Method for simultaneously recycling silicon in silicon waste materials and titanium in titanium-containing slag through metallic aluminum

A technology for metal aluminum and silicon waste, applied in the direction of improving process efficiency, can solve the problems of waste of titanium resources, low economic added value, low production capacity, etc., and achieve industrialized production, short process flow, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

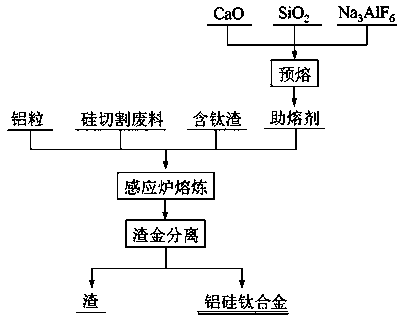

[0028] Embodiment 1: A kind of method that utilizes metal aluminum to simultaneously reclaim silicon in silicon waste and titanium in titanium-containing slag (see figure 1 ),Specific steps are as follows:

[0029] (1) Combine CaO and SiO 2 Mix the powder evenly, then add Na 3 AlF 6 Mix evenly to obtain a mixed powder; among them, CaO and SiO 2 The total mass of the powder is 100%, CaO accounts for 50%, SiO 2 Powder accounts for 50%; by mass percentage, Na in the mixed powder 3 AlF 6 15%;

[0030] (2) Pre-melt the mixed powder in step (1) at a temperature of 1600°C for 0.5 hours to obtain a pre-melt block, and grind the pre-melt block into powder after cooling to use as a flux; the particle size of the flux is 80 mesh;

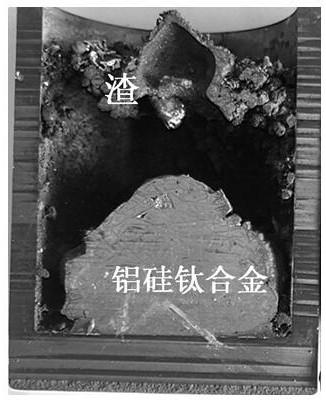

[0031] (3) Mix the metal aluminum particles, metal silicon waste, titanium-containing slag, and the flux in step (2) to obtain a mixed material, and place the mixed material at a temperature of 1700 ° C for 4 hours for high-temperature melting; among th...

Embodiment 2

[0035] Embodiment 2: A kind of method that utilizes metallic aluminum to reclaim silicon in silicon waste and titanium in titanium-containing slag simultaneously (see figure 1 ),Specific steps are as follows:

[0036] (1) Combine CaO and SiO 2 Mix the powder evenly, then add Na 3 AlF 6 Mix evenly to obtain a mixed powder; among them, CaO and SiO 2 The total mass of powder is 100%, CaO accounts for 60%, SiO 2Powder accounts for 40%; by mass percentage, Na in the mixed powder 3 AlF 6 20%;

[0037] (2) Pre-melt the mixed powder in step (1) at a temperature of 1600°C for 1.0 h to obtain a pre-melt, and grind the pre-melt into powder as a flux after cooling; the particle size of the flux is 120 mesh;

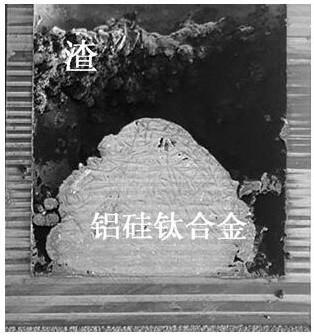

[0038] (3) Mix the metal aluminum particles, metal silicon waste, titanium-containing slag, and the flux in step (2) to obtain a mixed material, and place the mixed material at a temperature of 1800 ° C for 4 hours for high-temperature melting; among them, the metal aluminum p...

Embodiment 3

[0042] Embodiment 3: A kind of method that utilizes metallic aluminum to simultaneously reclaim silicon in silicon waste and titanium in titanium-containing slag (see figure 1 ),Specific steps are as follows:

[0043] (1) Combine CaO and SiO 2 Mix the powder evenly, then add Na 3 AlF 6 Mix evenly to obtain a mixed powder; among them, CaO and SiO 2 The total mass of the powder is 100%, CaO accounts for 40%, SiO 2 Powder accounts for 60%; by mass percentage, Na in the mixed powder 3 AlF 6 5%;

[0044] (2) Pre-melt the mixed powder in step (1) at a temperature of 1400°C for 0.5 h to obtain a pre-melt, and grind the pre-melt into powder as a flux after cooling; the particle size of the flux is 80 mesh;

[0045] (3) Mix the metal aluminum particles, metal silicon waste, titanium-containing slag, and the flux in step (2) to obtain a mixed material, and put the mixed material at a temperature of 1500 ° C for 2 hours at a high temperature; among them, the metal aluminum particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com