Patents

Literature

31results about How to "Simultaneous recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for recovering indium and germanium from zinc leaching residue

The invention discloses a method for recovering indium and germanium from a zinc leaching residue. The method comprises the following steps of: leaching the zinc leaching residue containing the indium and the germanium by using a sulfuric acid, eliminating ferric iron and removing silicon, and then, adding a hydroximic acid and P204 kerosene to synergistically extract the indium and the germanium, extracting 99% of the germanium and the indium, and then carrying out back extraction on the germanium through an ammonium fluoride and precipitating the germanium by ammonia gas or ammonia water, carrying out the back extraction on the indium through concentration and a hydrochloric acid, replacing the indium with aluminum, and roasting a germanium precipitation residue to respectively obtain an indium ingot and a germanium concentrate. By using the method, the germanium and the indium can be extracted from slag with a lower grade; a procedure is simple; the operation is easy; and fewer pollutants are discharged.

Owner:GUANGXI JINSHAN INDIUM & GERMANIUM METALLURGICAL CHEM

Method for recovering valuable elements in waste lithium ion battery electrode material

ActiveCN107955879AReduce sorting costsReduce recycling costsWaste accumulators reclaimingProcess efficiency improvementSlagElectrical battery

The invention discloses a method for recovering valuable elements in waste lithium ion battery electrode materials. The method comprises steps of roasting the waste lithium ion battery electrode materials in an inert gas atmosphere, the roasting temperature is 200 -600 DEG C, the time is 30-360 minutes, and the roasting slag is obtained; mixing the obtained roasting slag and an acidic solution with [H+] concentration of 0.5~8 mol / L according to the mass ratio of 1:3~10; leaching at the leaching temperature of 30-90 DEG C and leaching time of 1-8 hours, leach liquor and leach residues are filtered to be obtained; the leach liquor is used for recovering nickel, cobalt, manganese, aluminum and lithium, and the leach residues are used for preparing negative electrode materials. According to the method for recovering valuable elements in waste lithium ion battery electrode materials, a leaching reducing agent does not need to be additionally added, the battery sorting and recycling costs are reduced, the positive and the negative electrode materials can be recovered at the same time, and the economic benefits of lithium battery recovery can be improved.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

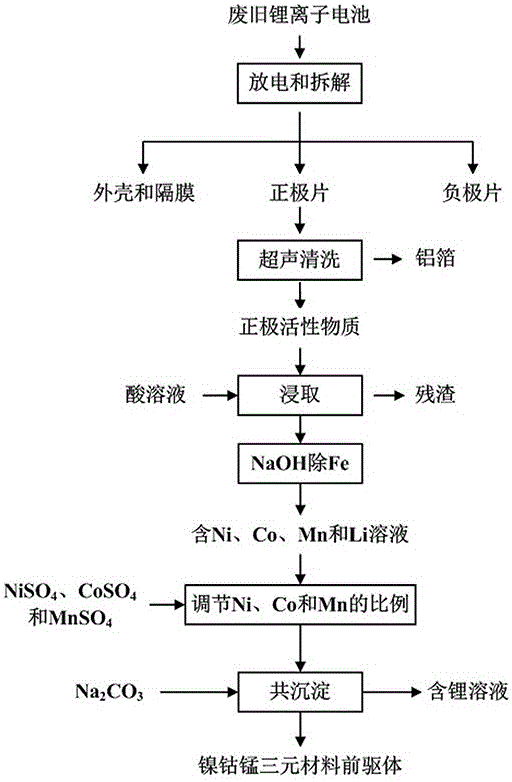

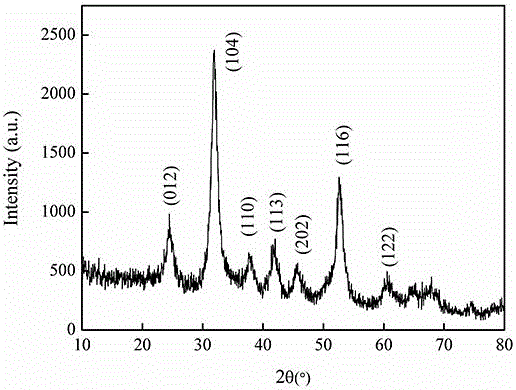

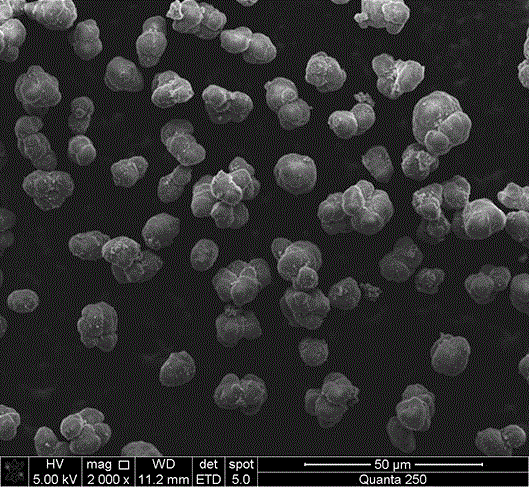

Method for preparing nickel-cobalt-manganese ternary material precursor from waste lithium ion battery

InactiveCN105789726AAvoid cross contaminationSimplify the subsequent impurity removal processWaste accumulators reclaimingBattery recyclingNickel saltFiltration

The invention discloses a method for preparing a nickel-cobalt-manganese ternary material precursor from a waste lithium ion battery. The method comprises the following steps: (1) physically disassembling the waste lithium ion battery which is fully discharged, and taking out a positive plate; (2) putting the separated positive plate into an ultrasonic cleaning machine for ultrasonic cleaning to let a positive active material fall off from a current collector aluminum foil, and directly recycling the aluminum foil after the aluminum foil is dried; (3) dissolving the positive active material obtained in the step (2) into acid, and adding sodium hydroxide to remove ferric; (4) measuring the concentration of metal ions in a leaching solution subjected to ferric removal, adding soluble nickel salt, cobalt salt and manganese salt to adjust the mole ratio of nickel, cobalt and manganese in the solution to be (1-3):(0.5-1):1; (5) adding a sodium carbonate precipitator to enable the three metal elements of nickel, cobalt and manganese to be precipitated at the same time, and performing filtration and drying to obtain the nickel-cobalt-manganese ternary material precursor. The process of the method is simple and flexible; the method is low in recycling cost, and recycled products have great value.

Owner:SUZHOU JUZHI TONGCHUANG ENVIRONMENTAL PROTECTION TECH

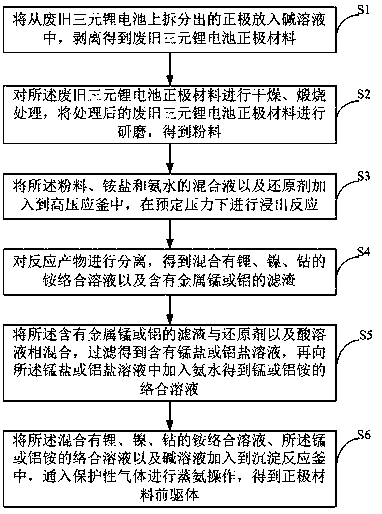

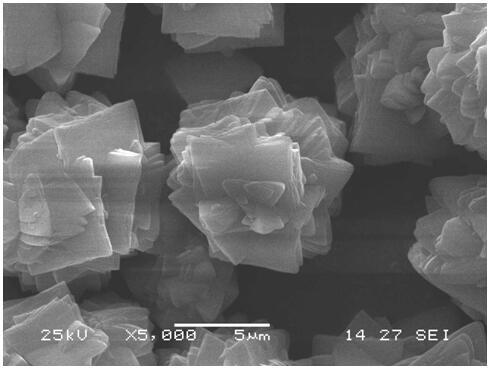

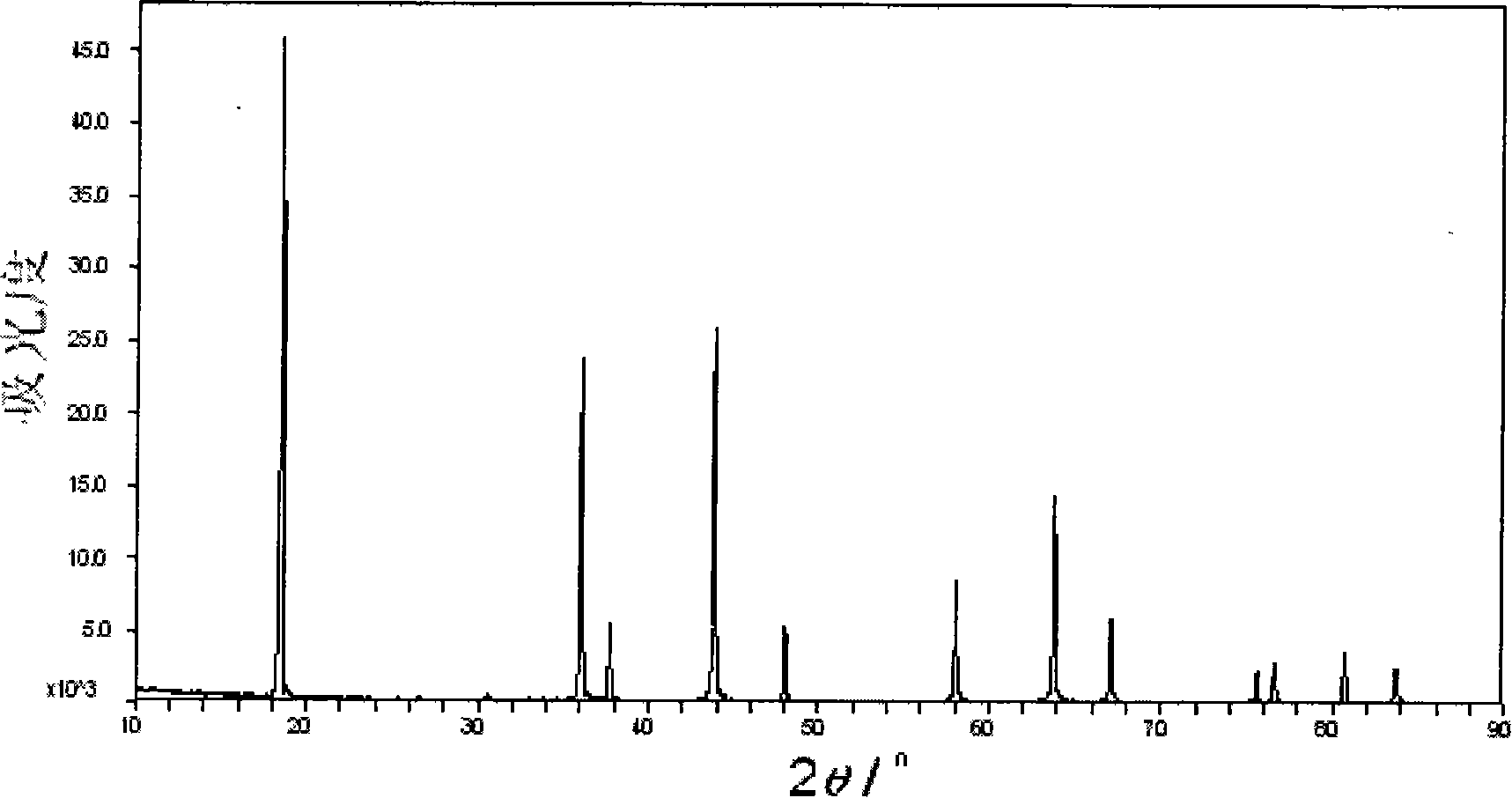

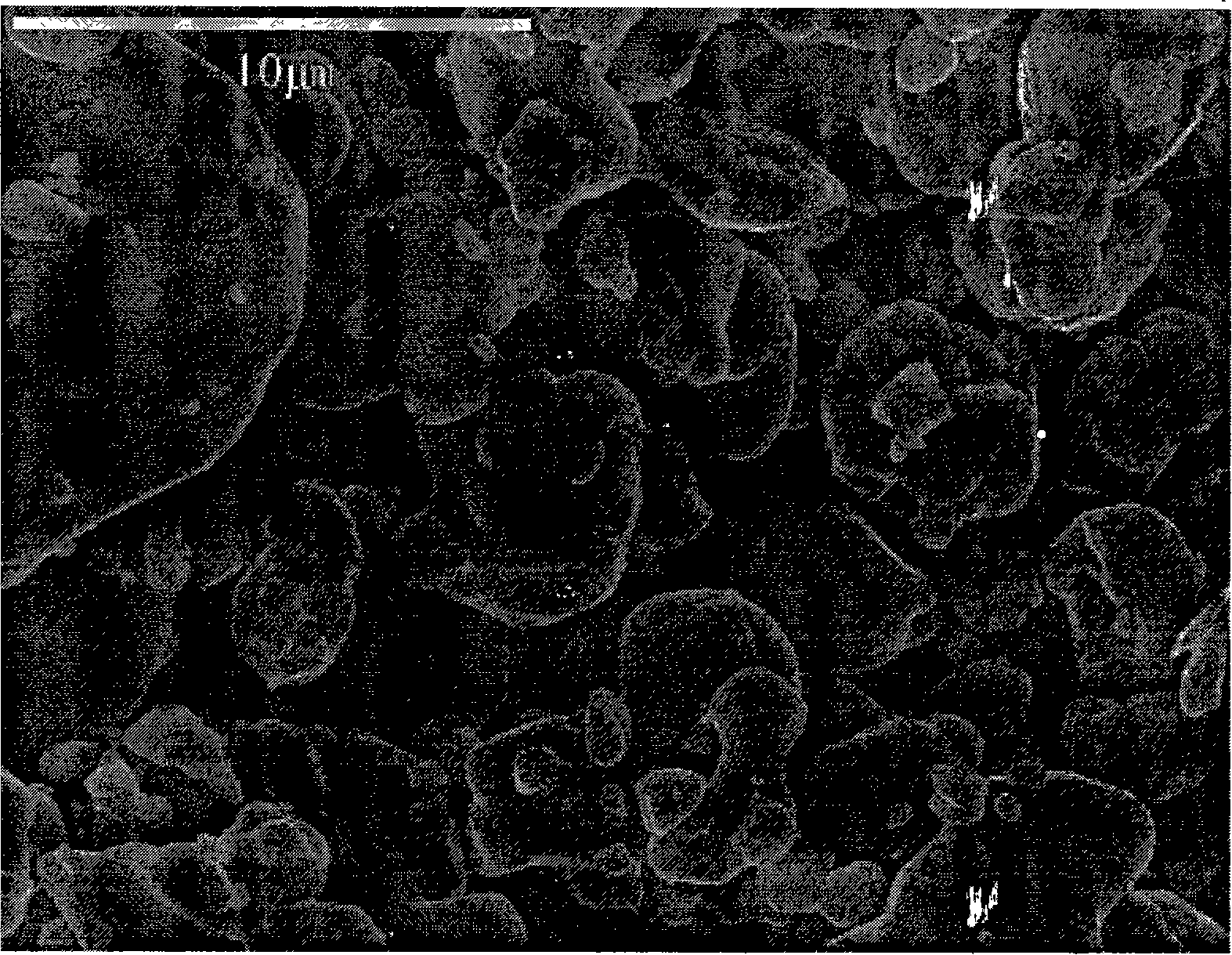

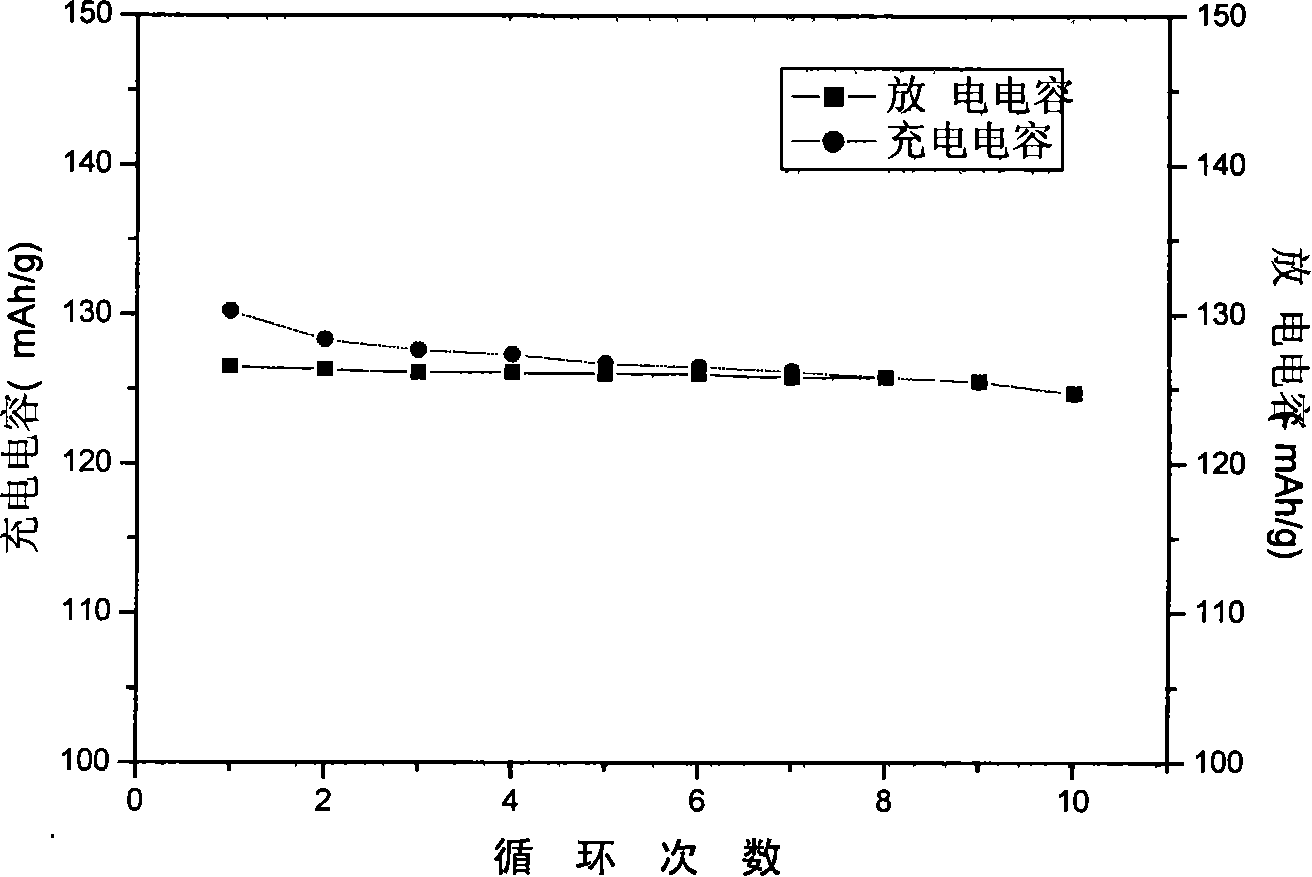

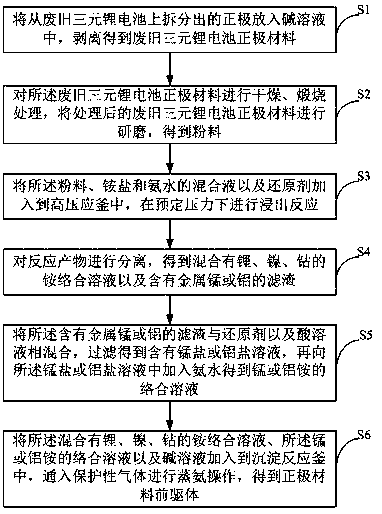

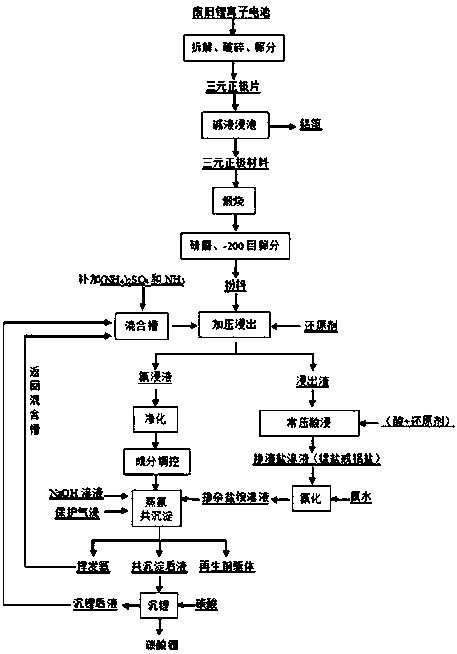

A method for prepare a positive electrode material precursor by using waste ternary lithium battery

ActiveCN109193057ALow costSimultaneous recyclingWaste accumulators reclaimingProcess efficiency improvementManganeseCobalt

The invention provides a method for preparing a positive electrode material precursor by using a waste ternary lithium battery, which adopts a first stage leaching as a pressurized ammonia leaching torealize simultaneous recovery of lithium, nickel and cobalt. The second stage leaching is atmospheric pressure acid leaching to realize the recovery of doped metal (manganese or aluminum). The invention realizes low cost of waste ternary positive electrode material, Short-process recovery and reuse, in which nickel is leached by ammonia under pressure, the comprehensive leaching rate of valuablemetals such as cobalt and lithium reaches 92%. The comprehensive recovery of valuable metals such as nickel, cobalt, lithium, manganese and aluminum is over 95% by two-stage leaching. Ammonia and leaching acid can be recycled in closed circuit. The precursor of ternary positive electrode materials prepared by regeneration can meet the needs of preparation of different series of ternary positive electrode materials, and has a good prospect of industrial application.

Owner:KUNMING UNIV OF SCI & TECH

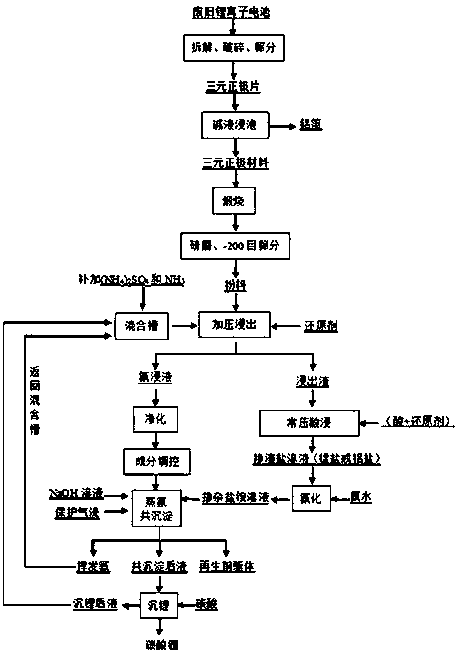

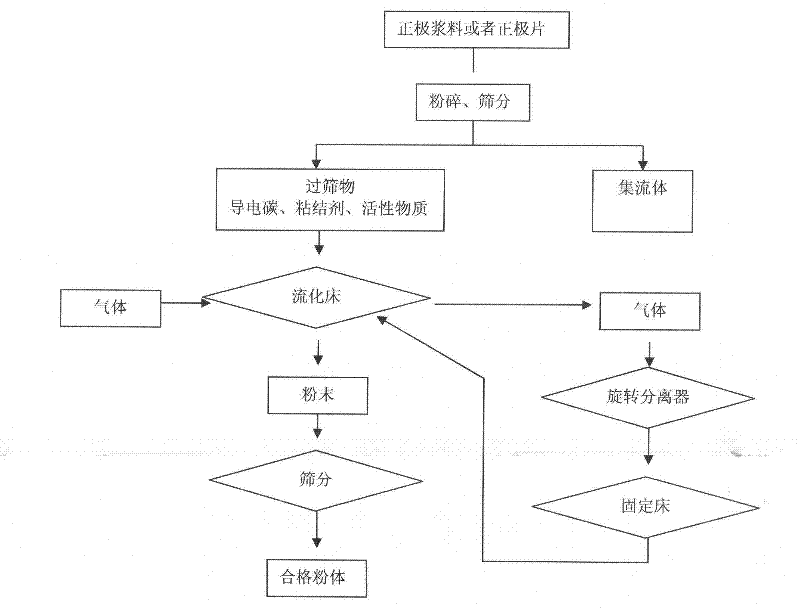

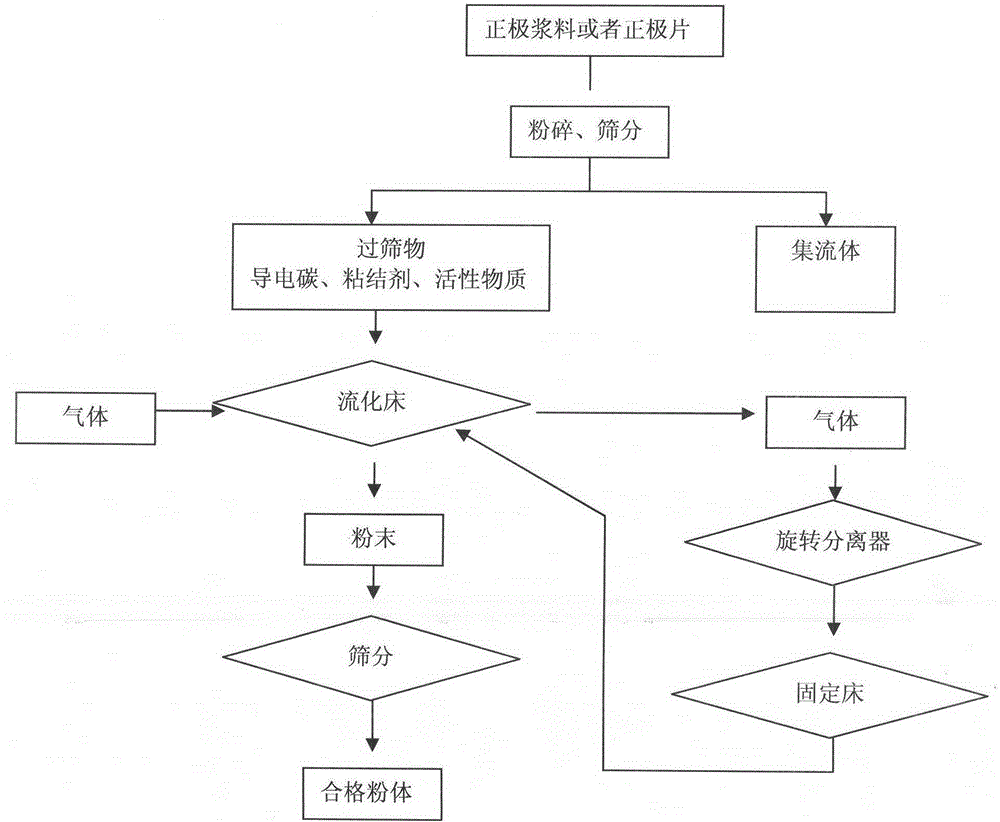

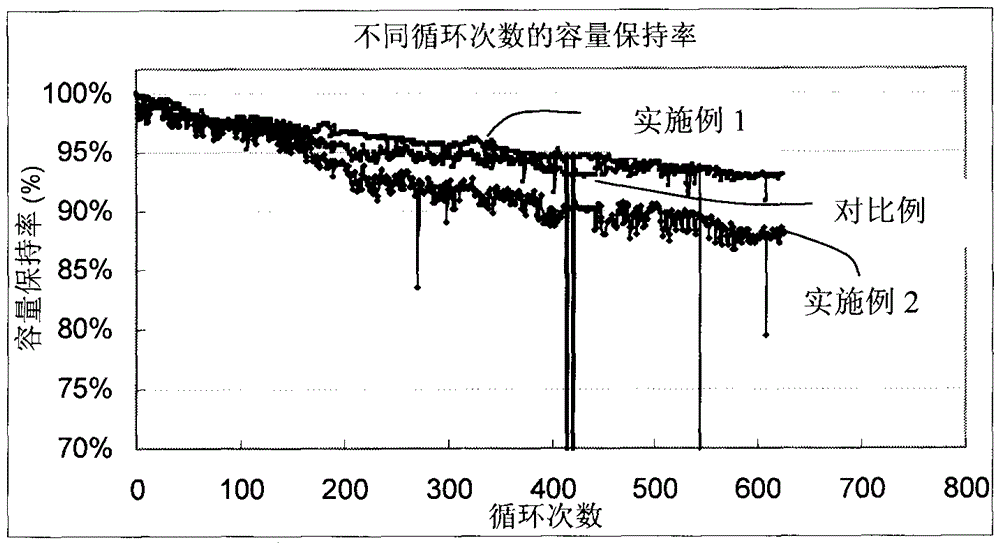

Lithium ion batteries cathode material recovery method

ActiveCN102694217AHigh recovery rateSimultaneous recyclingSolid waste disposalWaste accumulators reclaimingRecovery methodSide effect

The invention belongs to the field of battery materials, and specifically relates to a method for recovering positive active materials from battery material offcuts and slurry. The method comprises the following steps of: filling positive plate or dry positive slurry to be recovered into a pulverizer, screening into a powder, putting the powder into a fluidized bed and removing impurities of conductive carbon and a binder; letting a gas pass through a cyclone separator on the top of the fluidized bed to remove entrained powder, passing through a fixed bed to remove harmful gases, heating and blowing into the fluidized bed for cyclic utilization, cooling the powder at the bottom, and sieving to obtain a qualified positive powder. According to the invention, the process flow is short; the powder is in a fluidization state in the fluidized bed during the process of heat treatment; and the gas and the powder fully contact with each other and the reaction is complete. Therefore, the problems of high impurity content in the product and low recovery rate in a traditional technology are fundamentally resolved; in addition, cobalt and lithium elements are simultaneously recovered, the recovery rate of an active substance reaches up to 94%, and simultaneously side-effect will not be exerted on the active substance and it selectrochemical properties.

Owner:DONGGUAN AMPEREX TECH +2

Recycling method for valuable element in waste lithium ion battery electrode material

InactiveCN108023134AReduce lossReduce consumption costWaste accumulators reclaimingBattery recyclingRecovery methodSlag

A recycling method for a valuable element in a waste lithium ion battery electrode material comprises the following steps of roasting the waste lithium ion battery electrode material in air to obtainroasting slag, wherein the roasting temperature is 400-900 DEG C, and the heat preservation time is 30-300 minutes; and mixing the roasting slag and an acid solution with [H+] concentration being 0.5-9mol / L according to a mass ration being 1:(2-10), performing leaching under a leaching temperature being 30-95 DEG C and leaching time being 1-9 hours, and performing filtering to obtain a leaching liquid and leaching slag, wherein the leaching liquid is used for recycling nickel, cobalt, manganese, aluminum and lithium, and the leaching slag is used for recycling a carbon material. According to the recycling method, a positive electrode material and a negative electrode material of a battery are not needed to be separated, no extra leaching reduction agent is added, the recycling cost is reduced, the positive electrode material and the negative electrode material can be simultaneously recycled, and the recycling economic benefit of the lithium battery is improved.

Owner:GUANGDONG INST OF RARE METALS

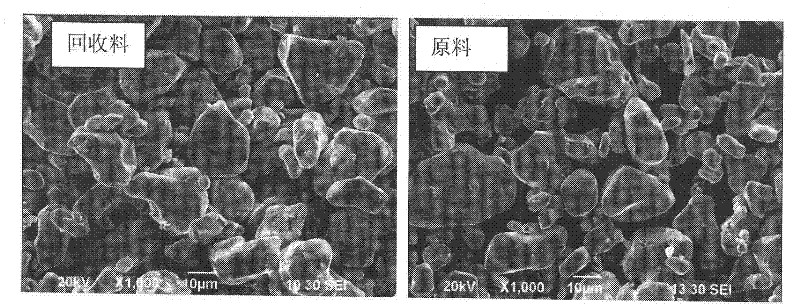

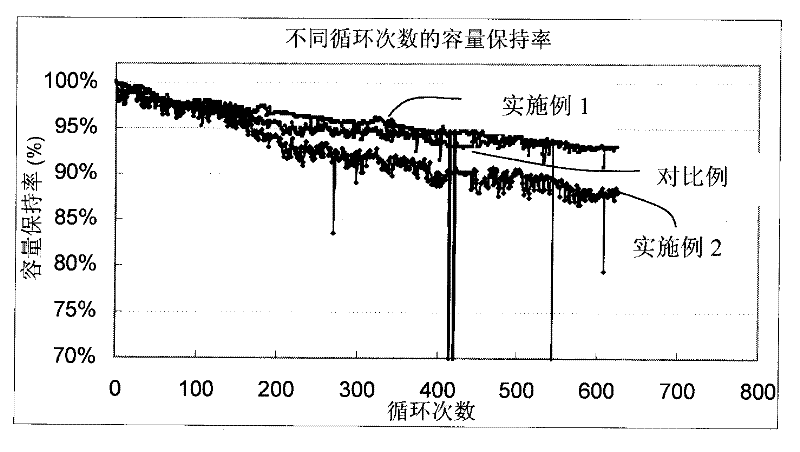

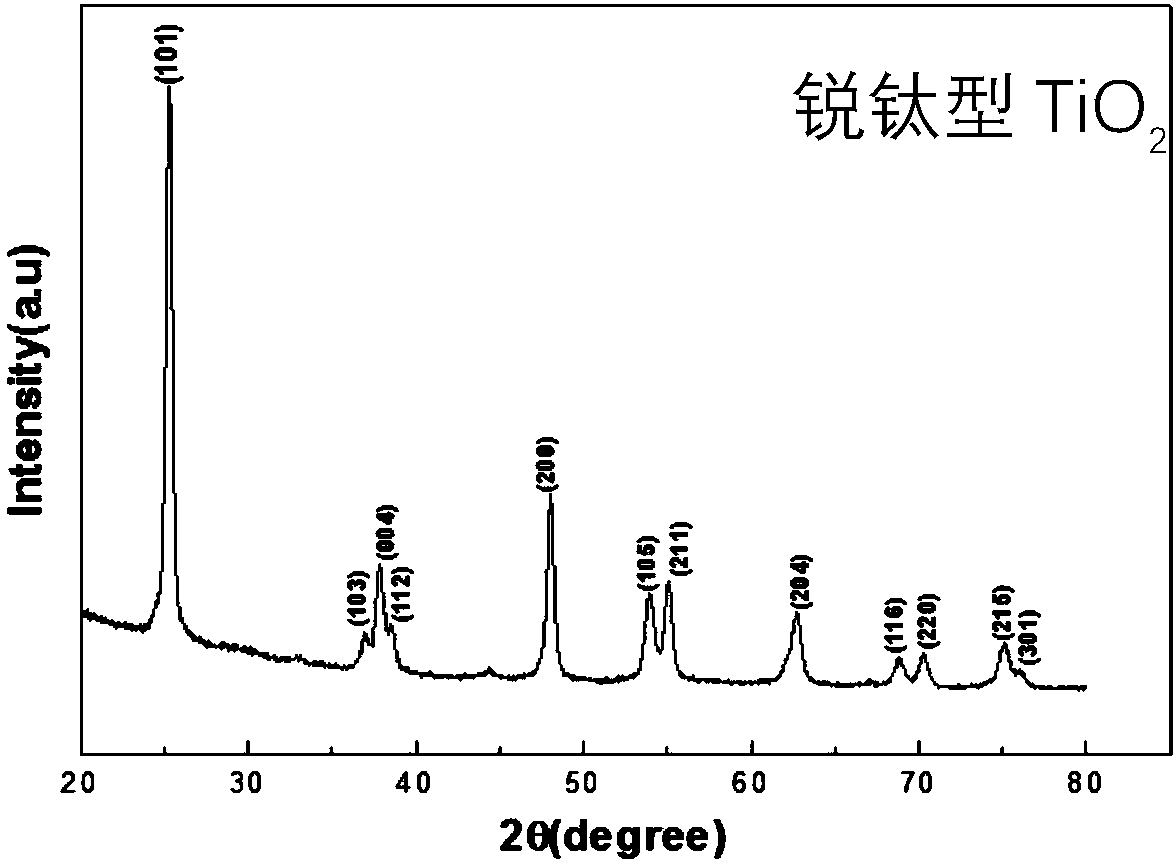

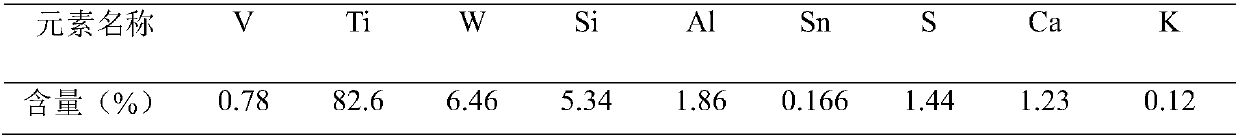

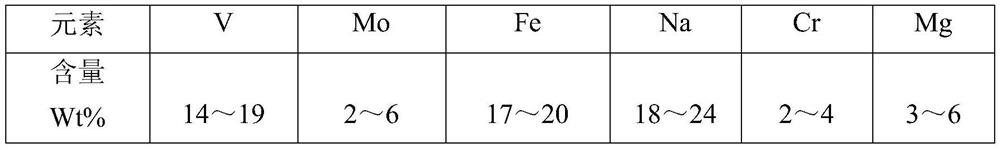

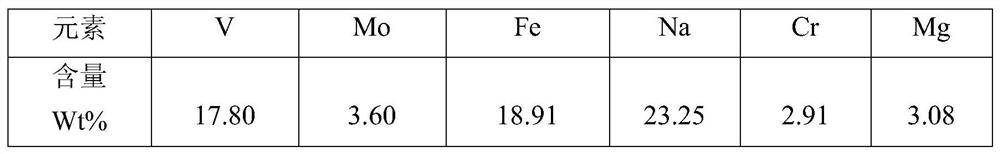

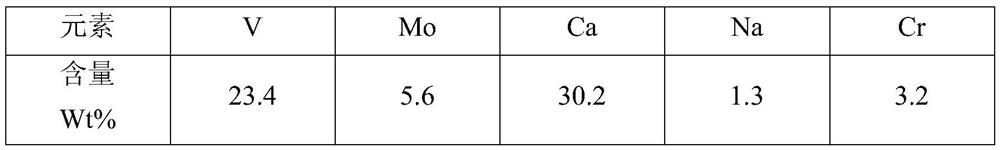

Method for recycling tungsten and vanadium from waste SCR denitration catalyst

InactiveCN107699695AEfficient leachingHigh selectivityProcess efficiency improvementKeroseneCrystallite

The invention provides a method for recycling tungsten and vanadium from a waste SCR denitration catalyst. The method includes the steps that firstly, tungsten and vanadium are leached out, wherein the waste SCR denitration catalyst is placed into a NaOH solution to be leached out, and by means of solid and liquid separation, alkaline leaching liquid containing tungsten and vanadium and residues TiO2 are obtained; secondly, tungsten and vanadium in the alkaline leaching liquid are extracted and purified, wherein a kerosene solution containing primary amine N1923 serves as an extracting agent for extraction; and thirdly, reextraction separating and recycling of tungsten and vanadium in an extracted organic phase are performed. According to a process for extracting tungsten and vanadium fromthe waste SCR denitration catalyst in an alkaline leaching manner, due to the fact that waste catalyst powder and the NaOH solution are subjected to one time of leaching in a high pressure state, a liquid phase containing Na2WO4 and Na2VO3 can be obtained, efficient leaching of tungsten and vanadium is achieved, the W leaching rate reaches 97.46%, the V leaching rate reaches 88.6%, it is also kept that crystalline grains of TiO2 are anatase, and anatase can be reused as a catalyst carrier.

Owner:BEIJING UNIV OF TECH

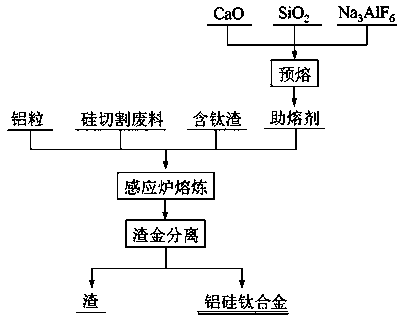

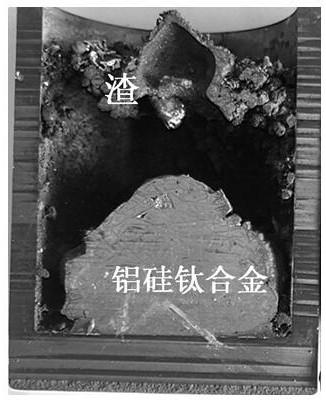

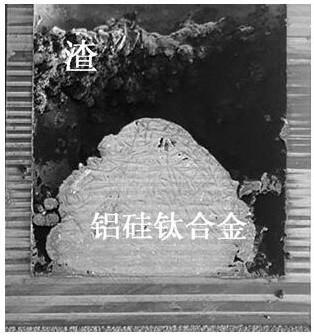

Method for simultaneously recycling silicon in silicon waste materials and titanium in titanium-containing slag through metallic aluminum

InactiveCN110218874AAvoiding the Direct Recycling ConundrumReduce difficultyProcess efficiency improvementMetallic aluminumSlag

The invention relates to a method for simultaneously recycling silicon in silicon waste materials and titanium in titanium-containing slag through metallic aluminum, and belongs to field of non-ferrous metal secondary resource comprehensive technologies. The method comprises the steps that CaO powder and SiO2 powder are uniformly mixed, then Na3AlF6 is added to be uniformly mixed, and mixed powderis obtained; the mixed powder is pre-molten for 0.5-1 h under the condition that the temperature is between 1,400 DEG C and 1,600 DEG C to obtain a pre-molten block, and the pre-molten block is cooled and then ground into powder to serve as a fluxing agent; metallic aluminum particles, the metallic silicon waste materials, the titanium-containing slag and the fluxing agent are uniformly mixed toobtain a mixed material, and the mixed material is smelted for 2-4 h at high temperature under the condition that the temperature is between 1,500 DEG C and 1,800 DEG C; and the high-temperature smelted material is cooled to room temperature at the constant speed, linear cutting treatment is conducted, and an alloy block containing aluminum, silicon and titanium is obtained. According to the method, the purpose of recycling silicon and titanium from the silicon waste materials and the titanium-containing slag simultaneously is achieved, and the current comprehensive recycling problem of the silicon waste materials and the titanium-containing slag is solved.

Owner:KUNMING UNIV OF SCI & TECH

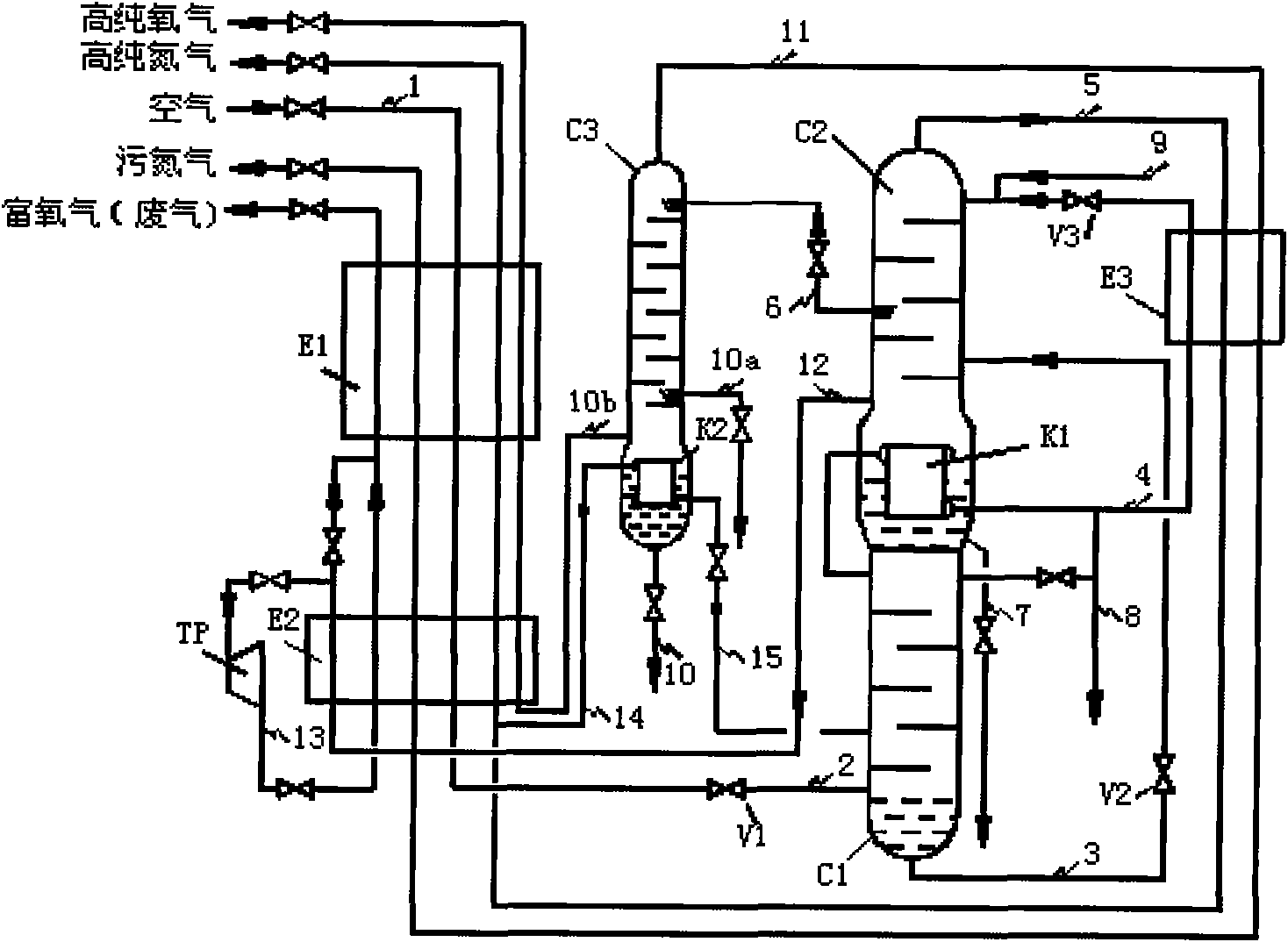

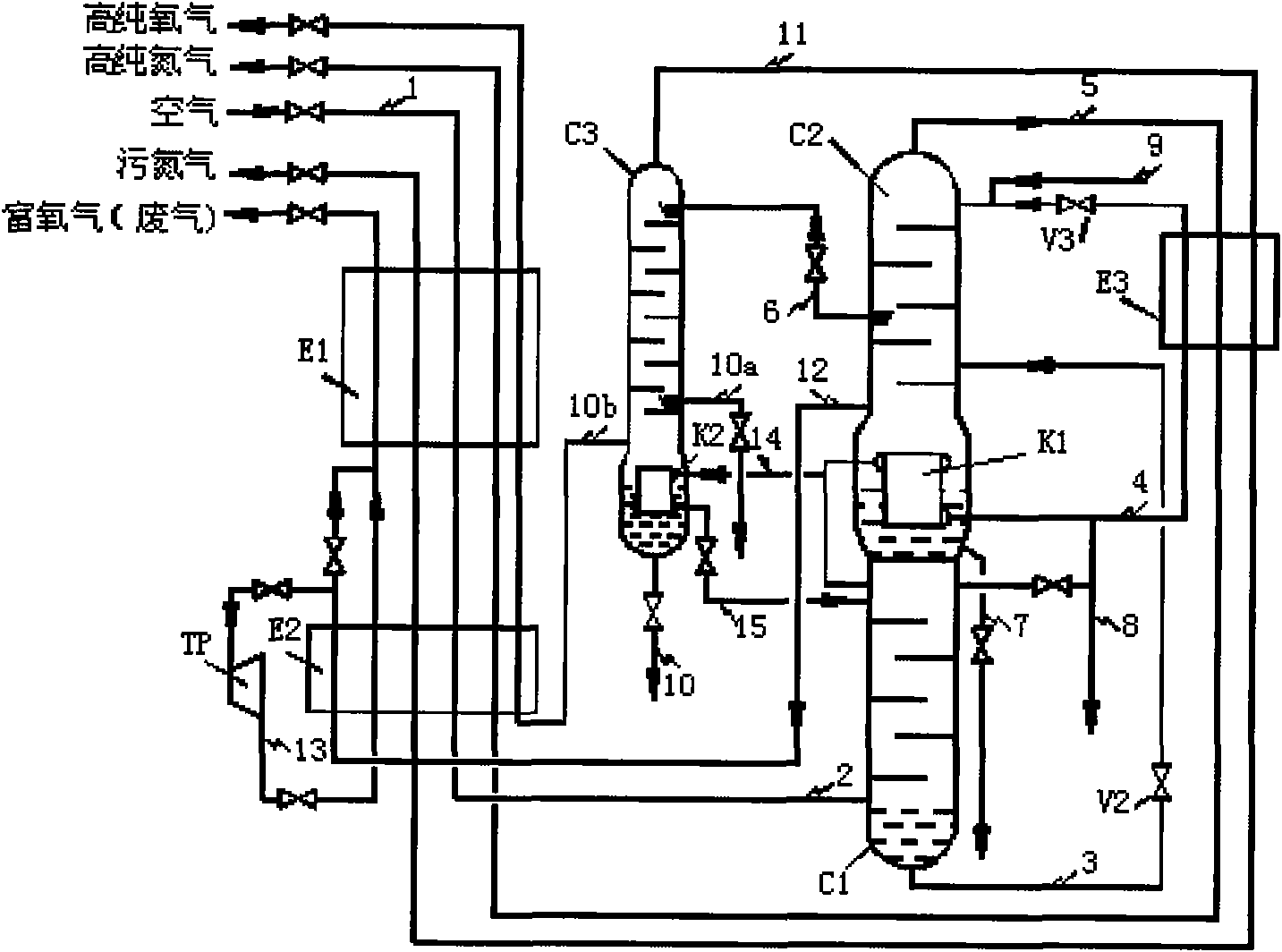

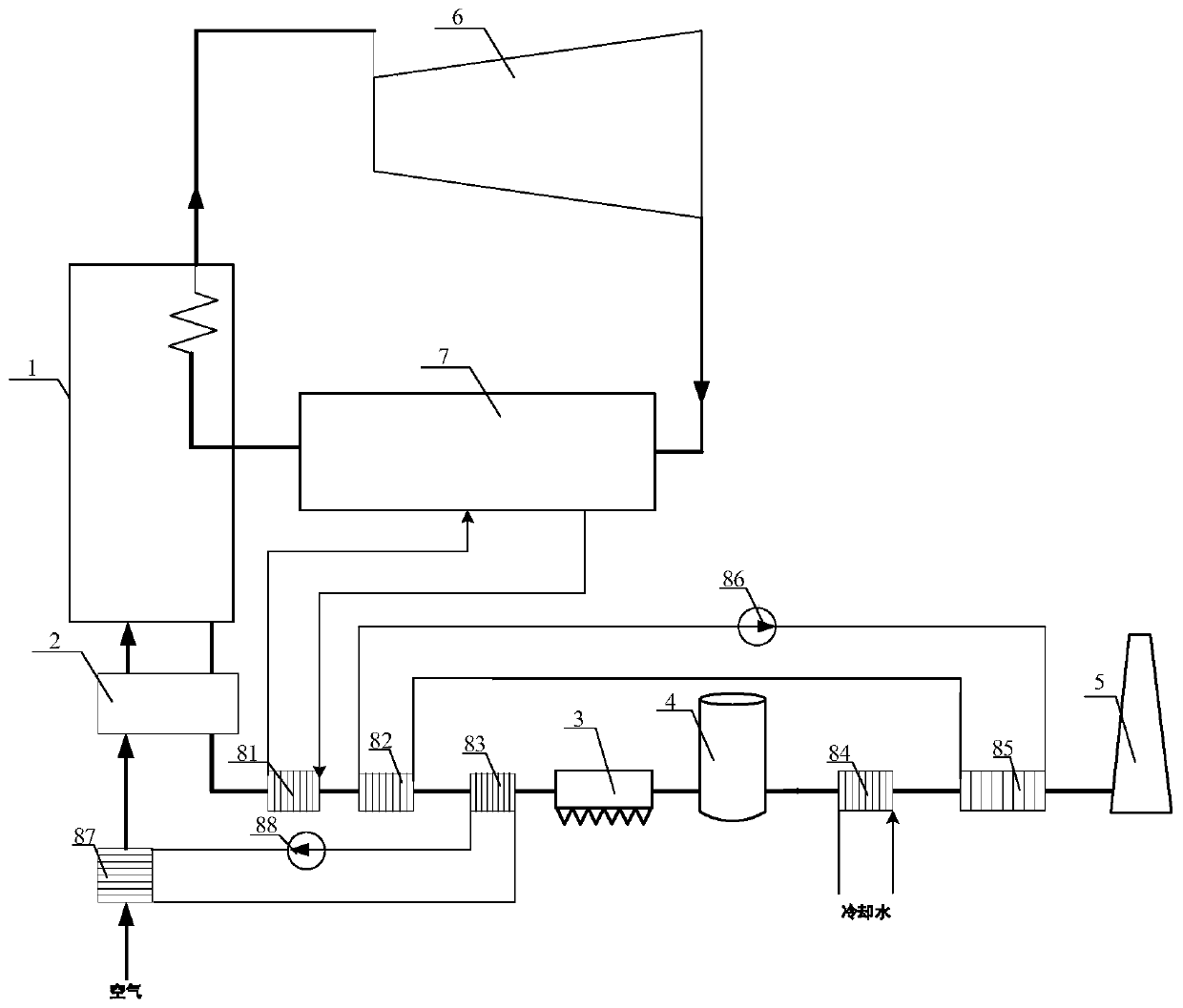

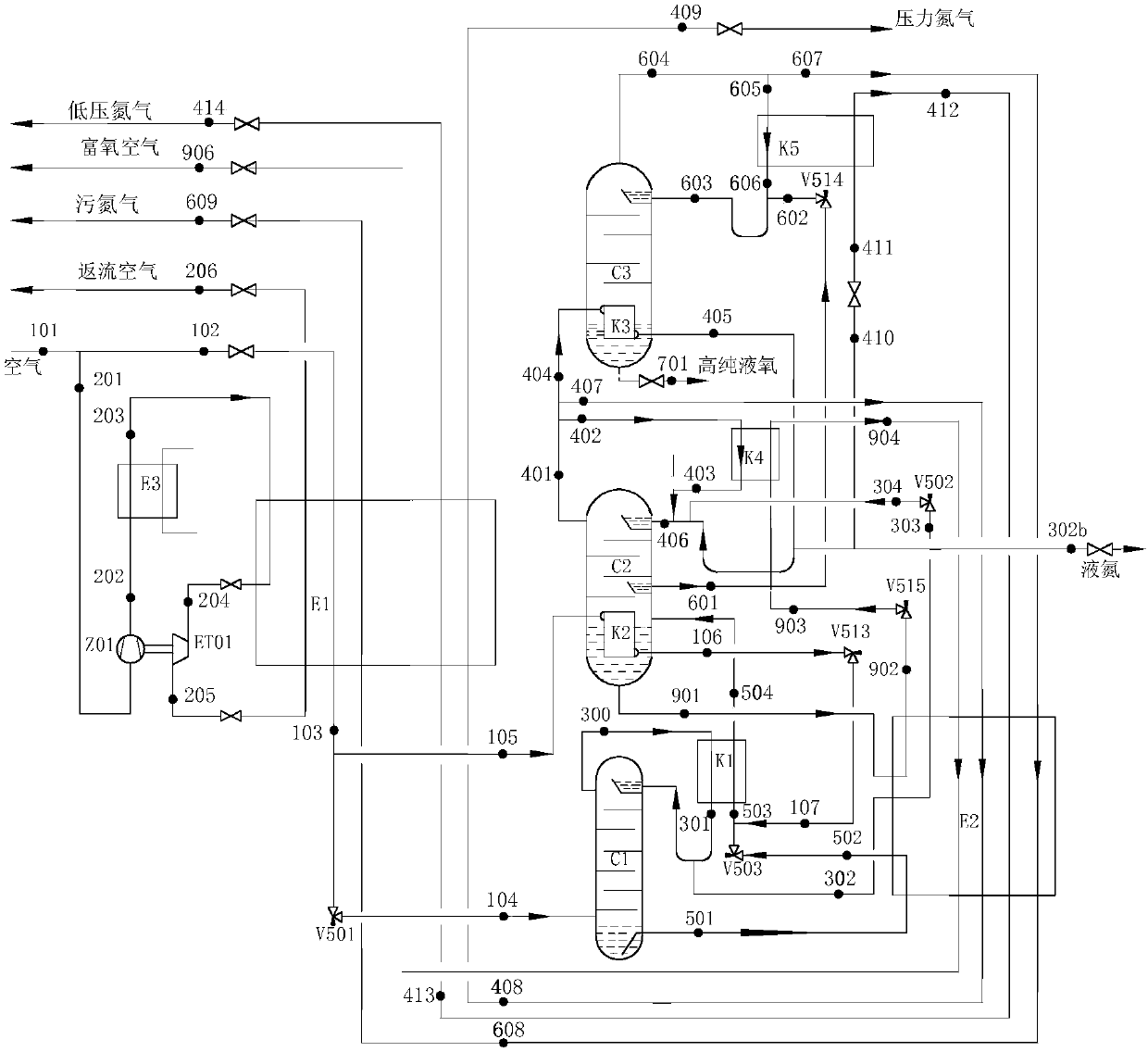

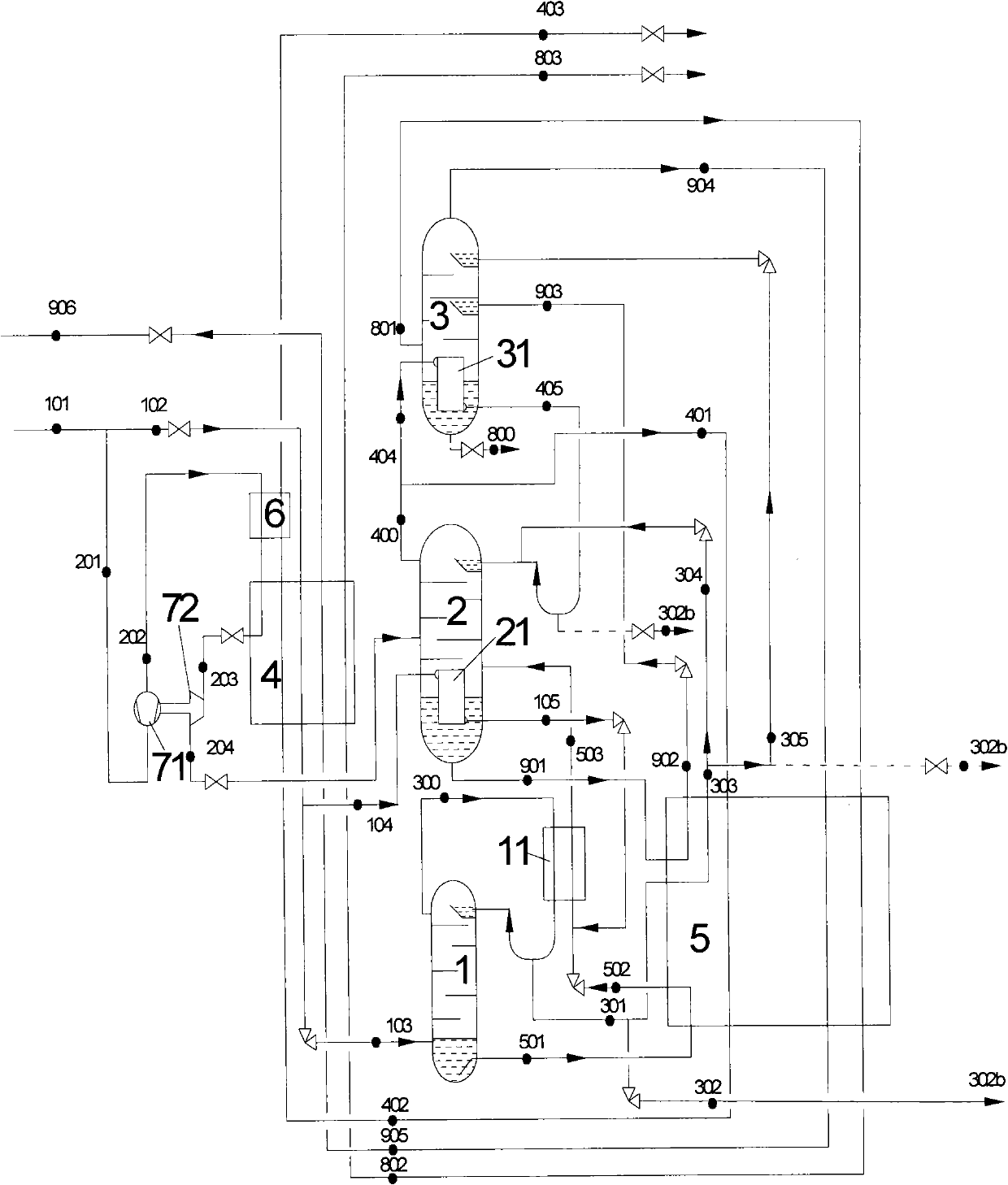

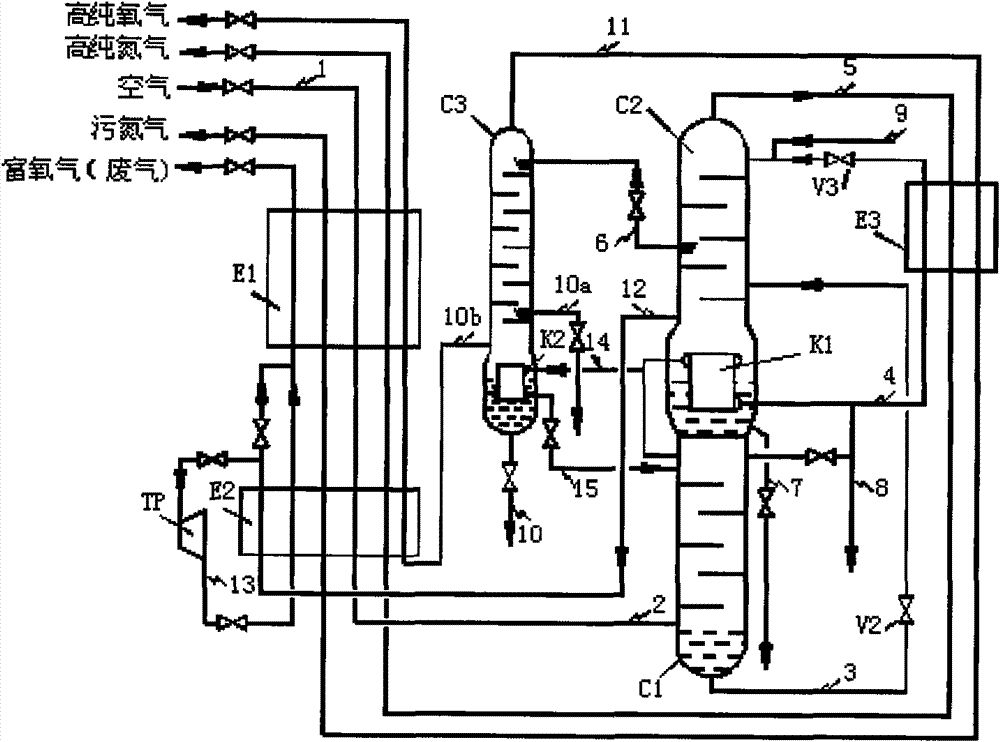

Method and device for producing pressure high-purity nitrogen and high-purity oxygen

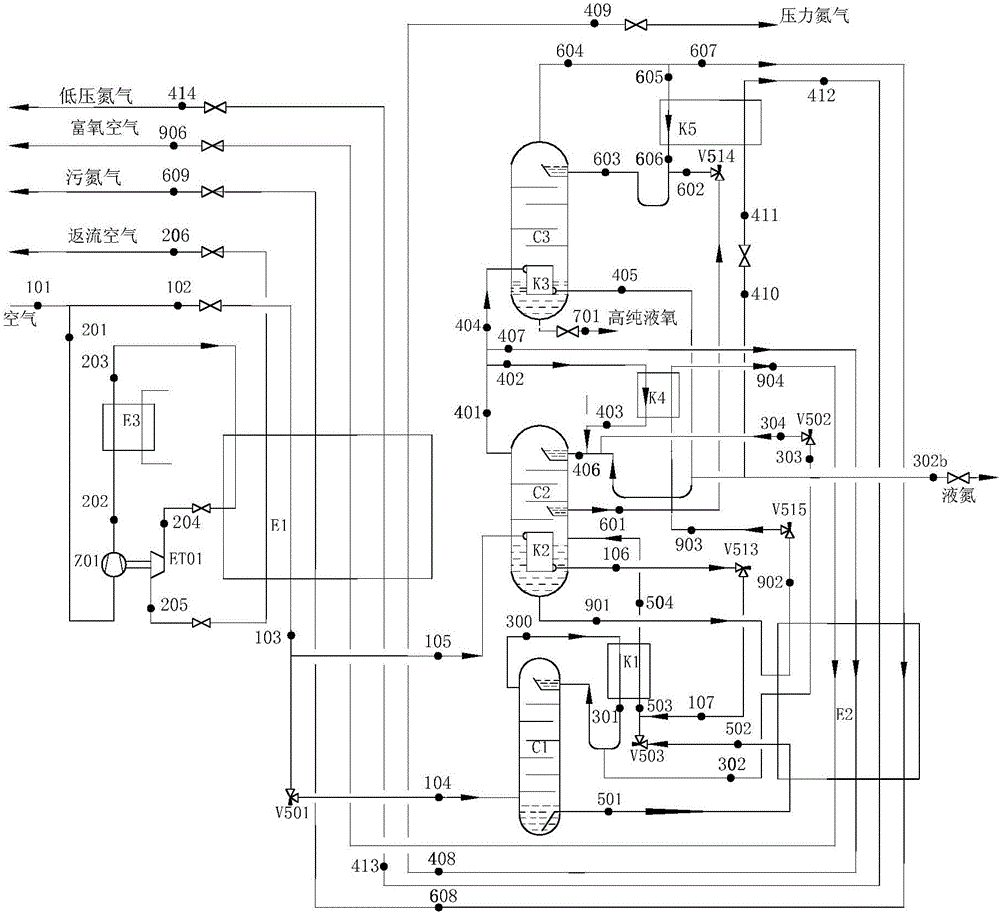

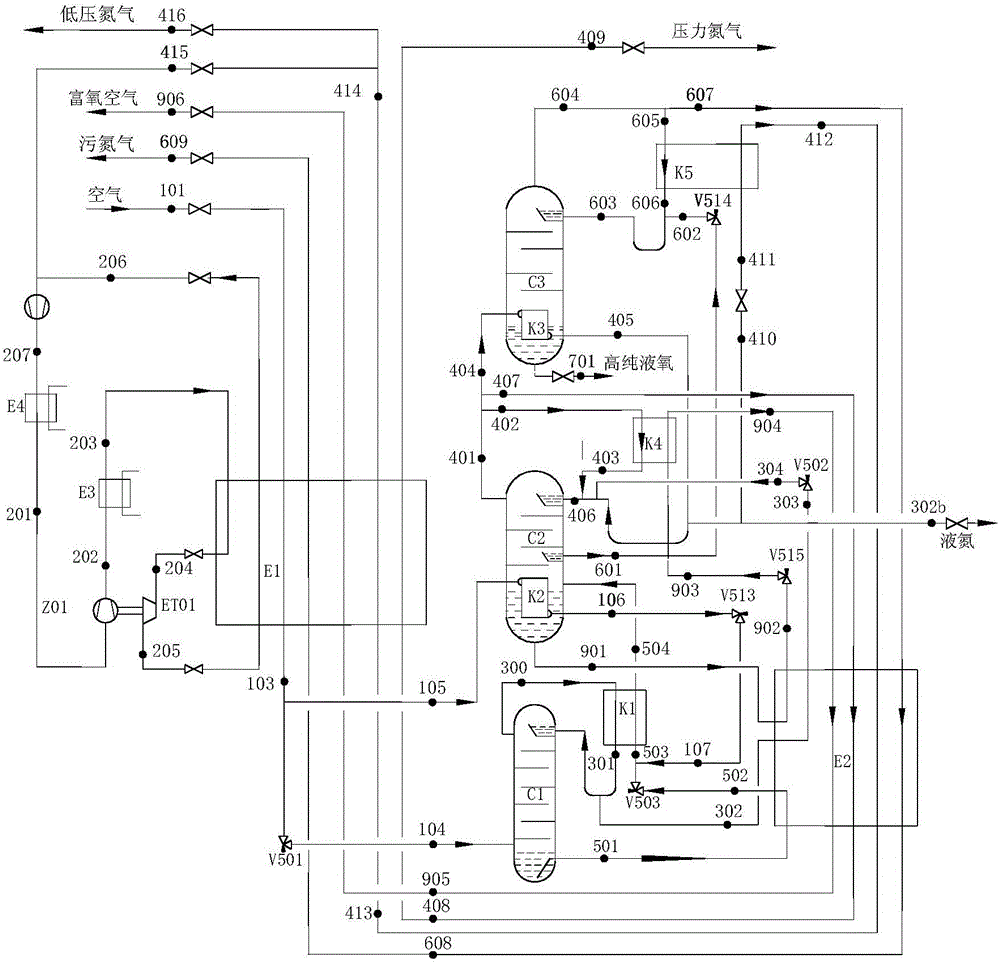

InactiveCN101886870ANo reduction in extraction rateSimultaneous recyclingSolidificationLiquefactionReboilerShielding gas

The invention relates to a method and a device for producing pressure high-purity nitrogen and high-purity oxygen. The device comprises a high-pressure tower, a medium-pressure tower and an oxygen tower. A reboiler is arranged at the bottom of the oxygen tower; and liquid nitrogen and oxygen-enriched liquid air separated from the air in the high-pressure tower enter the medium-pressure tower to be separated into medium-pressure nitrogen and oxygen-enriched liquid in the high-pressure tower. A part of low-purity oxygen which is rich in methane and other high boiling point components is exhausted from the bottom of the medium-pressure tower; a low methane-containing oxygen-enriched liquid extraction opening is formed on the side of the medium-pressure tower; and the oxygen-enriched liquid enters into the oxygen tower for rectification, and the high-purity oxygen is extracted from a tower bottom or a plurality of tower plates on the upper part of the tower bottom. Compared with the prior art, the device and the method can realize simultaneous preparation of pressure nitrogen and high-purity oxygen, wherein the extraction ratio of the pressure nitrogen is 65 to 72 percent, the nitrogen pressure is 0.15 to 0.4 MPa, and the extraction ratio of the high-purity oxygen is 10 to 20 percent of the oxygen in air. The device can prepare low-cost protective gas pressure nitrogen for the float glass and other industries using pressure nitrogen, and can produce high additional value high-purity oxygen products.

Owner:上海启元科技发展有限公司 +1

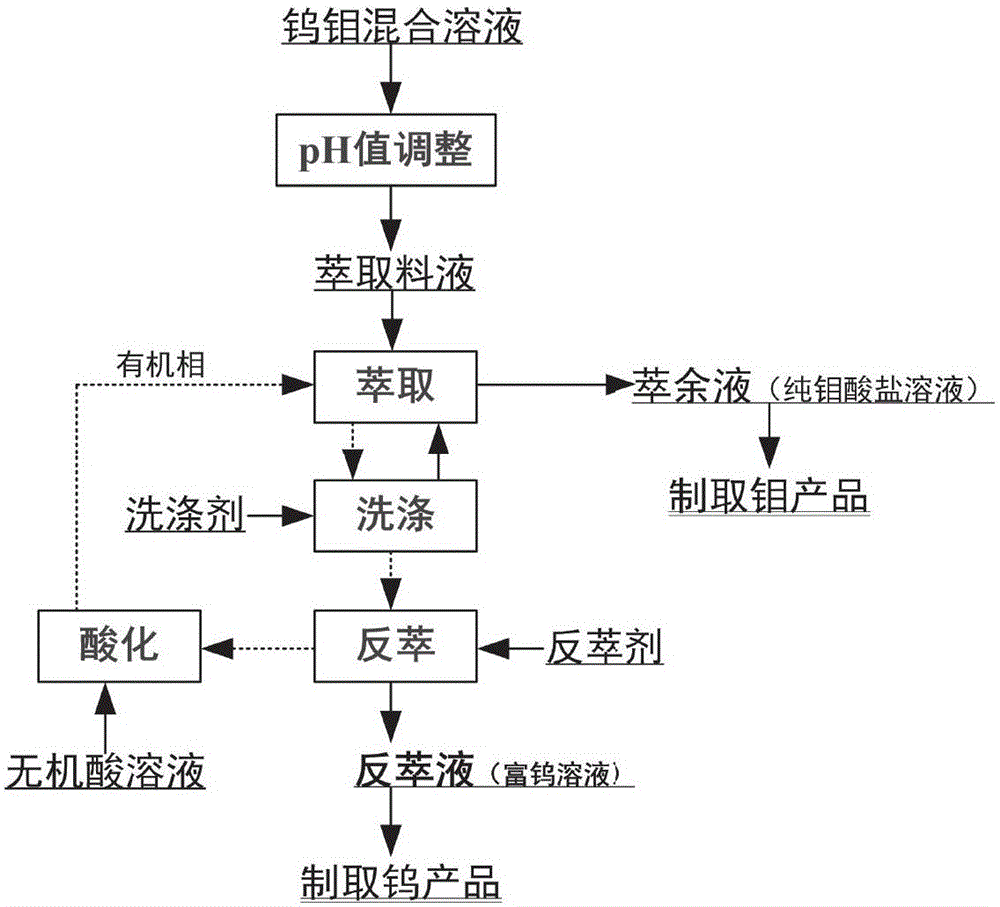

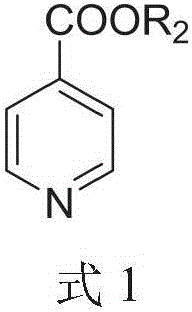

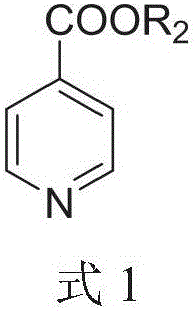

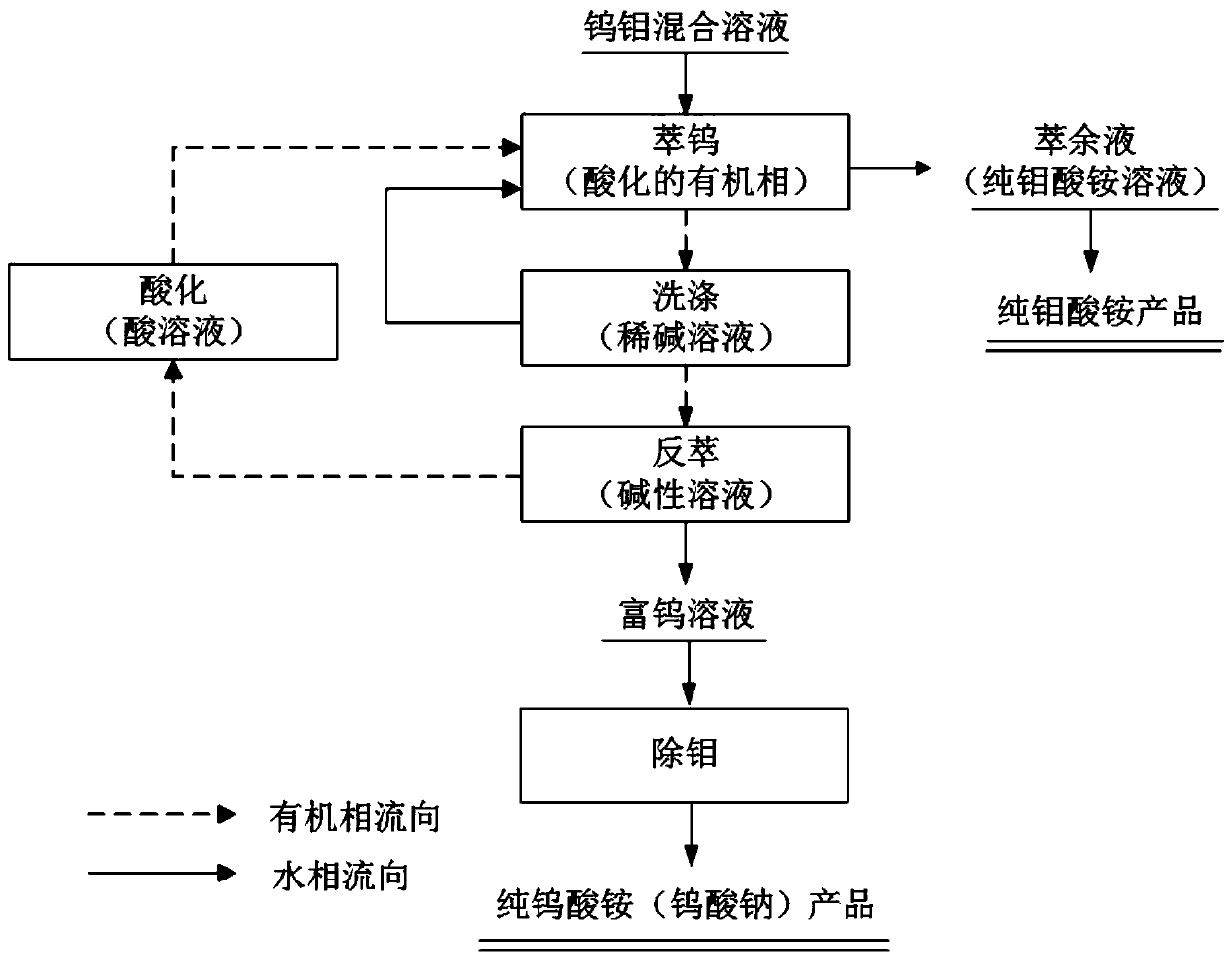

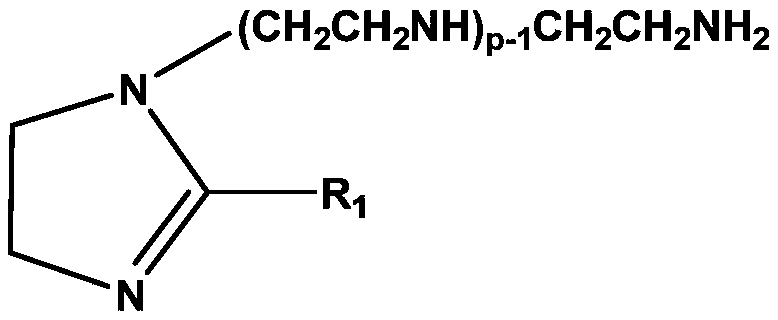

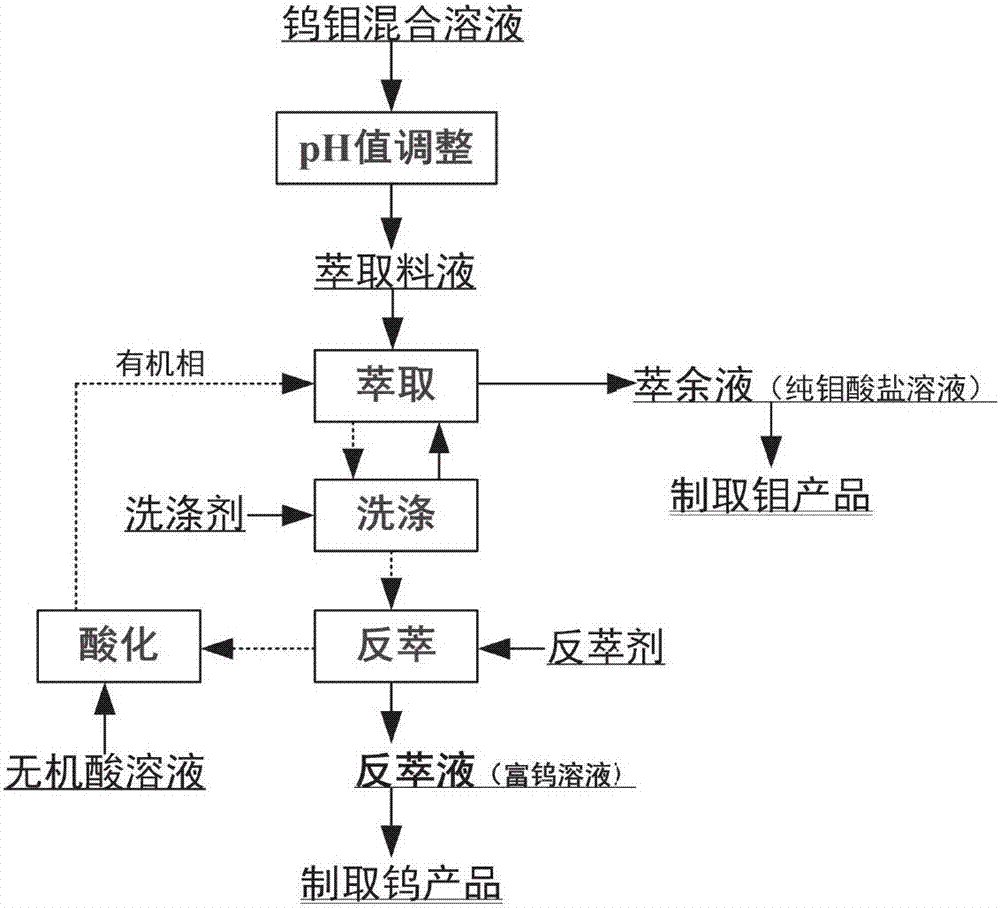

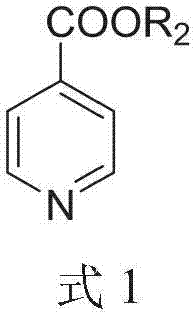

Synergic extraction agent for extracting and separating tungsten from molybdate solution, and method for extracting and separating tungsten from molybdate solution

ActiveCN106435181APhase separation effect is goodHigh separation factorProcess efficiency improvementMolybdateCarboxylic acid

The invention discloses a synergic extraction agent for extracting and separating tungsten from a molybdate solution. The synergic extraction agent for extracting and separating the tungsten from the molybdate solution comprises a primary amine extracting agent and pyridine carboxylic acid. In addition, the invention further discloses a method for extracting and separating the tungsten from the tungstenic molybdate solution. The method comprises the following steps of firstly adjusting a pH value of the tungstenic molybdate solution to be 7.5 to 8.5, and then contacting with an organic phase containing the synergic extraction agent subjected to acidizing so as to carry out multistage extraction, wherein a detergent is an alkaline solution, and during a multistage extraction process, the tungsten is enriched in the loaded organic phase, and molybdenum is enriched in raffinate, so that further removal of the tungsten in the molybdate solution is realized. The loaded organic phase adopts the alkaline solution for re-extracting to obtain a strip liquor rich in the tungsten. The re-extracted organic phase is treated through an inorganic acid solution so as to return to extraction. According to the synergic extraction agent for extracting and separating the tungsten from the molybdate solution and the method for extracting and separating the tungsten from the molybdate solution provided by the invention, the effect on removal of the tungsten in the molybdate solution with high tungsten content is good, the process flow is short, the cost is low, and the industrialization can be realized easily.

Owner:CENT SOUTH UNIV

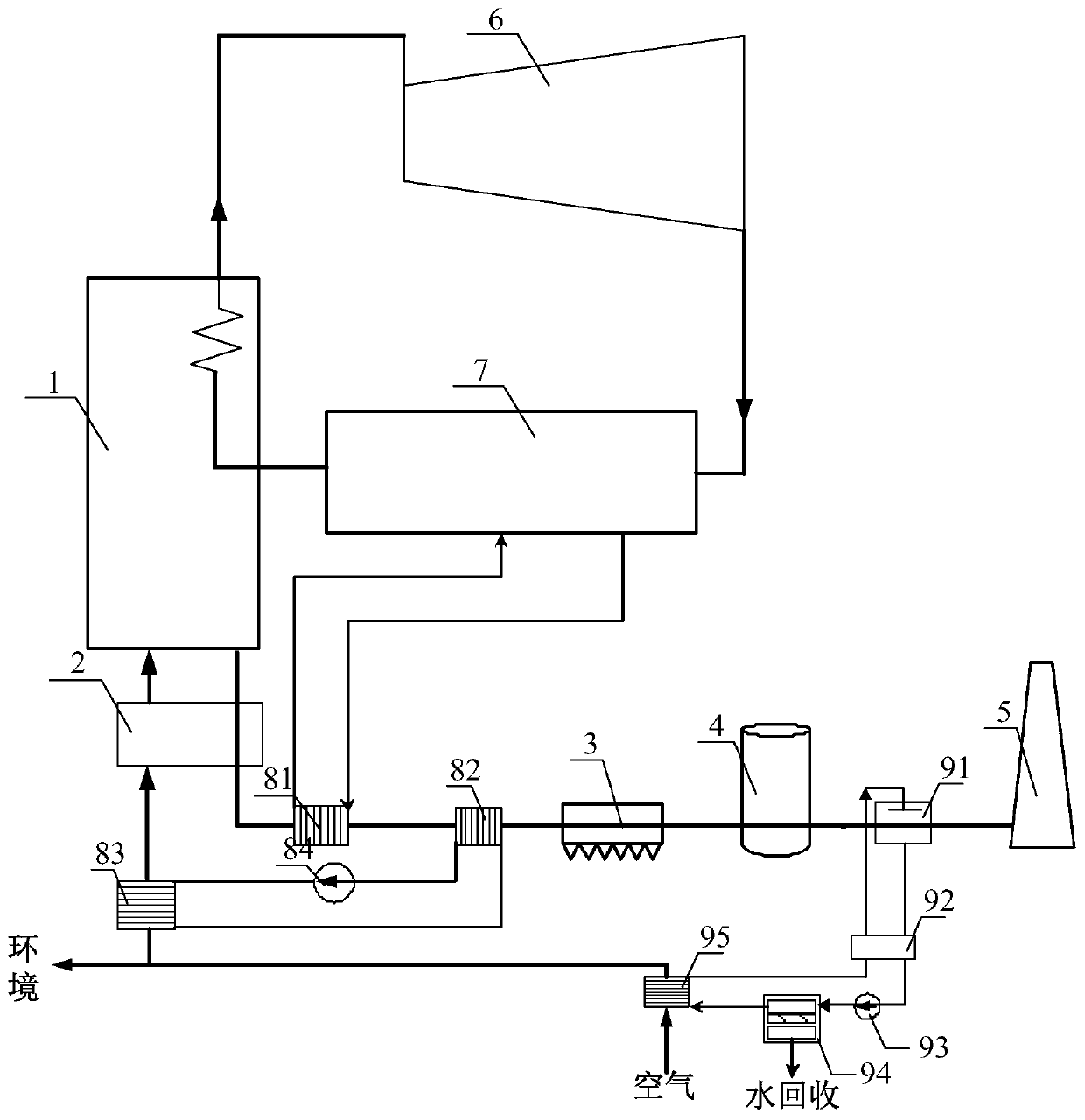

Boiler smoke waste heat utilization and white smoke removal integrated system

InactiveCN109798534ASimple systemLess investmentCombustion processIndirect carbon-dioxide mitigationIntegrated systemsPower station

The invention provides a boiler smoke waste heat utilization and white smoke removal integrated system. The boiler smoke waste heat utilization and white smoke removal integrated system comprises a smoke waste heat absorbing unit which is mounted on a smoke passageway and provided with a plurality of subunits; the multiple subunits are arranged on the smoke passageway in sequence, smoke waste heatis exchanged and recovered in a cascade mode through the multiple subunits, and heat energy of the waste heat at different temperatures is obtained; and a smoke waste heat utilization unit and the smoke waste heat absorbing unit are connected through a heat circulation pipeline, the smoke waste heat utilization unit is provided with a plurality of subunits, and the different subunits utilize theheat energy of the waste heat at the different temperatures to heat water, air and discharged smoke in a power station water system, an air system and a smoke system. Cascade utilization of the energyis achieved, and energy saving, water saving and white smoke removal can be simultaneously achieved.

Owner:DATANG BEIJING ENERGY MANAGEMENT +2

Method for extracting and separating tungsten from molybdate solution

InactiveCN109868363ASimultaneous recyclingNo bad smellProcess efficiency improvementMolybdateSingle stage

The invention discloses a method for extracting and separating tungsten from a molybdate solution, and belongs to the field of extraction and separation of rare metals. The concentration of tungsten in the molybdate solution is firstly adjusted before extraction, so that the concentration of WO3 is not lower than 5 g / L, the mass ratio of WO3 to Mo in the solution is 1 / 50 to 1 / 1, the pH of the tungsten-containing molybdate solution is adjusted to be 7.5-8.0, an organic phase containing a mixed amine extractant is in contact with the tungsten-containing molybdate solution for single-stage or multi-stage countercurrent extraction, the tungsten is enriched in the loaded organic phase, and molybdenum remains in a raffinate aqueous phase; and the loaded organic phase is washed by the extractantand then de-extracted by a stripping agent to obtain a tungsten-rich stripping solution, the organic phase obtained after reverse extraction is acidified, circulated and used in an extraction section.The mixed amine extractant used in the method has the advantages of low cost, large saturation capacity and the like, and the effect of removing tungsten from the high-tungsten-content molybdate solution is good, the process is short, and the method is prone to realizing industrialization.

Owner:CENT SOUTH UNIV

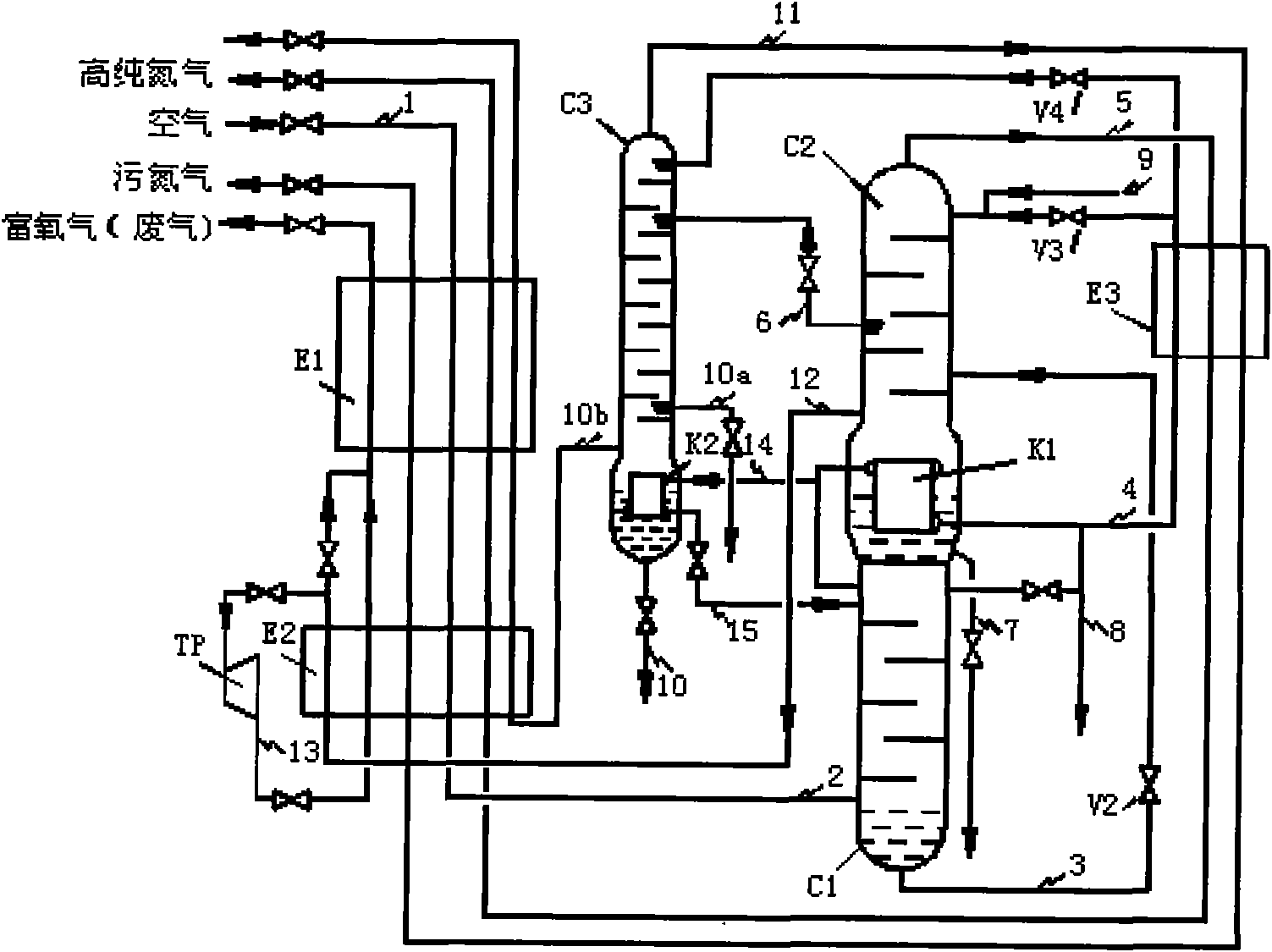

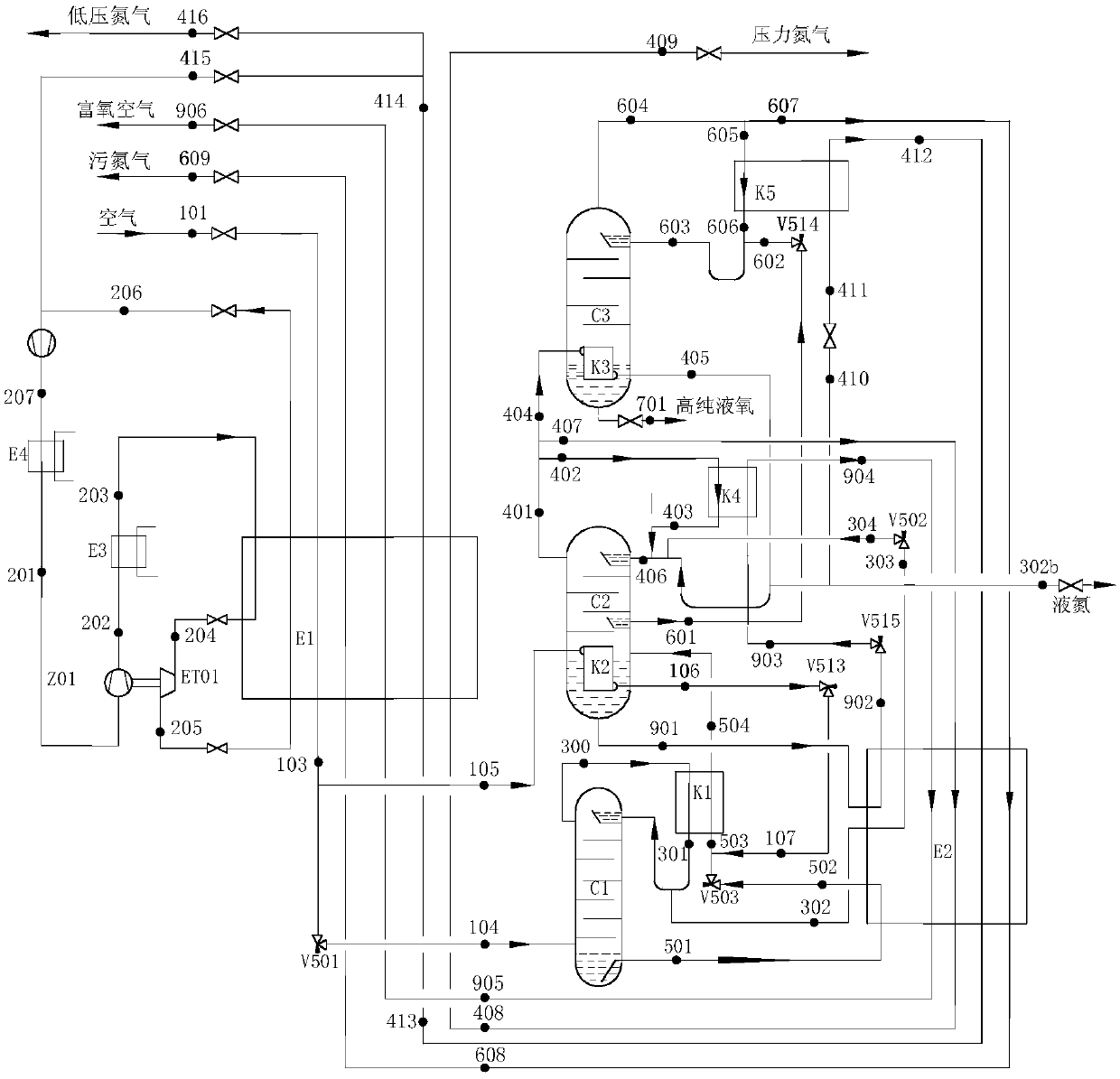

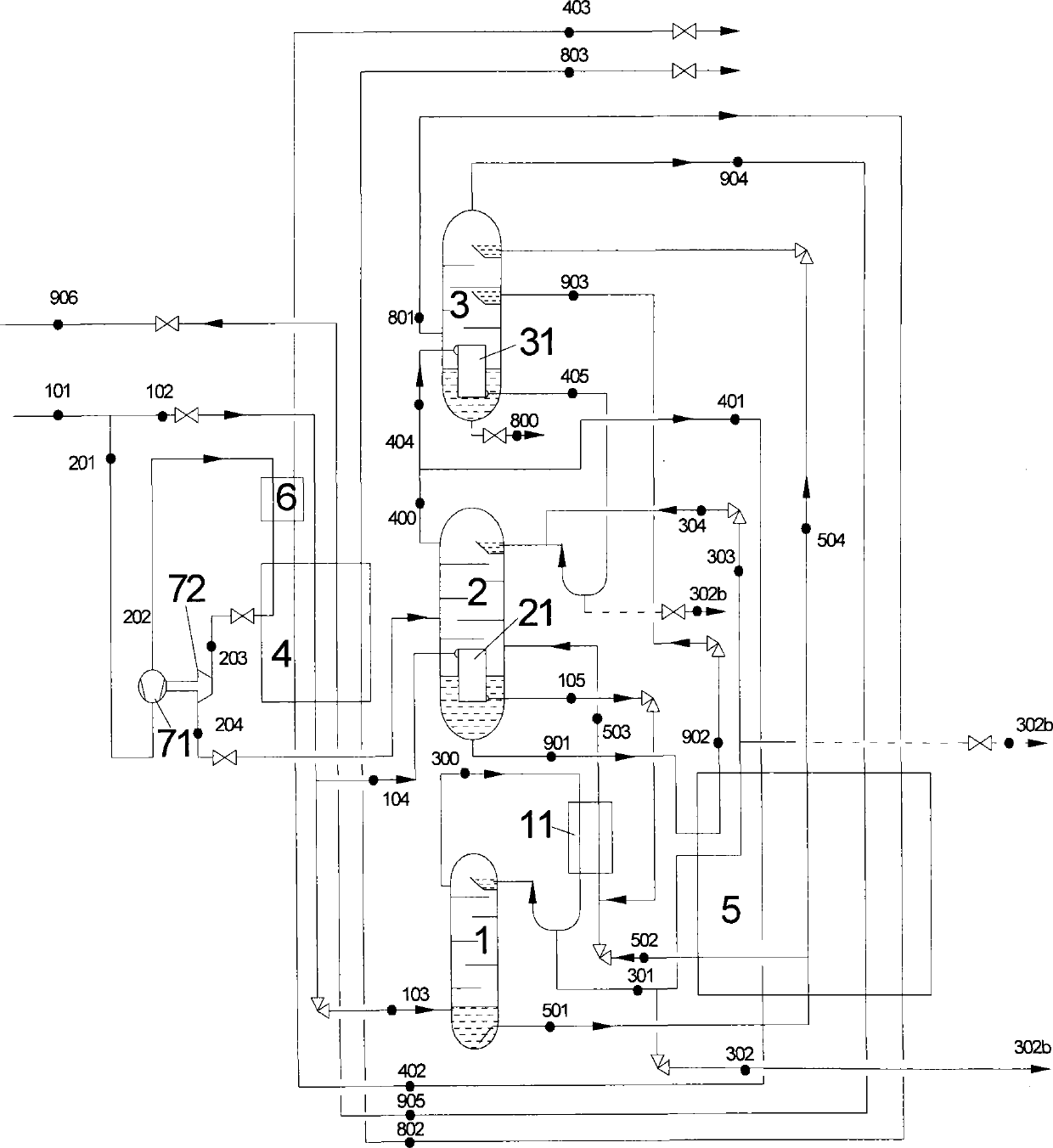

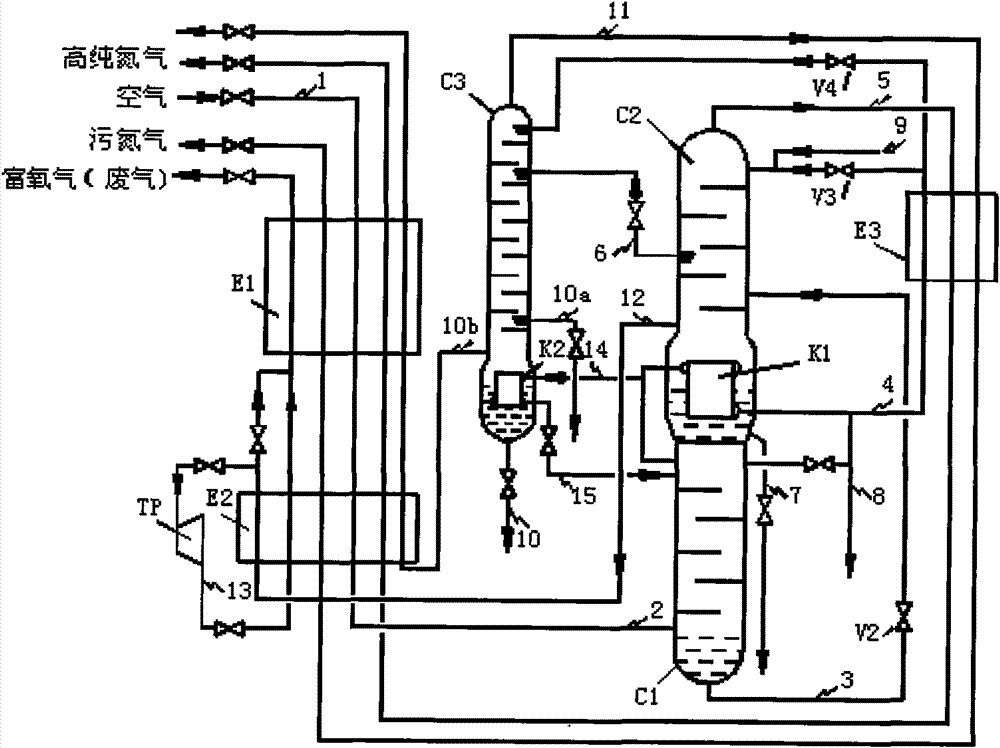

Method for efficient production of high-purity oxygen and high-purity nitrogen

ActiveCN105865148ANo reduction in extraction rateSimultaneous recyclingSolidificationLiquefactionReboilerNitrogen

The invention provides a method for efficient production of high-purity oxygen and high-purity nitrogen. A high pressure rectifying tower, a medium pressure rectifying tower and a low pressure rectifying tower are adopted; a reboiler is arranged at the bottom of the medium pressure rectifying tower, and a condensation evaporator is disposed at the bottom of the low pressure rectifying tower; high pressure nitrogen and oxygen-enriched liquid air are obtained through separation of part of air in the high pressure rectifying tower, and the other part of air enters the reboiler of the medium pressure rectifying tower to be condensed into liquid air; the liquid air and the oxygen-enriched liquid air are mixed, then enter a condensation evaporator of the high pressure rectifying tower to be evaporated into a gas state and then enter the medium pressure rectifying tower; and then a high-purity nitrogen product and oxygen-enriched liquid are obtained through separation in the medium pressure rectifying tower, and the oxygen-enriched liquid enters the low pressure rectifying tower to be rectified, so that a high-purity liquid oxygen product is obtained. The high-purity liquid oxygen and the high-purity nitrogen can be produced at the same time; the extraction ratio of the high-purity nitrogen reaches 60%-75%, and the extraction ratio of the high-purity oxygen reaches 70%-72%; and according to the method, air is used as a raw material which is economical and practical, the products are safe and reliable and can be widely applied, and the market prospects are good.

Owner:SHANGHAI QIYUAN GAS DEV

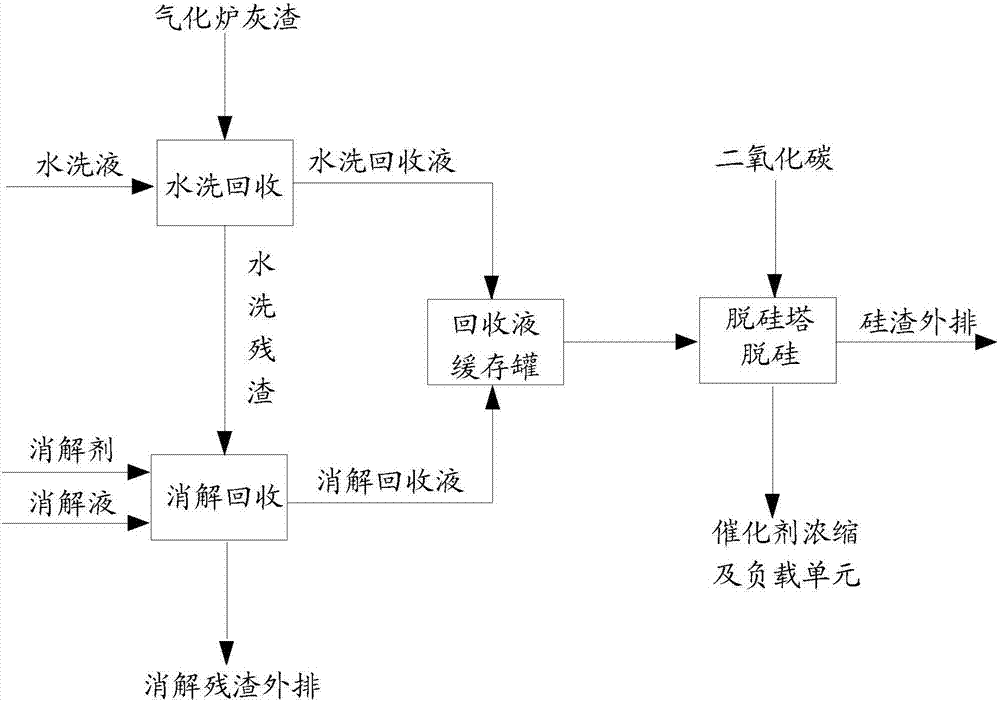

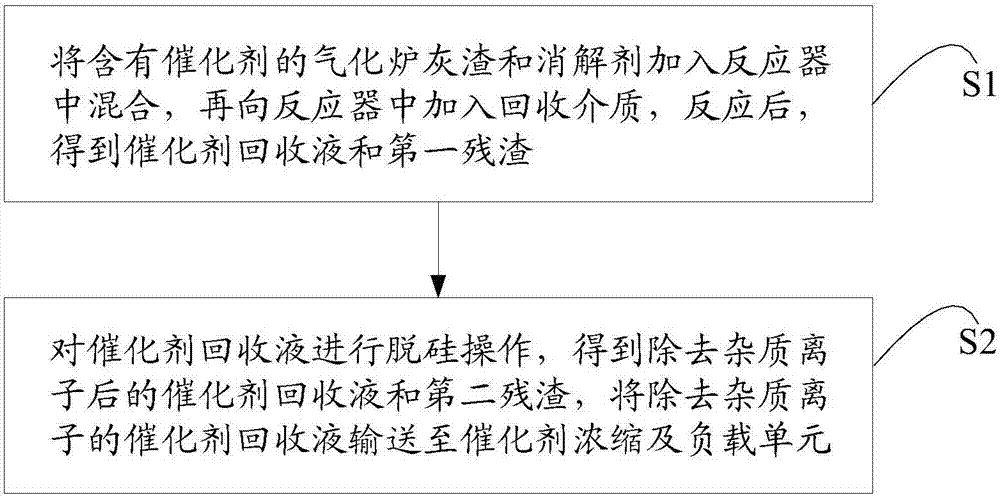

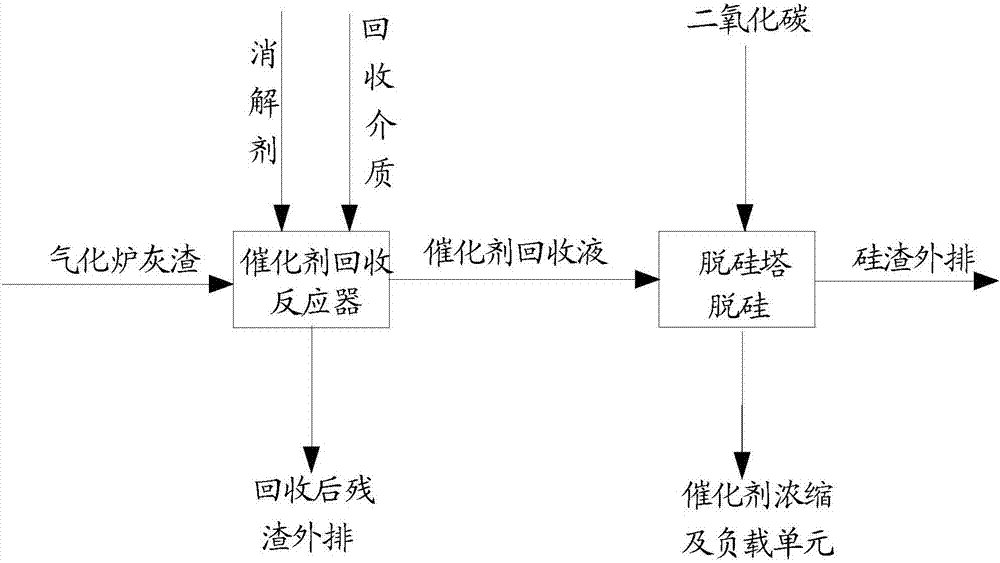

Catalyst recovery process

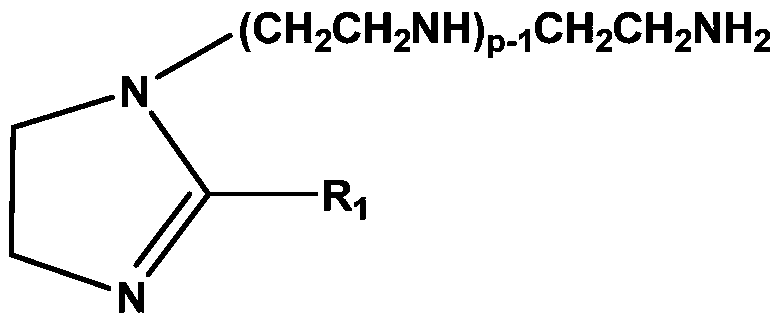

InactiveCN107159180AInhibition of agglomerationSimultaneous recyclingMetal/metal-oxides/metal-hydroxide catalystsChemistryWater soluble

The present invention provides a catalyst recovery process, which comprises: adding gasification furnace ash residue containing a catalyst and a digestion agent to a reactor, uniformly mixing, adding a recovery medium to the reactor, carrying out a reaction, and separating to obtain a catalyst recovery liquid and first residue; and carrying out desilication operation on the catalyst recovery liquid to obtain an impurity-ion-removing catalyst recovery liquid and second residue, and conveying the impurity-ion-removing catalyst recovery liquid to a catalyst concentration and loading unit. According to the present invention, with the process, the simultaneous recovery of the water-soluble catalyst and the insoluble catalyst is achieved, the water washing and the pressure filtration during the digestion are eliminated so as to simplify the process, the agglomeration phenomenon generated during the mixing of the digestion agent and the gasification furnace ash residue being subjected to the water washing is avoided so as to complete reaction and improve the catalyst recovery rate, and the water consumption in the water washing link is eliminated so as to save the water resource, improve the catalyst metal ion concentration in the recovery liquid, and reduce the energy consumption of the catalyst concentration unit.

Owner:ENN SCI & TECH DEV

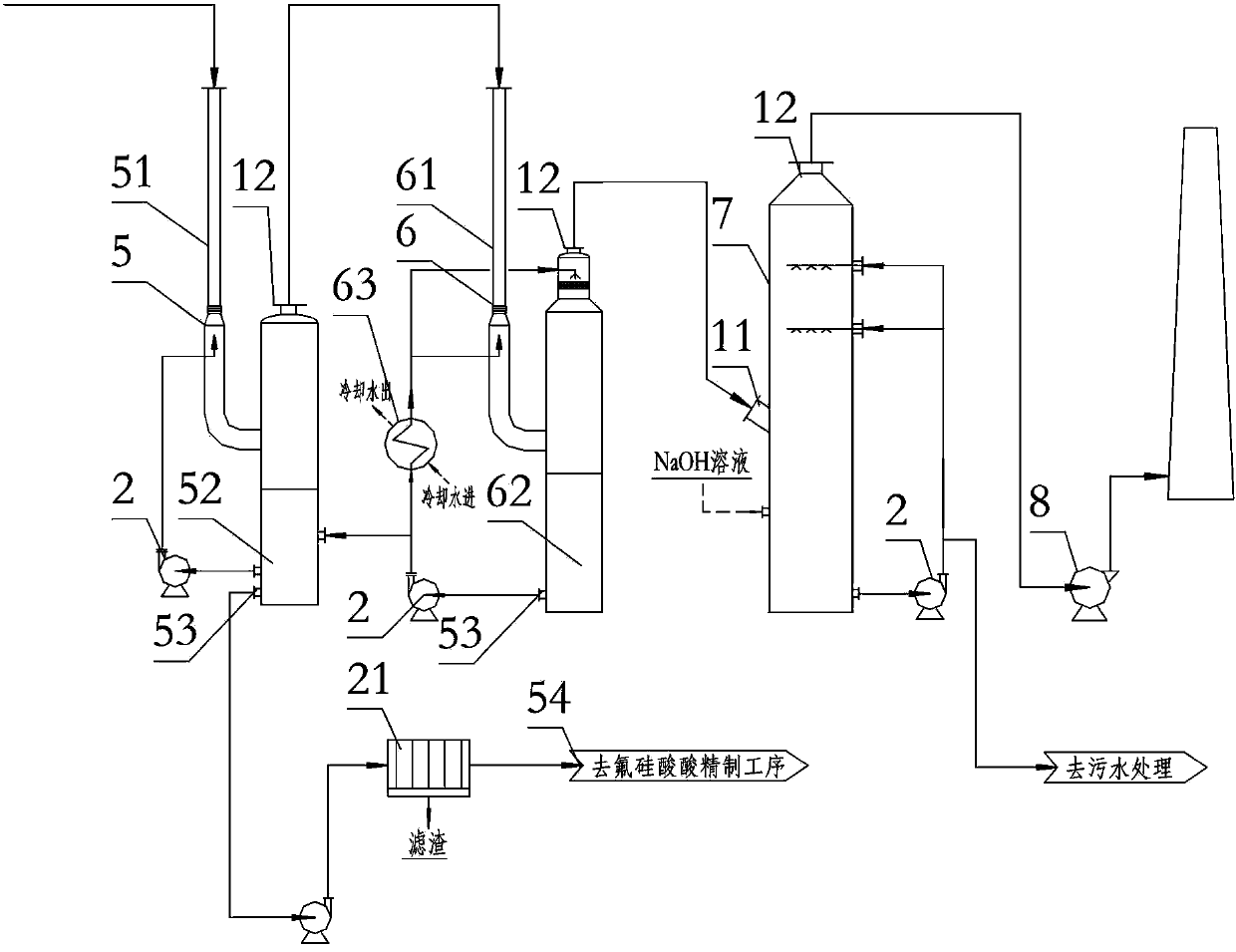

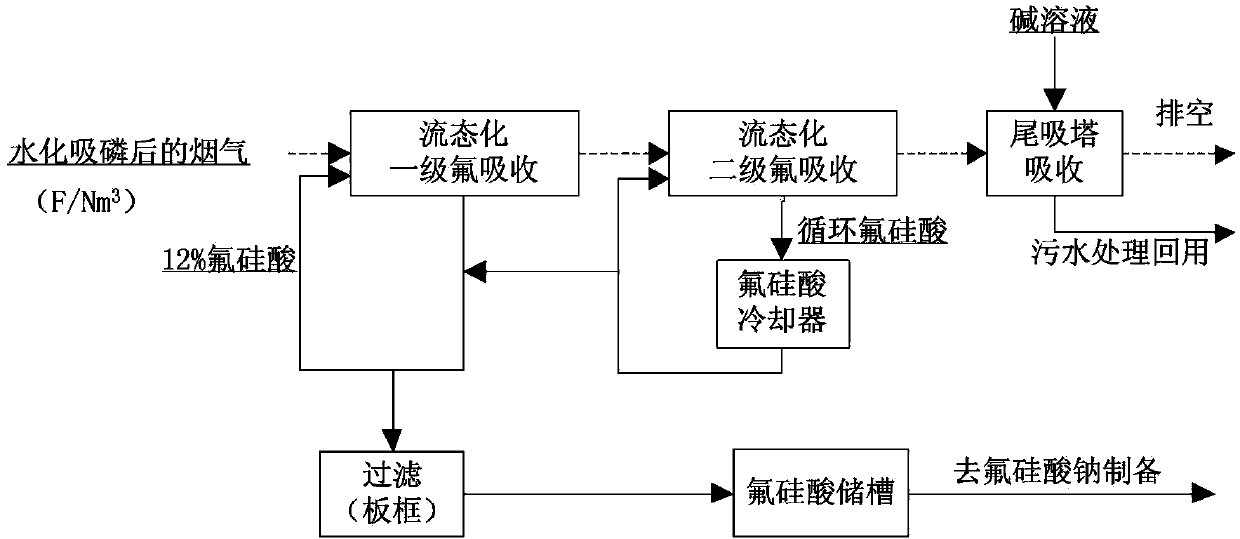

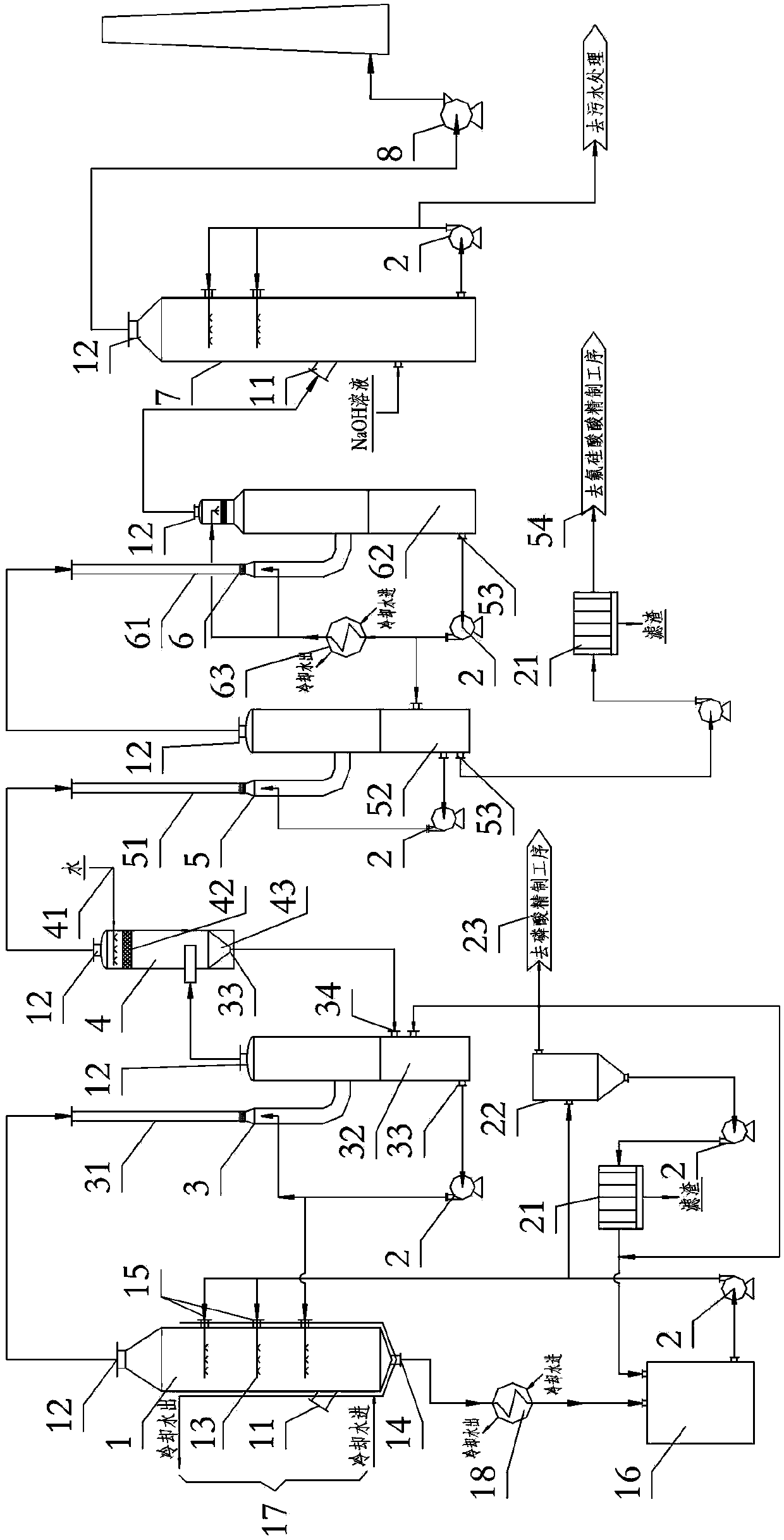

Equipment and process for recovery of fluorine from flue gas of hydration absorption of phosphorus in kiln-method phosphoric acid technology

Disclosed is a device and process for fluorine recovery from smoke after phosphorus absorption by hydration in a kiln process for the production of phosphoric acid, wherein the device comprises a first-stage and second-stage fluorine absorption tower, which are both fluidised counter-current washing towers; the first-stage fluorine absorption tower mainly consists of a fluorosilicic acid washing pipe and a fluorosilicic acid separation tank; the top of the separation tank is provided with a smoke outlet, and at the bottom thereof a fluorosilicic acid liquid outlet is connected to the fluorosilicic acid washing pipe via a circulating and conveying pipeline; the main structure of the second-stage fluorine absorption tower is similar to that of the first-stage fluorine absorption tower, the top of the second-stage fluorosilicic acid separation tank is provided with a defoaming layer and a smoke outlet, and at the bottom thereof a fluorosilicic acid liquid outlet is in communication with a nozzle in the second-stage fluorosilicic acid washing pipe and the fluorosilicic acid separation tank in the first-stage fluorine absorption tower via a circulating and conveying pipeline. The fluorine recovery process of the present invention comprises multiple operations of a first-stage fluorine absorption, a first-stage gas-liquid separation, a second-stage fluorine absorption, and a second-stage gas-liquid separation etc. The present invention has the advantages of simple structure, low investment cost, high raw material utilisation rate, and good fluorine recovery effects etc.

Owner:SICHUAN JIUCHANG SCI & TECH

A method for efficiently producing high-purity oxygen and high-purity nitrogen

ActiveCN105865148BNo reduction in extraction rateSimultaneous recyclingSolidificationLiquefactionReboilerNitrogen

The invention provides a method for efficient production of high-purity oxygen and high-purity nitrogen. A high pressure rectifying tower, a medium pressure rectifying tower and a low pressure rectifying tower are adopted; a reboiler is arranged at the bottom of the medium pressure rectifying tower, and a condensation evaporator is disposed at the bottom of the low pressure rectifying tower; high pressure nitrogen and oxygen-enriched liquid air are obtained through separation of part of air in the high pressure rectifying tower, and the other part of air enters the reboiler of the medium pressure rectifying tower to be condensed into liquid air; the liquid air and the oxygen-enriched liquid air are mixed, then enter a condensation evaporator of the high pressure rectifying tower to be evaporated into a gas state and then enter the medium pressure rectifying tower; and then a high-purity nitrogen product and oxygen-enriched liquid are obtained through separation in the medium pressure rectifying tower, and the oxygen-enriched liquid enters the low pressure rectifying tower to be rectified, so that a high-purity liquid oxygen product is obtained. The high-purity liquid oxygen and the high-purity nitrogen can be produced at the same time; the extraction ratio of the high-purity nitrogen reaches 60%-75%, and the extraction ratio of the high-purity oxygen reaches 70%-72%; and according to the method, air is used as a raw material which is economical and practical, the products are safe and reliable and can be widely applied, and the market prospects are good.

Owner:SHANGHAI QIYUAN GAS DEV

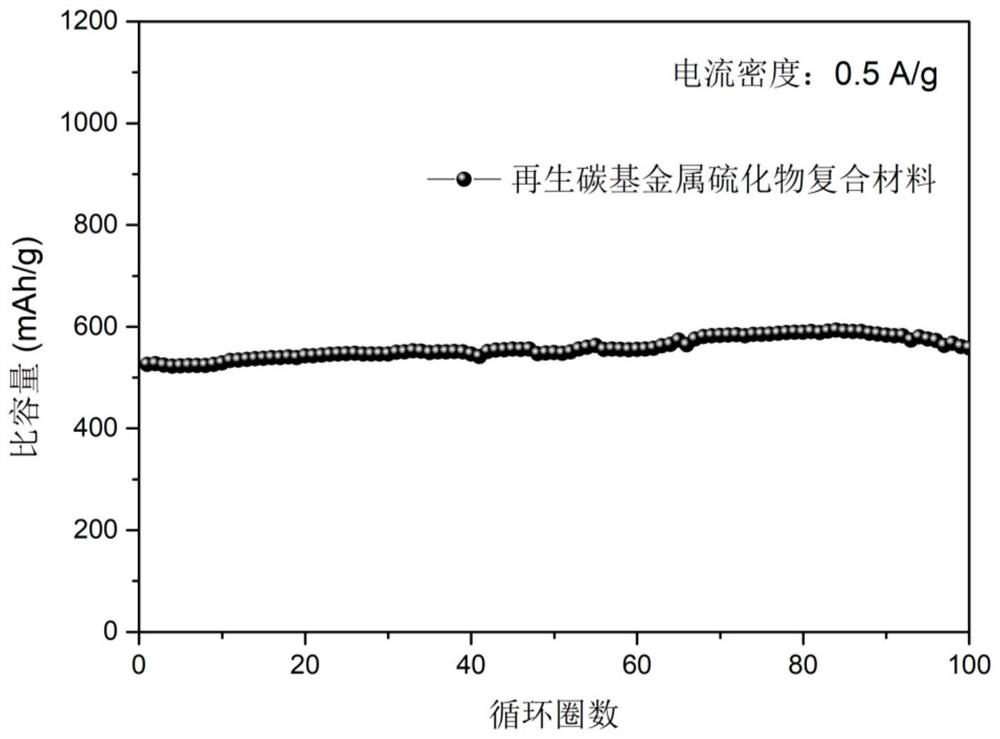

Method for simultaneously recycling and preparing carbon-based metal sulfide negative electrode material from waste nickel-cobalt-manganese lithium ion battery positive electrode material and waste cobalt-manganese lithium ion battery negative electrode material

ActiveCN113206227AIncrease contentImprove electrochemical performanceNegative electrodesWaste accumulators reclaimingElectrical batteryManganese

The invention designs a simple, convenient and efficient regeneration process for a waste nickel-cobalt-manganese ternary lithium ion electrode material, so that a waste nickel-cobalt-manganese positive electrode material and a graphite negative electrode material are simultaneously recycled and regenerated into a sodium ion battery negative electrode material, and belongs to the technical field of lithium ion battery material recycling. The method mainly comprises the following steps: 1, mixing waste anode powder, waste cathode powder and sublimed sulfur according to a certain proportion, and carrying out mechanical ball milling to realize uniform compounding; 2, performing high-temperature calcination in a tubular furnace, and achieving the preparation of the carbon-based metal sulfide composite material in one step; 3, extracting lithium from the composite material by water leaching, and drying the leaching residue to directly use the leaching residue as a sodium ion battery negative electrode material. According to the invention, the pressure of environment and resources can be effectively relieved, and huge economic benefits are brought. Meanwhile, the method is simple and efficient in process and beneficial to large-scale preparation.

Owner:CENT SOUTH UNIV

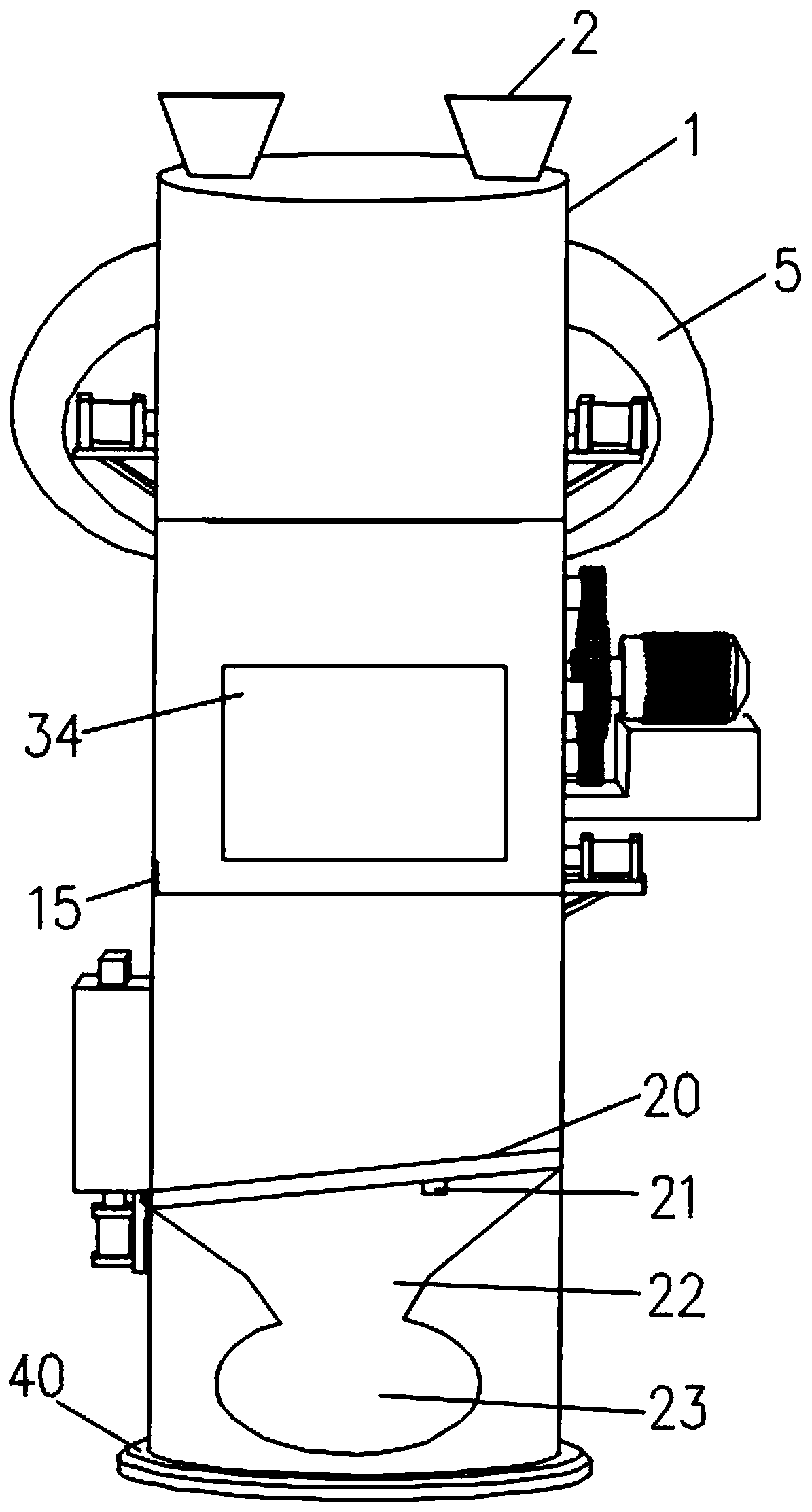

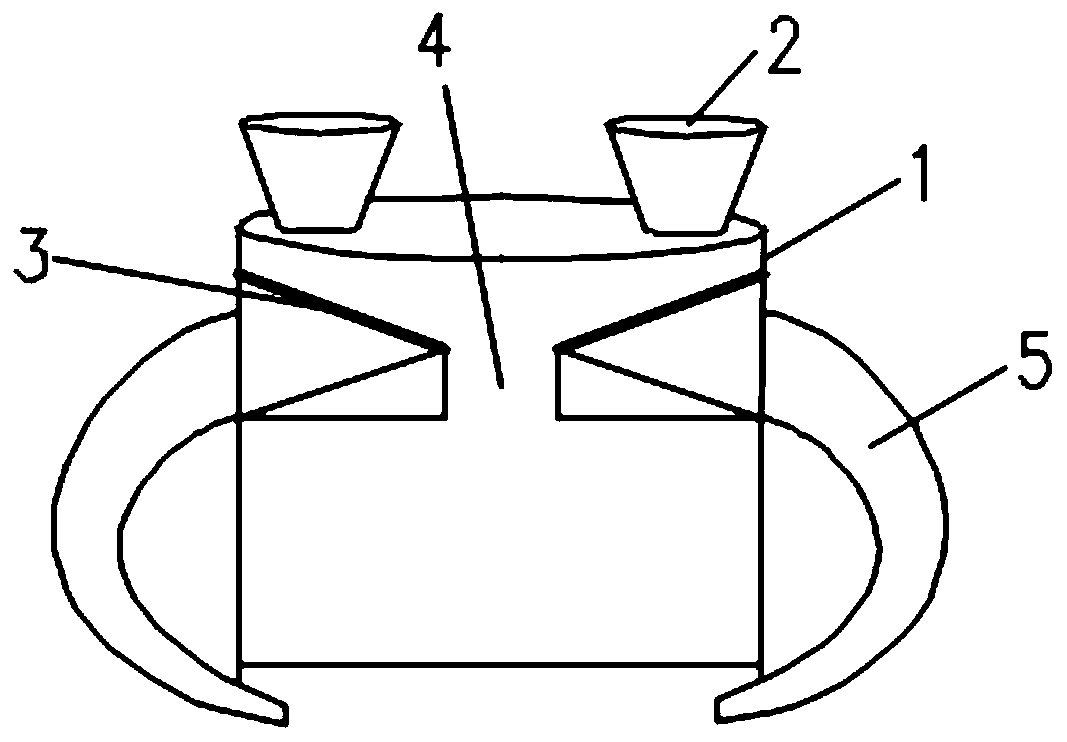

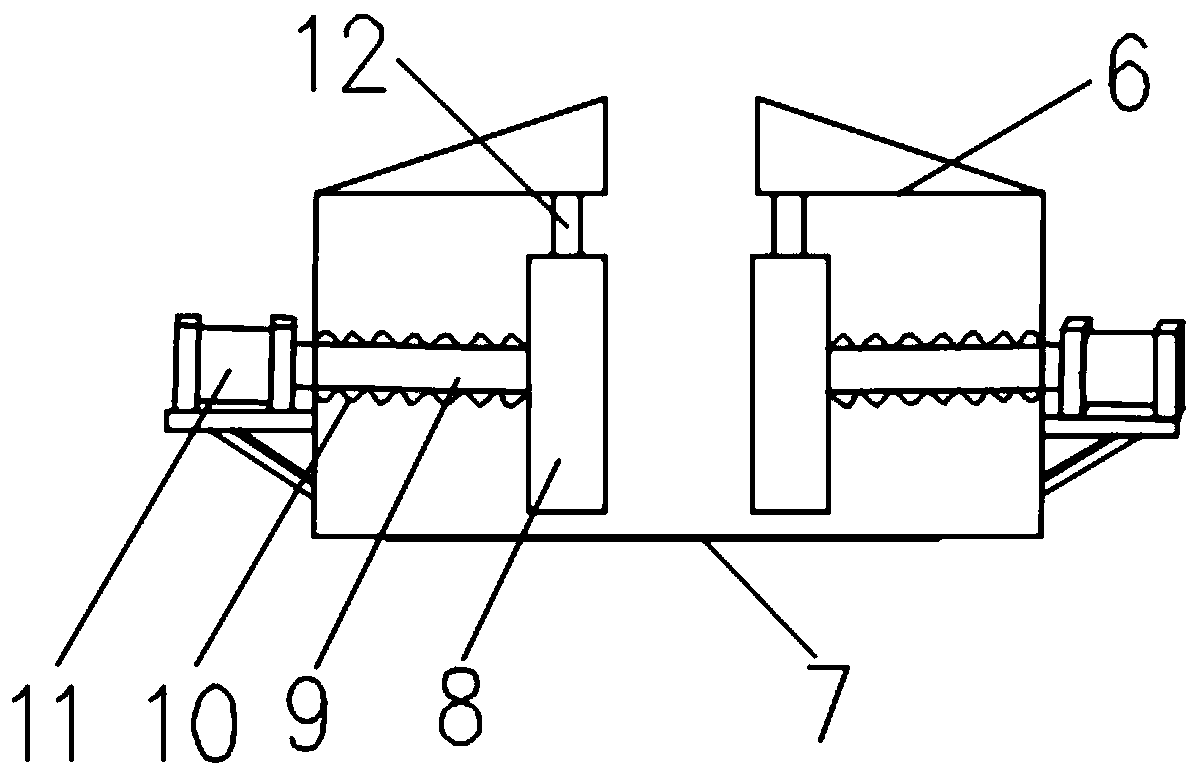

Construction waste recycling and crushing equipment and using method thereof

ActiveCN109894186AImprove crushing effectImprove recycling qualityMagnetic separationGrain treatmentsLarge sizeImpurity

The invention relates to a construction waste recycling and crushing equipment and a using method thereof. The equipment comprises a machine box, a discharging device, a crushing device, a impurity removing device and a collection box; and the crushing device comprises a first crushing device and a second crushing device, the discharging device is arranged at the upper end of the machine box, thefirst crushing device is arranged at the lower end of the discharging device, the impurity removing device is arranged at the lower end of the first crushing device, the second crushing device is arranged at the lower end of the impurity removing device, and the collection box is arranged at the lower end of the second crushing device. The method comprises the following steps that construction waste is treated by the discharging device, large-size materials sequentially pass through the first crushing device and the impurity removing device, small-size materials directly enter the impurity removing device, and the impurity removing device enters the second crushing device after being treated, and finally enters the collection box. According to the construction waste recycling and crushingequipment, centralized treatment of the large-size building waste is realized, resources are saved, the equipment operation is stable, the efficiency is high, the service life is long, various metalsdoped in the construction waste are separated, and the recovery processing quality of the construction waste is improved.

Owner:LIUPANSHUI NORMAL UNIV

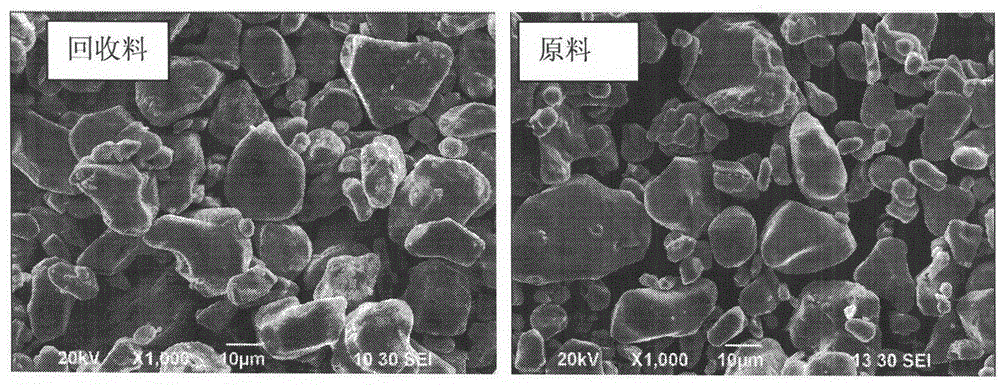

Method for recovering and preparing lithium cobaltate from waste lithium ionic cell

ActiveCN101383442BSimultaneous recyclingLow priceLithium compoundsWaste accumulators reclaimingTemperature resistanceCobalt

The invention discloses a method for reclaiming and preparing lithium cobalt oxide from waste lithium ion batteries. The method is characterized in that the waste lithium batteries are disassembled and the shells are removed to select positive plates with the anode made of lithium cobalt oxide; the positive plates are crushed and screened to obtain minus sieve containing waste lithium cobalt oxide as the main component; in a constant-temperature resistance furnace, caking agent and conductive agent acetylene black in the minus sieve are removed in high temperature, sodium hydroxide is adoptedto remove aluminum, and filtering, washing and drying are performed to obtain inactive lithium cobalt oxide containing little impurity; the content of lithium and cobalt is detected in the inactive lithium, then lithium carbonate with proper proportion is mixed in, at last, active lithium cobalt oxide battery material is synthesized by high-temperature agglomeration in a muffle furnace. Through the application of the method, the coefficient of recovery of cobalt in waste lithium ion batteries can reach more than 95.0 percent, and the coefficient of recovery of lithium can reach more than 97.0percent.

Owner:GUANGDONG BRUNP RECYCLING TECH +1

A method for preparing positive electrode material precursor by using waste ternary lithium battery

ActiveCN109193057BLow costSimultaneous recyclingWaste accumulators reclaimingProcess efficiency improvementManganeseCathode material

The invention provides a method for preparing a positive electrode material precursor by using a waste ternary lithium battery, which adopts a first stage leaching as a pressurized ammonia leaching torealize simultaneous recovery of lithium, nickel and cobalt. The second stage leaching is atmospheric pressure acid leaching to realize the recovery of doped metal (manganese or aluminum). The invention realizes low cost of waste ternary positive electrode material, Short-process recovery and reuse, in which nickel is leached by ammonia under pressure, the comprehensive leaching rate of valuablemetals such as cobalt and lithium reaches 92%. The comprehensive recovery of valuable metals such as nickel, cobalt, lithium, manganese and aluminum is over 95% by two-stage leaching. Ammonia and leaching acid can be recycled in closed circuit. The precursor of ternary positive electrode materials prepared by regeneration can meet the needs of preparation of different series of ternary positive electrode materials, and has a good prospect of industrial application.

Owner:KUNMING UNIV OF SCI & TECH

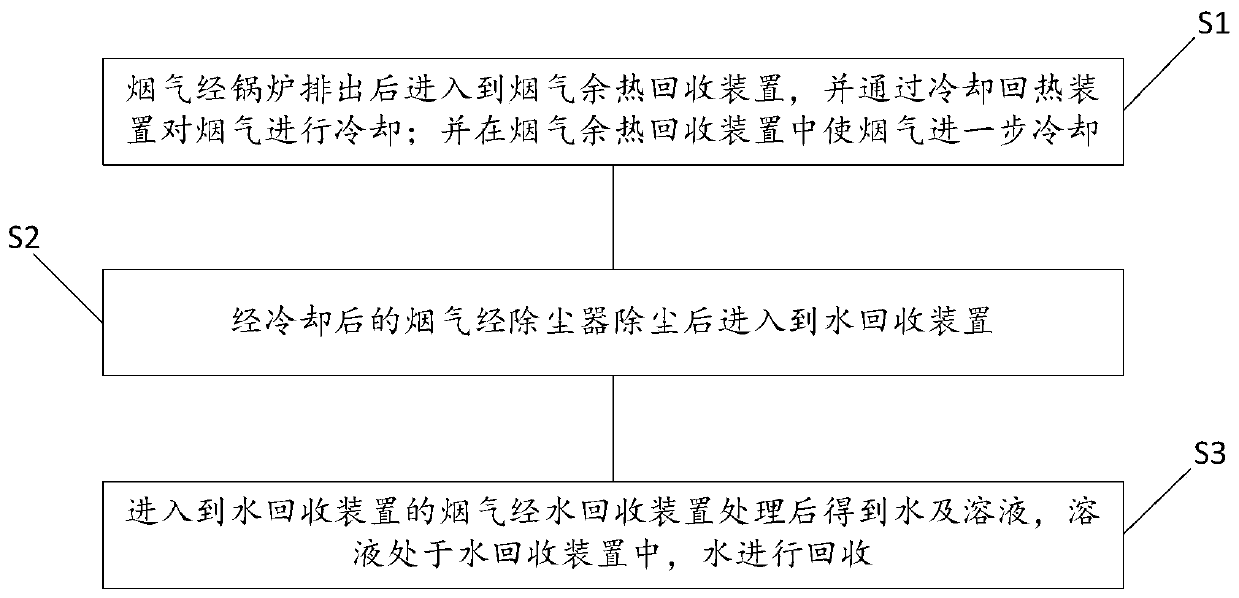

Waste heat and water recovery system and method for coal-fired power plant

PendingCN111425877AReasonable structureLess investmentCombustion processWaste water treatment from gaseous effluentsAir preheaterDust control

The invention provides a waste heat and water recovery system and method for a coal-fired power plant. The system comprises a boiler, an air pre-heater, a dust collector, a desulfurizer, a chimney, asteam turbine and a cooling regenerator, wherein the system further comprises a fume waste heat recovery device that is installed between the air pre-heater and the dust collector and is respectivelyconnected to the cooling regenerator and the air pre-heater, and a water recovery device installed between the desulfurizer and the chimney. The method comprises the following steps that the fume enters the fume waste heat recovery device after being discharged from the boiler, and is cooled by the cooling regenerator; the fume is further cooled in the fume waste heat recovery device; the cooled fume enters the water recovery device after being de-dusted by the dust collector; the fume entering the water recovery device is treated by the water recovery device to obtain water and solution, thesolution is put in the water recovery device, and the water is recovered. The waste heat and water recovery system and method for the coal-fired power plant provided by the invention reduce the overall investment while conserving energy and reducing emission.

Owner:DATANG ENVIRONMENT IND GRP

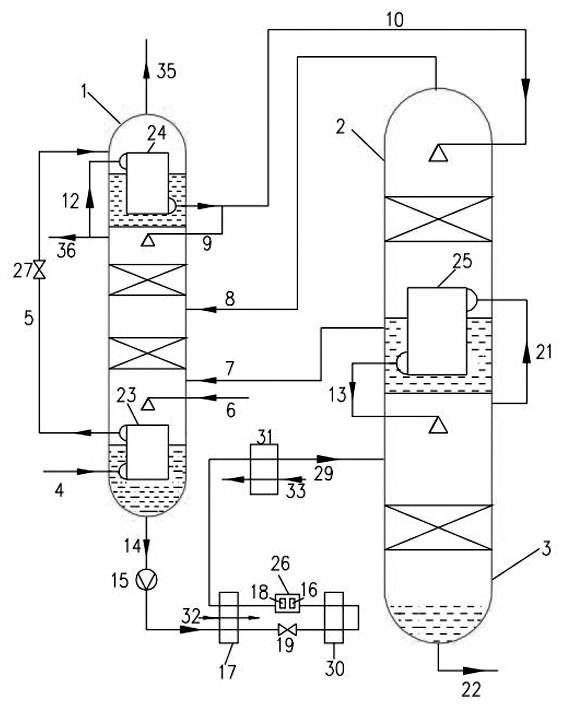

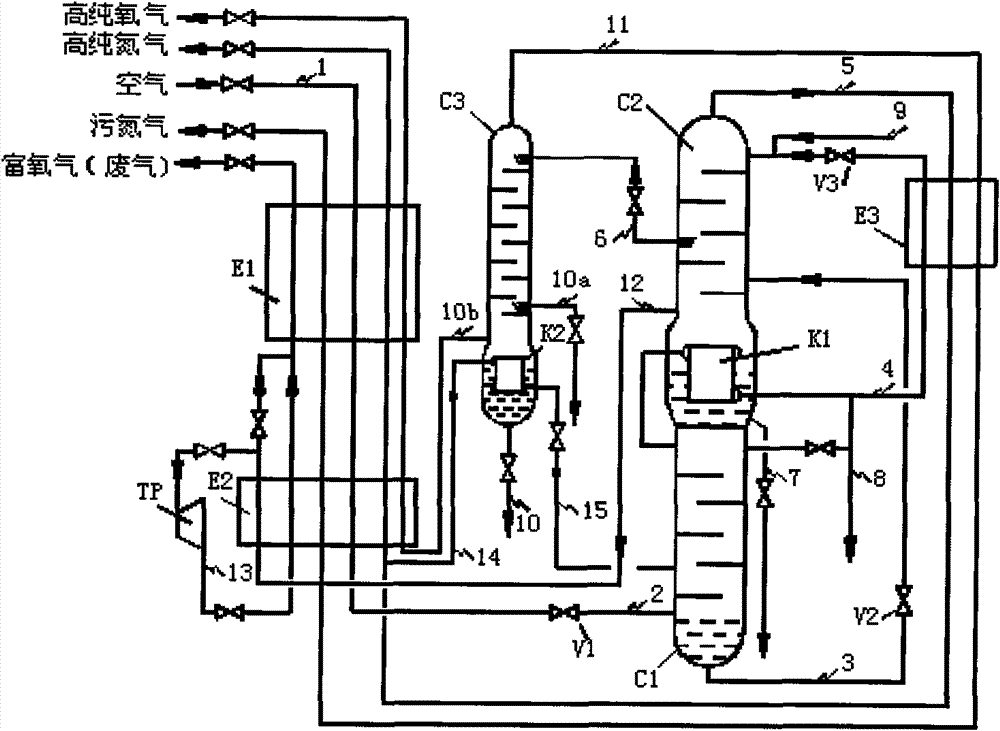

Device and method for extracting krypton and xenon in liquid oxygen through low-temperature rectification

A device for extracting krypton and xenon in liquid oxygen through low-temperature rectification comprises a first-stage concentrating tower, a second-stage concentrating tower, a third-stage concentrating tower, a high-pressure oxygen pump, a water bath type vaporizer, a high-pressure throttle valve, a heat regenerator, an impurity and methane removing module and a heat exchanger, wherein one side of the lower portion of the first-stage concentrating tower is connected with a first pipeline for feeding raw material liquid oxygen, the bottom of the first-stage concentrating tower is sequentially connected with the high-pressure oxygen pump, a liquid oxygen channel of the water bath type vaporizer, the high-pressure throttle valve, the heat regenerator, the impurity and methane removing module, an oxygen channel of the water bath type vaporizer and an oxygen channel of the heat exchanger through pipelines, and the oxygen channel of the heat exchanger is connected with the upper portionof the third-stage concentrating tower through a sixth pipeline. The second-stage concentrating tower is mounted above the third-stage concentrating tower, the top of the second-stage concentrating tower is connected with the middle of the first-stage concentrating tower through a pipeline, and a second reboiler is arranged between the second-stage concentrating tower and the third-stage concentrating tower. The device for extracting the krypton and the xenon in the liquid oxygen through low-temperature rectification is wide in application range and can operate independently, treat a large amount of liquid oxygen without being limited by the scale of an air separation device, and produce the krypton and the xenon on a large scale.

Owner:HANGZHOU HANGYANG

Synergistic extractant for extracting and separating tungsten from molybdate solution and method for extracting and separating tungsten from molybdate solution

ActiveCN106435181BSuitable for deep tungsten removalSimultaneous recyclingProcess efficiency improvementMolybdateCarboxylic salt

The invention discloses a synergistic extractant comprising a primary amine extractant and a pyridine carboxylate for extracting and separating tungsten from a molybdate solution. In addition, a method for deep tungsten removal by extraction from a tungsten-containing molybdate solution is disclosed; firstly, the pH value of the tungsten-containing molybdate solution is adjusted to 7.5-8.5, and then an acidified solution containing a synergistic extractant is combined with The organic phase is contacted for multi-stage extraction, and the detergent is an alkaline solution. During the multi-stage extraction process, tungsten is enriched in the loaded organic phase, and molybdenum is enriched in the raffinate to achieve deep tungsten removal in the molybdate solution. The loaded organic phase is back-extracted with an alkaline solution to obtain a tungsten-rich back-extraction solution. After the reaction, the organic phase was treated with an inorganic acid solution and then returned to extraction. The invention has good tungsten removal effect from the molybdate solution with high tungsten content, short process, low cost, and is easy to realize industrialization.

Owner:CENT SOUTH UNIV

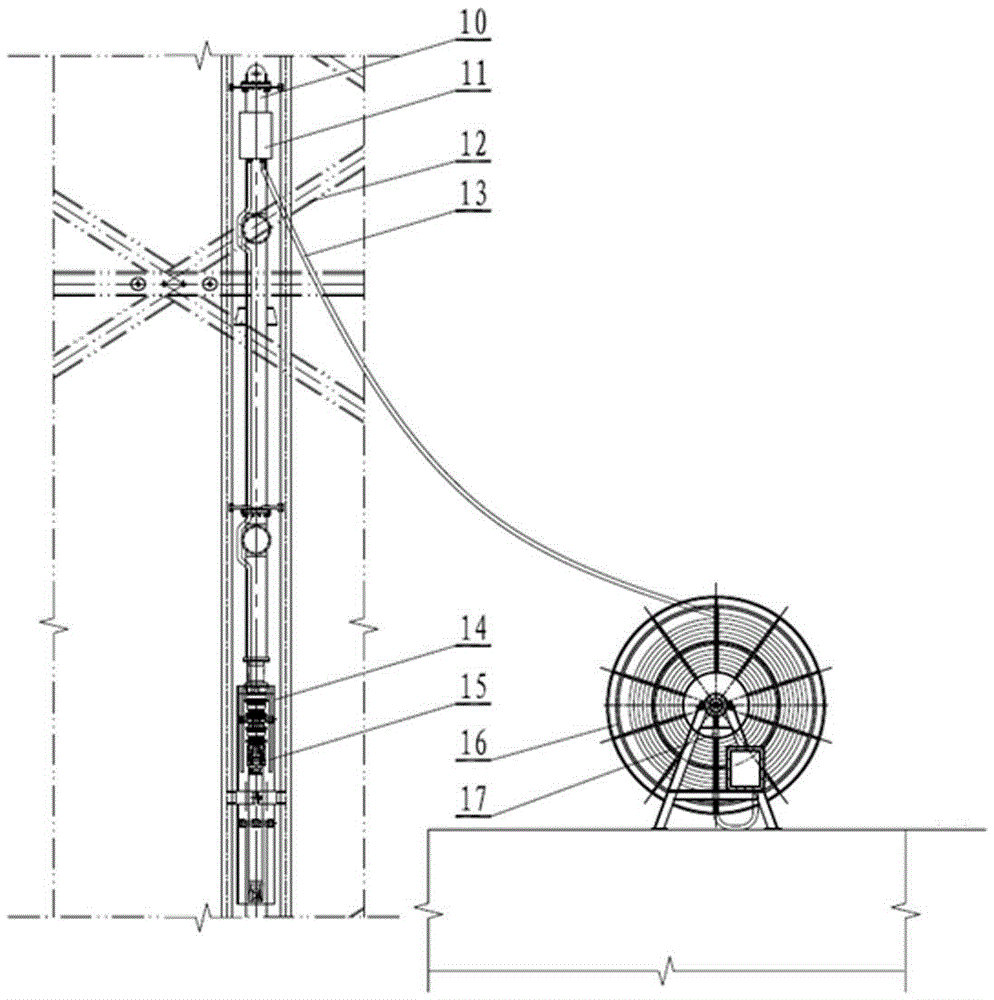

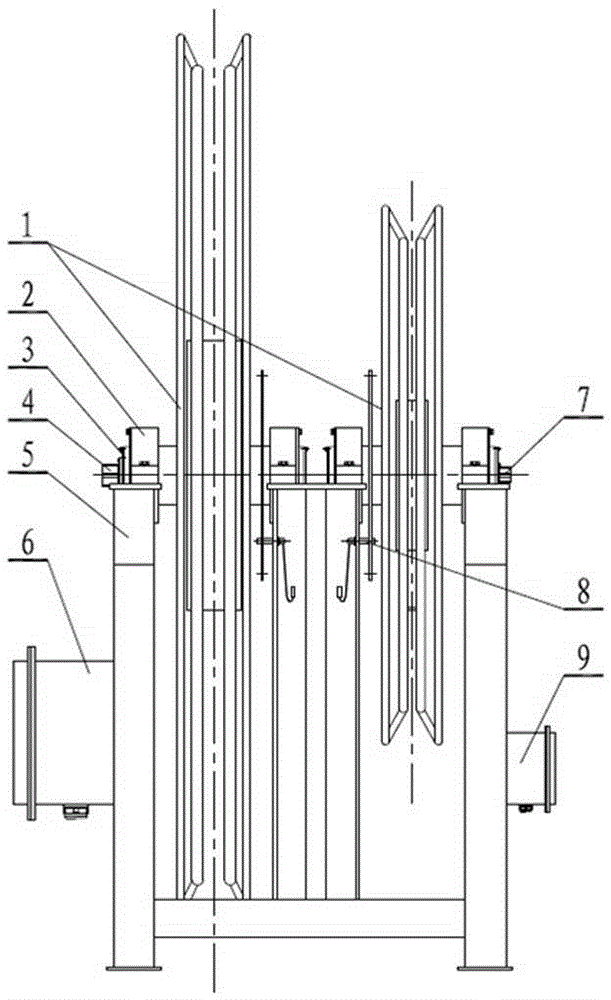

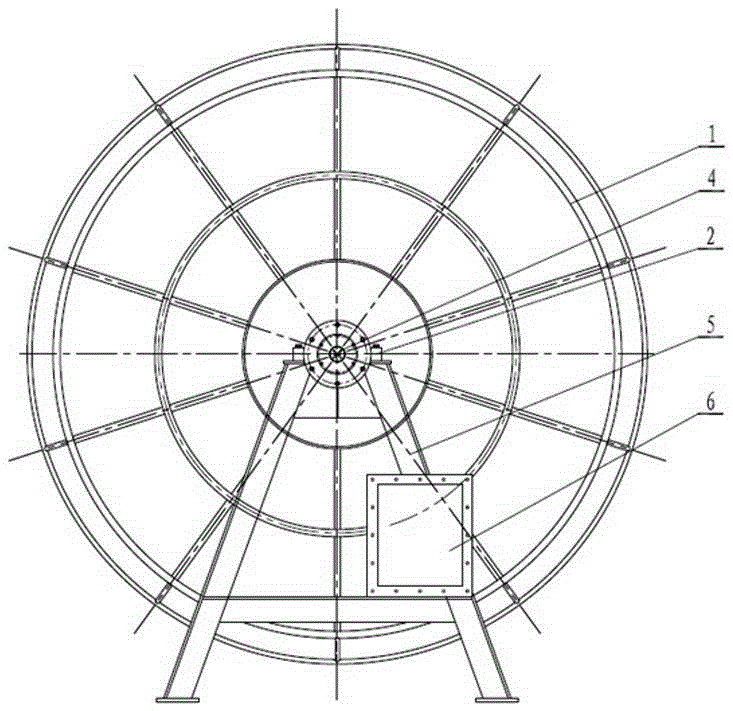

Offshore platform tower type submersible pump cable take-up and release apparatus

InactiveCN106469897AAvoid Continuous DistortionExtended service lifeArrangements using take-up reel/drumDistortionPiping

The invention relates to an offshore platform tower type submersible pump cable take-up and release apparatus. Cables are respectively led out from a junction box (11) of a lifting pipe (10) arranged on pile legs (12), and wind around respective cable take-up devices (16). When a submersible pump (14) needs to ascend or descend to satisfy different operation water depths of a platform, the cable take-up devices (16) are manually rotated to enable the cables and the submersible pump to elevate in a synchronous manner, and at the moment, connection cables (17) between the take-up devices (16) and a deck junction box should be disconnected. When the submersible pump is elevated to the operation water depth of the platform, locking pins (8) of the take-up devices are inserted so that rotating discs (1) are fixed, finally the connection cables (17) between the take-up devices (16) and the deck junction box are connected, and the submersible pump can operate. According to the apparatus, the distortion of cables of the submersible pump and marine growth preventing cables is avoided, the service lifetime of the cables is prolonged, and the labor intensity is reduced.

Owner:LIAONING PETROLEUM EQUIP INST

A kind of lithium-ion battery cathode material recovery method

ActiveCN102694217BHigh recovery rateSimultaneous recyclingSolid waste disposalWaste accumulators reclaimingRecovery methodSide effect

The invention belongs to the field of battery materials, and specifically relates to a method for recovering positive active materials from battery material offcuts and slurry. The method comprises the following steps of: filling positive plate or dry positive slurry to be recovered into a pulverizer, screening into a powder, putting the powder into a fluidized bed and removing impurities of conductive carbon and a binder; letting a gas pass through a cyclone separator on the top of the fluidized bed to remove entrained powder, passing through a fixed bed to remove harmful gases, heating and blowing into the fluidized bed for cyclic utilization, cooling the powder at the bottom, and sieving to obtain a qualified positive powder. According to the invention, the process flow is short; the powder is in a fluidization state in the fluidized bed during the process of heat treatment; and the gas and the powder fully contact with each other and the reaction is complete. Therefore, the problems of high impurity content in the product and low recovery rate in a traditional technology are fundamentally resolved; in addition, cobalt and lithium elements are simultaneously recovered, the recovery rate of an active substance reaches up to 94%, and simultaneously side-effect will not be exerted on the active substance and it selectrochemical properties.

Owner:DONGGUAN AMPEREX TECH +2

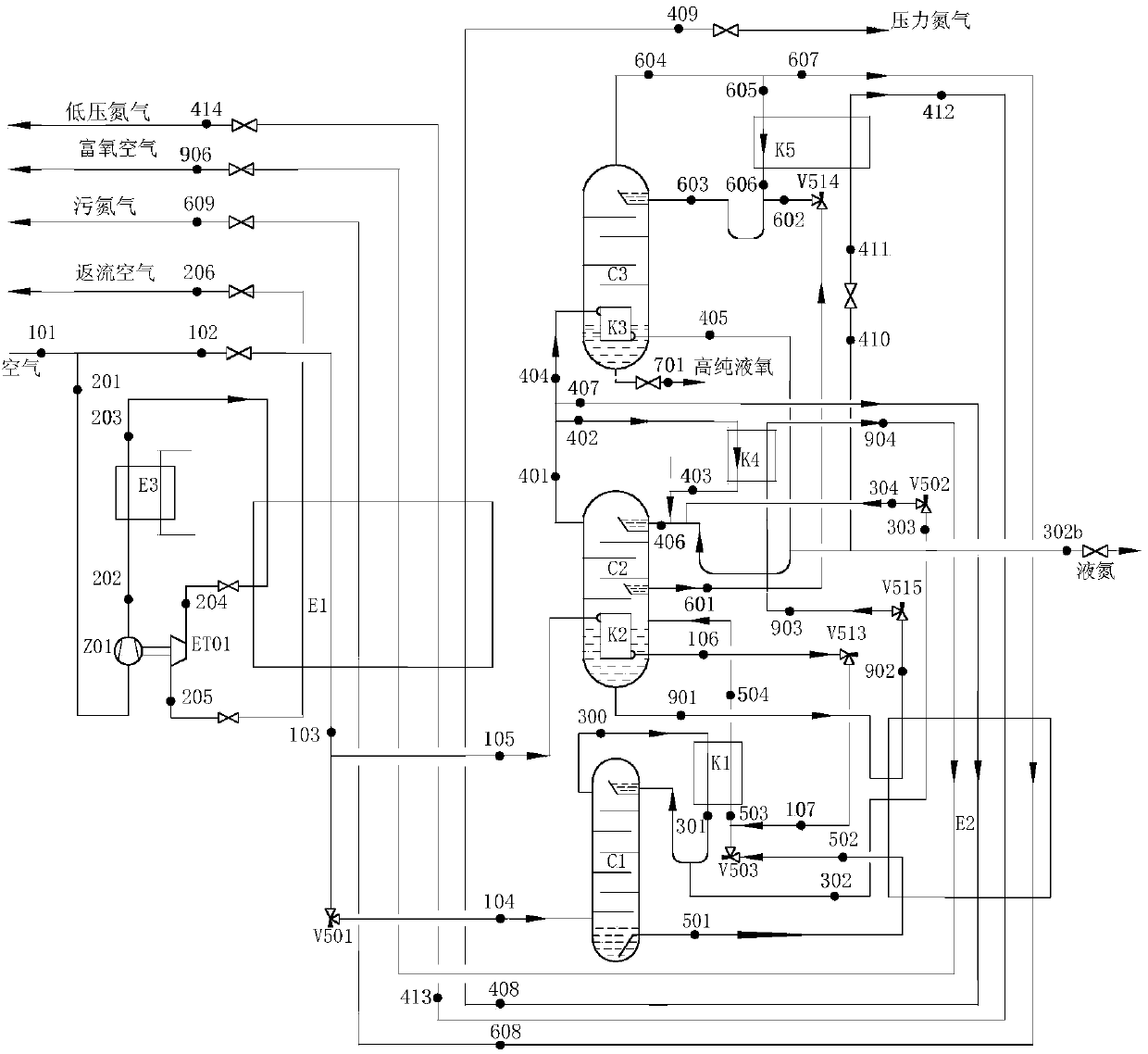

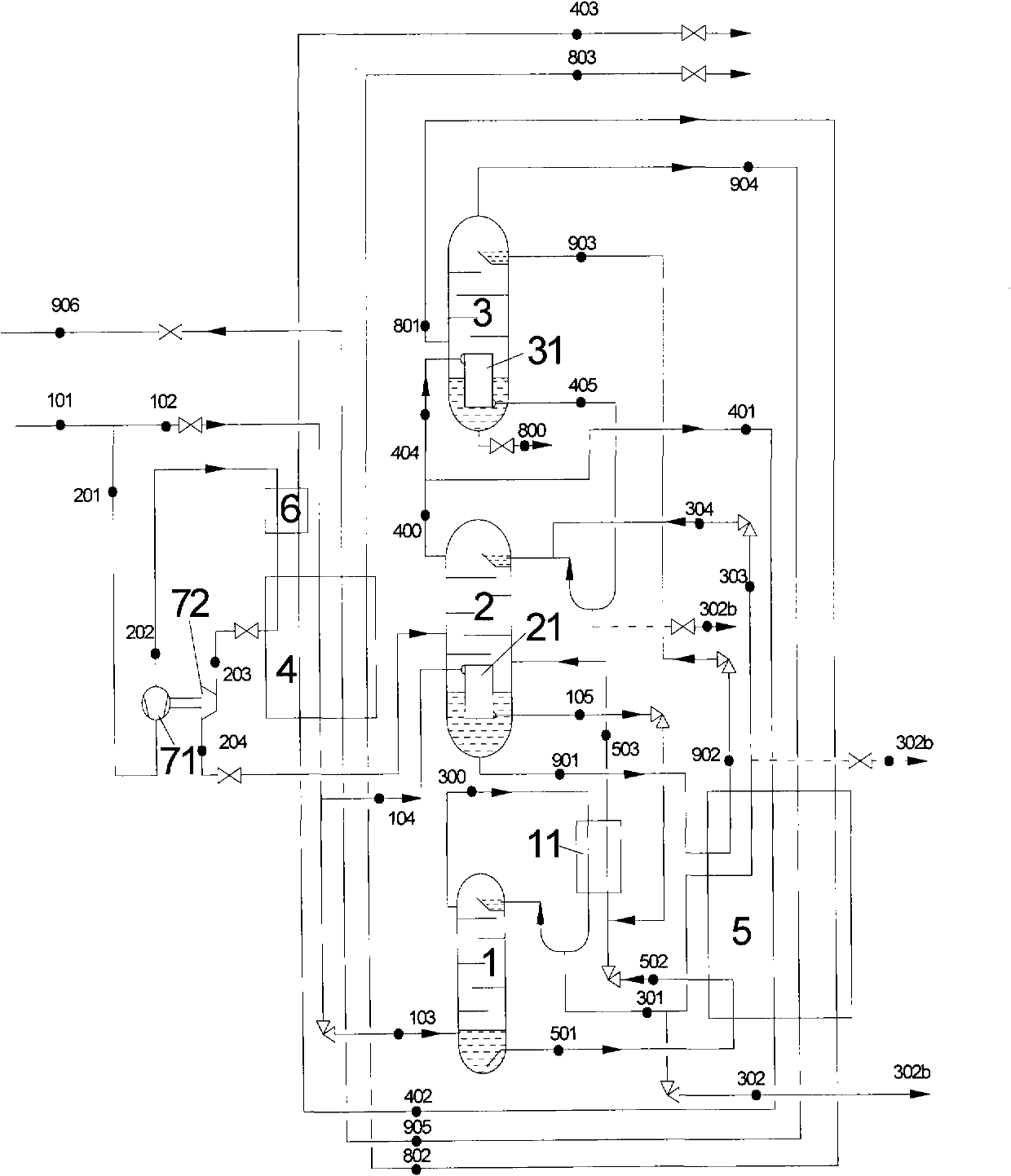

Method and device for producing high-pressure nitrogen and low-pressure oxygen

InactiveCN102080921BHigh extraction rateLess investmentSolidificationLiquefactionElectricityDistillation

The invention relates to a method and device for producing high-pressure nitrogen and low-pressure oxygen. The high-pressure nitrogen and the low-pressure oxygen are simultaneously prepared by adopting three distillation towers comprising a high-pressure tower, a nitrogen tower and an oxygen tower. The high-pressure nitrogen is prepared in the nitrogen tower and the low-pressure oxygen is prepared in the oxygen tower. The method and device for producing the high-pressure nitrogen and the low-pressure oxygen can realize the simultaneous recycling of the pressure nitrogen and the pure oxygen, wherein the extraction rate of the pressure nitrogen ( wherein the oxygen content is less than 3ppm) reaches 75-80 percent, and the nitrogen pressure reaches 0.4-0.5MPa; the extraction rate of the pure oxygen (not less than 99.6 percent of O2) reaches 40-70 percent, the pressure reaches 0.02-0.05MPa; and the comprehensive electricity consumption of the oxygen and the nitrogen is only 0.18-0.2KWh / NM3(N2+O2), and the energy-saving effect is more remarkable.

Owner:上海启元科技发展有限公司 +1

Method and device for producing pressure high-purity nitrogen and high-purity oxygen

InactiveCN101886870BNo reduction in extraction rateSimultaneous recyclingSolidificationLiquefactionReboilerShielding gas

The invention relates to a method and a device for producing pressure high-purity nitrogen and high-purity oxygen. The device comprises a high-pressure tower, a medium-pressure tower and an oxygen tower. A reboiler is arranged at the bottom of the oxygen tower; and liquid nitrogen and oxygen-enriched liquid air separated from the air in the high-pressure tower enter the medium-pressure tower to be separated into medium-pressure nitrogen and oxygen-enriched liquid in the high-pressure tower. A part of low-purity oxygen which is rich in methane and other high boiling point components is exhausted from the bottom of the medium-pressure tower; a low methane-containing oxygen-enriched liquid extraction opening is formed on the side of the medium-pressure tower; and the oxygen-enriched liquid enters into the oxygen tower for rectification, and the high-purity oxygen is extracted from a tower bottom or a plurality of tower plates on the upper part of the tower bottom. Compared with the priorart, the device and the method can realize simultaneous preparation of pressure nitrogen and high-purity oxygen, wherein the extraction ratio of the pressure nitrogen is 65 to 72 percent, the nitrogen pressure is 0.15 to 0.4 MPa, and the extraction ratio of the high-purity oxygen is 10 to 20 percent of the oxygen in air. The device can prepare low-cost protective gas pressure nitrogen for the float glass and other industries using pressure nitrogen, and can produce high additional value high-purity oxygen products.

Owner:上海启元科技发展有限公司 +1

A method for recovering valuable elements in waste lithium-ion battery electrode materials

ActiveCN107955879BReduce sorting costsReduce recycling costsWaste accumulators reclaimingProcess efficiency improvementMass ratioElectrical battery

The invention discloses a method for recovering valuable elements in waste lithium ion battery electrode materials. The method comprises steps of roasting the waste lithium ion battery electrode materials in an inert gas atmosphere, the roasting temperature is 200 -600 DEG C, the time is 30-360 minutes, and the roasting slag is obtained; mixing the obtained roasting slag and an acidic solution with [H+] concentration of 0.5~8 mol / L according to the mass ratio of 1:3~10; leaching at the leaching temperature of 30-90 DEG C and leaching time of 1-8 hours, leach liquor and leach residues are filtered to be obtained; the leach liquor is used for recovering nickel, cobalt, manganese, aluminum and lithium, and the leach residues are used for preparing negative electrode materials. According to the method for recovering valuable elements in waste lithium ion battery electrode materials, a leaching reducing agent does not need to be additionally added, the battery sorting and recycling costs are reduced, the positive and the negative electrode materials can be recovered at the same time, and the economic benefits of lithium battery recovery can be improved.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

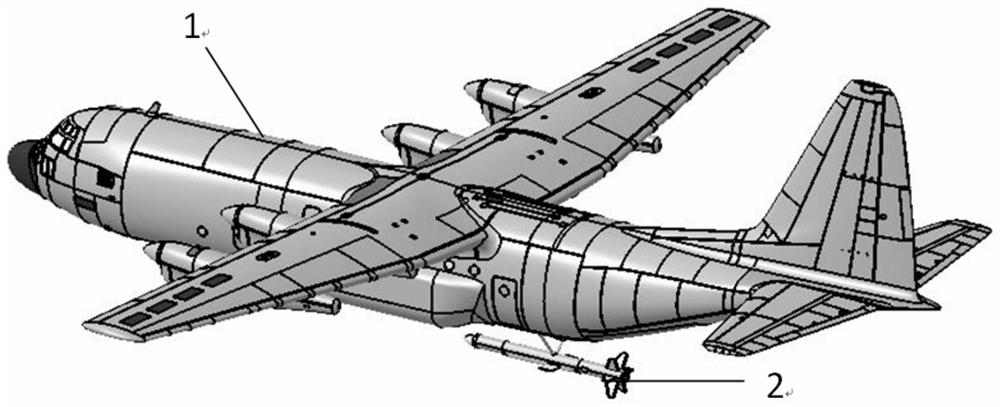

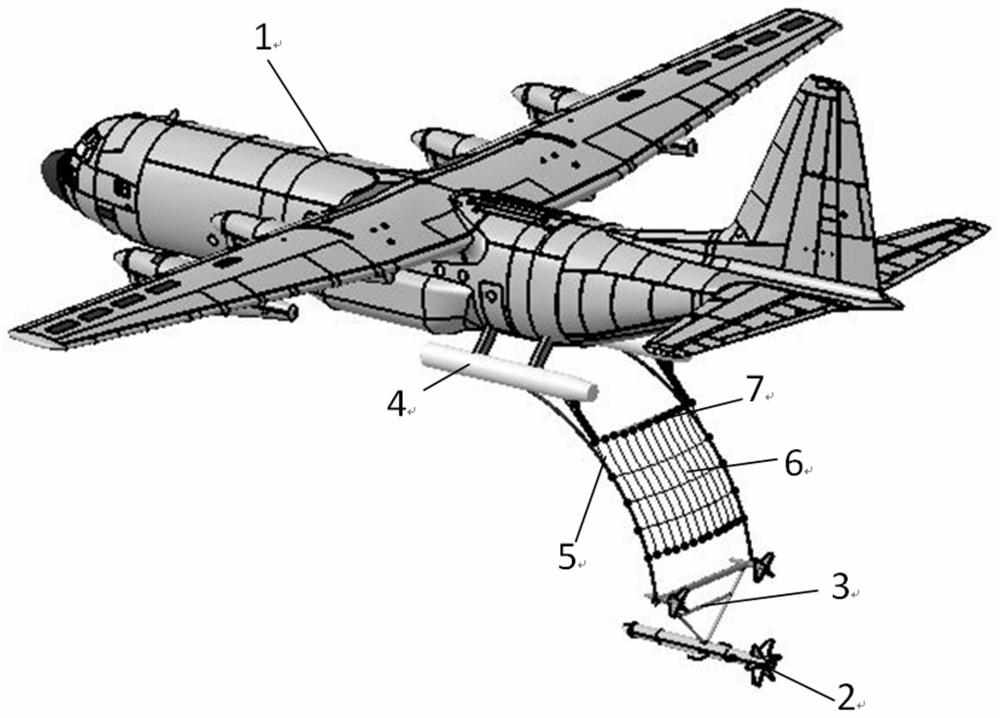

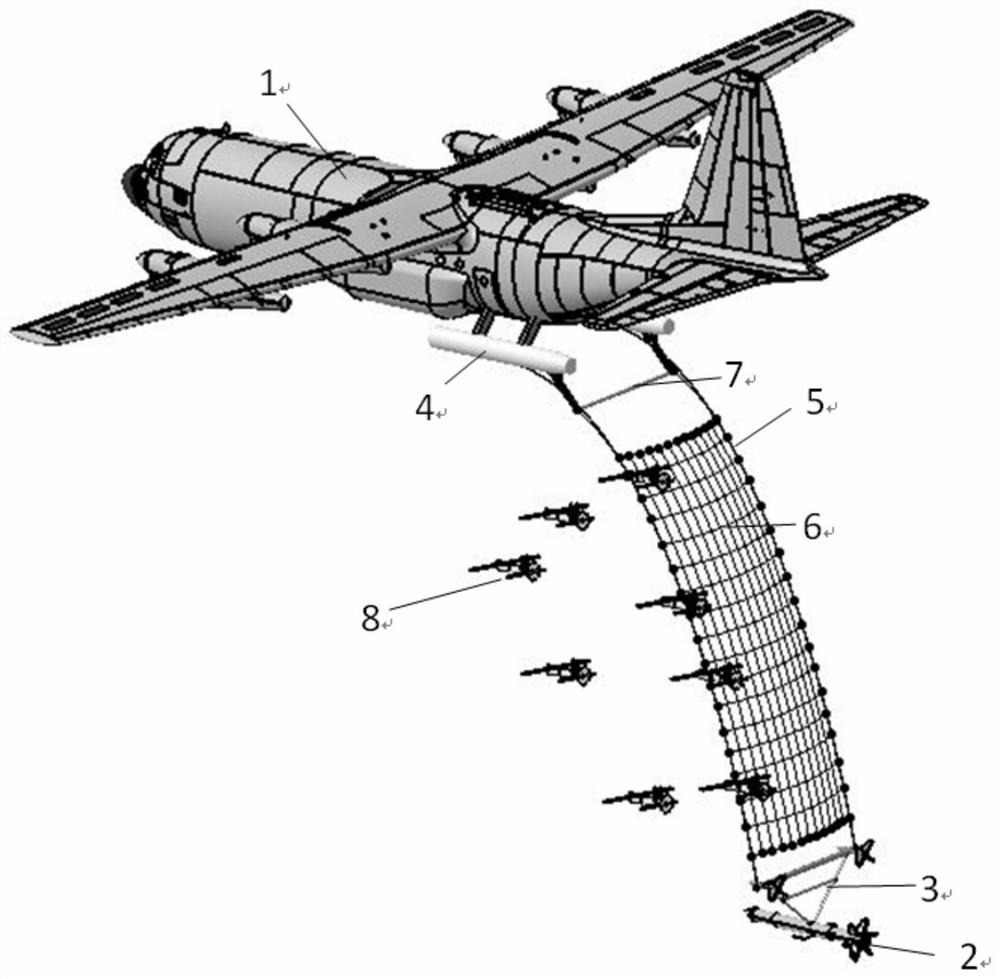

An unmanned aerial vehicle air-based towed net type recovery device and method

ActiveCN107792381BSimultaneous recyclingImprove air recovery efficiencyAircraft landing aidsAviationUncrewed vehicle

The invention discloses an unmanned aerial vehicle air-based towed net recovery device and method. The device includes a retractable mounting bracket, two aviation winches, two tow cables, a tow net, a net winding device and a tow net stabilization system. With the help of the towing target technology and the towing net stabilization system, the present invention releases the towing cable synchronously through two aviation winches during recovery, unfolds the towing net installed between the two towing cables, and drags the net under the action of the stabilizing towing target Keep a steady posture. When the UAV hits the net, the UAV is recovered with the tow net to realize space-based recovery. A certain number of UAVs can be recovered at the same time, which shortens the time spent by the UAV cluster in the recovery process, improves the recovery efficiency, and reduces the risk of damage to the UAV and the parent aircraft. The towing net has a large area and has low requirements on the accuracy of UAV recovery, which is easy to implement.

Owner:BEIHANG UNIV

A resource recovery and treatment method for smelting wastewater sedimentation slag

ActiveCN111534693BHigh puritySimple purification processSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisPregnant leach solutionSlag

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com