Fluorine adulterated photocatalytic multicrystal material possessing photocatalytic performance under visible light

A photocatalytic, polycrystalline technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of short life, limited visible light utilization, low photocatalytic activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

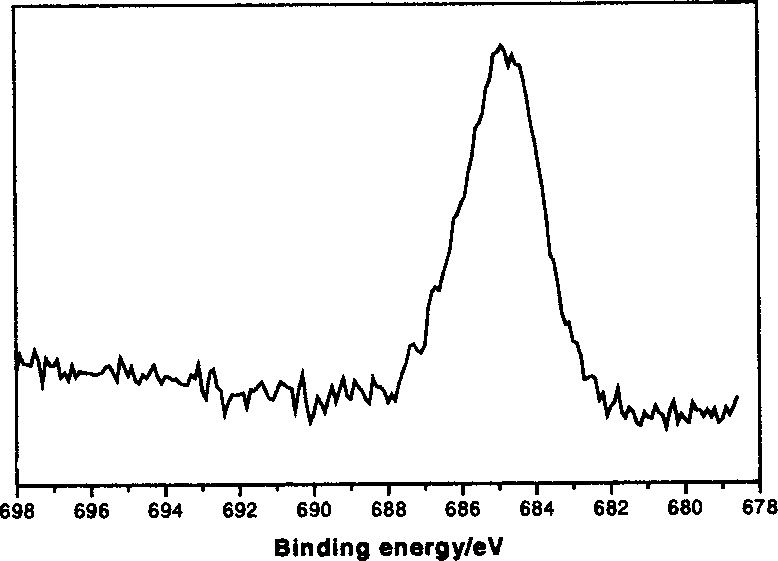

[0020] In the prepared fluorine-doped photocatalytic polycrystalline material, the content of titanium accounts for 44.6%, the content of oxygen accounts for 16.7% and the content of fluorine accounts for 38.7%.

[0021] 20ml of hydrogen fluoride solution (0.5M / L) was reacted with 20ml of tetrabutyl titanate (mass percentage>98.0%) until white precipitate was completely formed. The white precipitate was directly heated in an oven, treated at 120°C for 4 hours, evaporated to remove water and part of the alcohols produced in the reaction to obtain a solid dry product. Then grind the obtained dry solid to make the particles uniform and reduce soft agglomeration. Put it into a muffle furnace after grinding, and calcinate at 200° C. for 2 hours to obtain a fluorine-doped photocatalytic polycrystalline material with high catalytic activity under visible light.

Embodiment 2

[0023] In the prepared fluorine-doped photocatalytic polycrystalline material, the content of titanium accounts for 52.7%, the content of oxygen accounts for 39.4% and the content of fluorine accounts for 7.9%.

[0024] 12ml of hydrogen fluoride solution (0.5M / L) was reacted with 20ml of tetrabutyl titanate (mass percentage>98.0%) until white precipitate was completely formed. The white precipitate was directly heated in an oven, treated at 120°C for 4 hours, evaporated to remove water and part of the alcohols produced in the reaction to obtain a solid dry product. Then grind the obtained dry solid to make the particles uniform and reduce soft agglomeration. Put it into a muffle furnace after grinding, and calcinate at 450° C. for 2 hours to obtain a fluorine-doped photocatalytic polycrystalline material with high catalytic activity under visible light.

Embodiment 3

[0026] In the prepared fluorine-doped photocatalytic polycrystalline material, the content of titanium accounts for 50.6%, the content of oxygen accounts for 22.2% and the content of fluorine accounts for 27.2%.

[0027] 15ml of hydrogen fluoride solution (0.5M / L) was reacted with 20ml of tetrabutyl titanate (mass percentage>98.0%) until a white precipitate was completely formed. The white precipitate was directly heated in an oven, treated at 120°C for 4 hours, evaporated to remove water and part of the alcohols produced in the reaction to obtain a solid dry product. Then grind the obtained dry solid to make the particles uniform and reduce soft agglomeration. Put it into a muffle furnace after grinding, and calcinate at 285° C. for 2 hours to obtain a fluorine-doped photocatalytic polycrystalline material with high catalytic activity under visible light.

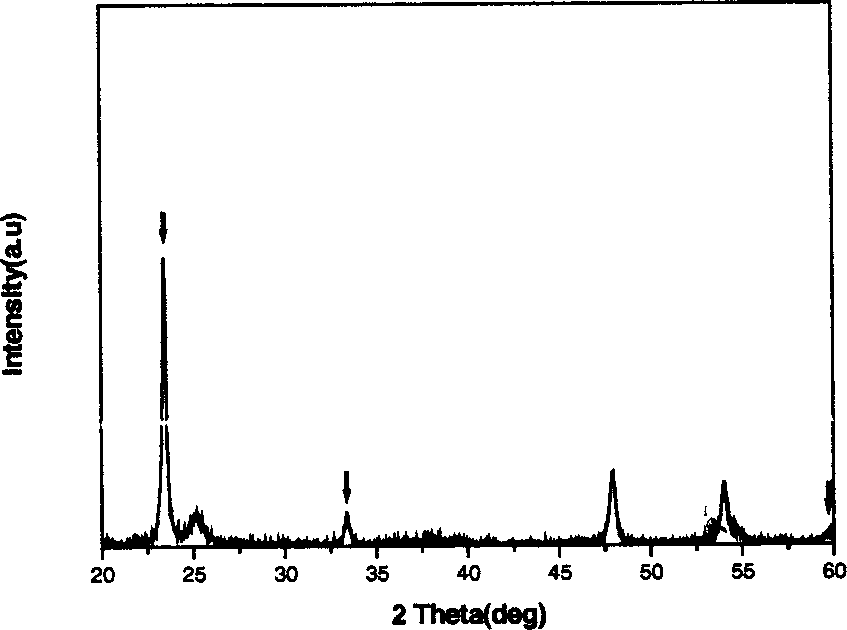

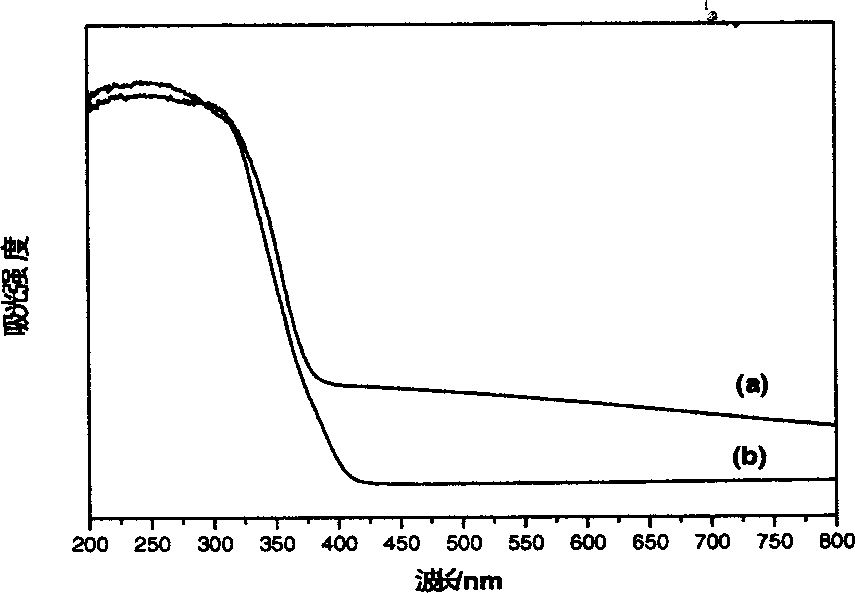

[0028] Such as figure 1 As shown, by X-ray diffraction detection, in Example 3, the crystalline phase of the fluorine-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com