Electrochemical stripping method for preparing fluorine-doped graphene

A fluorine doping and electrochemical technology, applied in chemical instruments and methods, graphene, inorganic chemistry, etc., can solve problems such as unfavorable industrialization promotion, increase production cost, highly toxic fluorine-containing substances, etc., and achieve a wide range of applications, The effect of low cost and high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

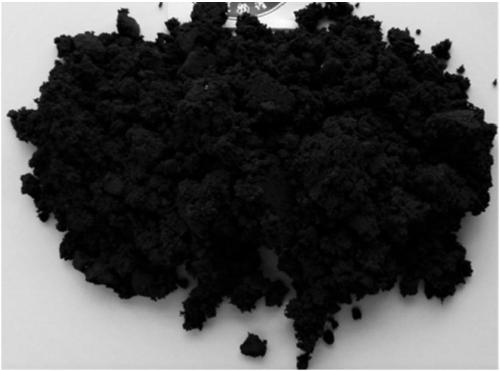

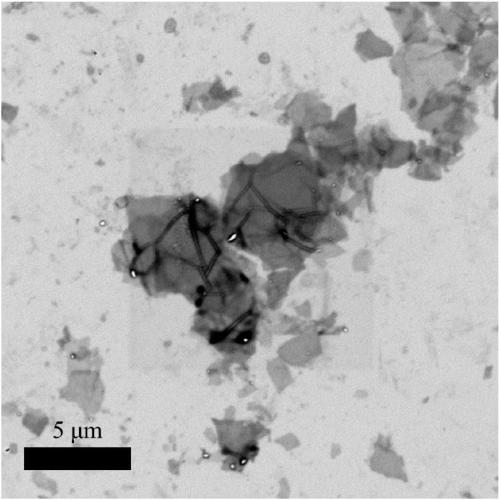

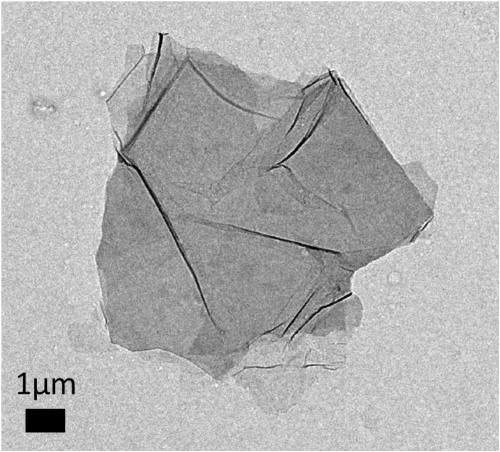

[0032] Add the aqueous solution of ammonium tetrafluoroborate (0.5mol / L) to the electrolytic cell, then connect the positive electrode of the DC power supply with graphite paper, and connect the negative electrode of the DC power supply with the glassy carbon electrode, so that the graphite electrode and the glassy carbon electrode are immersed in the area of the electrolyte solution The ratio is 0.5, and the two electrodes are separated by 1 cm. A cell voltage of 10V was applied, peeled off at room temperature for 1 h, the reaction product was filtered and washed, and sonicated in water for 15 min to obtain a fluorine-doped graphene slurry, and the slurry was freeze-dried to obtain a fluorine-doped graphene powder. The powder diagram of the prepared fluorine-doped graphene is as follows figure 1 As shown in the figure, the powder is about 1.8g, indicating that the method can be scaled up to produce fluorine-doped graphene on a large scale; the scanning electron microscope p...

Embodiment 2

[0034] Add the aqueous solution of tetraethylammonium tetrafluoroborate (0.1mol / L) to the electrolytic cell, then connect the positive electrode of the DC power supply with a graphite rod, and connect the negative electrode of the DC power supply with a copper electrode, so that the graphite electrode and the copper electrode are immersed in the electrolyte The area ratio of the solution is 1, and the two electrodes are separated by 1 cm. A cell voltage of 15V was applied, peeled off at room temperature for 1.5h, the reaction product was filtered and washed, and ultrasonicated in water for 15min to obtain a slurry of fluorine-doped graphene, and the slurry was freeze-dried to obtain a powder of fluorine-doped graphene. According to the analysis and test, the size of the nanosheet is 1-30 μm, the fluorine content is 5%, and the specific capacity of the electrode material can reach 150F / g.

Embodiment 3

[0036] Add an aqueous solution of sodium tetrafluoroborate (0.1mol / L) to the electrolytic cell, then connect the positive electrode of the DC power supply with graphite paper, and connect the negative electrode of the DC power supply with a platinum sheet electrode, so that the graphite electrode and the platinum sheet electrode are immersed in the area of the electrolyte solution. The ratio was 0.25, and the two electrodes were separated by 1 cm. A cell voltage of 10 V was applied, peeled off at room temperature for 30 min, the reaction product was filtered and washed, and sonicated in water for 15 min to obtain a slurry of fluorine-doped graphene. According to the analysis and test, the size of the nanosheet is 1-40 μm, the fluorine content is 0.1%, and the specific capacity of the electrode material can reach 120F / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com