Method for preparing Ti-Fe alloy oxide photonic crystal electrode with high periodicity

A photonic crystal and periodic technology, applied in the field of nanomaterials, can solve the problems of reducing the high specific surface area of nanotubes, destroying the pipe structure, and uneven doping, etc., and achieve the effect of enhanced photocatalytic activity, strong visible light absorption, and easy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

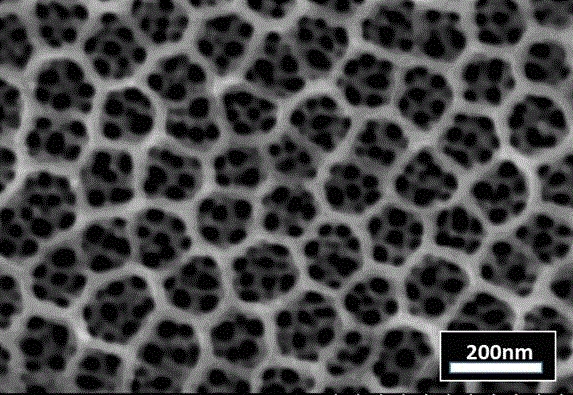

[0024] Before anodizing, Ti6Fe (6 wt % Fe) was polished with 180 mesh, 320 mesh, 600 mesh and metallographic sandpaper in sequence to make the surface uniform and smooth as a mirror surface, and then ultrasonically cleaned in distilled water and acetone for 15 min each, Finally in N 2 Dry at room temperature under atmosphere. At room temperature, the pretreated titanium-iron alloy plate was used as the anode, and the Pt sheet was used as the counter electrode. 4 F and 2vol% H 2 The ethylene glycol solution of O was used as the electrolyte, and the distance between the electrodes was 1 cm. Under magnetic stirring, firstly, the titanium-iron alloy plate was anodized under 60V constant potential condition for 3h, and then the obtained nanotubes were ultrasonically removed in deionized water; then the same plate was anodized under 60V constant potential condition for 1h, using The same method was used to remove the obtained nanotube layer; finally, the same plate was anodized a...

Embodiment 2

[0027] The pretreatment of the titanium-iron alloy plate and the anodizing electrolyte are the same as in Example 1. The titanium-iron alloy plate was anodized at a constant potential of 60V for 3h, and then the obtained nanotubes were ultrasonically removed in deionized water, and then the same plate was anodized at a constant potential of 20V, 25V and 30V for 30min respectively. The treatment after anodization was the same as in Example 1, and Ti-Fe-O NTPC (cracked) was prepared.

Embodiment 3

[0029] The pretreatment of the titanium-iron alloy plate and the anodizing electrolyte are the same as in Example 1. The ferro-titanium alloy plates were anodized at constant potentials of 20V, 25V and 30V for 30min respectively. The treatment after anodization was the same as in Example 1, and Ti-Fe-O NTPC was prepared.

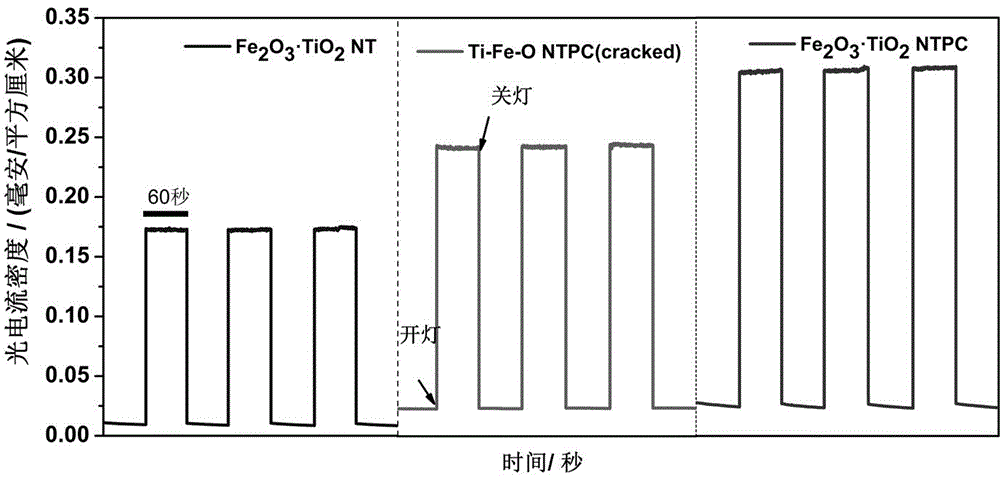

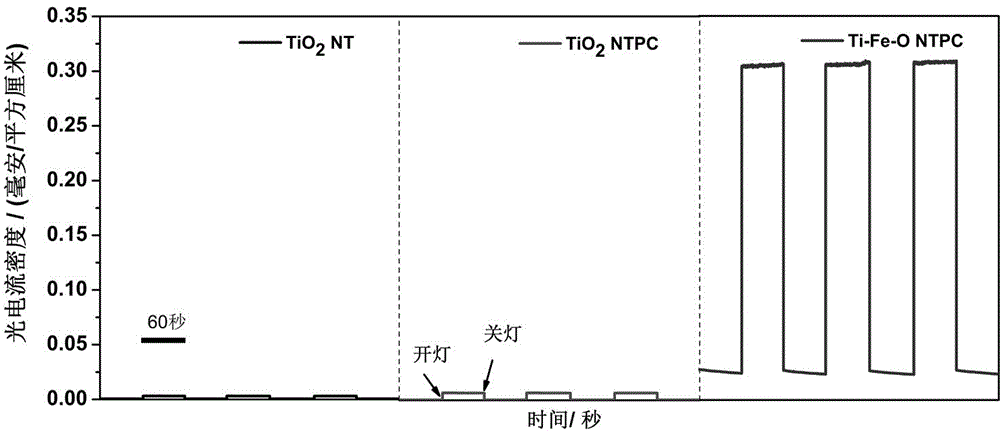

[0030] figure 2is the current density map of nanotube nanomaterials synthesized in Examples 1, 2 and 3 of the present invention, which shows that layered Ti-Fe-O NTPC electrodes have higher photocurrents compared to pure Ti-Fe-O NTs The dense, highly ordered nanonetwork can enhance the photoelectric response of the electrode by increasing the visible light absorption and the presence of the upper nanonetwork can also increase the specific surface area of the electrode. Compared with the highly ordered Ti-Fe-O NTPC, the photocurrent density of Ti-Fe-O NTPC (cracked) under the same test conditions is lower, which may be due to its weaker visible light abs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com