Equipment and process for recovery of fluorine from flue gas of hydration absorption of phosphorus in kiln-method phosphoric acid technology

A flue gas and phosphoric acid technology, which is applied in the field of fluorine recovery, can solve the problems of complex equipment system structure, air pollution, and great energy waste, and achieve the effects of simplifying the system structure, improving economic benefits, and improving environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

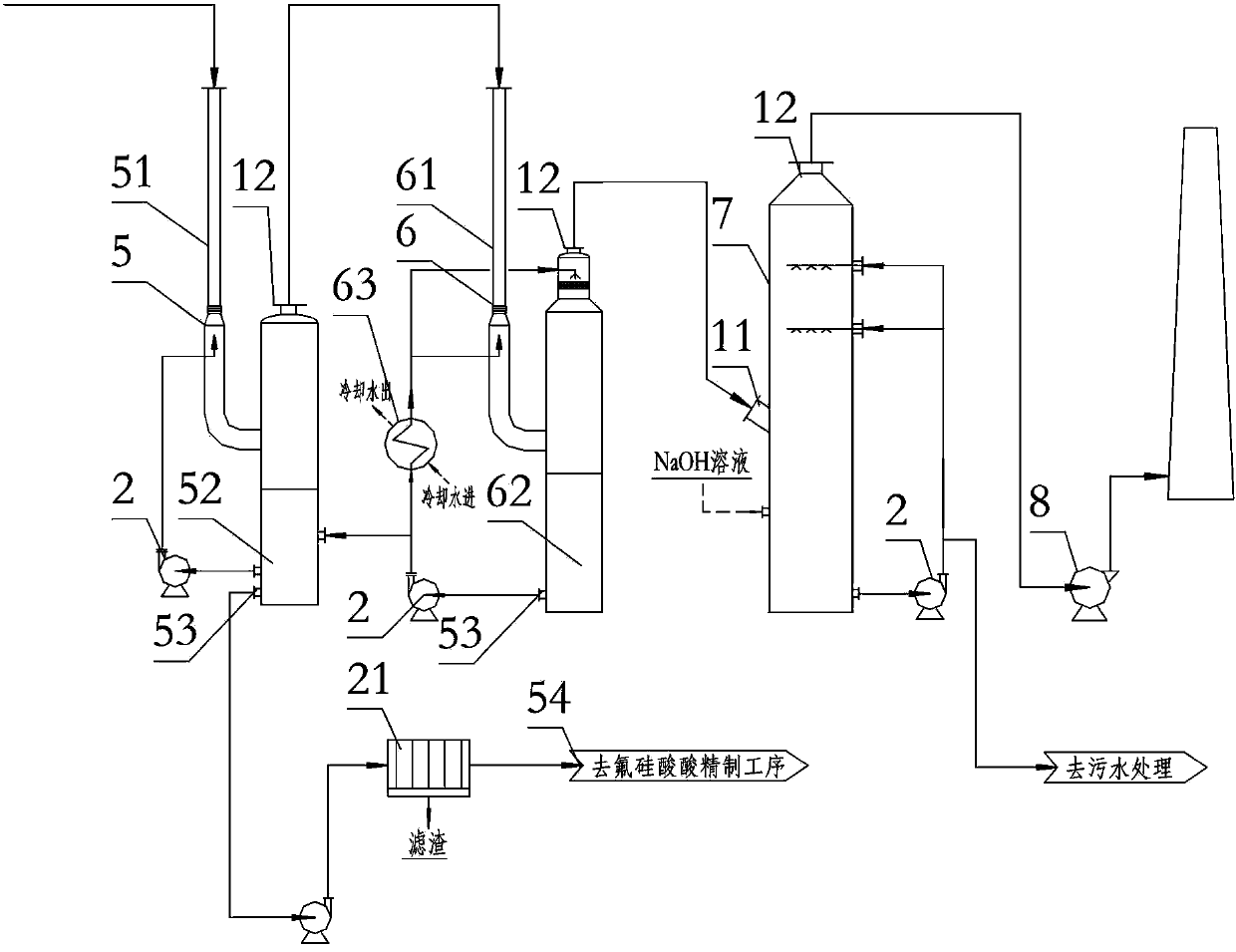

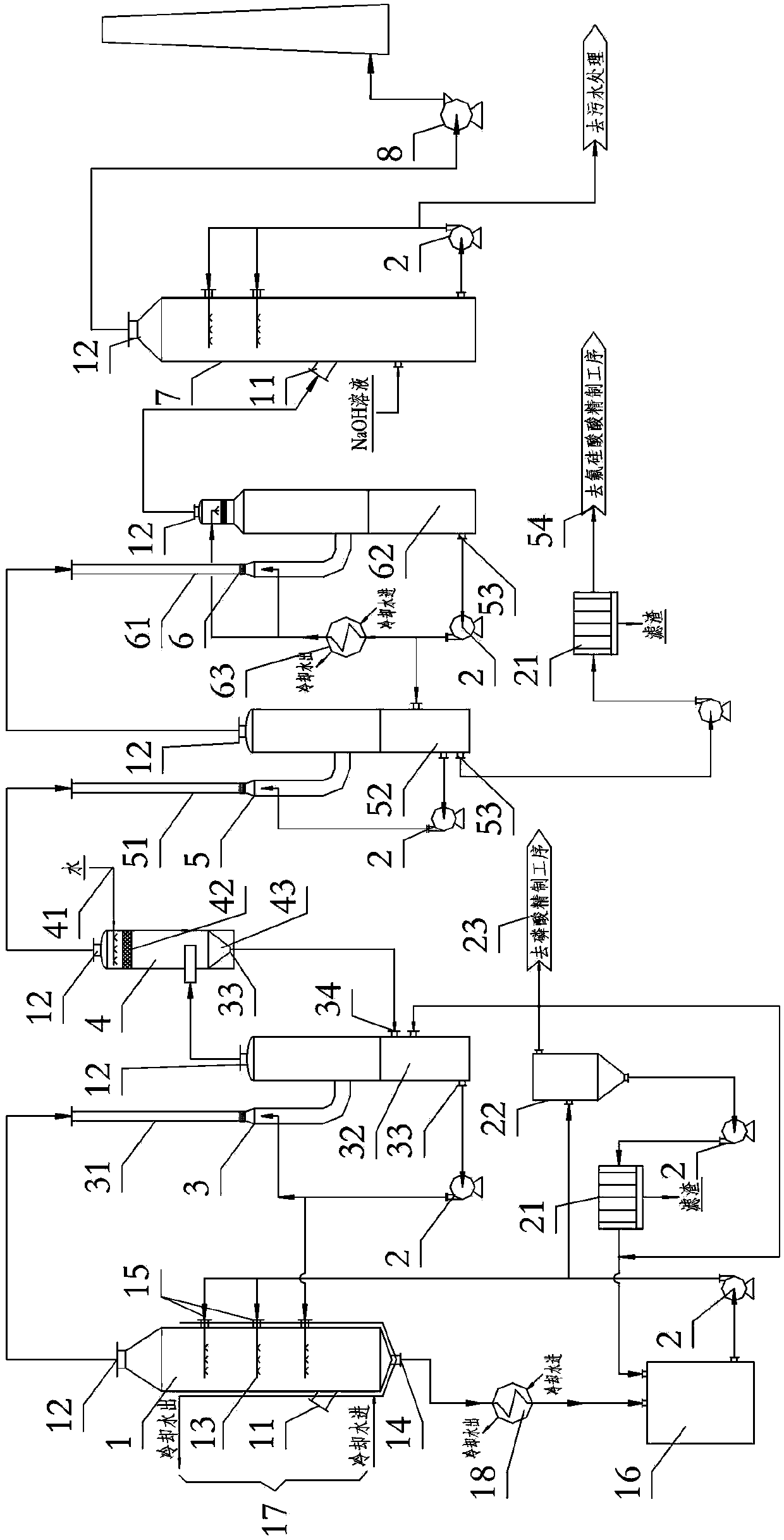

[0052] a kind of like figure 1 The device for recovering fluorine from flue gas after hydration and phosphorus absorption in the kiln phosphoric acid process shown in the present invention includes a primary fluorine absorption tower 5 and a secondary fluorine absorption tower 6 . Both the primary fluorine absorption tower 5 and the secondary fluorine absorption tower 6 are fluidized countercurrent scrubbers. The primary fluorine absorption tower 5 is mainly composed of a fluosilicic acid washing pipe 51 and a fluosilicic acid separation tank 52. The inlet of the fluosilicic acid washing pipe 51 is connected to the flue gas conveying pipe after hydration and phosphorus absorption, and the fluosilicic acid washing pipe The outlet of 51 is connected to the middle part of the fluosilicic acid separation tank 52, the top of the fluosilicic acid separation tank 52 is provided with a flue gas outlet 12, and the bottom is provided with a fluosilicic acid liquid outlet 53, and the flu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com