy and reduce emission; after being treated, the added purifying agent can be recycled, so that the method is in accordance with the requirements of green chemical industry and environmental protection; and the ethyl acetate product purified by the method is stable in quality and high in purity, and has the prospect of industrial production.

Owner:TAICANG HUSHI REAGENT

Silver nitrate purifying method

The invention discloses a silver nitrate purifying method. Industrial-grade silver nitrate is taken as the raw material; the deionized water is added into the silver nitrate; stirring operation is conducted to dissolve the silver nitrate into the deionized water; then a complexing agent (A) independently researched and developed by the company is added to hydrolyze and precipitate various impurities; and the filtered solution is collected through the conventional method to obtain the purified silver nitrate. The purity of the silver nitrate obtained through the silver nitrate purifying method is up to more than 99.99%, the yield is 95-98%; the contents of foreign ions of both heavy metal and precious metal are lower than 1 ppm; compared with the prior art, through the adoption of the complexing agent (A) independently researched and developed by the company, the foreign ions of heavy metal and precious metal in the industrial-grade silver nitrate can be effectively removed; the product quality is stable; the operation is simple and convenient; the energy consumption is low; the purity is high, and therefore, the silver nitrate purifying method has the prospect of industrial production.

Owner:TAICANG HUSHI REAGENT

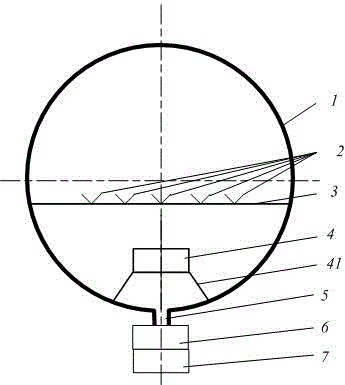

Hot and light balloon

The invention relates to a hot and light balloon, in particular to a hot and light balloon which is internally provided with high-temperature light gas, can suspend in the air at a certain height and can be controlled to descend. The hot and light balloon is composed of a bag body, a structure net, a plurality of turbulators, a remote control heating module installed in a hot balloon body through a support, a gas nozzle, a state sensor and controller module, a gas pump and a gas storage device. When the bag body is full of hot and light gas, the load capacity of the hot and light balloon is the highest; when the mass of the light gas in the bag body is small and the temperature of the light gas in the bag body is low, the bag body is deformed under the action of air pressure outside the bag body, the size is reduced, and the load capability of the hot and light balloon is reduced.

Owner:台州科金中高技术转移有限公司

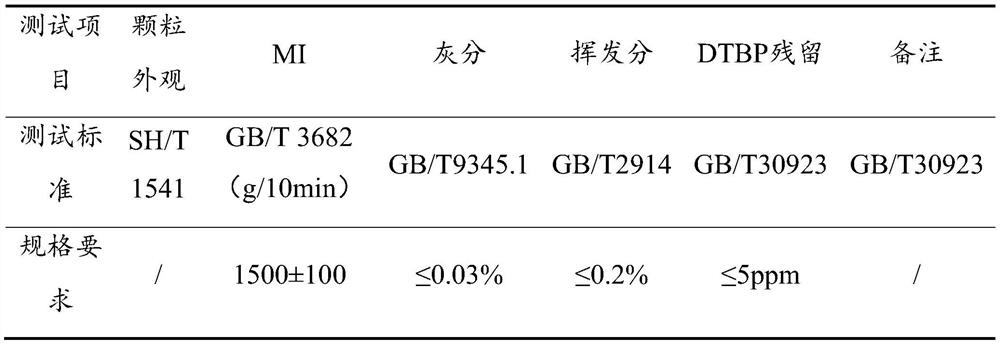

Melt-blown polypropylene material as well as preparation equipment and method thereof

The invention discloses a melt-blown polypropylene material and a preparation method thereof, and belongs to the technical field of polypropylene. The melt-blown polypropylene material is prepared from the following raw materials of: 94 to 94.2 parts of homopolymerized polypropylene resin with a melt index of 20 to 30g / 10min; 0.5 to 0.6 part of a chain breaking agent; 3 to 7 parts of a softener; 0.1 to 0.2 part of a nucleating agent; and 0.1 to 0.2 part of an antioxidant. Equipment for producing the melt-blown polypropylene material is improved; a screw rod with the screw length-diameter ratiohigher than 52: 1 is used in the equipment, the proportion of a mixing section in a screw combination is larger than or equal to 45%, the proportion of a strong shearing block in the screw combination is smaller than or equal to 10%, and the proportion of a uniform conveying section after vacuum extraction in a conveying section is larger than or equal to 30% of the total length after extraction.The melt-blown polypropylene material prepared by the formula and the equipment has a high melt index; the ash content and volatile components of the material are controlled at a low level; the material meets national standards. The preparation method is simple, adopts easy-to-obtain raw materials and is suitable for industrial production.

Owner:GUANGDONG JUSHI CHEM CO LTD

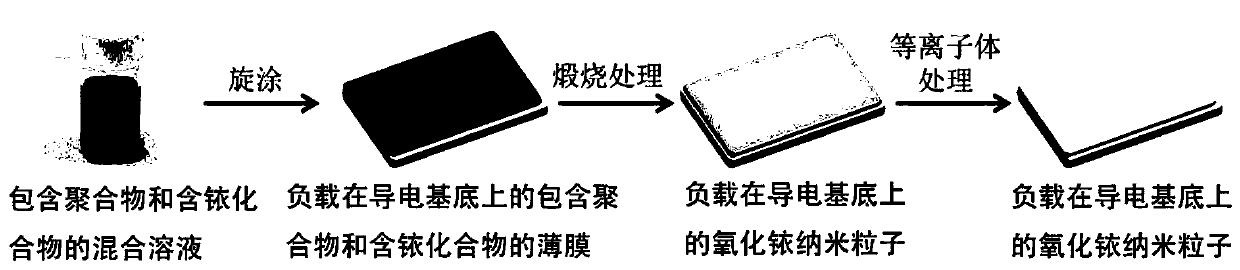

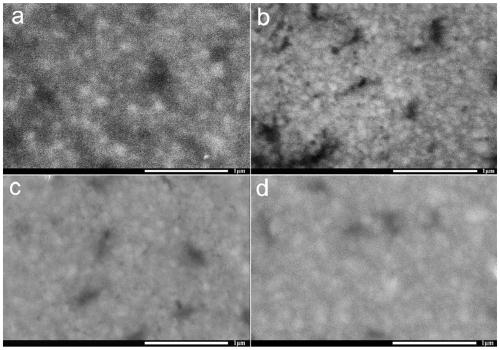

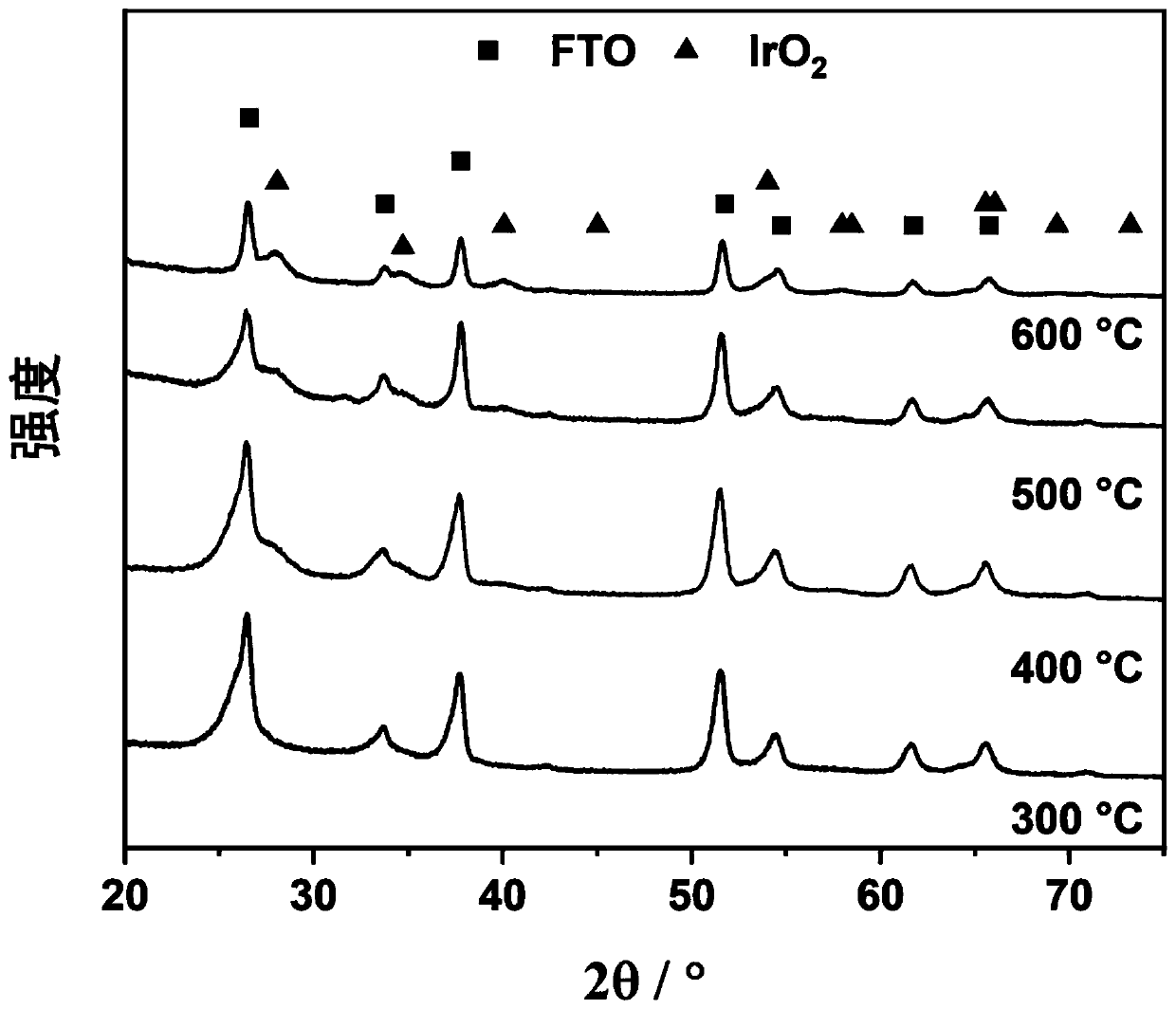

Preparation method and application of iridium oxide nanoparticle catalyst

ActiveCN111375408ASmall particle sizeLarge electrochemical active areaMaterial nanotechnologyRuthenium/rhodium/palladium/osmium/iridium/platinum oxides/hydroxidesPtru catalystPlasma generator

The invention discloses a preparation method and application of an iridium oxide nanoparticle catalyst. A mixed solution containing a polymer and an iridium-containing compound is uniformly applied toa treated conductive substrate; calcining in an air atmosphere is carried out to convert the iridium-containing compound into iridium oxide and the polymer is decomposed at the same time; the iridiumoxide nanoparticle material which is small in particle size, amorphous and of a porous structure is obtained, polymers remaining on the iridium oxide nanoparticle material are removed through a plasma generator, and the surfaces of iridium oxide nanoparticles are rich in hydroxyl. The film formed by the polymer in the mixed solution is utilized to solve the problem that the iridium-containing compound is agglomerated to form large particles when being calcined to generate the iridium oxide nanoparticles, thereby obtaining the small-particle-size iridium oxide nanoparticles. Besides, the plasma generator is used for removing residual polymers in the calcining process, the contact area of the iridium oxide nano particles is increased, and therefore the catalytic efficiency of the iridium oxide nano particles is improved.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Preparation method of photocatulyzed active bromine adulerated titanium dioxide nano-material

InactiveCN1556151AImprove photon quantum efficiencyAchieve full frequency absorptionInorganic pigment treatmentTitanium dioxideQuantum efficiencyNano catalyst

A Br doped nano TiO2 material with photocatyletic activity is prepared by introducing Br to TiO2 crystal. It contains Ti (48-73 wt.%), O (26.9-42) and Br (0.1-10). Its energy gap can be triggered by visual light, so realizing full-frequency absorption of visual light and increasing the light quantum efficiency of TiO2 material.

Owner:SHANGHAI JIAO TONG UNIV

Pull assisting glove

InactiveCN105167260ALow costReduce processing costsProtective garmentMechanical engineeringEngineering

The invention relates to a wearable power assisting device, in particular to a pull assisting glove capable of providing auxiliary pull force for a wearer. The wearer consists of an elastic holding portion, a palm fixing portion and a connecting portion, wherein one end of the connecting portion is connected with the palm fixing portion, the other end of the palm fixing portion is connected with a winding belt, the winding belt of the pull assisting glove is wound on the wrist portion and the front-arm front end of a user to disperse the pull force borne by the hand, and the elastic holding portion hooks an object to be pulled to disperse the pull force borne by the fingers of the user.

Owner:唐哲敏

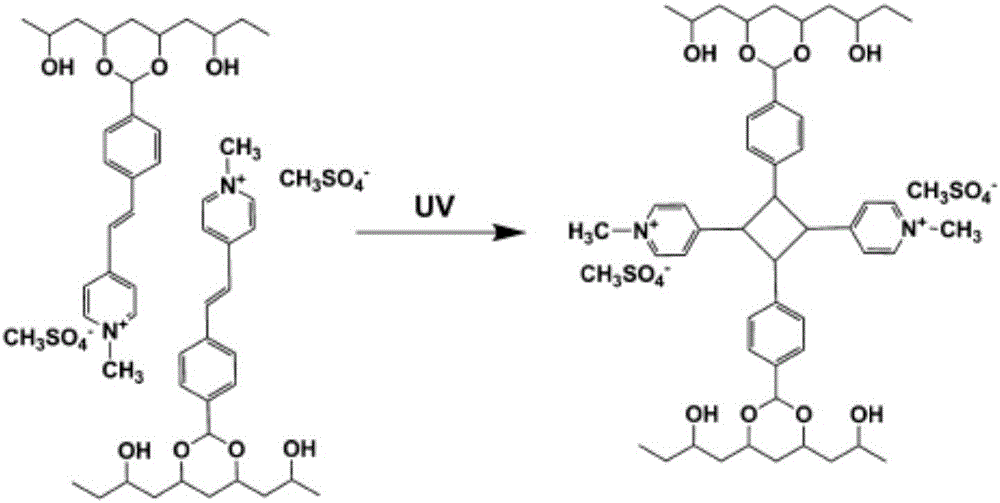

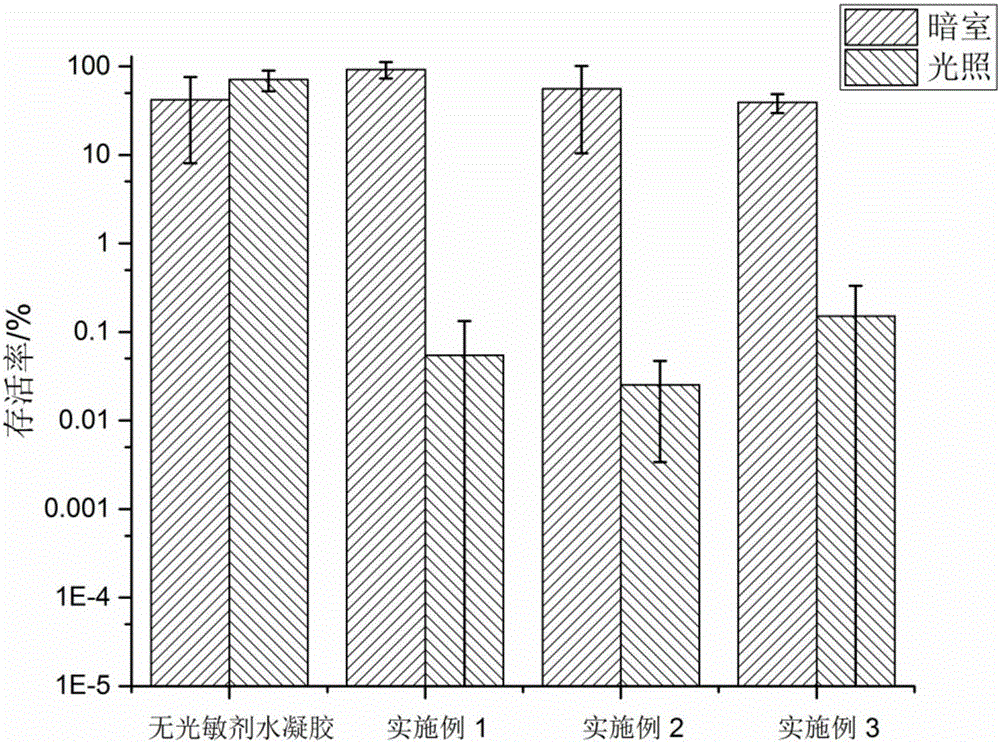

Photosensitive antibacterial hydrogel and preparation method thereof

The invention discloses photosensitive antibacterial hydrogel and a preparation method thereof.The method comprises the following steps that 1, imvite and a photosensitizer are dissolved into deionized water respectively to form an imvite water solution and a photosensitizer water solution; 2, the imvite water solution and the photosensitizer water solution are mixed to obtain a photosensitive water solution modified by imvite; 3, polyvinyl alcohol-aminostyrylpyridinium salt is dissolved into deionized water to form a water solution which is mixed with the photosensitive water solution modified by imvite obtained in the step 2; 4, finally, the mixed solution obtained in the step 3 is placed under an ultraviolet lamp to be irradiated, so that the photosensitive antibacterial hydrogel is obtained.The photosensitive antibacterial hydrogel can generate phototoxic singlet oxygen under visual light irradiation, the singlet oxygen can efficiently kill viruses, bacteria and fungi, and no drug resistance is generated.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com