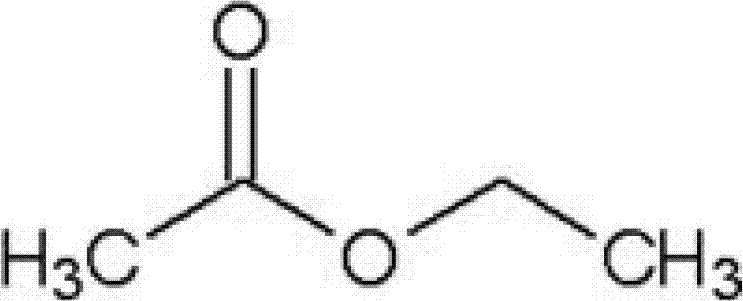

Method for purifying ethyl acetate

An ethyl acetate, purification method technology, applied in chemical instruments and methods, carboxylate preparation, organic chemistry and other directions, can solve the problems of complicated operation steps, long time, high cost, and achieve a safe and simple purification process, stable quality, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Add 1000ml of industrial ethyl acetate into a 2000ml three-neck flask equipped with rectification device, thermometer, heating and stirring device, add 20ml of sodium sulfite solution with a mass fraction of 4% and 10ml of saturated calcium chloride solution in turn, and stir for 10min to remove Organic impurities in ethyl acetate, then add 50g of anhydrous potassium carbonate, heat and reflux for 1h, then add 40g4A molecular sieves for adsorption and purification for 20min, and finally carry out rectification and collection at a flow rate of 20mL / min to obtain 907ml of purified ethyl acetate, the yield It is 90.7%, and the purity is 99.53%.

Embodiment 2

[0021] Add 1000ml of industrial ethyl acetate into a 2000ml three-necked flask equipped with rectification device, thermometer, heating and stirring device, add 25ml of sodium sulfite solution with a mass fraction of 5% and 15ml of saturated calcium chloride solution in turn, and stir for 15min to remove Organic impurities in ethyl acetate, then add 60g of anhydrous potassium carbonate, heat and reflux for 1.5h, then add 50g4A molecular sieves for adsorption and purification for 25min, and finally carry out rectification and collection at a flow rate of 15mL / min to obtain 919ml of purified ethyl acetate, collected The rate is 91.9%, and the purity is 99.78%.

Embodiment 3

[0023] Add 1000ml of industrial ethyl acetate into a 2000ml three-neck flask equipped with rectification device, thermometer, heating and stirring device, add 30ml of sodium sulfite solution with a mass fraction of 6% and 20ml of saturated calcium chloride solution in turn, and stir for 20min to remove Organic impurities in ethyl acetate, then add 70g of anhydrous potassium carbonate, heat and reflux for 2h, then add 60g4A molecular sieves for adsorption and purification for 30min, and finally carry out rectification and collection at a flow rate of 10mL / min to obtain 927ml of purified ethyl acetate, the yield It is 92.7% and the purity is 99.91%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com