Preparaton method of photo catalytic active nitrogen adulterated titanium dioxide nano material

A photocatalytic activity, titanium dioxide technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

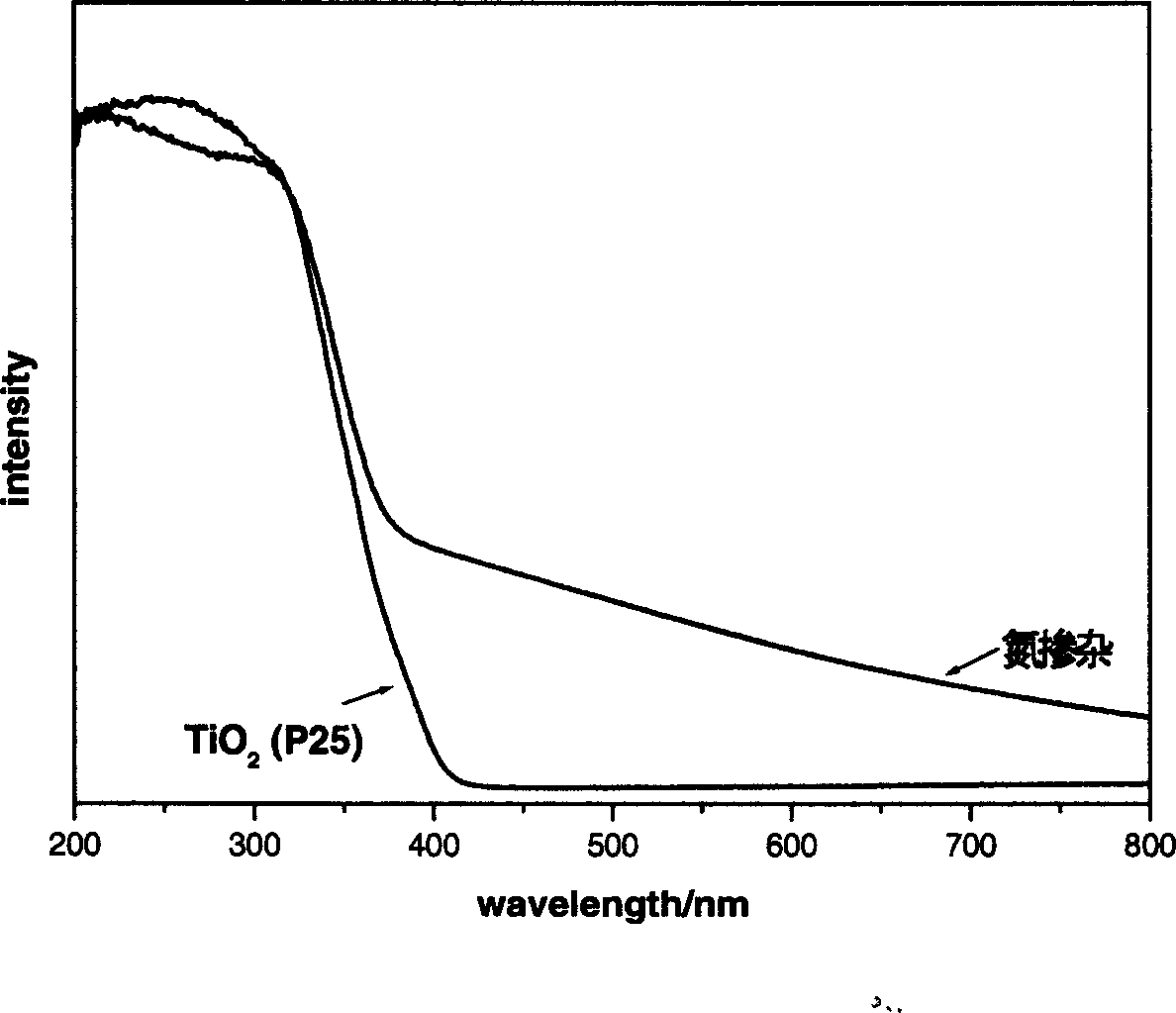

Embodiment 1

[0026] 20ml of nitrogen solution (0.5M / L) was reacted with 20ml of tetrabutyl titanate (mass percentage>98.0%) until white precipitate was completely formed. The white precipitate was directly heated in an oven, treated at 120°C for 4 hours, evaporated to remove water and part of the alcohols produced in the reaction to obtain a solid dry product. Then grind the obtained dry solid to make the particles uniform and reduce soft agglomeration. Put it into a muffle furnace after grinding, and calcinate at 400° C. for 1 hour to obtain a nitrogen-doped titanium dioxide nano-catalyst material with high catalytic activity under visible light. In the catalyst material activity test, the first order reaction kinetics apparent rate constant k=3.86×10 of this catalyst catalyzes the degradation of phenol -3 min -1 , is titanium dioxide powder (P25, Degussa) first-order reaction kinetics apparent rate constant k=1.04×10 -3 min -1 3.7 times, this is due to the nitrogen doping technology ...

Embodiment 2

[0029] Precipitate 20ml of ammonia solution (0.5M / L) and 20ml of titanium sulfate (mass percentage>40.0%) until white precipitate is completely formed. Rinse the resulting white precipitate with deionized water until the anion (sulfate ion) concentration is less than 0.5 mg / L. It was then filtered to collect the precipitated material washed with deionized water. The white precipitate was directly heated in an oven, treated at 120°C for 4 hours, evaporated to remove water and part of the alcohols produced in the reaction to obtain a solid dry product. Then grind the dry solid to make the particles uniform and reduce soft agglomeration. Then it is placed in a muffle furnace and calcined at 400° C. for 1 hour to obtain a nitrogen-doped titanium dioxide nano-catalyst material with high catalytic activity under visible light. In the catalytic activity test, the first-order reaction kinetics apparent rate constant k=3.41×10 of the catalyst material catalyzes the degradation of phe...

Embodiment 3

[0031] 20ml of ammonia water (0.5M / L) and 20ml of tetrabutyl titanate (mass percentage>98.0%) were subjected to a precipitation reaction until a white precipitate was completely formed. The white precipitate was directly heated in an oven, treated at 120°C for 4 hours, evaporated to remove water and part of the alcohols produced in the reaction to obtain a solid dry product. Then grind the obtained dry solid to make the particles uniform and reduce soft agglomeration. Put it into a muffle furnace after grinding, and calcinate at 400° C. for 1 hour, 1.5 hours, and 2 hours respectively to obtain a nitrogen-doped titanium dioxide nano-catalyst material with high catalytic activity under visible light. In the catalytic activity test, the apparent rate constants of the first-order reaction kinetics of the catalyst material to catalyze the degradation of phenol are k=3.86.×10 -3 min -1 , 3.81×10 -3 min -1 , 3.76×10 -3 min -1 . It can be seen that after heat treatment for 1 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com