Patents

Literature

54results about How to "The process is easy to scale up" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing polyvinylidene fluoride affinity membrane using amino acid as ligand

InactiveCN101596422AImprove adsorption efficiencyStable physical and chemical propertiesSemi-permeable membranesHaemofiltrationPolyvinylidene difluorideBlood plasma

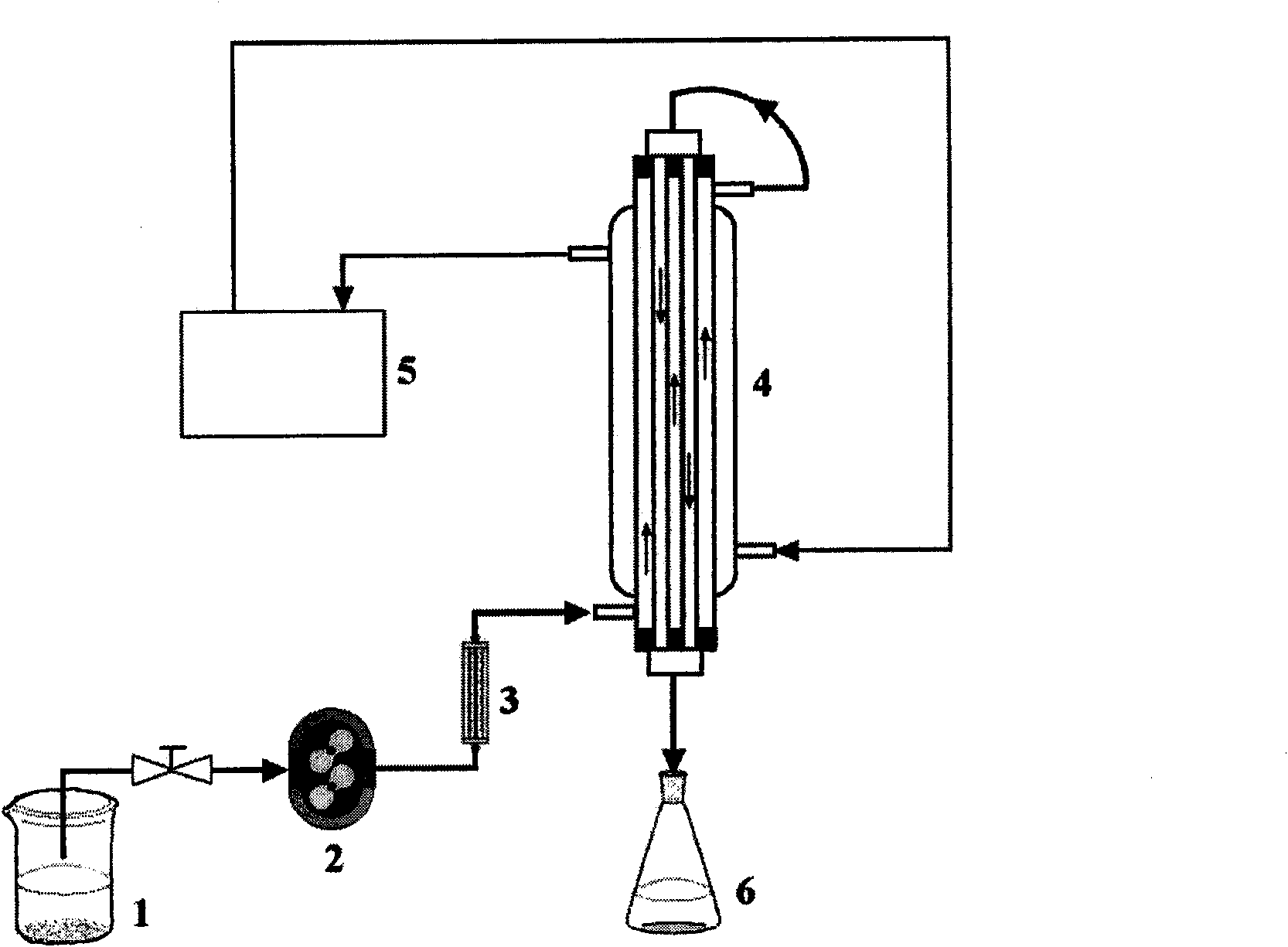

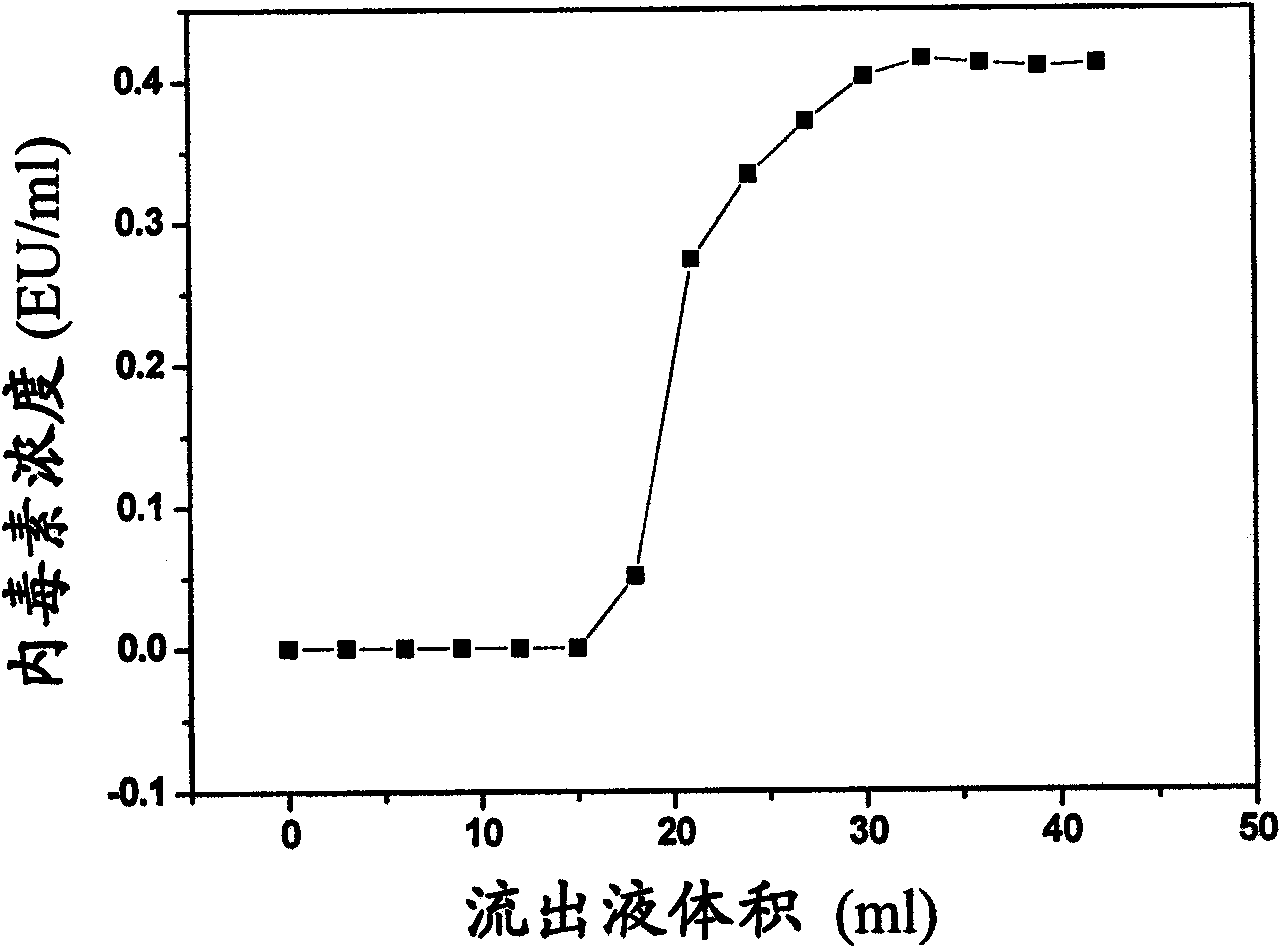

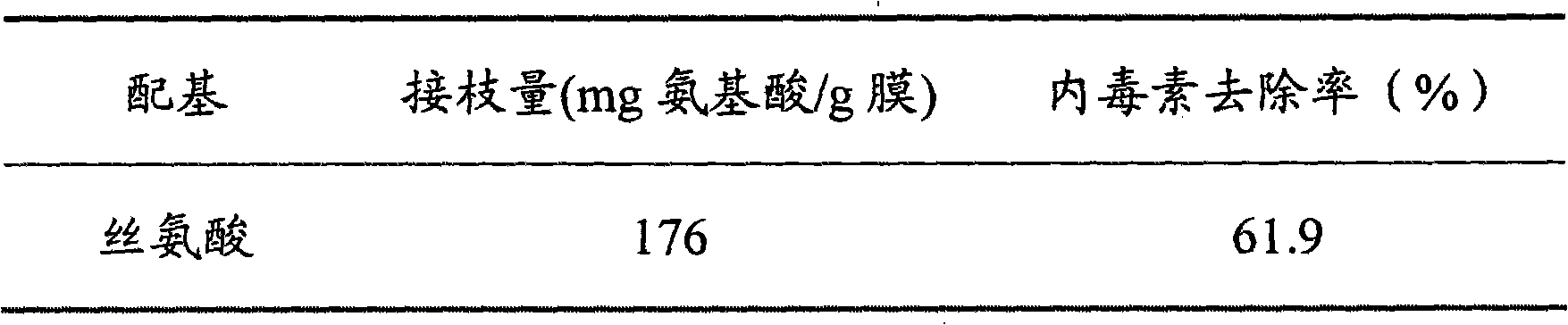

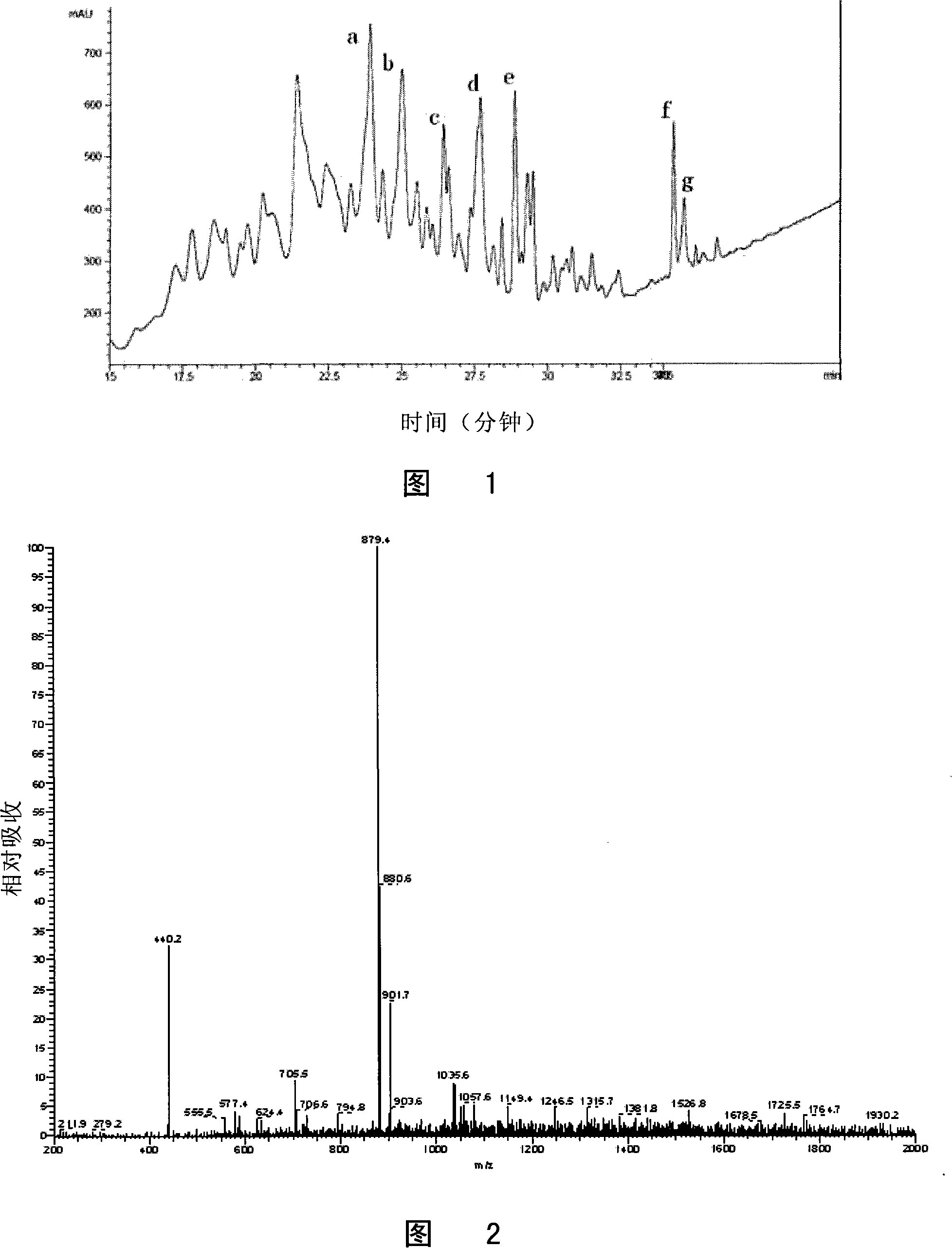

The invention discloses a method for preparing a polyvinylidene fluoride affinity membrane using amino acid as a ligand. The affinity membrane is prepared by hydrophilically modifying a polyvinylidene fluoride hollow fiber membrane and grafting the amino acid ligand. The grafting amount of the amino acid is 150 to 250mg / g for each membrane. The invention also discloses application of the affinity membrane in removing endotoxin in blood plasma, which removes the endotoxin in the blood plasma by a dynamic absorption means. The polyvinylidene fluoride affinity membrane prepared by the method has stable performance, good bio-compatibility and high endotoxin removing efficiency, and can be used for whole blood perfusion as well as blood plasma perfusion.

Owner:ZHEJIANG UNIV

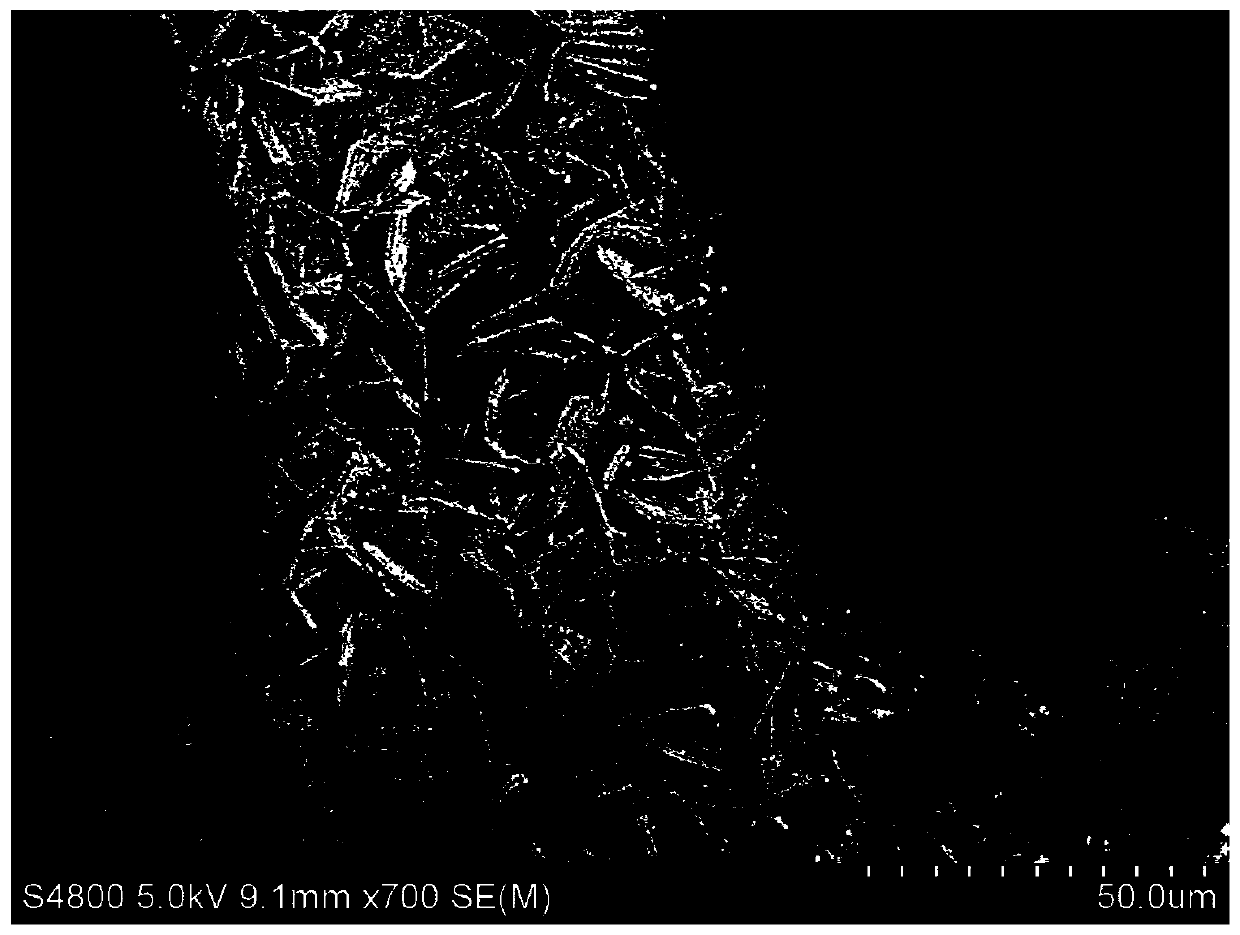

High-strength and high-conductivity graphene reinforced copper matrix composite material, preparation method and application thereof

ActiveCN108145169AIncrease mechanical stirringImprove drying efficiencyTransportation and packagingMetal-working apparatusHot isostatic pressingElectronics

The invention relates to the technical field of composite material preparation, in particular to a high-strength and high-conductivity graphene reinforced copper matrix composite material and a preparation method and application thereof. Spherical copper powder is used as a matrix material, graphene is used as a reinforcing phase, through the steps such as graphene liquid phase dispersion, ball milling predispersion, surface coating, hot isostatic pressing, hot extrusion and so on, and the high-strength and high-conductivity graphene reinforced copper matrix composite material with nearly fulldense, good conductivity, high tensile strength, high hardness, and high elongation is prepared. The preparation method has good process controllability and is easy to produce on a large scale. The prepared high-strength and high-conductivity grapheme reinforced copper matrix composite material is uniform in structure, the graphene is in good combination with the interface of a matrix, the performance is stable, and great application prospects in the fields of automobiles, aerospace and electronics are obtained.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

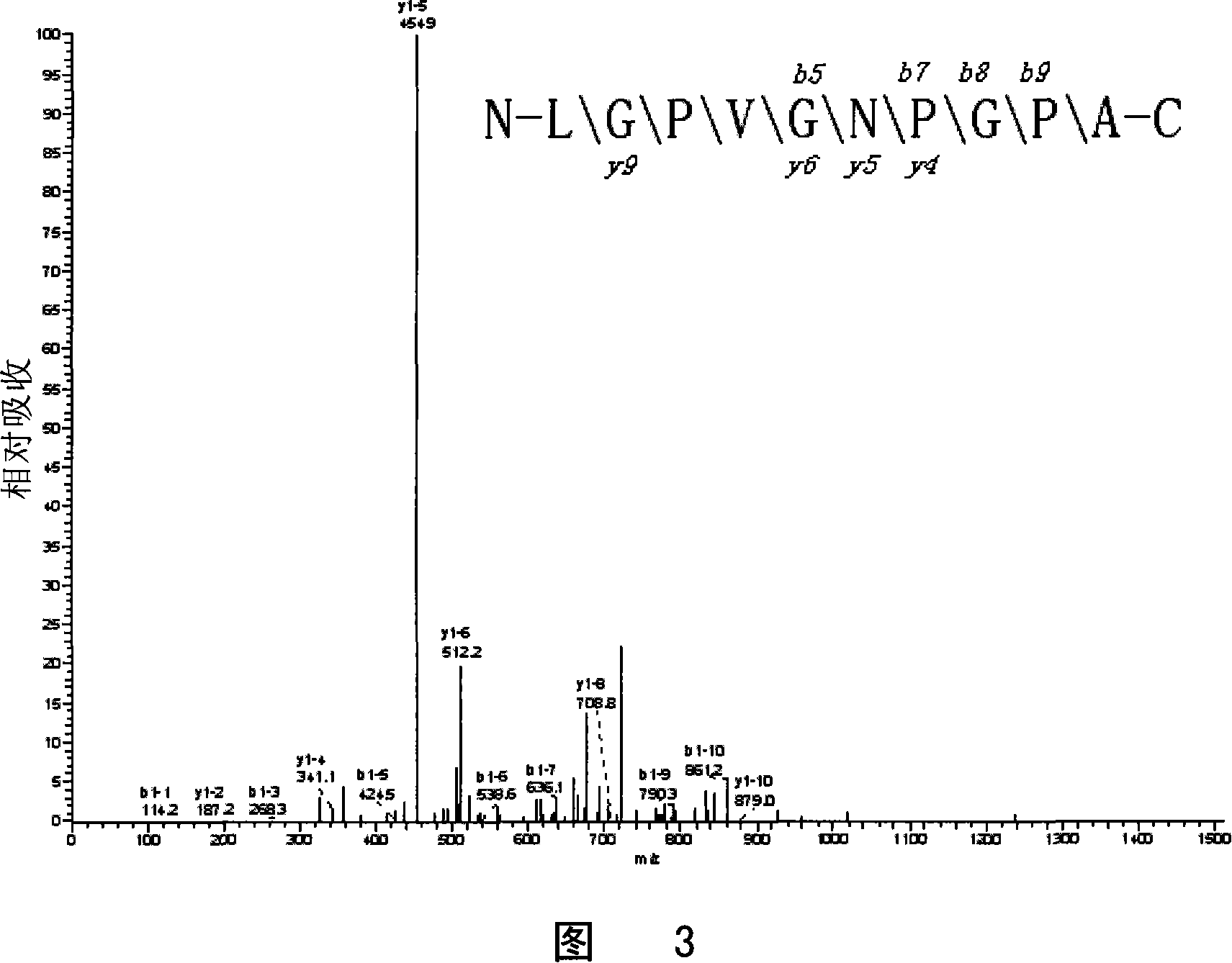

Novel peptide with angiotonin transferase restraining liveness and method of producing the same

InactiveCN101153055AGood ACE inhibitory activityHigh prolinePeptide/protein ingredientsPeptidesUltrafiltrationDecomposition

The present invention discloses a method of using biological enzyme decomposition to prepare a hydrolysis compound containing peptide of angiotensin transfer enzyme inhibitory activity, and three novel peptides of high ACE inhibitory activity. For the hydrolysis compound containing peptide of angiotensin transfer enzyme inhibitory activity of the present invention, the oxhide rich in praline is used as the raw material; the product of ACE inhibitory activity IC50 equal to 0.168mg / m can be prepared through the compounding and hydrolysis of biological enzyme. After ultrafiltration, the IC50 is equal to 0.079mg / ml. The means of analysis and detection determines the peptides, ISVPGPM, LGPVGNPGPA and DLSFLPQPPQQ, containing high ACE inhibitory activity. The three peptide sections are novel peptide sections containing high ACE inhibitory activity. Therefore, the three peptides have potential function of lowering blood pressure. The compounding and decomposition of biological enzyme of oxhide is a peptide type hydrolysis product, has inhibitory effects on angiotensin transfer enzyme (ACE), and can be widely used for health food, functional food, auxiliary drugs for lowering blood pressure and other products; the peptide has broad market prospects.

Owner:EAST CHINA UNIV OF SCI & TECH +1

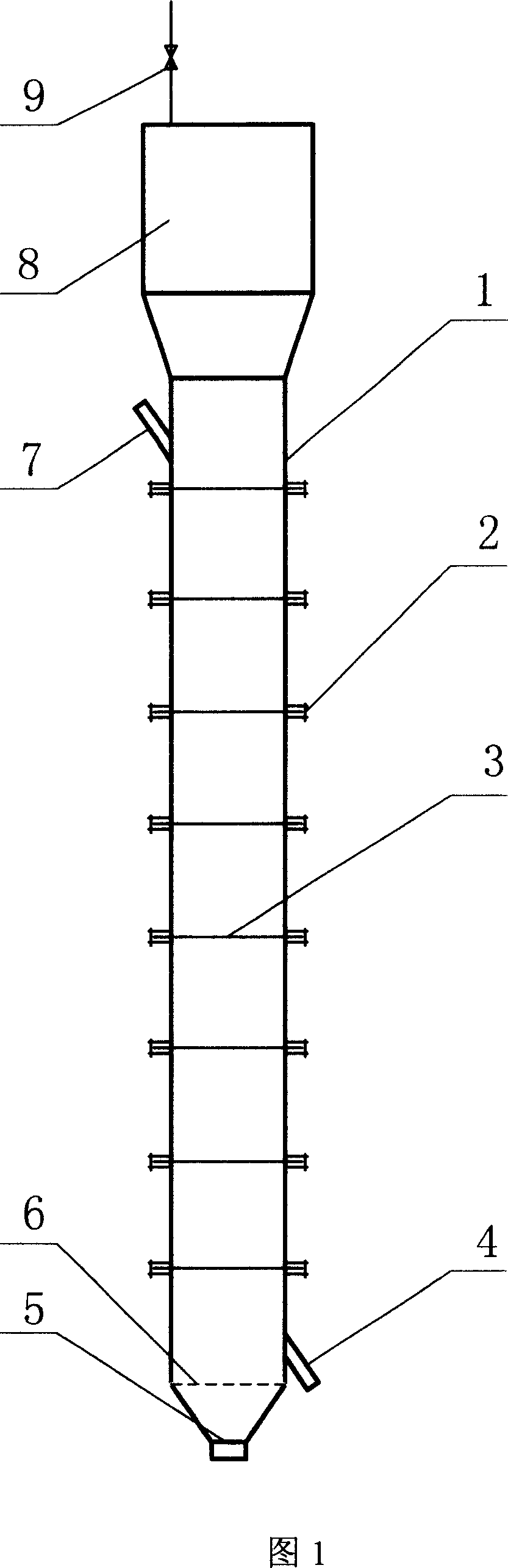

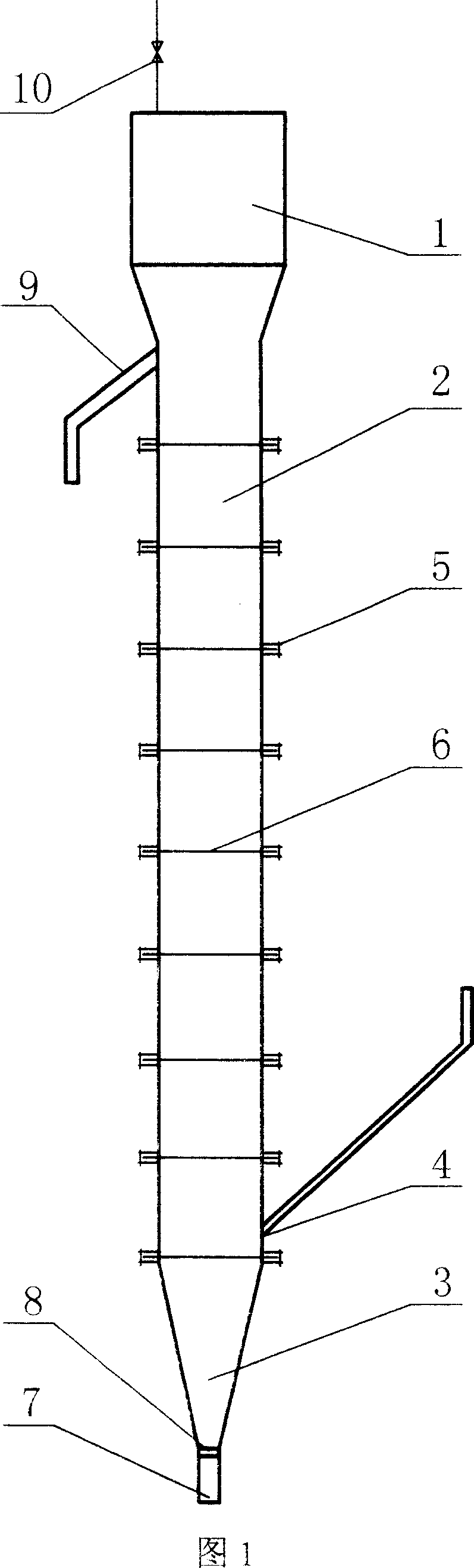

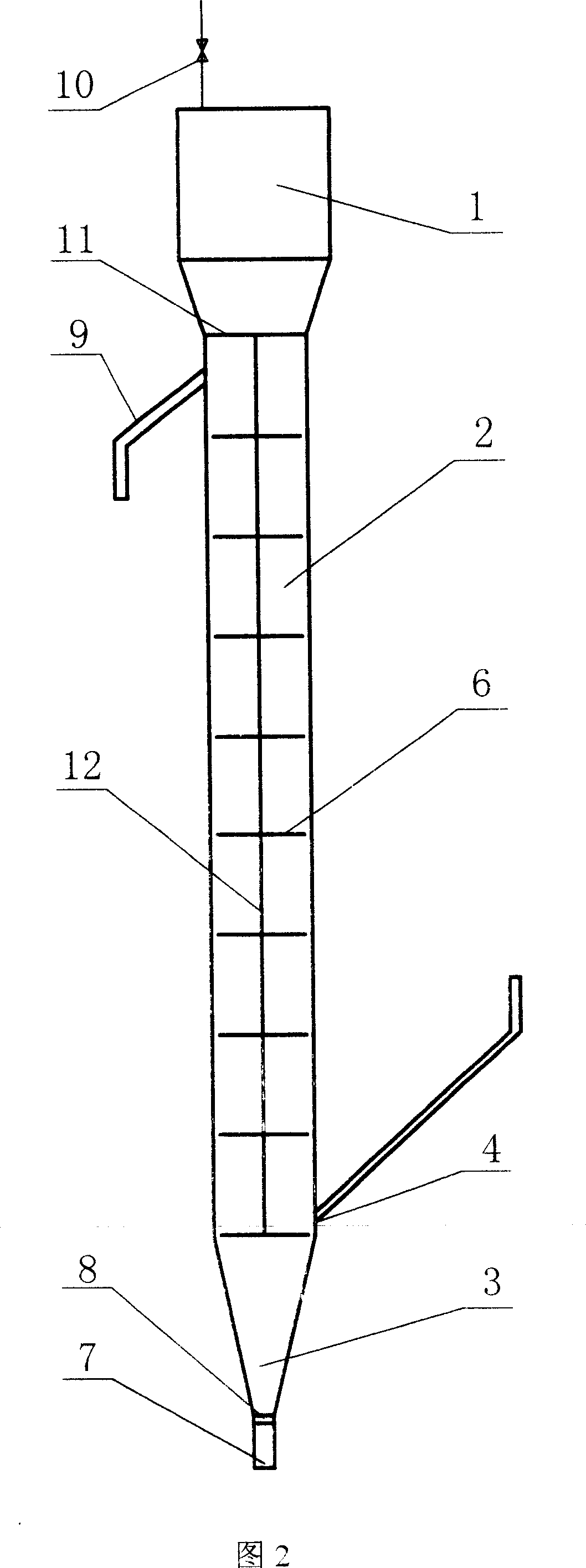

Fluidized-bed reactor for oxidizing carbon black through ozone

InactiveCN1958145AEliminate channelingElimination of Broken AgglomeratesPigmenting treatmentChemical/physical processesFluidized bedProduct gas

A fluidized-bed reactor for oxidizing carbon black by ozone with stable fluidizing and no coagulation of carbon black particles has a main body with lower carbon black discharging outlet, gas inlet on its bottom, upper carbon black inlet, gas outlet on its top, internal barrier plate with slits, and gas distributing plate under the carbon black discharging outlet.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

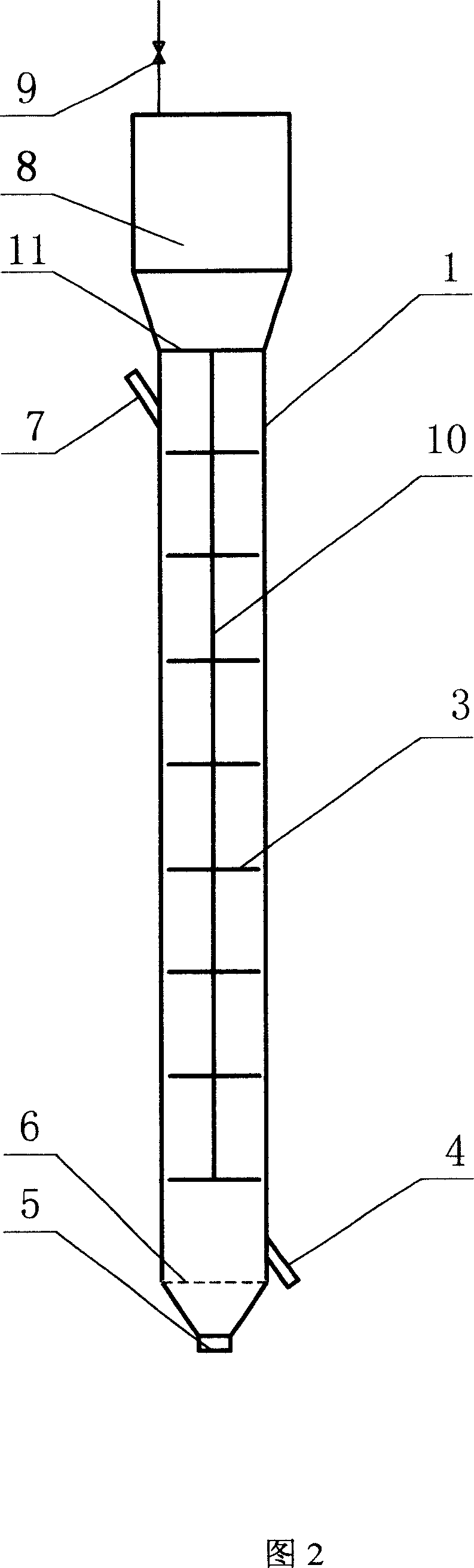

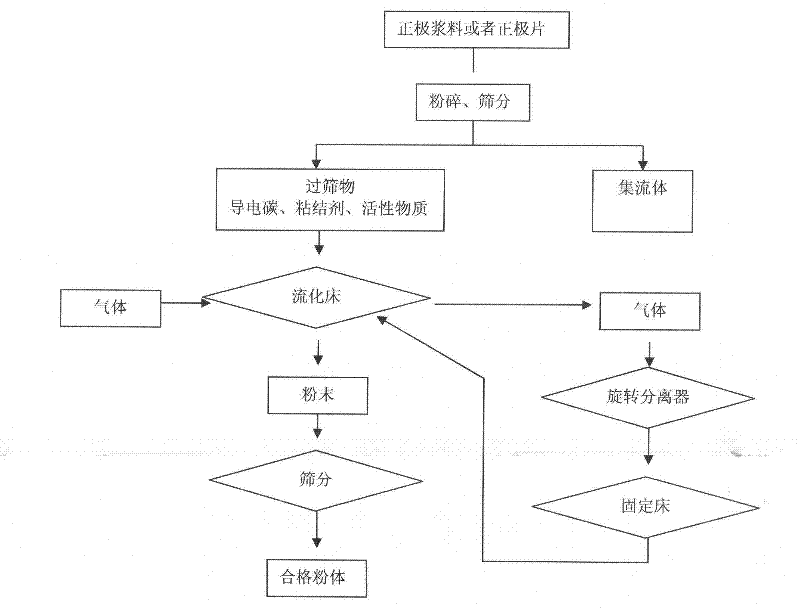

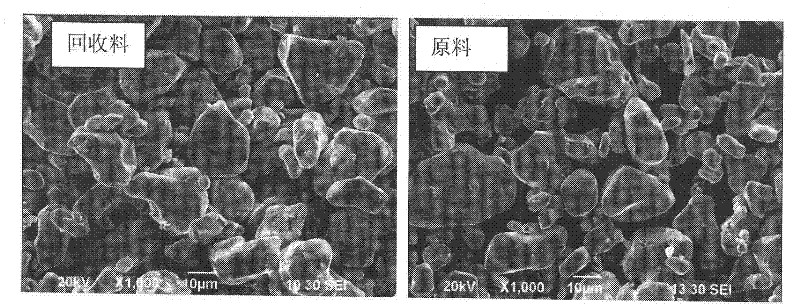

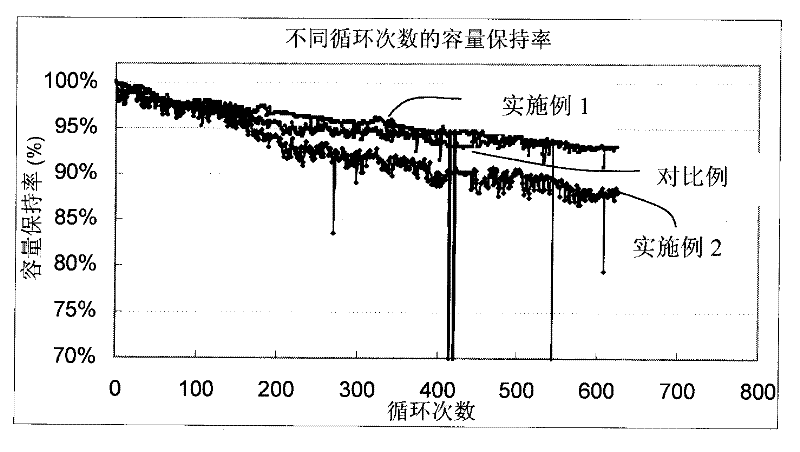

Lithium ion batteries cathode material recovery method

ActiveCN102694217AHigh recovery rateSimultaneous recyclingSolid waste disposalWaste accumulators reclaimingRecovery methodSide effect

The invention belongs to the field of battery materials, and specifically relates to a method for recovering positive active materials from battery material offcuts and slurry. The method comprises the following steps of: filling positive plate or dry positive slurry to be recovered into a pulverizer, screening into a powder, putting the powder into a fluidized bed and removing impurities of conductive carbon and a binder; letting a gas pass through a cyclone separator on the top of the fluidized bed to remove entrained powder, passing through a fixed bed to remove harmful gases, heating and blowing into the fluidized bed for cyclic utilization, cooling the powder at the bottom, and sieving to obtain a qualified positive powder. According to the invention, the process flow is short; the powder is in a fluidization state in the fluidized bed during the process of heat treatment; and the gas and the powder fully contact with each other and the reaction is complete. Therefore, the problems of high impurity content in the product and low recovery rate in a traditional technology are fundamentally resolved; in addition, cobalt and lithium elements are simultaneously recovered, the recovery rate of an active substance reaches up to 94%, and simultaneously side-effect will not be exerted on the active substance and it selectrochemical properties.

Owner:DONGGUAN AMPEREX TECH +2

Preparation method of charcoal material surface gradient coating for resisting oxidation

The present invention is preparation process of gradient oxidation resisting coating on the surface of carbon material. The preparation process includes the steps of: cleaning and stoving the surface of the carbon material; compounding slurring with silica powder, water and adhesive in certain weight proportion, and coating the slurry onto the surface of the carbon material through soaking, spraying or brushing; compounding silica powder, molybdenum powder, water and adhesive into slurry A of Mo / Si ratio 0.3-0.4, slurry B of Mo / Si ratio 0.8-1.2 and slurry C of Mo / Si ratio 1.8-2.3, and coating slurry A, slurry B and slurry C successively onto the surface of the carbon material through soaking, spraying or brushing; and sintering to obtain the product. The present invention has simple technological process, high production efficiency, good repeatability and low production cost and is suitable for industrial production.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

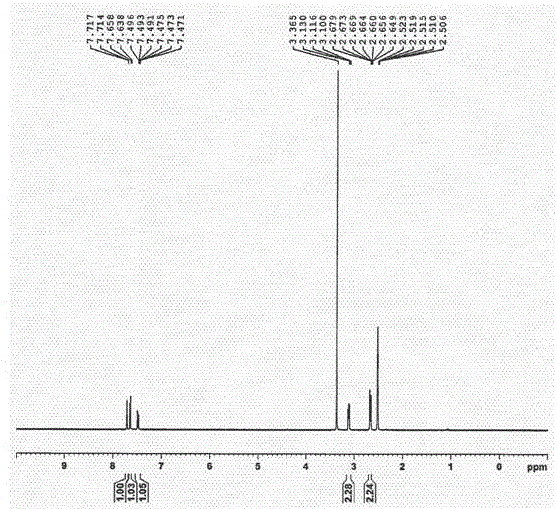

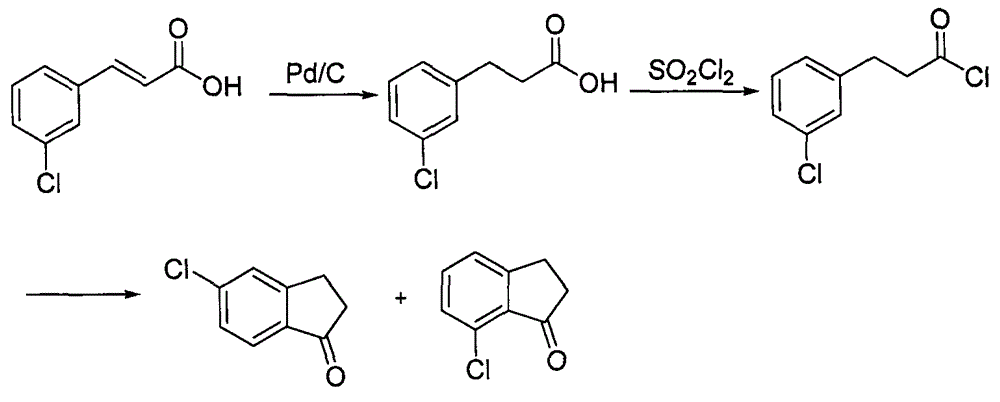

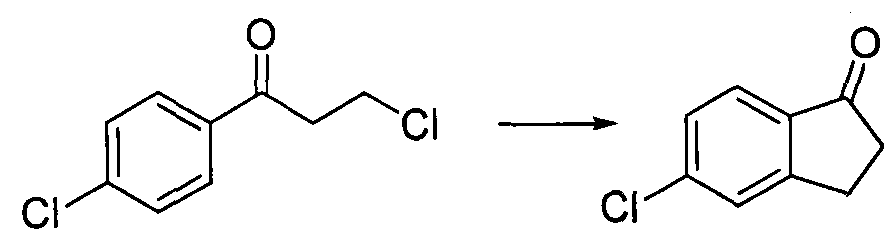

Synthetic method of 5-chloro-1-indanone

ActiveCN104910001AEasy to operateEasy to handleCarboxylic preparation by ozone oxidationCarbonyl compound preparation by condensationPropanoic acidChlorobenzene

The invention discloses a synthetic method of 5-chloro-1-indanone, and belongs to the field of organic synthesis. 3-chlorobenzaldehyde as raw material first reacts with propionic acid to prepare 3-chloro-phenylpropionic acid, which is then subjected to Friedel-Crafts acylation reaction to prepare 5-chloro-1-indanone. Organic solvents of formic acid diethylamine participate in the first step, and the reaction temperature is 20-150 DEG C. An organic solvent of methylene chloride and a catalyst of zinc chloride participate in the second step, and the reaction temperature is -10 to 80 DEG C. The synthesis process of 5-chloro-1-indanone provided by the invention is simple and easy for magnification, resolves the technical problems of in the presence of long synthetic route, expensive catalysts or raw materials, harsh reaction conditions and high cost in the current synthetic method; particularly in the environment, compared with the conventional synthetic method of 5-chloro-1-indanone process, the method provided by the invention avoids environmental pollution problem caused by strong acid and treatment of a large amount of wastewater.

Owner:上海博栋化学科技有限公司

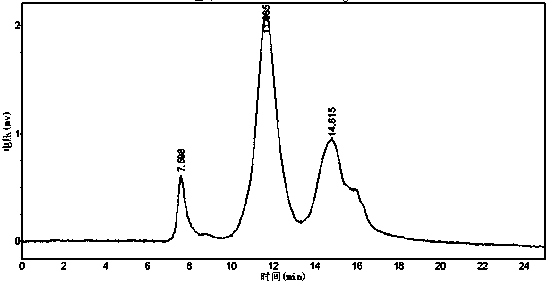

Electrochemical stripping method for preparing fluorine-doped graphene

The invention discloses an electrochemical stripping method for preparing fluorine-doped graphene, and belongs to the technical field of controllable preparation and doped control of graphene materials. According to the method, negative ion fluorine-containing soluble salt serves as stripping electrolyte, water or nitrile serves as a solvent, graphite serves as a raw material, and fluorine-doped graphene nano-sheets are prepared by the electrochemical stripping method in a one-step manner. The preparation method has the advantages that the method is green, environmentally friendly, simple in device, convenient to operate, mild in condition, low in cost, and a process is easily amplified. The prepared fluorine-doped grapheme is high in quality and good in performance and has an important application prospect in the fields such as super-capacitors, lithium batteries, lubrication, conductive ink and catalysis.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for performing modification of chitosan or derivative thereof on surface of medical polyurethane material

The invention discloses a method for performing modification of chitosan or a derivative thereof on the surface of a medical polyurethane material. The method comprises the steps that: the medical polyurethane material is cleaned and dried; an oxidation treatment is carried out upon a clean surface of the medical polyurethane material, wherein the oxidation treatment includes Jones reagent, ozone or ultraviolet irradiation treatment; the medical polyurethane material obtained after oxidation treatment is placed in a 2-5wt% carbodiimid solution, and a reaction is allowed for 7-9h; washing and drying are carried out; the obtained medical polyurethane material is placed into a solution of chitosan or a derivative thereof, such that a grafting reaction is carried out; the grafted medical polyurethane material is cleaned by washing, and is subjected to vacuum drying, such that a medical polyurethane material with chitosan or chitosan derivative modification on the surface is obtained. The method provided by the invention has the characteristics of easy-to-control reaction conditions, simple procedure, easy-to-enlarge process, and the like. The obtained material has good hydrophilicity and biocompatibility.

Owner:SOUTHEAST UNIV

Production method of pentafluoroethane

InactiveCN1724490AImprove conversion rateHigh selectivityHalogenated hydrocarbon preparationHydrogen fluorideTetrafluoroethylene

The invention relates to a process for synthesizing pentafluoroethane (HFC-125) from tetrafluoroethylene and hydrogen fluoride at the presence of catalyst, wherein the catalyst is a dual system comprising tertiary amine compounds and carbonyl-containing compounds by the proportion of 1:0.05-10, the reaction condition being, the reaction temperature 10-150 deg. C, the reaction pressure 0.6-2.5 MPa, the reacting time 1-10 hours. The invention can realize high conversion rate of tetrafluoroethylene and good selectivity of pentafluoroethane.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

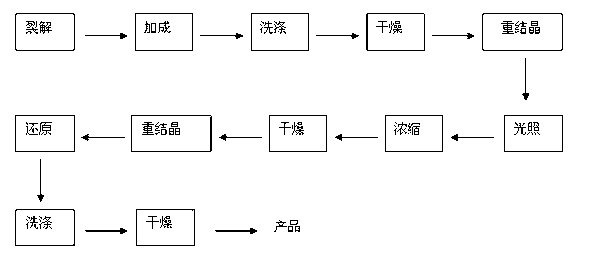

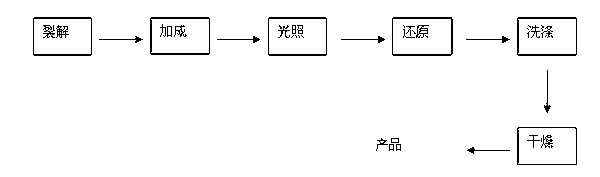

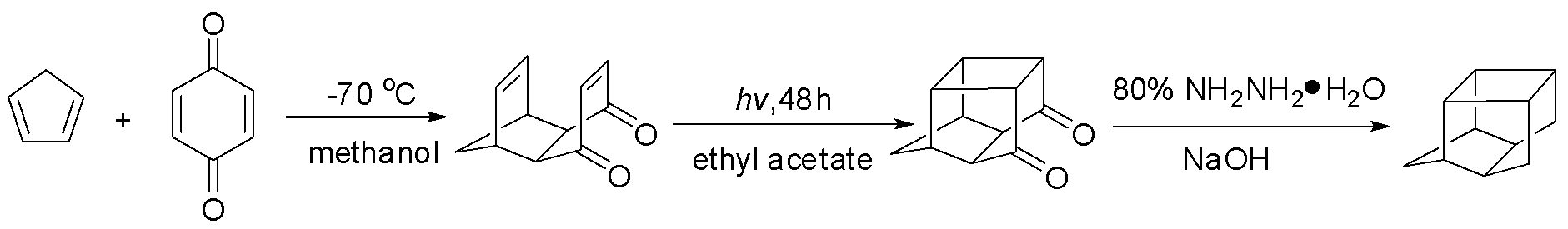

Synthetic method of pentacycloundecane

ActiveCN103204760AImprove efficiencyShort cycleHydrocarbonsHydrocarbon preparationRamjetSynthesis methods

The invention provides a synthetic method of pentacycloundecane (PCUD). The method uses cyclopentadiene and benzoquinone as initial raw materials, and a high boiling solvent; and the pentacycloundecane is synthesized through the following three reactions: Diels-Alder addition, ultraviolet cyclization and carbonyl reduction. According to the invention, the Diels-Alder addition, the ultraviolet cyclization and the carbonyl reduction can be continuously carried out without post-treatment, and unnecessary processes in the reactions is simplified, thereby achieving purposes of improving efficiency and reducing cost. The method has advantages of short period, low cost and easily expanded technology; and the synthesized target compound PCUD can be used as a high-energy additive for fuel of solid turbine stamping engines or liquid rocket fuel.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

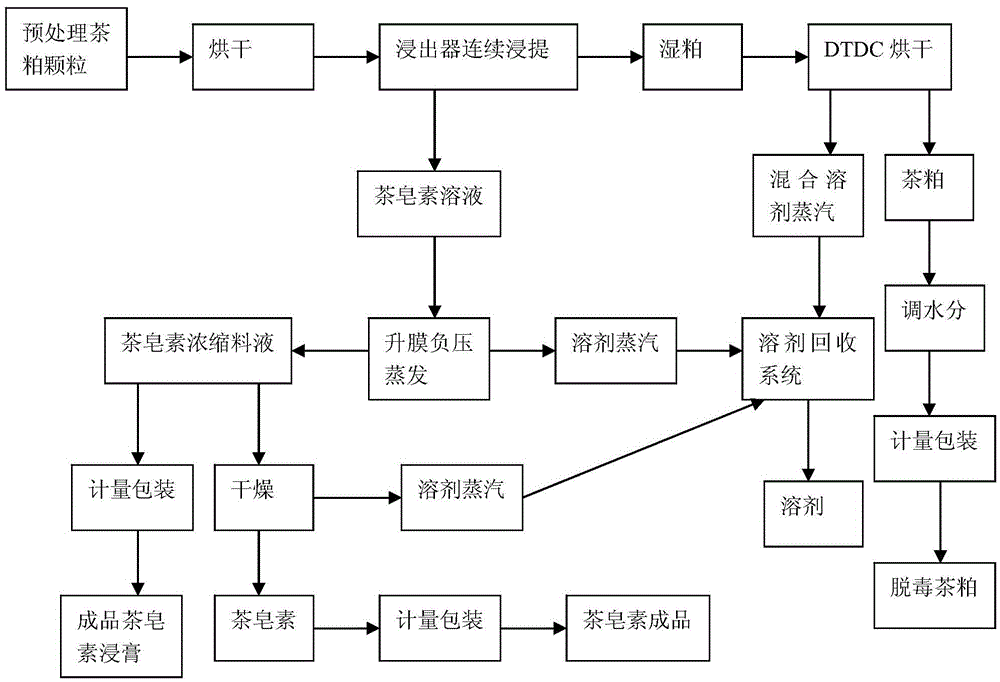

Low-cost, efficient and continuous tea saponin extraction process

ActiveCN105461780AResidue reductionReduce consumptionSugar derivativesSteroidsCamellia oleiferaProcessing cost

The invention discloses a low-cost, efficient and continuous tea saponin extraction process. The low-cost, efficient and continuous tea saponin extraction process comprises steps as follows: (1) pretreated oil-tea meal is dried; (2) the tea meal with water content adjusted enters an extractor for continuous extraction; (3) extracted wet meal enters a DTDC (desoloventizer, toaster, dryer and cooler) type dryer with multiple material layers and is dried, after the moisture content of dried meal is adjusted, the meal is metered and packaged, and feed grade tea meal is obtained; (4) a tea saponin mixed solution discharged out of the extractor enters a cyclone device for separation; (5) a separated tea saponin concentrated solution is fed into a drying section for drying, and a tea saponin crude product is obtained. With the adoption of the process, the extraction efficiency of tea saponin is effectively improved, and the processing cost is effectively reduced; the tea saponin can be taken as a raw material for feed; the purity of the extracted saponin crude product is improved; large-scale extraction of the tea saponin is easier to realize, the processing benefits of by-products are effectively improved, and the technical bottleneck problem in the aspect of development of byproducts of tea oil is solved.

Owner:RES INST OF SUBTROPICAL FORESTRY CHINESE ACAD OF FORESTRY

Composite catalytic membrane applied to catalytic esterification and preparation method thereof

InactiveCN102958586BAchieving controllable equipmentImprove catalytic performanceSemi-permeable membranesMembranesBiodieselSulfonated polymer

Owner:TIANJIN POLYTECHNIC UNIV

Combined preparation process of sophora flavescens total flavone and sophora flavescens total alkaloid

The invention provides a combined preparation process of sophora flavescens total flavone and sophora flavescens total alkaloid. The combined preparation process comprises the following steps: crushing raw sophora flavescens; extracting by using low-carbon alcohol; concentrating an extraction solution into extract; dissolving the extract by using acid water to obtain an acid water layer and a solid; washing the solid with water till the solid is neutral; dissolving the solid with a proper amount of ethanol; separating a solution by using polyamide resin; eluting with acid alcohol; collecting eluate; concentrating and drying the eluate to obtain high-purity sophora flavescens total flavone; taking the acid water layer, blending with alkali and precipitating; filtering out precipitates, and dissolving the precipitates with acetone; adding ammonia water into an acetone solution, and separating out and crystallizing; filtering out crystals, and refluxing and dissolving the crystals with 80-95% ethanol to obtain the sophora flavescens total alkaloid. The combined preparation process is easy to operate; the utilization ratio of the raw material is high; the sophora flavescens total flavone and the sophora flavescens total alkaloid with relatively high purity are prepared; and the combined preparation process is easy to expand.

Owner:苏州宝泽堂医药科技有限公司

LLarge scale human urine protein collection method

InactiveCN103509104ARealize online adsorptionExpand the scope of collectionAlbumin peptidesPeptide preparation methodsPro proteinProtein activity

The invention discloses a large scale human urine protein collection method. The method comprises the following steps: placing absorption agents, which are used for absorbing urine proteins and have been packaged, in the places where urine will pass through to make the absorption agent be able to absorb the urine proteins in the urine; collecting the absorption agents which have absorbed the urine proteins; subjecting the collected absorption agents to a pretreatment; refrigerating and storing the pre-treated absorption agents; and transporting the absorption agents to a processing factory in batches to carry out urine protein desorption process to produce corresponding urine protein raw materials or urine protein products. The large scale human urine protein collection method is suitable for the mass industrial urine protein production, improves the processing amount of urine protein, reduces the transportation cost of absorption agents and the production cost of urine proteins, furthermore, the absorption agents containing urine proteins are subjected to a pre-treatment before storage, thus the urine protein activity is preserved, the urine protein degradation is reduced, the microorganism generation is reduced, so that the urine protein product quality is improved.

Owner:YANGZHOU AIDEA BIOTECH

Preparation method for collagen hydrogel

The invention discloses a preparation method for collagen hydrogel. The method comprises the following steps that (1) a collagen solution is prepared, specifically, a certain amount of collagen is weighed and put into a reaction kettle, a 0.05-0.5 mol / L organic acid solution with 40-200 times the weight of the collagen is added, and the solution is enabled to pass through a 50-400-mesh sieve repeatedly under the action of a peristaltic pump so as to reach a uniform state; (2) amino acid is added, specifically a certain amount of amino acid is added into the collagen solution prepared in the step (1), and the solution is continuously enabled to pass through a 50-400-mesh sieve repeatedly under the action of the peristaltic pump so as to reach a uniform state; (3) the pH is adjusted, specifically, the solution prepared in the step (2) is placed at a low temperature of 0-10 DEG C, solution replacement is carried out by adopting an ultrafiltration method, ultra-pure water or a buffer solution with the pH value of 6-8 is added in the ultrafiltration process, and ultrafiltration is continuously carried out until the difference value between the pH of permeate liquid and the pH of the added ultrapure water or the buffer solution is less than 0.2; and (4) irradiating is carried out, specifically, a sample prepared in the step (3) is subjected to split packaging and then is irradiated.The preparation method for the collagen hydrogel has the advantages that the uniform hydrogel can be prepared, and the problem of liquid precipitation after irradiation can be solved.

Owner:HEBEI COLLAGEN BIOTECH

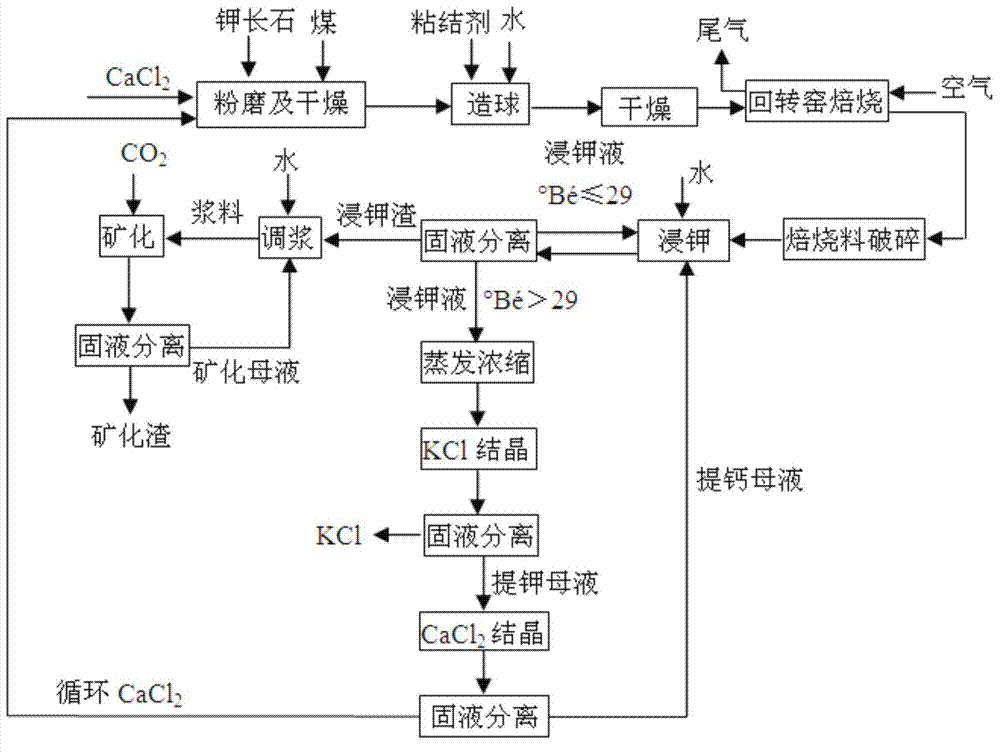

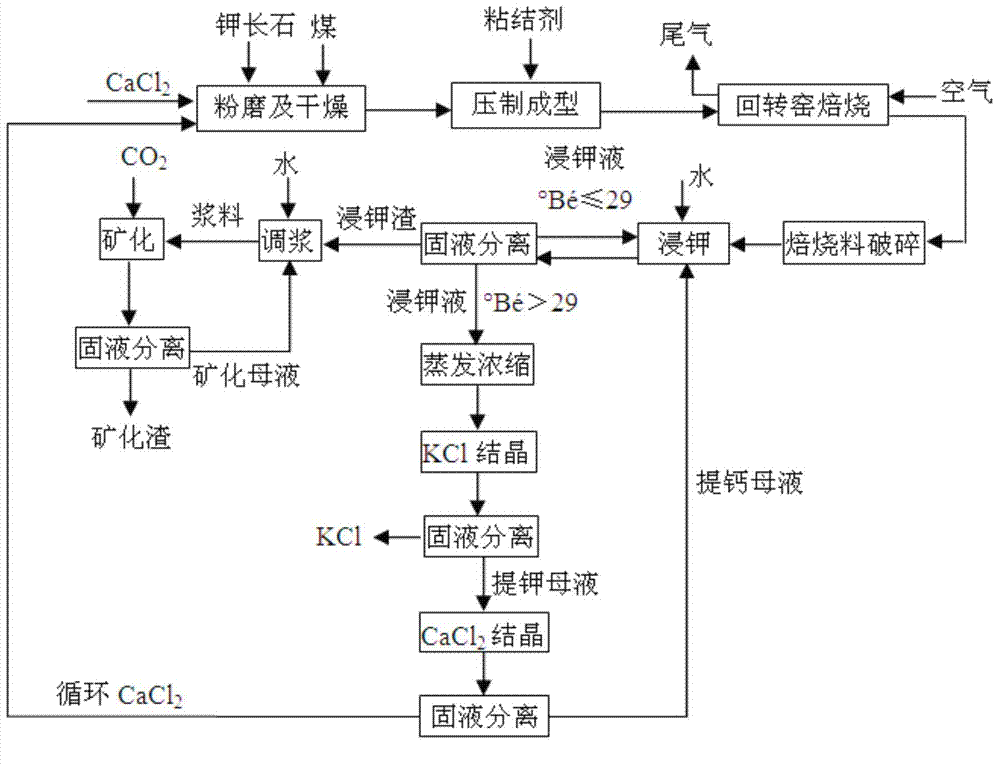

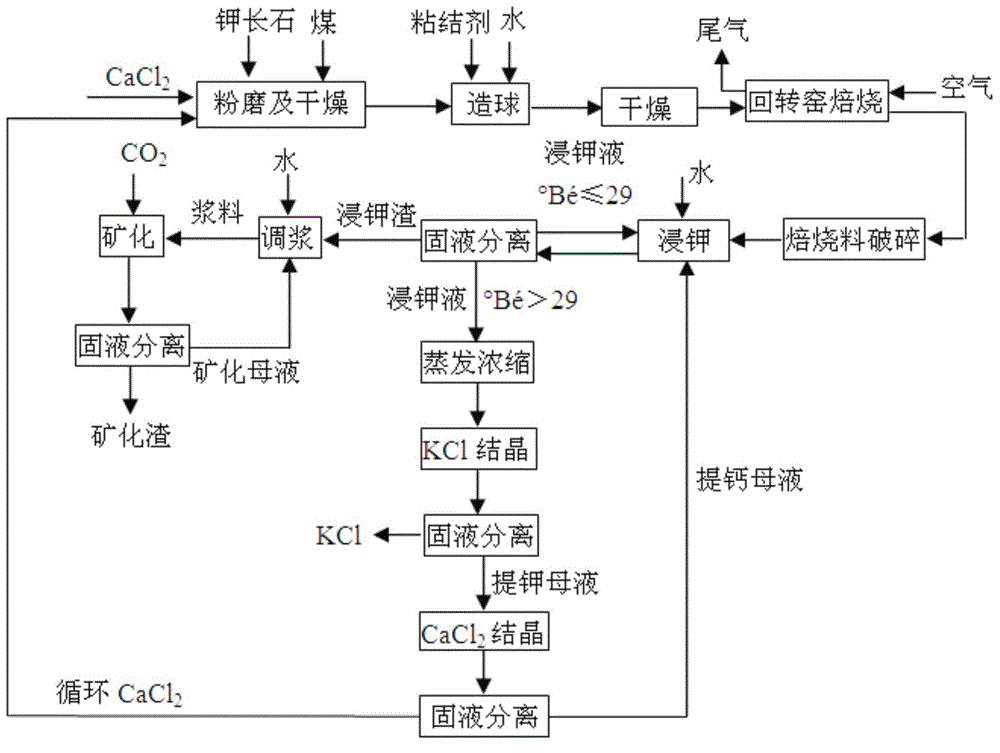

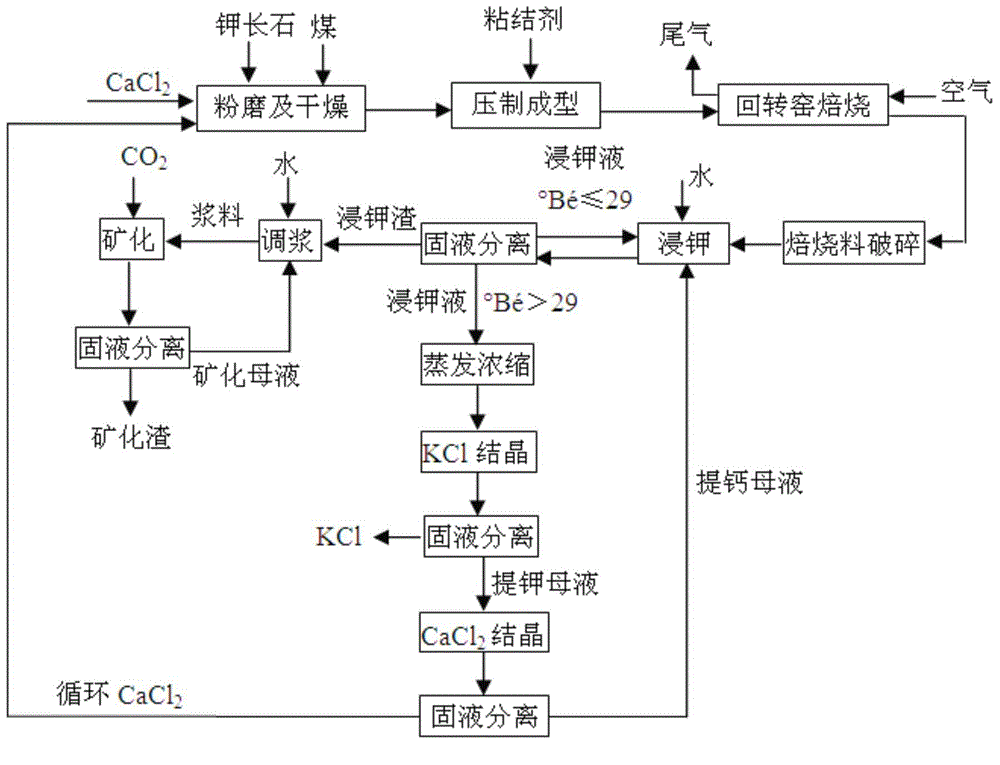

Method for concurrent production of potassium chloride and mineralization fixation of CO2

InactiveCN103693659ARaise the ash melting pointHigh melting pointDispersed particle separationAlkali metal chloridesEvaporationPotassium

The invention belongs to the comprehensive field of potassium fertilizer production and CO2 emission reduction, and provides a method for concurrent production of potassium chloride and mineralization fixation of CO2. The process steps comprise: (1) adopting potassium feldspar, calcium chloride and coal as raw materials, preparing materials, carrying out ball milling, and carrying out pressing molding or pelletizing; (2) conveying the molded material or the material balls into a rotary kiln from the kiln tail, conveying air into the rotary kiln from the kiln head, and controlling a residence time of the molded material or the material balls at a temperature range of 800-1000 DEG C to 20-40 min; (3) crushing the calcinated material, and adding water to carry out potassium leaching through the water; (4) adding water to the potassium leaching residue to carry out pulp conditioning, and introducing CO2 to carry out a mineralization reaction; (5) carrying out returning of the potassium leaching solution so as to be used for leaching of potassium from the calcinated material when the Baume degree of the potassium leaching solution is less than or equal to 29, and carrying out evaporation concentration on the potassium leaching solution to achieve the Baume degree of 42-42.5 when the Baume degree of the potassium leaching solution is more than 29, and cooling to carry out potassium chloride crystallization; and (6) cooling the potassium extraction mother liquor to carry out calcium chloride crystallization, and carrying out solid-liquid separation to obtain calcium chloride and the calcium extraction mother liquor.

Owner:SICHUAN UNIV

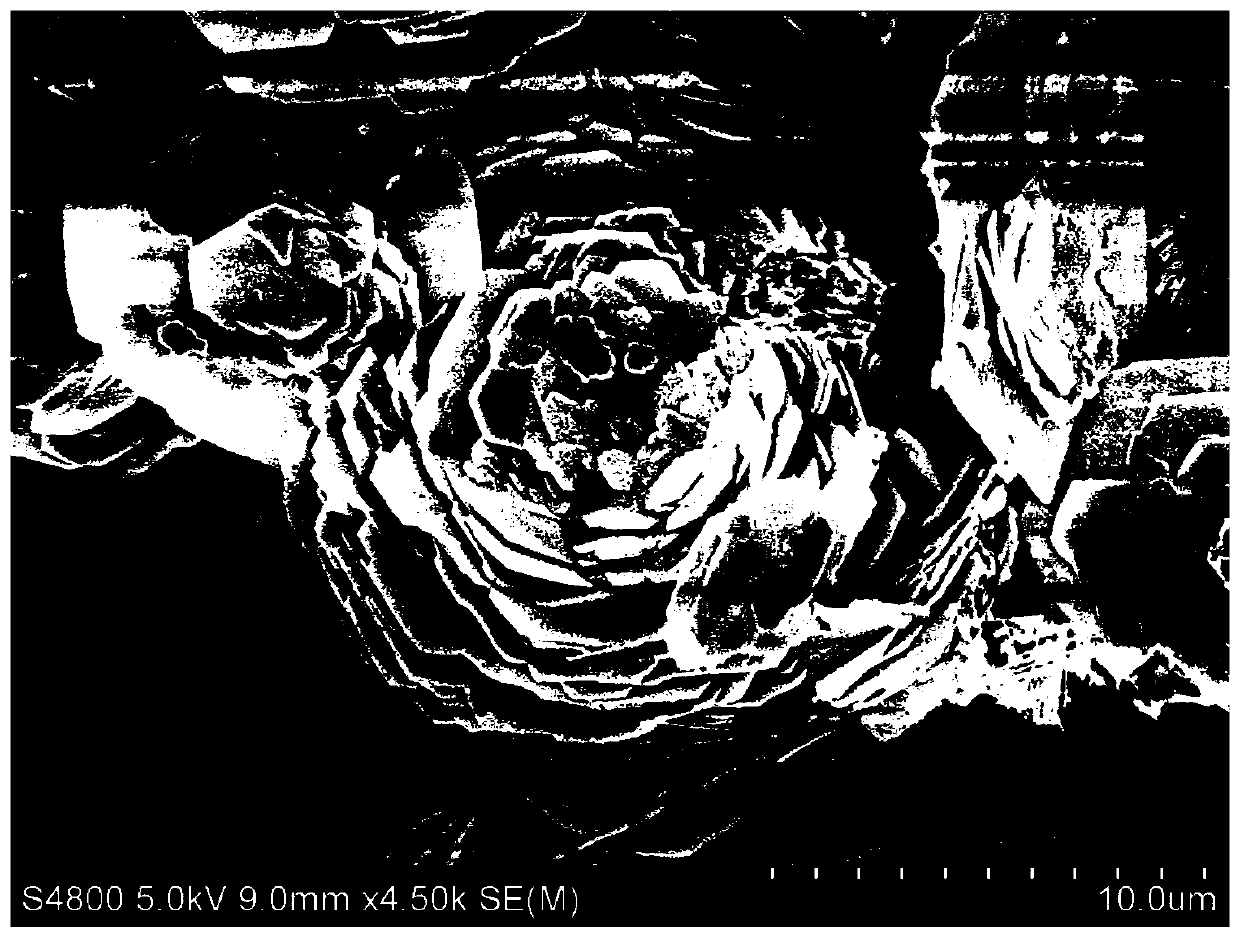

Conductive carrier self-supporting flower-shaped Co3V2O8 lithium ion battery negative electrode material and preparation

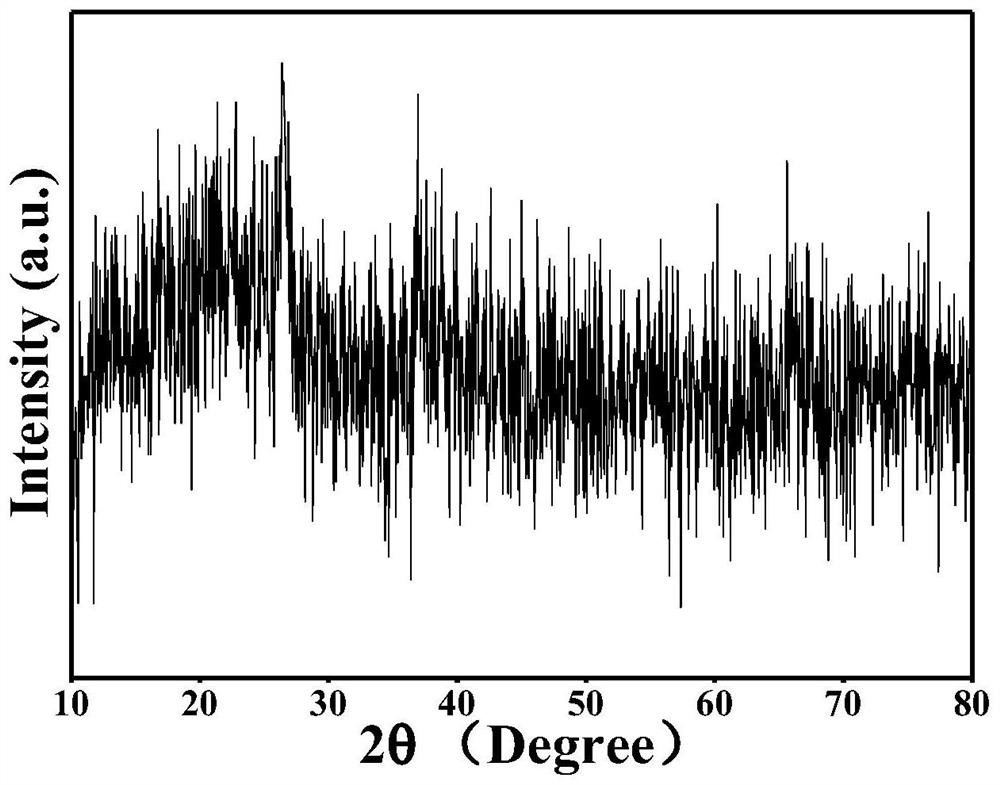

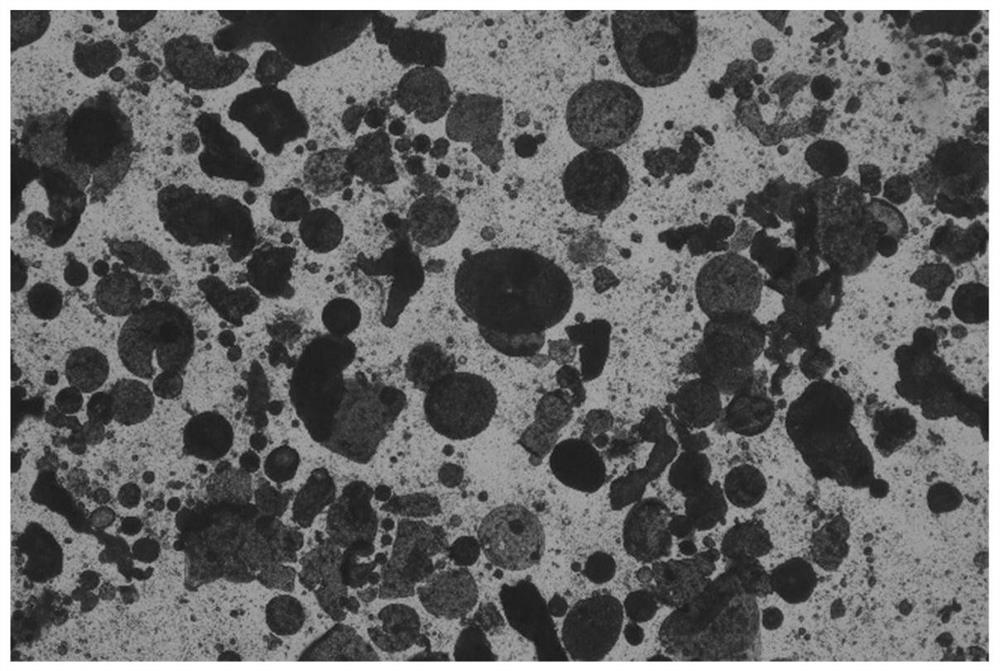

ActiveCN110120520ASimple methodThe process is easy to scale upCell electrodesSecondary cellsCobalt saltVanadium oxide

The invention discloses a conductive carrier self-supporting flower-shaped Co3V2O8 lithium ion battery negative electrode material and preparation, and belongs to the field of preparation and application of energy materials. In the composite material, flower-shaped Co3V2O8 uniformly grows on a conductive carrier. The flower-shaped Co3V2O8 is formed by laminating at least one sheet-shaped Co3V2O8.The preparation method of the composite material comprises the following steps: step 1, taking cobalt salt and urea as raw materials, and growing at least one layer of cobalt hydroxide as a precursoron a conductive carrier in situ by using a hydrothermal method; step 2, soaking the precursor template of the conductive carrier self-supporting cobalt hydroxide into the metavanadate solution for secondary hydrothermal treatment to obtain a conductive carrier self-supporting cobalt vanadium oxide composite material; and step 3, annealing the conductive carrier of the self-supporting cobalt-vanadium oxide in air to obtain the conductive carrier self-supporting flower-shaped Co3V2O8 composite material. The method is simple and feasible, the process can be enlarged, and the method can be appliedto the field of commercial lithium ion negative electrode materials.

Owner:BEIJING UNIV OF CHEM TECH

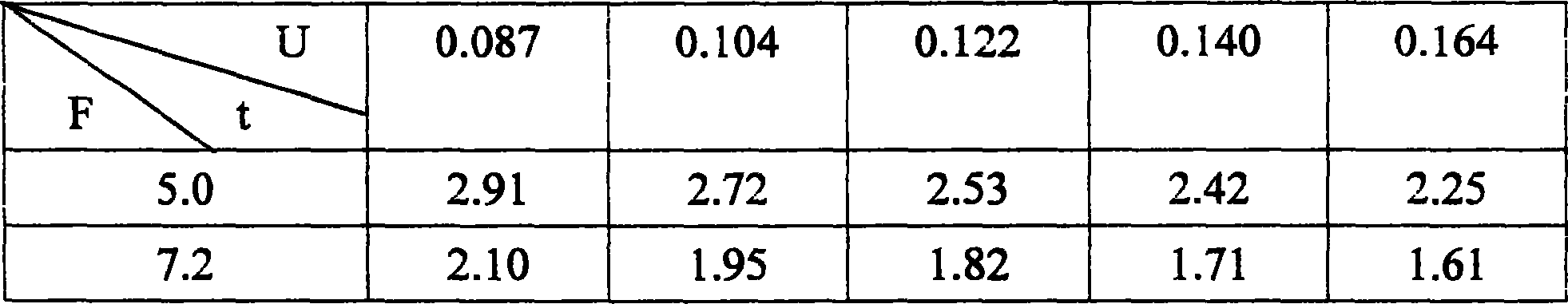

Fluid-bed reactor for oxido-reduction sintering of high calcium magnesium titanium slag

InactiveCN101117665AReduce axial backmixingImproved solid phase residence time distributionFluidised-bed furnacesProcess efficiency improvementOxido reductionMagnesium

The present invention relates to a fluidized bed reactor used for oxidizing and deoxidizing and baking high calcium magnesium titanium slag to remove calcium for improving the titanium inert solid grade, and comprises a cylindrical column material settlement section, a cylindrical column material reaction section, and a coniform column air preheating section. The main body of the cylindrical fluidized bed reactor is the cylindrical column material reaction section, and the top part is of a horn mouth shape, the top part of the horn mouth column body is connected with the cylindrical column material settlement section, the bottom end of the reaction is connected with the air preheating section. The upper part of the air preheating section is provided with a material feeding port, and the bottom part is arranged with an air distribution plate under which an air inlet is provided. The lower part of the material reaction is provided with a material discharging port, and the top part is provided with an air outlet. More than one baffle with holes is arranged in the material reaction. The present invention can make the residence time of particles of the high calcium magnesium titanium slag prolong following the increase of the grain size to satisfy the requirements of the reaction time of different grain sizes of particles.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

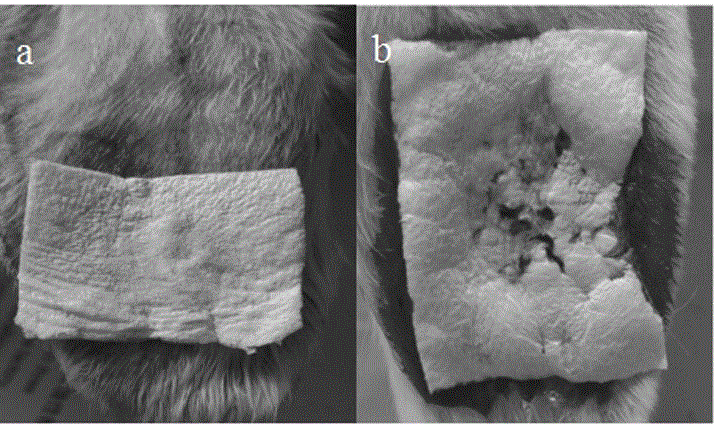

Method for preparing internal haemostatic dressing through programmed cooling

ActiveCN106729958AHigh mechanical strengthGood hemostatic effectSurgical adhesivesPharmaceutical delivery mechanismBiocompatibility TestingBiological materials

The invention discloses a preparation method of an internal haemostatic dressing. The preparation method is characterized by taking human-like collagen as a raw material, adding injection water, stirring and dissolving, then freezing by setting a specific cooling rate for accurately cooling and pre-freezing, vacuum freezing and drying, then carrying out thermal crosslinking, irradiating Co60 and sterilizing to finally obtain an internal haemostatic dressing. The internal haemostatic dressing prepared by the method is high in safety, high in biocompatibility and obvious in haemostatic effect, can be applied to hemostasis of various wounds and post-operation hemostasis, and has good application prospects in relevant fields of biomedical materials and tissue engineering.

Owner:NORTHWEST UNIV(CN)

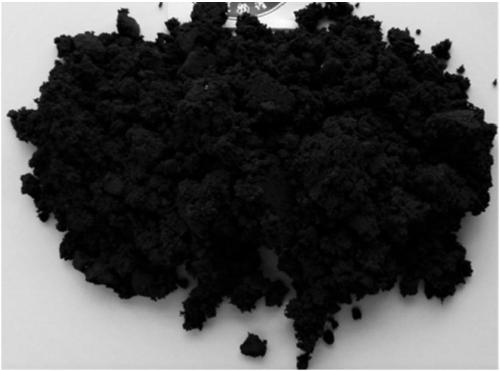

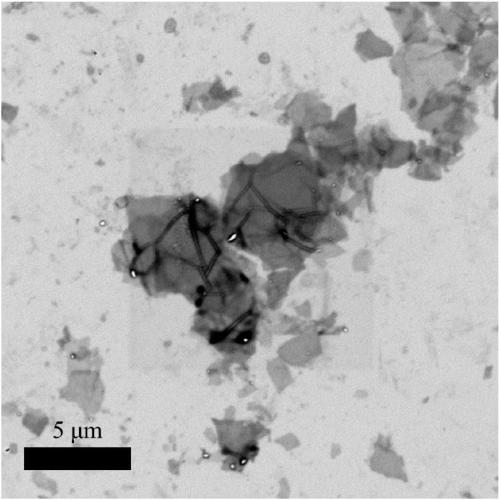

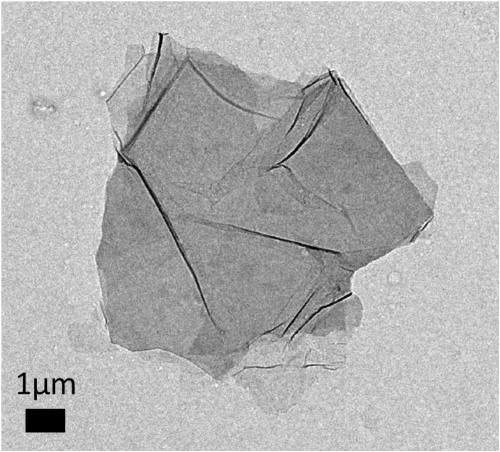

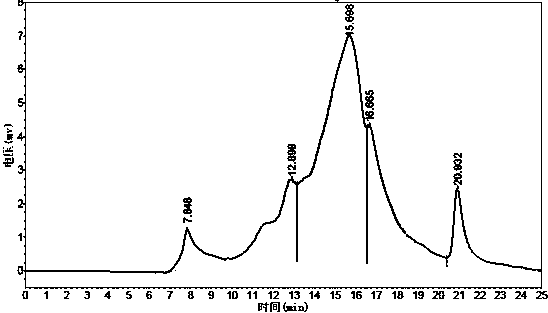

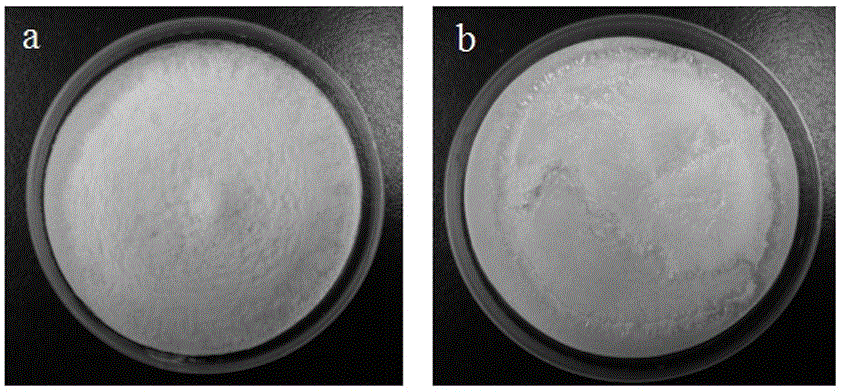

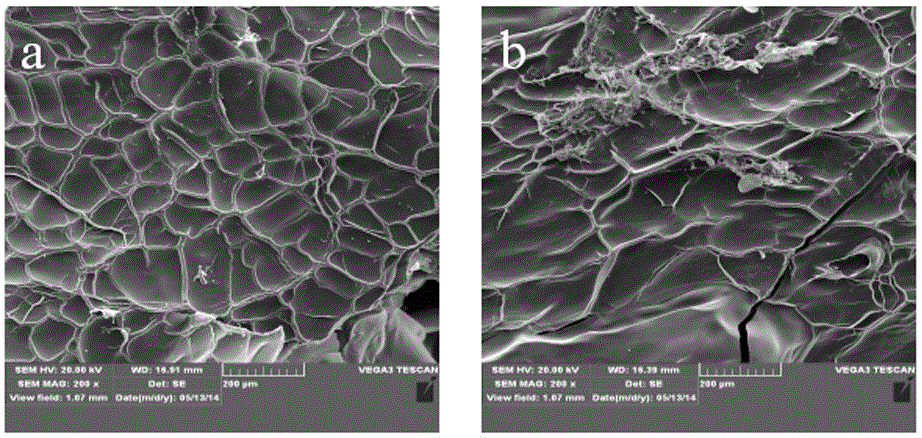

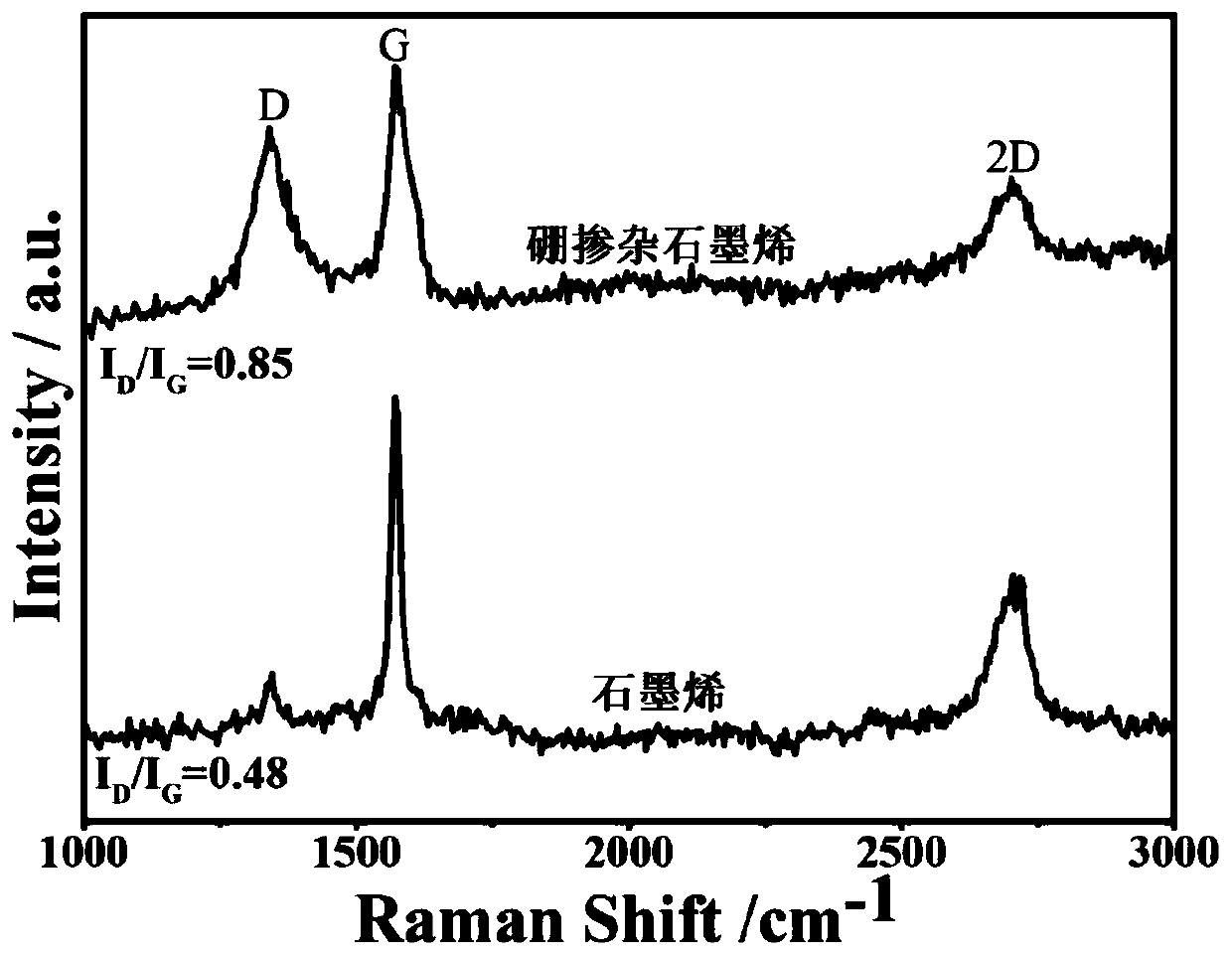

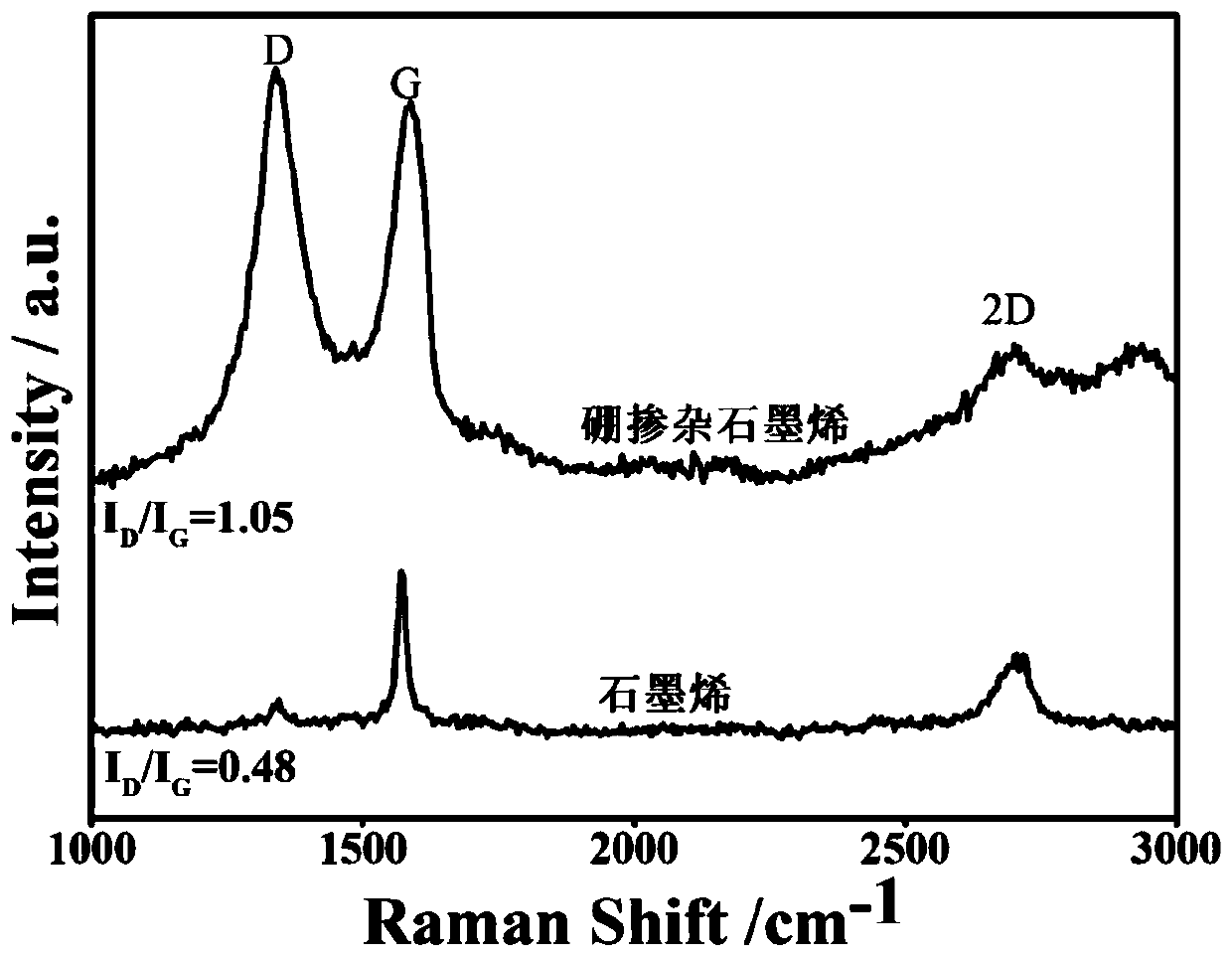

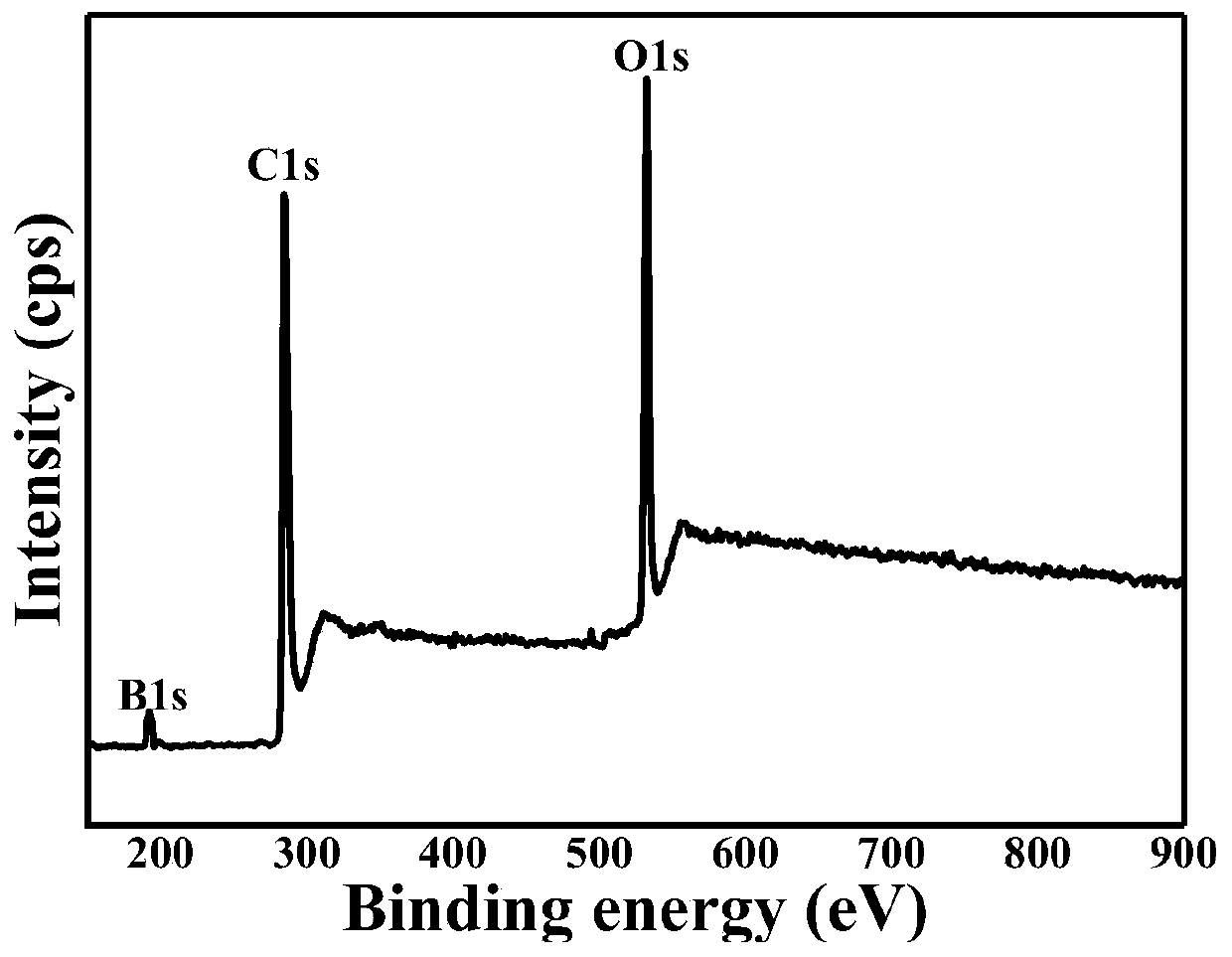

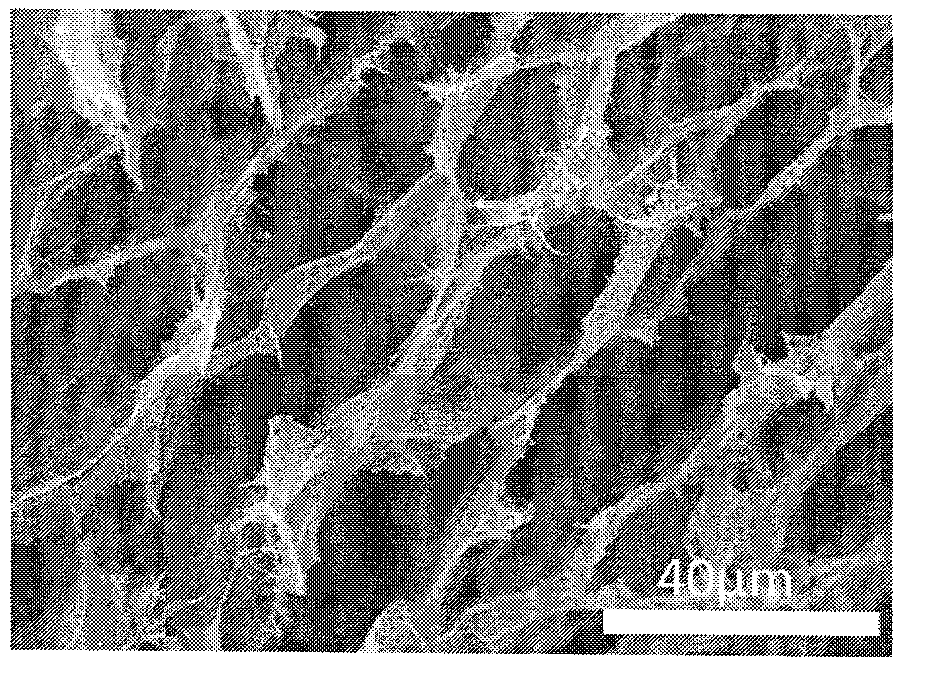

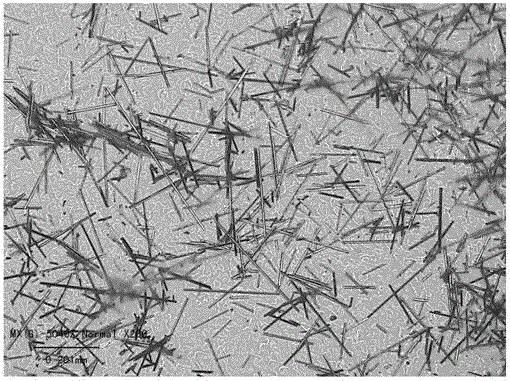

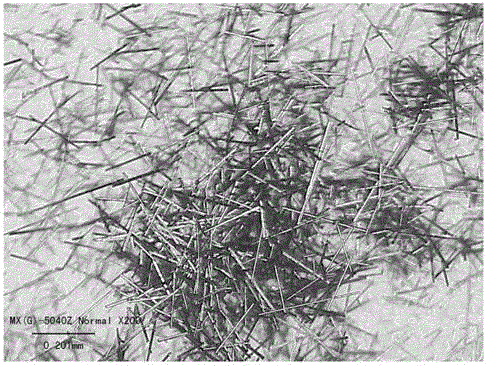

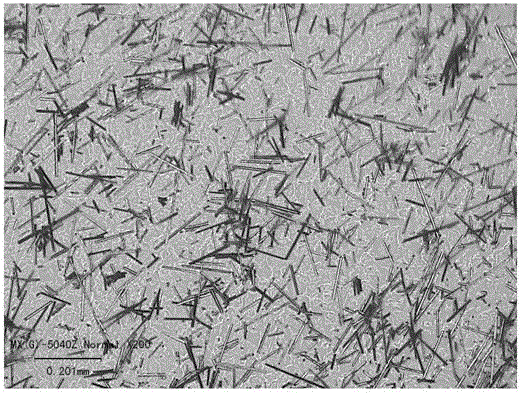

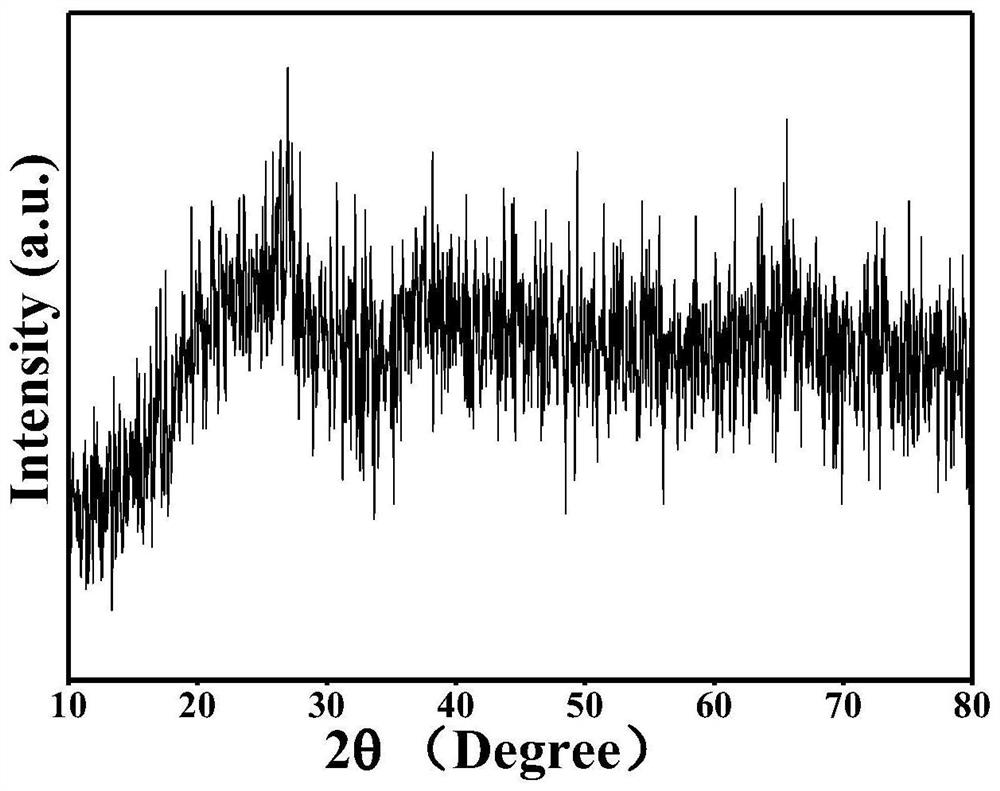

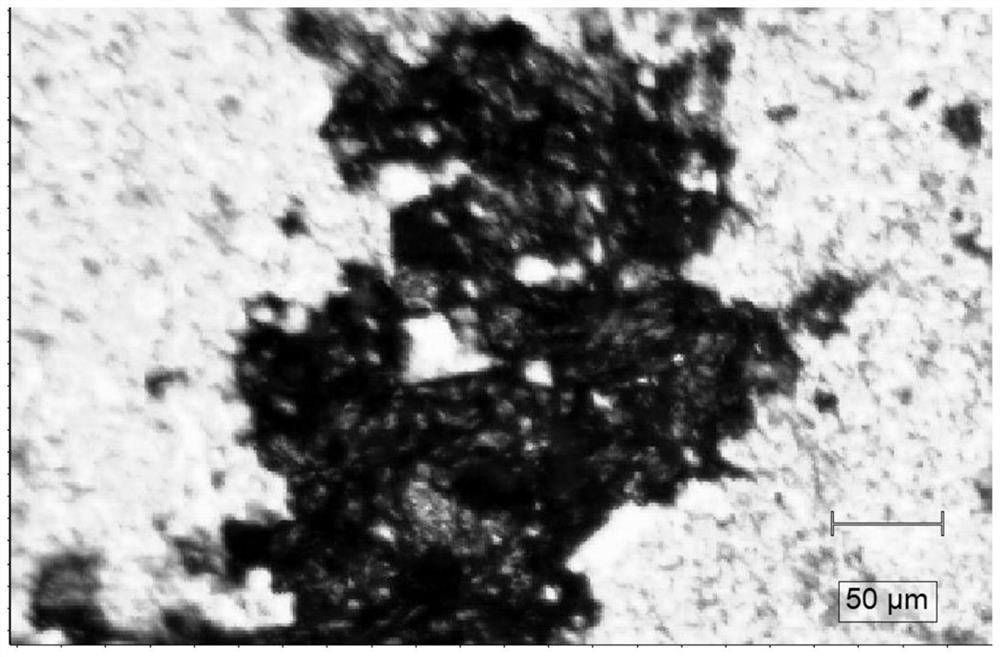

Method for preparing boron-doped graphene through electrochemical stripping of double graphite electrodes

PendingCN110980706AReduce usageThe process is easy to scale upGrapheneElectrolytic agentDoped graphene

The invention provides a method for electrochemically preparing boron-doped graphene through double graphite electrodes, and belongs to the technical field of controllable preparation of graphene materials and doping control of the graphene materials. The boron-doped graphene is prepared in one step by taking an aqueous solution of a soluble salt of which anions contain boron elements as an electrolyte and graphite foil as a raw material and adopting a double-graphite-foil electrochemical stripping method. As double graphite foils are used as positive and negative electrodes respectively, theuse of noble metal electrodes is reduced, and the cost is effectively reduced. The method can be simply implemented in a common beaker or glassware. The preparation method is green and environment-friendly, equipment is simple, operation time is short, operation is convenient, the process is simple and easy to amplify, and the prepared boron-doped graphene has the advantages of being high in quality, good in conductivity, excellent in dispersity in water and the like.

Owner:SHAANXI SCI TECH UNIV

Preparation method of graphene three-dimensional material

ActiveCN101982408BImprove conductivityHigh strengthFixed capacitor electrodesIron oxides/hydroxidesManganeseUltrasonic dispersion

The invention discloses a graphene three-dimensional material as well as a preparation method and an application thereof. The material consists of 10 to 99% of graphene and 1 to 90% of the oxide of manganese, nickel, iron or cobalt. The preparation method comprises the following steps: performing ultrasonic dispersion on graphite oxide to prepare a graphite oxide solution; adding a metal salt solution while stirring or under ultrasonic conditions, and adding a hydrazine hydrate solution; conducting reaction in a drying oven or a hydro-thermal reaction kettle; and then drying to obtain the graphene three-dimensional material. The graphene three-dimensional material is applied to a super capacitor with the capacity of 200 to 800 F / g, or used for making the cathode of a lithium ion battery with the capacity of 300 to 1,400 mAh / g. According to the invention, the preparation process is simple; the prepared graphene three-dimensional macroscopic material has high conductivity and strength; and when being used for the cathode of the lithium ion battery and the super capacitor, the material has high performance.

Owner:TIANJIN UNIV

Method for concurrent production of potassium chloride and mineralization fixation of CO2

InactiveCN103693659BRaise the ash melting pointHigh melting pointDispersed particle separationAlkali metal chloridesEvaporationPotassium

The invention belongs to the comprehensive field of potassium fertilizer production and CO2 emission reduction, and provides a method for concurrent production of potassium chloride and mineralization fixation of CO2. The process steps comprise: (1) adopting potassium feldspar, calcium chloride and coal as raw materials, preparing materials, carrying out ball milling, and carrying out pressing molding or pelletizing; (2) conveying the molded material or the material balls into a rotary kiln from the kiln tail, conveying air into the rotary kiln from the kiln head, and controlling a residence time of the molded material or the material balls at a temperature range of 800-1000 DEG C to 20-40 min; (3) crushing the calcinated material, and adding water to carry out potassium leaching through the water; (4) adding water to the potassium leaching residue to carry out pulp conditioning, and introducing CO2 to carry out a mineralization reaction; (5) carrying out returning of the potassium leaching solution so as to be used for leaching of potassium from the calcinated material when the Baume degree of the potassium leaching solution is less than or equal to 29, and carrying out evaporation concentration on the potassium leaching solution to achieve the Baume degree of 42-42.5 when the Baume degree of the potassium leaching solution is more than 29, and cooling to carry out potassium chloride crystallization; and (6) cooling the potassium extraction mother liquor to carry out calcium chloride crystallization, and carrying out solid-liquid separation to obtain calcium chloride and the calcium extraction mother liquor.

Owner:SICHUAN UNIV

Method for preparing astaxanthin from haematococcus pluvialis

ActiveCN110437116ASimple and efficient operationSimple regeneration methodOrganic chemistryChemistryHaematococcus pluvialis

The invention aims to provide a method for preparing astaxanthin from haematococcus pluvialis. The astaxanthin in the haematococcus pluvialis can be quickly and efficiently identified, the productiontime is greatly shortened, mechanical stability and thermal recessiveness are realized, the process is simple, operation is convenient, and industrial production is easy to realize.

Owner:ZHEJIANG LIZIYUAN FOOD CO LTD

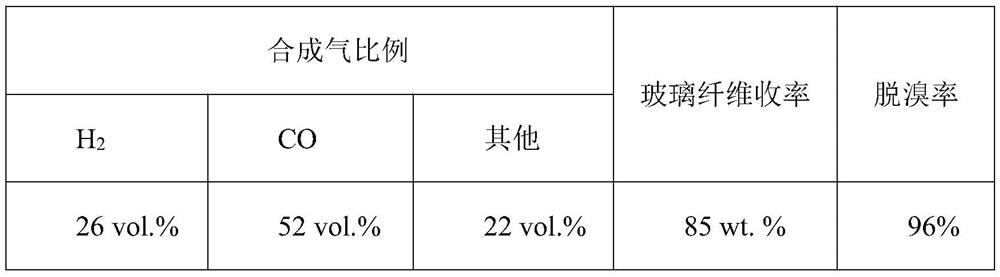

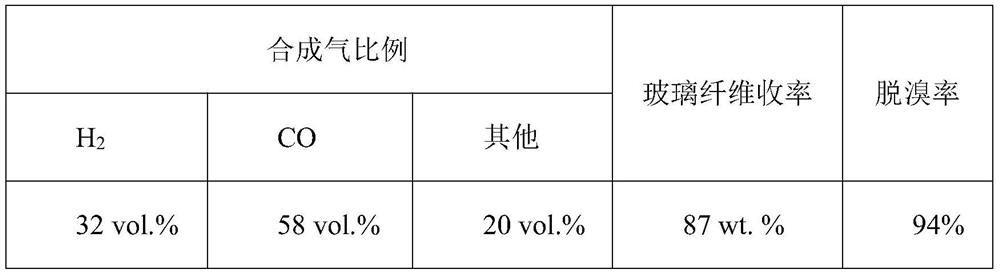

Method for preparing synthesis gas by co-processing waste printed circuit board and organic waste liquid

PendingCN114231319AReduce energy consumptionSimple processGasification processes detailsGranular/pulverulent flues gasificationPrinted circuit boardPyrolysis

The invention discloses a method for preparing synthesis gas by co-processing a waste printed circuit board and an organic waste liquid, a heavy product obtained by low-temperature pyrolysis of the waste printed circuit board, waste lubricating oil and the organic waste liquid are used for preparing multi-element slurry for a synthesis gas preparation process, organic matters in the three wastes are fully utilized, and meanwhile, clean water resources are saved; the method has the characteristics of being high in resource utilization efficiency, turning waste into wealth and being environment-friendly, meanwhile, the debromination effect is good, and the problems that in the prior art, when the waste printed circuit boards are subjected to pyrolysis treatment, the recovery value of nonmetal parts is low, liquid products are difficult to utilize and the debromination effect is poor are solved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI +1

Conductive graphene film and self-assembly preparation method thereof

The invention relates to a conductive graphene film and a self-assembly preparation method thereof. A graphene powder material and a dispersing aid are added into a reactor according to the mass ratioof 100-5: 1, then the mixture is added into a solvent, the mass-volume ratio of the solvent and graphene is 1-10: 1, the ultrasonic oscillation is performed for 30 minutes to 10 hours, the ultrasonicpower is between 20 and 300 W, and a graphene solution with good dispersion is obtained; and the graphene solution with good dispersion is transferred into a water bath with a temperature of between5 and 90 DEG C, the water bath temperature is lower than a boiling point of the solvent, the graphene solution is maintained in the water bath for 5 minutes to 3 hours, the graphene self-assembles ona gas-liquid surface to form a graphene film, and the graphene film is fished out from the liquid level and is dried at normal temperature to obtain the conductive graphene film. The square resistanceof the graphene film is within the range of between 5 and 3,000 omega / sq, the graphene film has good strength, and the thickness is between 2 and 100 mu m. The method has simple preparation process and easy operation; and the graphene film has the advantages of good conductivity and strength, controllable thickness, cuttable shape, adjustable scale, low cost, and easy process scale-up.

Owner:深圳清研紫光科技有限公司

Method for preparing carbon fiber powder

ActiveCN105088421AReduce pollutionSimple preparation processFibre chemical featuresFiberMolten state

The present invention relates to a method for preparing carbon fiber powder, and mainly solves the problems of high energy consumption and low production efficiency in the prior art, the method for preparing carbon fiber powder comprises the steps: (1) a carbon fiber and said thermoplastic resin-containing mixture is obtained from continuous carbon fiber and thermoplastic resin in a molten state by shearing, grinding and mixing; (2) the thermoplastic resin in the mixture is dissolved by a good solvent for the thermoplastic resin; and (3) the carbon fiber powder is obtained by solid-liquid separation, by the technical scheme, the technical problems are solved, and the method can be used in industrial production of the carbon fiber powder.

Owner:CHINA PETROLEUM & CHEM CORP +1

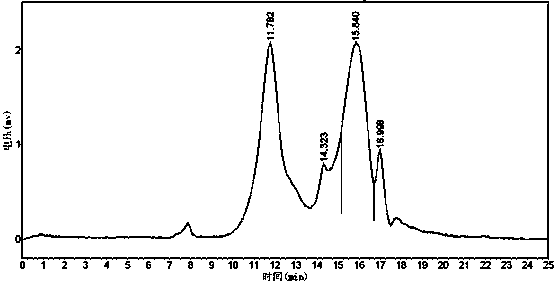

Method for electrochemically preparing manganese dioxide-graphene compound

PendingCN112225257AReduce usageLow costGrapheneManganese oxides/hydroxidesElectrolytic agentPermanganic acid

The invention provides a method for electrochemically preparing a manganese dioxide-graphene compound, and belongs to the technical field of controllable preparation of inorganic nano materials. Soluble salt containing ammonium, sulfate, peroxysulphate or halogen anions and soluble salt containing permanganate or manganate are used as electrolyte, graphite foils or graphite rods are used as electrodes, and the manganese dioxide-graphene compound is prepared in one step by adopting an electrochemical method. As two graphite foils are respectively used as the anode and the cathode, the use of noble metal electrodes is reduced, and the cost is effectively reduced. The method disclosed by the invention is simple and can be implemented in a general beaker or glassware. The preparation method isgreen, environment-friendly, simple in equipment, short in operation time, convenient to operate, simple in process and easy to amplify.

Owner:SHAANXI SCI TECH UNIV

Preparation method of PLGA (poly (lactic-co-glycolic acid)) drug sustained release microspheres

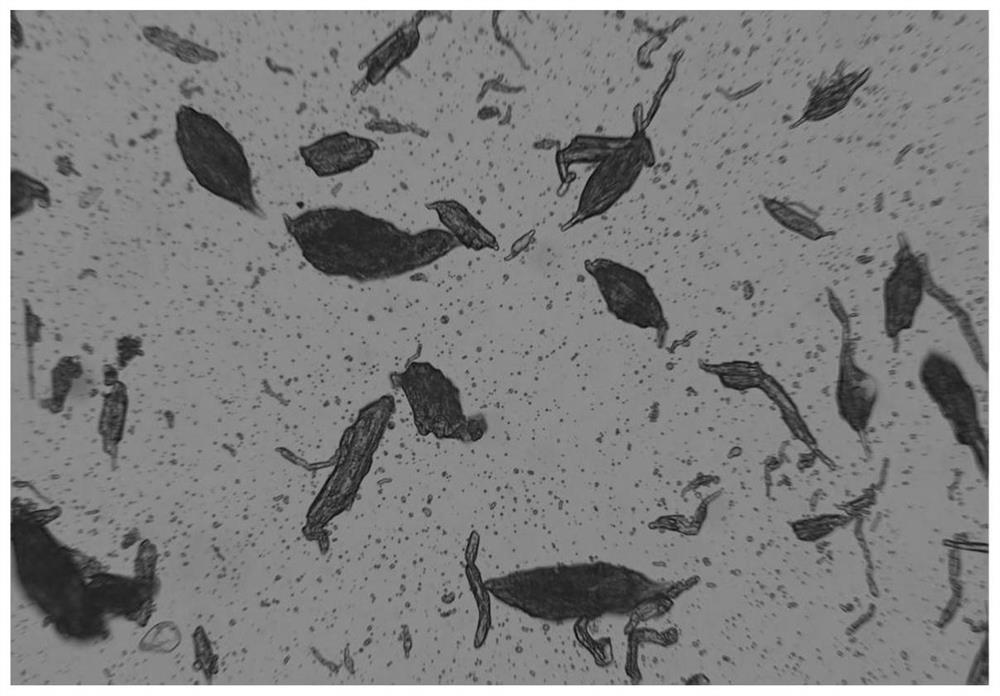

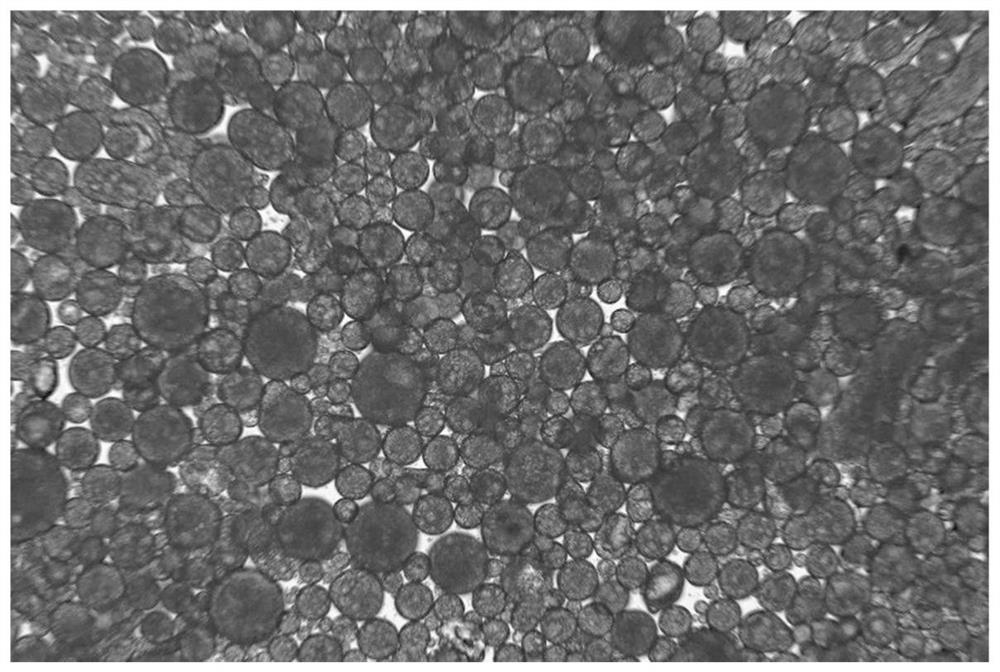

ActiveCN114588115ARapid Particle Size DistributionRapid dispersion into uniform particle size distributionPharmaceutical non-active ingredientsGranular deliveryProcess equipmentMicrosphere

The invention relates to a preparation method of PLGA (poly (lactic-co-glycolic acid)) drug sustained-release microspheres, which is characterized in that emulsification and partial curing are quickly realized by combining a polymer-assisted phase inversion method on the basis of an emulsifying solvent volatilization method. According to the preparation method, the drug loading rate exceeding 50% and the drug encapsulation rate exceeding 90% can be achieved at the same time, and the preparation method has the advantages that the particle size is easy to control, the process is easy to amplify, the solvent toxicity is low, and process equipment is simple.

Owner:SHANGHAI RUINING BIOTECH CO LTD

Production method of pentafluoroethane

InactiveCN1286786CImprove conversion rateHigh selectivityHalogenated hydrocarbon preparationTetrafluoroethyleneHydrogen fluoride

The invention relates to a production method for synthesizing pentafluoroethane (HFC-125) with tetrafluoroethylene and hydrogen fluoride in the presence of a catalyst. The catalyst used is a binary system composed of a tertiary amine compound and a carbonyl-containing compound. The ratio is 1:0.05-10, the reaction temperature is 10°C-150°C, the reaction pressure is 0.6-2.5Mpa, and the reaction time is 1-10 hours. The tetrafluoroethylene raw material of the invention has high conversion rate, good pentafluoroethane selectivity, simple and convenient process, and is suitable for industrialized production.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com