Method for recovering and preparing lithium cobaltate from waste lithium ionic cell

A technology of lithium ion battery and lithium cobalt oxide, which is applied in the field of preparation and recycling of lithium cobalt oxide, can solve the problems of high equipment requirements, secondary pollution, and a large amount of waste water, and achieves low raw material price, short reaction process and high added value of products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] After the polymer lithium-ion battery was disassembled, 100 g of the positive electrode sheet was selected and crushed with a vertical high-speed rotary grinder. The crushing time was set at 5 minutes. After crushing, it was sieved with an 80-mesh standard sieve. The total weight of the oversize is 12.6g, and the total weight of the undersize is 87.4g; detected by the atomic absorption instrument, the aluminum content in the oversize is 73.8%, and the cobalt content is 12.3%; the aluminum content in the undersize is 0.8%, containing The amount of cobalt is 53.1%. Therefore, it is calculated that the aluminum removal rate is 93.0%, and the cobalt loss caused by the cobalt contained in the aluminum slag of the sieve is 3.2%.

Embodiment 2

[0025] Take 50 g of the undersize in Example 1, put it into a high-temperature electric furnace, keep the air circulation, raise the temperature to 600 ° C, keep the temperature for 4 hours, and the burnt residue weighs 44.5 g. The CS800 infrared carbon and sulfur detector was used to detect that the carbon content was about 0.02%, indicating that the binder and acetylene black were basically removed completely. Take 20g of the burning residue and put it into a 500mL beaker, add 100mL of 0.2mol / L sodium hydroxide, put the beaker into a constant temperature water bath, adjust the temperature to 65°C, keep stirring with a magnetic stirrer, react for 40min, filter, and pass through After repeated washing with distilled water to neutrality, put it into an oven and dry it at 150°C for 12 hours. After grinding and pulverizing, waste lithium cobaltate was obtained, weighing 19.8g. ICP is used to detect that the aluminum content is 0.01%, that is, the aluminum is basically completely ...

Embodiment 3

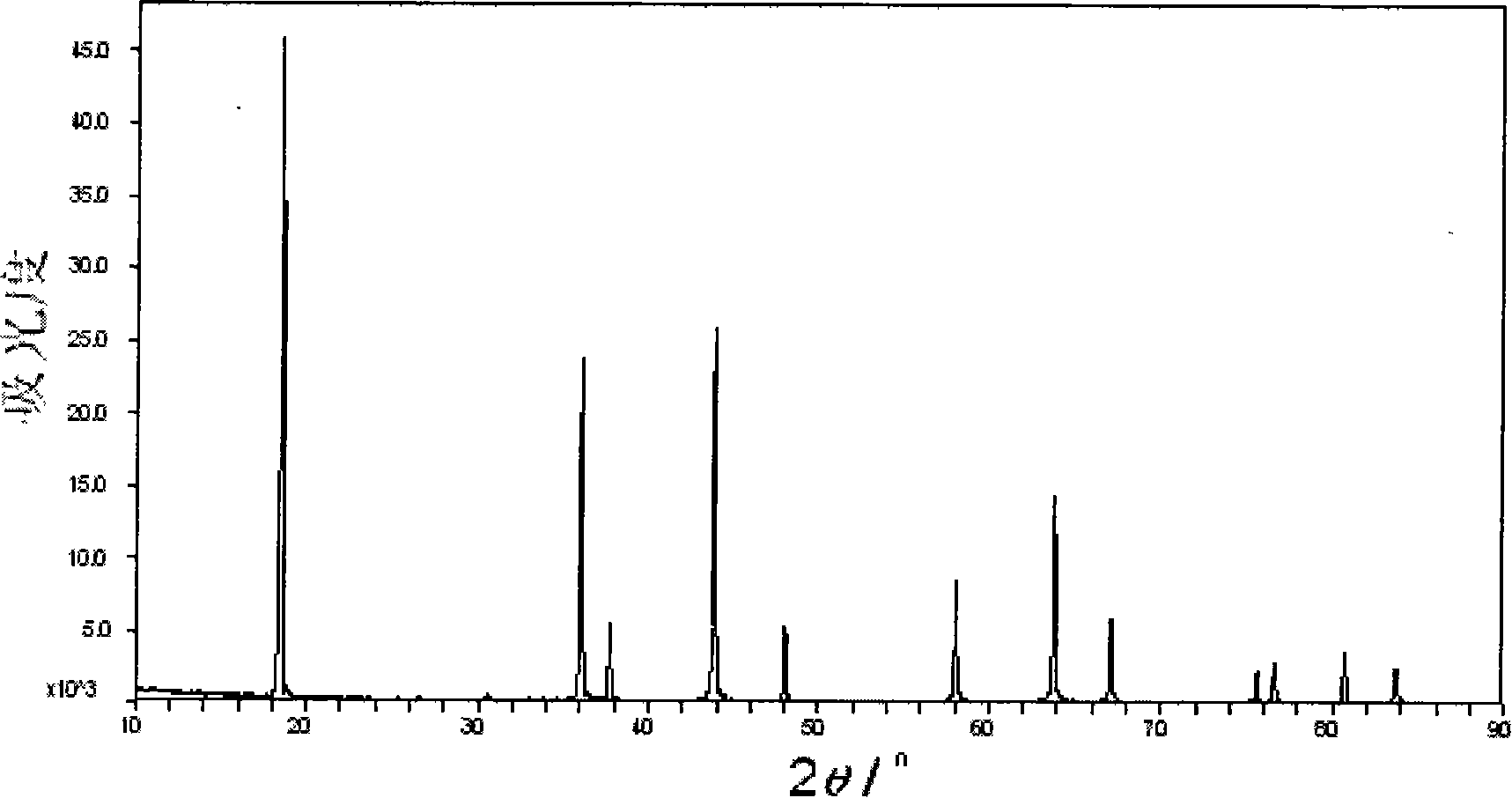

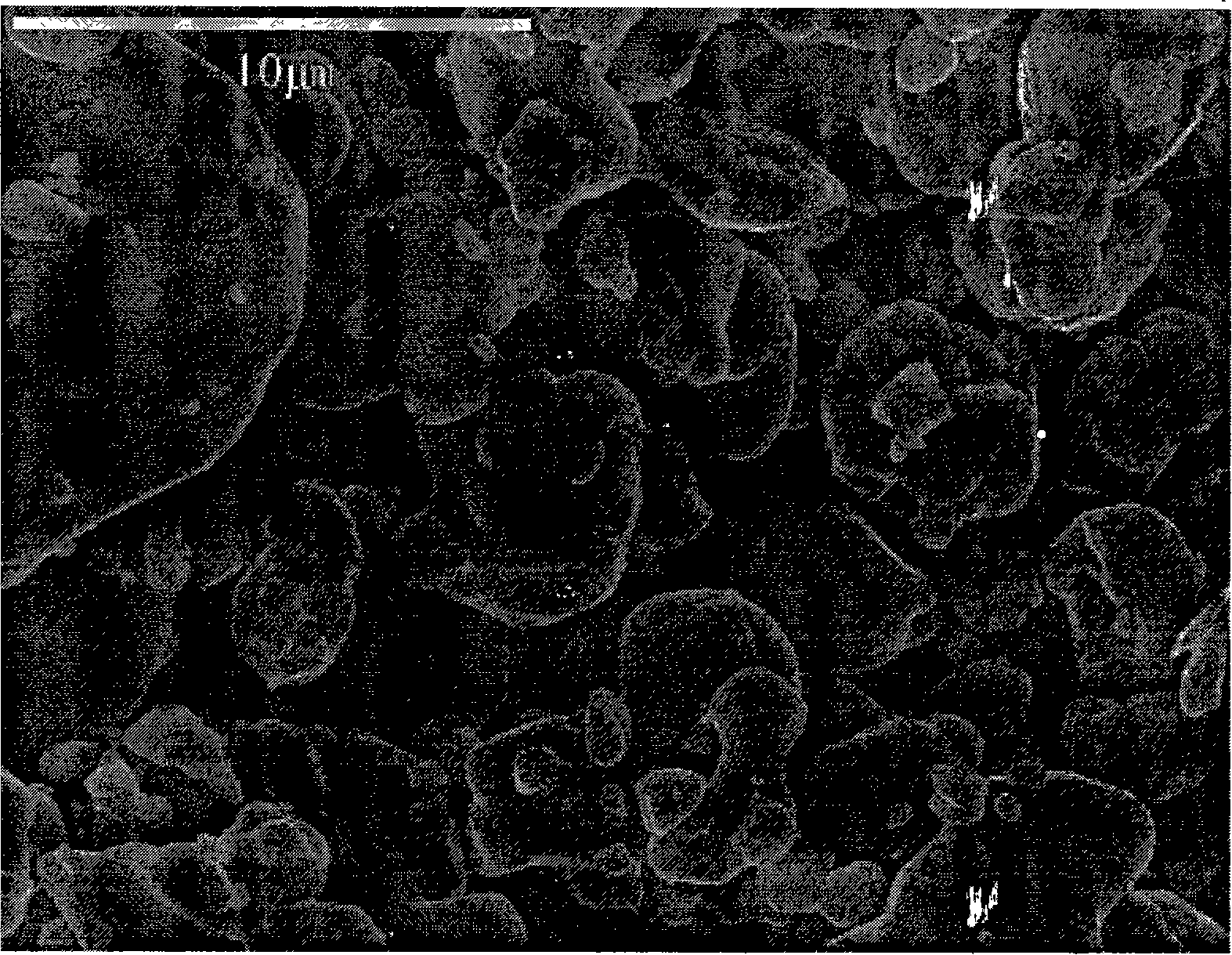

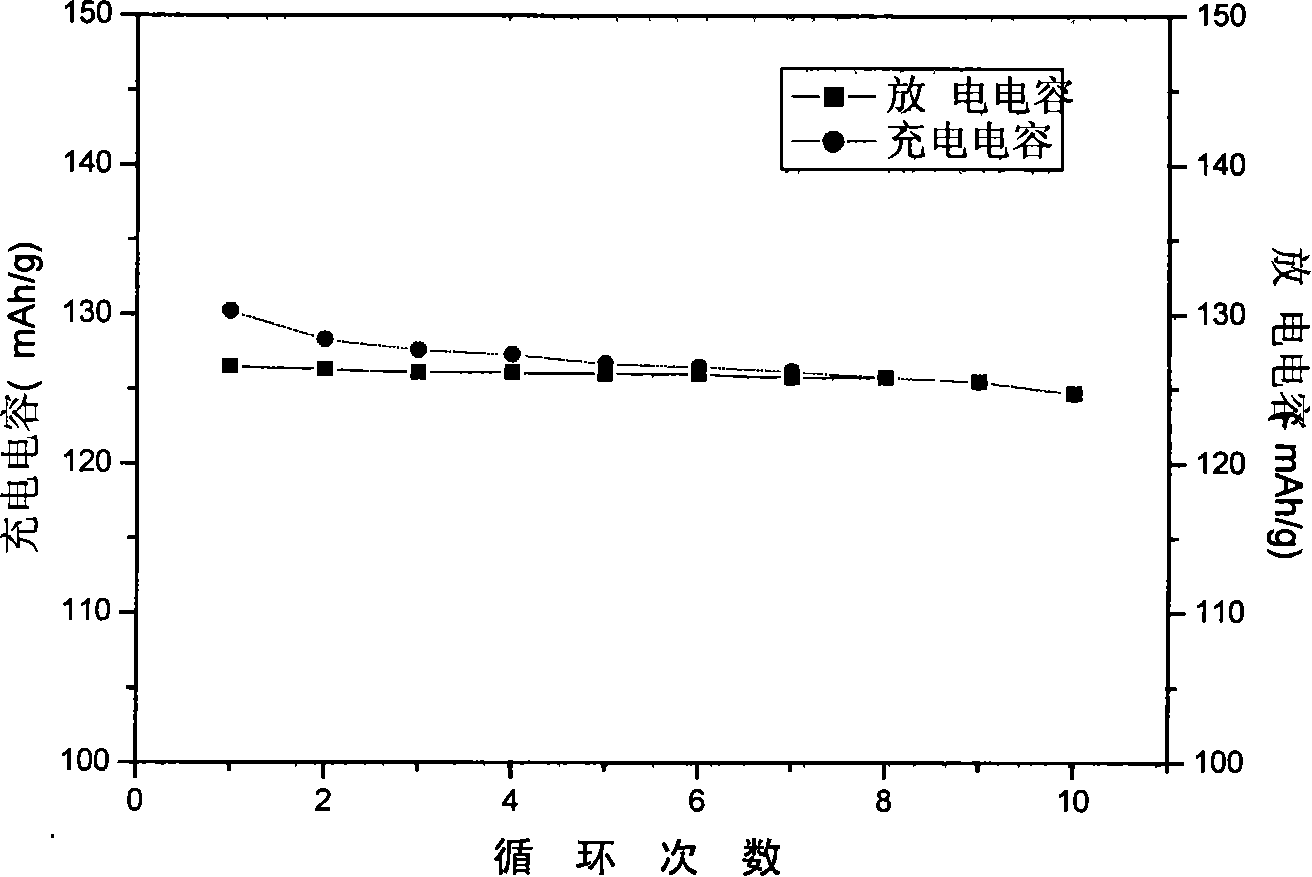

[0027] Take 15g of waste lithium cobaltate in Example 2, add 0.7g of battery-grade lithium carbonate, fully grind and mix the above-mentioned raw materials in an agate mortar, put them into a corundum crucible, and sinter at a high temperature in a muffle furnace to obtain The temperature was raised to 750°C at a rate of 2°C / min, kept at a constant temperature for 15 hours, and then slowly lowered to room temperature at a rate of 1°C / min to prepare lithium cobaltate. The XRD and SEM characterization results are shown in the appendix figure 1 with attached figure 2 . figure 1 It shows that its impurity content is low and its crystal structure is complete; and the average particle size of the particles is 7.0μm, and its specific surface area is 0.52m after testing 2 / g, the tap density is 2.21g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com