Preparation method of Curdlan oligomers

A technology of oligosaccharides and polysaccharides, which is applied in the field of degrading codlan polysaccharides to prepare codlan oligosaccharides by acid method, can solve the problem that it is not conducive to the study of oligosaccharide structure and biological activity function, and the technology of codran oligosaccharides is difficult, difficult and Cost prohibitive and other issues, to achieve the effect of enhancing natural immunity, inducing plant disease resistance, and promoting environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: the preparation method (A) of cotlan oligosaccharide

[0022] Weigh 5g of candlan polysaccharide in 50ml of potassium iodide and cadmium ethylenediamine solution (ratio: 1:1) and stir well until completely dissolved, slowly add 0.5 M oxalic acid mixed solution 3ml, reacted for 60min, precipitated with 50mL of ethanol and acetone mixed solution (V / V=1), while stirring, to obtain milky white powder, suction filtered, and vacuum dried at 50°C to obtain 4.25g, yield up to 85.12%.

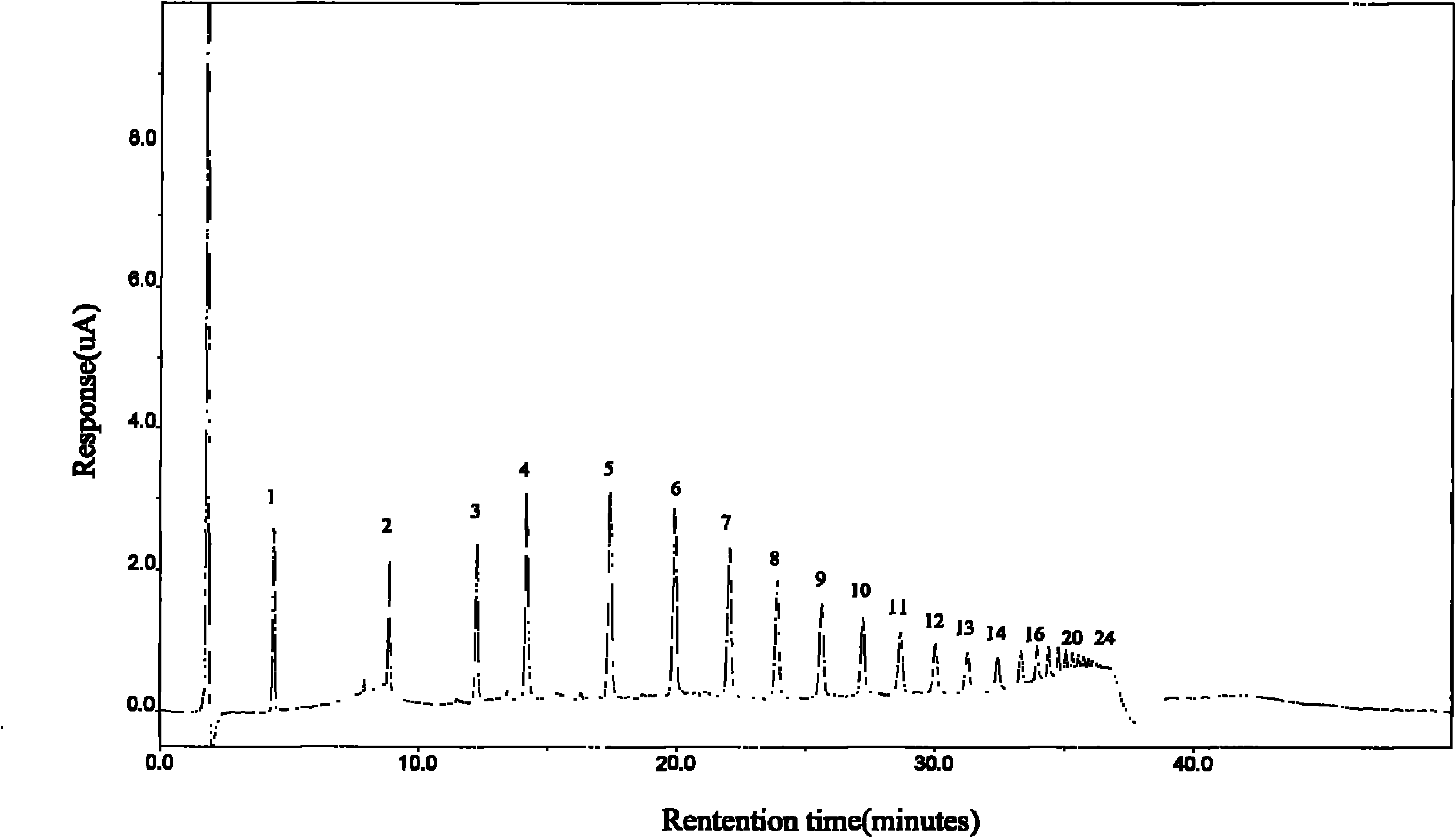

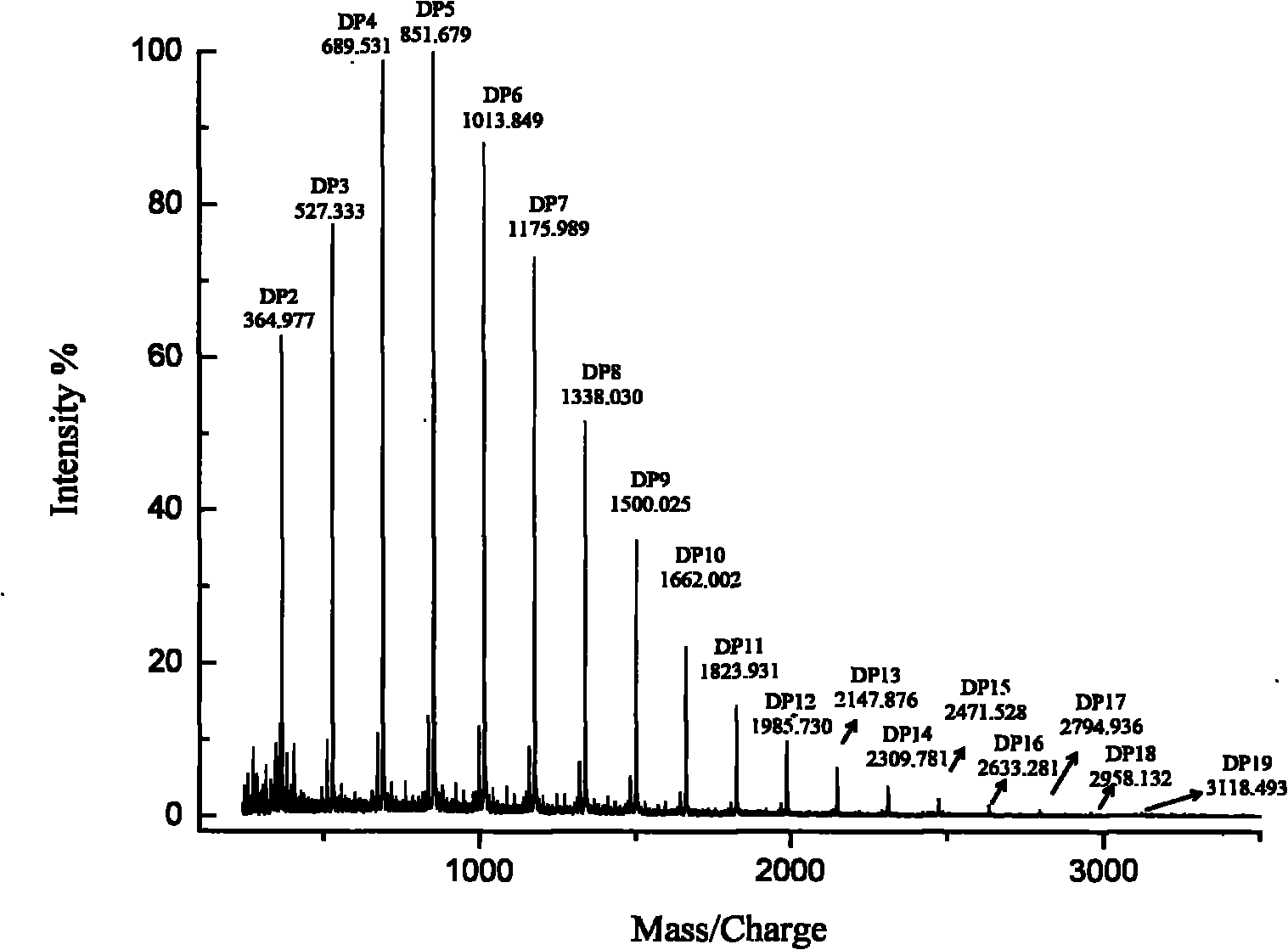

[0023] The obtained substance was proved to be Cortlan oligosaccharide by detection by high performance liquid chromatography and matrix-assisted laser desorption ionization time-of-flight mass spectrometry.

Embodiment 2

[0024] Embodiment 2: the preparation method (B) of cotlan oligosaccharide

[0025] Weigh 5g of candlan polysaccharide in 50ml of dimethyl sulfoxide and potassium iodide solution (ratio: 1:1), stir well until completely dissolved, and slowly add 3ml of 0.5M trifluoroacetic acid mixed solution, reacted for 60min, neutralized with mixed alkali solution, neutralized with mixed alkali solution, concentrated to 10ml by rotary evaporation at 45°C (can be operated at 30-150°C), and was light The yellow transparent liquid was precipitated with 50mL of a mixed solution of ethanol and acetone (V / V=1) while stirring to obtain a milky white powder, which was filtered by suction and vacuum-dried at 50°C to obtain 4.51g of cotlan oligosaccharides, with a yield of 90.2 %.

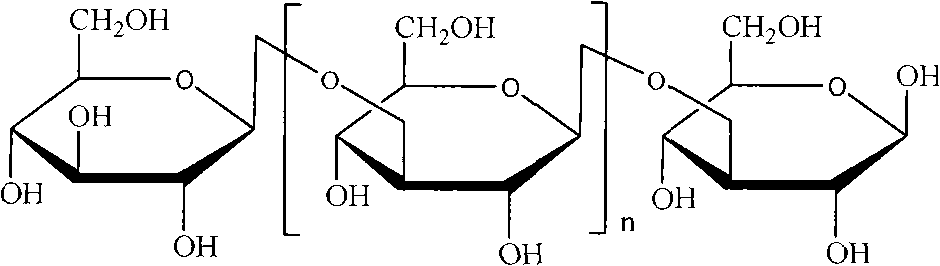

[0026] The raw material of the present invention candlan polysaccharide is so far the only β-1,3-glucan found in nature that does not contain branched chain structure, which is different from other glucans containing bran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com