Method for carrying out solid-phase grafting modification on polypropylene by assistance of supercritical carbon dioxide

A technology of carbon dioxide and solid phase grafting, applied in the production of bulk chemicals, etc., can solve problems such as high reaction pressure, environmental pollution, solvent recovery, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

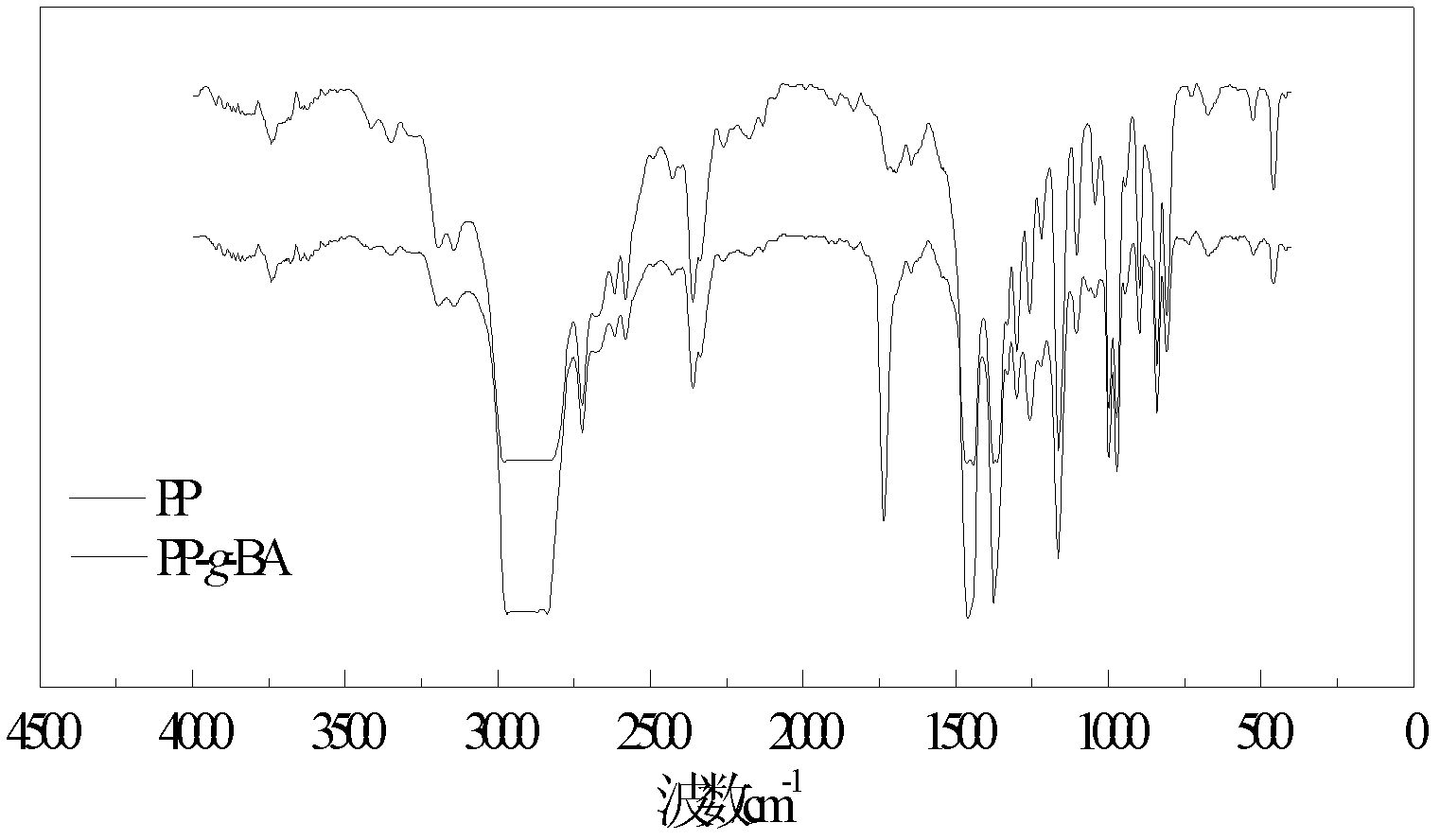

[0023] Embodiment 1 prepares PP-g-BA

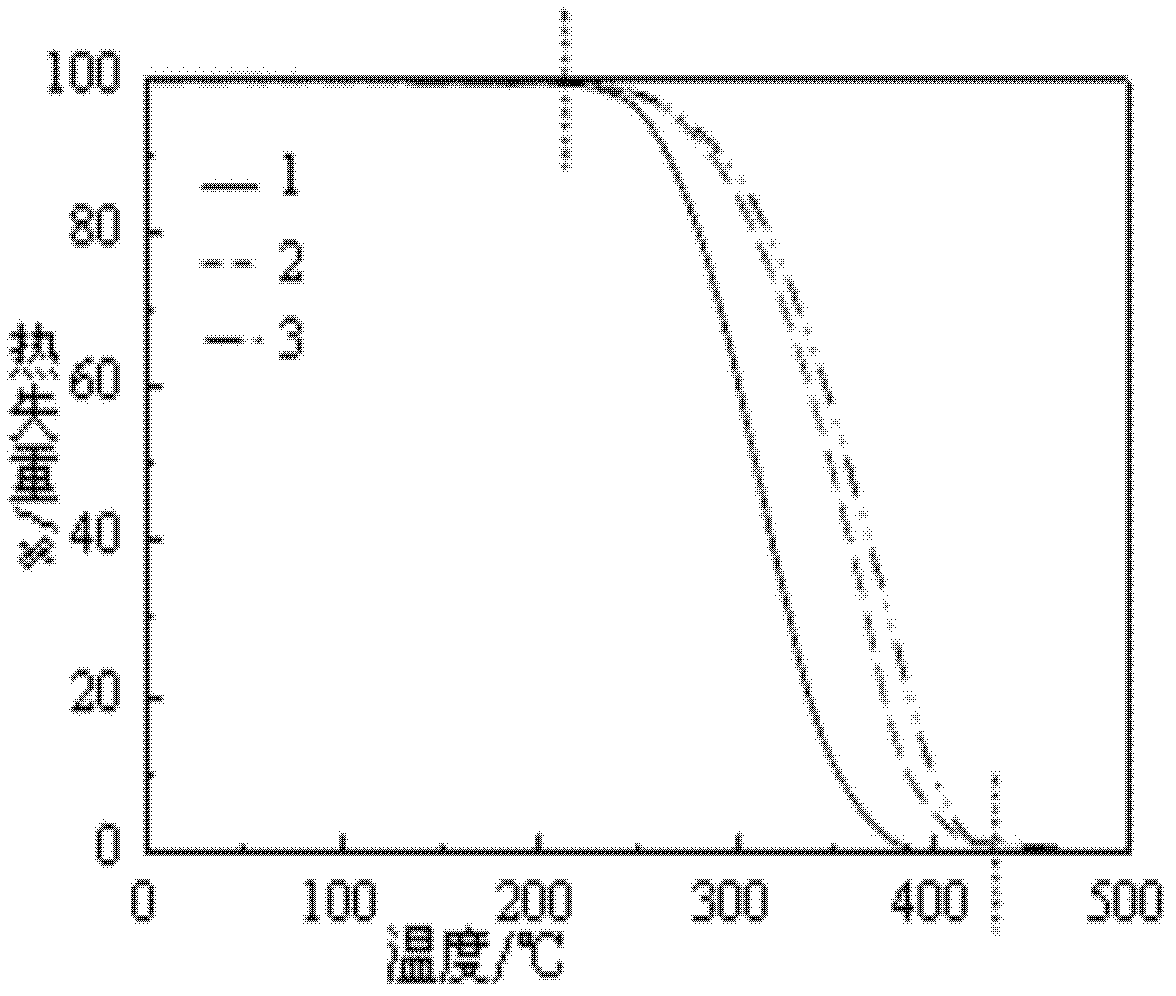

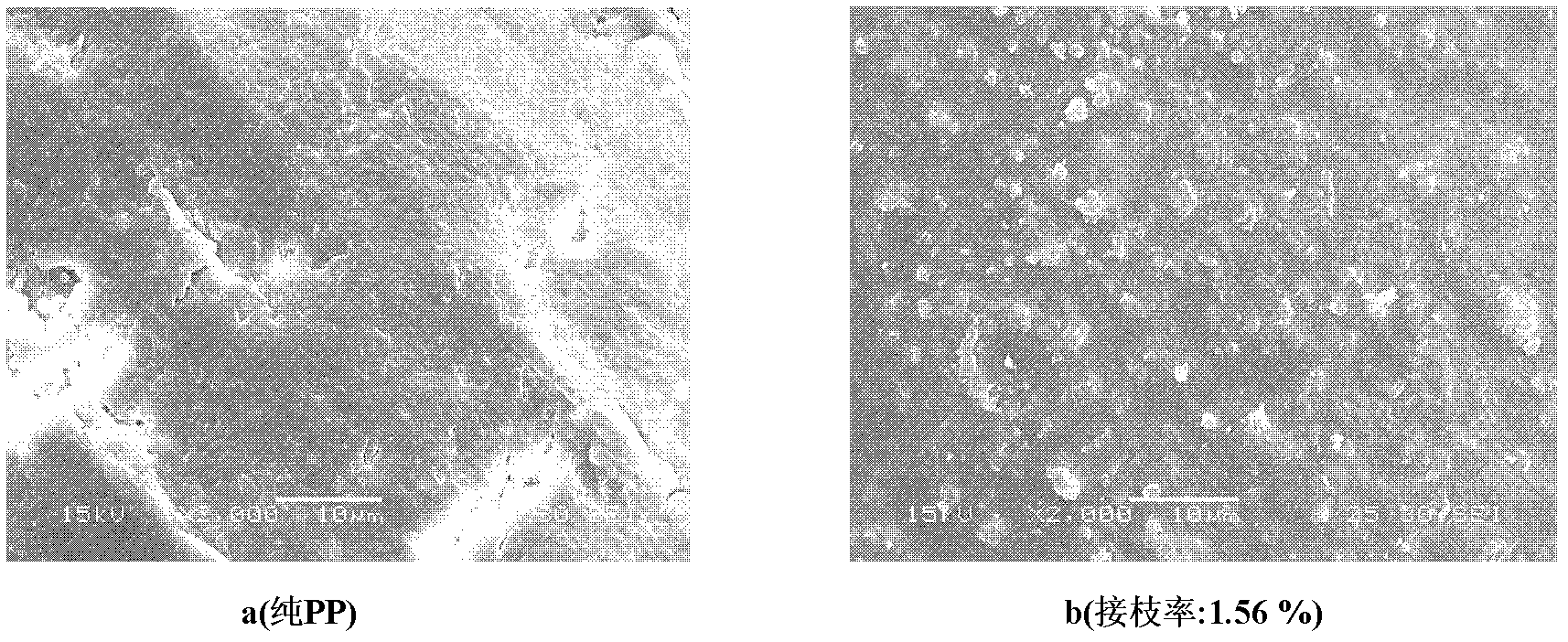

[0024] Polypropylene, butyl acrylate (BA) and initiator azobisisobutyronitrile (AIBN) are placed in the autoclave according to the mass ratio of 100 / 4 / 0.3 and 100 / 6 / 0.3 respectively, and put into the preset In the constant temperature water bath with high temperature, first fill the low-pressure carbon dioxide to replace the air in the kettle, and then use the high-pressure pump to inject carbon dioxide to the specified pressure. The swelling temperature is controlled at 41°C and the swelling pressure is 8.1MPa. After swelling for 4 hours, the autoclave was taken out, cooled with ice water, and the pressure was slowly released. Transfer the swollen polypropylene to the reactor, add the interface agent xylene at a ratio of 1% by weight to the polypropylene, pass in nitrogen, react at 80°C for 2 hours, cool the reactor, and take out sample 2 No. and No. 3 were purified, dried, and the grafting rate was calculated and characterized.

[00...

Embodiment 2

[0031] Weigh 100.0g of polypropylene with mixed particle size, add 1.0% initiator AIBN, BA is 10%, fill with CO at a temperature of 41°C 2 , the swelling pressure was 8.6MPa, and the swelling was 4h; the grafting reaction time was 2h, and the reaction temperature was 78°C; it was purified and dried, and the calculated grafting rate was 4.56%. The measured MFR of the product is 2.9g·10min -1 , the tensile strength is 34.2MPa, and the elongation at break is 680%.

Embodiment 3

[0033] Weigh 100.0g polypropylene with mixed particle size, add 0.3% initiator AIBN, AA is 5%, fill with CO under the pressure of 8.1MPa 2 , swelling for 4h, the temperature is 35°C; the grafting reaction time is 2.5h, the reaction temperature is 80°C; purification, drying, the calculated grafting rate is 2.04%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com